Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Maintaining Water Treatment Equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Maintaining Water Treatment Equipment Interview

Q 1. Describe your experience with maintaining reverse osmosis (RO) systems.

Reverse Osmosis (RO) systems are crucial for producing high-quality water by removing dissolved salts and other impurities. My experience spans over eight years, encompassing installation, routine maintenance, and troubleshooting of various RO systems, from small residential units to large-scale industrial applications. Maintaining an RO system involves a multi-faceted approach.

- Regular Cleaning and Sanitization: This involves periodic chemical cleaning of the membranes to remove accumulated solids and biofilms. For example, I’ve used citric acid solutions to remove scaling and sodium hypochlorite for sanitization, always following manufacturer guidelines and safety protocols. Failure to do this leads to reduced performance and premature membrane failure.

- Pressure Monitoring: Consistent monitoring of feed water pressure and system operating pressure is essential. A drop in pressure often indicates membrane fouling or a problem with the pre-filtration stages. I use pressure gauges and data loggers to track this information over time to catch issues early.

- Membrane Replacement: RO membranes have a limited lifespan, typically ranging from 2-5 years depending on water quality and operating conditions. I have extensive experience in correctly identifying when replacement is needed based on performance data, and then safely replacing the membranes, ensuring proper alignment and sealing to maintain system integrity.

- Pre-treatment System Maintenance: RO systems rely heavily on pretreatment systems like sediment filters and carbon filters. Neglecting their maintenance will lead to rapid fouling of the RO membranes. My routine includes regular filter changes and backwashing to ensure optimal pre-filtration.

For example, I once worked on an industrial RO system where high levels of iron were causing rapid membrane fouling. By implementing a more robust pre-treatment system incorporating a multi-media filter and an iron removal filter, we significantly extended the membrane lifespan and improved water quality.

Q 2. Explain the process of troubleshooting a malfunctioning water softener.

Troubleshooting a malfunctioning water softener involves a systematic approach. The key is to understand how water softeners work – using ion exchange resin to remove hardness minerals (calcium and magnesium). Problems often arise from resin exhaustion, brine tank issues, or control valve malfunctions.

- Check Salt Levels: The first step is always to check the brine tank’s salt level. Insufficient salt means the resin can’t regenerate properly, resulting in hard water. Adding salt usually solves this quickly.

- Inspect the Control Valve: The control valve orchestrates the regeneration cycle. A malfunctioning valve can prevent proper regeneration or lead to continuous regeneration. This often requires checking for physical damage, electrical faults, or even replacing the valve.

- Examine the Resin Bed: If salt levels and the control valve are fine, the issue may be with the resin bed itself. This might involve checking for channeling (uneven water flow), compaction, or contamination of the resin. Channeling can be identified by observing the flow of water during the regeneration process. In severe cases, resin replacement may be necessary.

- Water Test: Finally, conducting a water hardness test confirms if the softener is working correctly. This helps you verify the effectiveness of your troubleshooting steps.

I recall an incident where a water softener wasn’t producing soft water despite seemingly adequate salt levels. Upon inspection, we found a blockage in the brine line preventing proper salt delivery to the resin bed. A simple cleaning of the line solved the issue.

Q 3. How do you perform preventative maintenance on water filtration systems?

Preventative maintenance is key to extending the lifespan and maximizing the performance of water filtration systems. My approach is proactive, combining regular inspections with scheduled servicing.

- Regular Inspections: This involves visually checking for leaks, corrosion, and any signs of damage. I also monitor pressure gauges for significant drops indicating filter clogging.

- Filter Replacements: Following the manufacturer’s recommendations for filter replacements is vital. Different filters (sediment, carbon, etc.) have different lifespans depending on water quality and flow rates. I always keep a stock of replacement filters on hand.

- Backwashing (where applicable): Systems with backwashing capabilities should be backwashed regularly to remove accumulated debris. This helps extend filter lifespan and maintain flow rates. Proper backwashing procedures are crucial to avoid damage to the filter media.

- System Flushing: Periodically flushing the entire system helps remove accumulated sediment and ensures proper flow.

- Documentation: Maintaining detailed records of maintenance activities including dates, actions taken, and any observations is essential for trend analysis and preventative measures.

For instance, in a commercial building with a large filtration system, I implemented a scheduled maintenance program, including monthly inspections, quarterly backwashing, and annual filter replacements. This resulted in significant cost savings by preventing unexpected breakdowns and extending the life of the equipment.

Q 4. What are the common causes of scaling in water treatment equipment?

Scaling in water treatment equipment is a common problem caused by the precipitation of dissolved minerals, primarily calcium and magnesium carbonates, when water is heated or when the water’s pH changes. Several factors contribute:

- High Water Hardness: Water with high concentrations of calcium and magnesium ions is more prone to scaling.

- High Water Temperature: Heating water increases the solubility product of calcium carbonate, leading to precipitation and scale formation. This is especially prominent in boilers and hot water heaters.

- Changes in pH: A change in pH can cause a shift in mineral solubility, resulting in scaling. For example, a rise in pH can lead to more calcium carbonate precipitation.

- Water Evaporation: Evaporation concentrates dissolved minerals, increasing the likelihood of scaling.

For example, I’ve worked on numerous projects where scaling within heat exchangers and reverse osmosis systems severely reduced efficiency and flow rates. In these cases, regular chemical cleaning with acid solutions (following strict safety protocols) is often necessary to remove the scale.

Q 5. How do you address issues with high turbidity in treated water?

High turbidity in treated water indicates the presence of suspended solids, making the water cloudy. Addressing this requires identifying the source and implementing appropriate solutions:

- Identify the Source: This could involve checking the raw water source for increased sediment load, problems with pretreatment filters (e.g., clogged filters), or issues within the treatment process itself.

- Enhance Pre-treatment: If the source is raw water quality, upgrading the pre-treatment steps (e.g., adding more efficient filtration stages like multimedia filters or adding coagulants) might be necessary.

- Check Filtration System: Inspect the main filtration units, ensuring they are functioning correctly and not clogged. This may involve cleaning or replacing filters.

- Optimize Treatment Parameters: Adjusting treatment parameters like pH or coagulant dosage can improve the efficiency of particle removal.

- Consider Clarification: In cases where turbidity remains high, additional clarification techniques like sedimentation or dissolved air flotation may be considered.

I recall a case where high turbidity persisted despite regular filter changes. Investigation revealed that the raw water source had experienced a significant increase in suspended sediment due to recent heavy rainfall. Implementing an additional pre-filtration stage using a lamella clarifier resolved the problem effectively.

Q 6. Explain your experience with different types of water treatment membranes.

My experience encompasses various water treatment membranes, each with its own strengths and weaknesses.

- Reverse Osmosis (RO) Membranes: These are widely used for desalination and high-purity water production, removing dissolved salts and other impurities. I’ve worked with both thin-film composite and cellulose acetate RO membranes, understanding their different characteristics and applications.

- Ultrafiltration (UF) Membranes: UF membranes remove larger particles and colloids, commonly used in pretreatment for RO systems or for water clarification. I have experience selecting appropriate UF membrane pore sizes for different applications based on the specific contaminants needing removal.

- Microfiltration (MF) Membranes: MF membranes remove even larger particles, often used as pre-treatment for other membrane processes or for water polishing. I understand how different MF membrane materials (e.g., ceramic, polymeric) influence their performance and lifespan.

- Nanofiltration (NF) Membranes: NF membranes are a hybrid between RO and UF, rejecting dissolved salts and larger organic molecules, finding application in softening or partial desalination.

Understanding the specific properties of each membrane type, such as pore size, material, and operating pressure, is crucial for selecting the right membrane for a given application and ensuring optimal performance. The choice depends on the desired level of water purity, the nature of the contaminants, and economic considerations.

Q 7. Describe your experience with chemical feed systems in water treatment.

Chemical feed systems are essential for many water treatment processes, providing necessary chemicals like coagulants, disinfectants, or pH adjusters. My experience involves the installation, maintenance, and troubleshooting of various chemical feed systems.

- Types of Feed Systems: I’m proficient with different types of systems, including diaphragm pumps, peristaltic pumps, and gravity feed systems, each suited to different applications and chemical characteristics.

- Calibration and Maintenance: Accurate calibration of chemical feed rates is crucial for optimal treatment. I know how to calibrate pumps, check for leaks, and maintain chemical storage tanks to ensure consistent and safe operation. This involves understanding and adhering to safety data sheets for the chemicals being used.

- Safety Procedures: Handling chemicals requires adherence to strict safety protocols. I have received specialized training in chemical handling, personal protective equipment (PPE) use, and emergency response procedures.

- Troubleshooting Issues: I can troubleshoot common problems such as pump malfunctions, clogged lines, and inaccurate feed rates, and identify if the issues are mechanical, electrical, or due to chemical incompatibility.

For instance, I once worked on a project where a malfunctioning chemical feed pump was causing inconsistent chlorine disinfection levels. By systematically checking the pump’s components, including the diaphragm and motor, and replacing a faulty solenoid valve, we restored the system to optimal function.

Q 8. How do you ensure compliance with water quality regulations?

Ensuring compliance with water quality regulations is paramount in water treatment. It involves a multifaceted approach encompassing regular testing, meticulous record-keeping, and adherence to all relevant local, state, and federal guidelines. We begin by understanding the specific regulations applicable to our facility and the type of water we’re treating (e.g., potable water, industrial wastewater). This includes knowing the permitted levels for various contaminants like bacteria, chlorine, heavy metals, and pH.

Regular testing is crucial. We utilize calibrated instruments to monitor parameters like turbidity, chlorine residuals, and pH levels, comparing results against regulatory limits. Any deviation triggers immediate investigation and corrective action. Detailed records of these tests, including dates, times, results, and corrective actions, are maintained meticulously. This detailed record-keeping provides a clear audit trail demonstrating our compliance efforts and allows us to identify trends or potential issues.

Furthermore, we implement a preventive maintenance program for our equipment to ensure consistent performance and avoid failures that could lead to non-compliance. This program includes regular inspections, calibrations, and repairs of all critical components. Finally, we regularly review and update our procedures to stay informed about changes in regulations and best practices in water treatment.

Q 9. What are the safety precautions you take when handling chemicals used in water treatment?

Handling chemicals in water treatment requires strict adherence to safety protocols. It’s not just about following the instructions on the chemical containers; it’s about creating a safety-conscious culture. Before starting any work, we always consult the Safety Data Sheets (SDS) for every chemical we handle. These sheets provide crucial information about hazards, safe handling procedures, personal protective equipment (PPE) required, and emergency response measures.

PPE is our first line of defense. This includes things like chemical-resistant gloves, safety glasses or goggles, respirators (if required), and protective clothing. We use proper ventilation systems to minimize exposure to fumes and airborne particles. We also ensure all chemical storage areas are well-ventilated, properly labeled, and secured to prevent unauthorized access or spills.

Spill response plans are essential. We conduct regular training sessions on how to handle chemical spills safely and effectively. This includes knowing the appropriate neutralization procedures (if applicable) and how to use spill containment materials. Proper disposal of used chemicals and containers is equally important. We adhere to all environmental regulations for disposal of chemical waste.

Q 10. Explain the different types of pumps used in water treatment and their maintenance.

Water treatment facilities utilize various types of pumps, each designed for specific tasks and pressures. Centrifugal pumps are the workhorses of most plants, used for moving large volumes of water at moderate pressures. They’re relatively simple to maintain, requiring regular lubrication, impeller inspections, and seal replacements. Problems often manifest as reduced flow or increased vibrations.

Diaphragm pumps are ideal for handling slurries or fluids containing solids, as the pumping action is achieved without impellers. Maintenance involves replacing diaphragms and valves periodically. Positive displacement pumps, such as piston or gear pumps, are used for high-pressure applications, requiring careful attention to packing and lubrication. Submersible pumps are often used for well water extraction, requiring periodic inspection and cleaning of the intake screens.

Regardless of the pump type, preventive maintenance is crucial. This involves regular visual inspections for leaks, corrosion, and wear. Vibration analysis can help detect early signs of mechanical problems. Scheduled maintenance includes lubricating moving parts, replacing worn seals, and ensuring proper alignment. A well-maintained pumping system guarantees efficient and reliable water treatment operations.

Q 11. How do you diagnose and repair problems with water treatment valves?

Diagnosing and repairing problems with water treatment valves requires a systematic approach. First, we isolate the problem valve and identify the symptoms. Is it leaking? Is it failing to open or close completely? Is there unusual noise or vibration? The answers to these questions will guide our diagnostic steps.

Once the problem is identified, we inspect the valve for obvious issues, such as corrosion, damage to the valve stem or seat, or clogging. For gate valves, we check for proper alignment and seating. For ball valves, we look for debris or damage to the ball. For butterfly valves, we check for wear on the seat and the butterfly disc. We use specialized tools like valve stem torque wrenches to test for proper operation and ensure we’re not applying excessive force.

Repairs can range from simple tasks like cleaning or lubricating the valve to more complex operations like replacing seals, stems, or even the entire valve body. We might need to perform pressure tests to check for leaks after repairs. Documentation is important throughout the process, noting the problem, the repairs made, and the results of any testing.

Q 12. What is your experience with PLC programming in water treatment systems?

My experience with PLC programming in water treatment systems is extensive. I’ve worked with various PLC platforms, including Allen-Bradley, Siemens, and Schneider Electric, to program and maintain control systems for water treatment plants of varying sizes. My skills encompass everything from designing ladder logic programs to troubleshooting existing systems.

I’ve been involved in projects such as automating chemical feed systems, implementing SCADA (Supervisory Control and Data Acquisition) integration, and developing custom control algorithms for optimizing treatment processes. I am proficient in using HMI (Human Machine Interface) software to create user-friendly interfaces for operators to monitor and control the plant’s processes. This includes designing displays, creating alarms, and setting up data logging functionalities.

My experience also includes working with various field devices, including flow meters, level sensors, and analyzers, and integrating them into the PLC system. I’m adept at using programming tools for debugging, simulating, and optimizing PLC programs. My programming expertise significantly contributes to efficient and reliable operation of water treatment plants.

Q 13. Describe your experience with troubleshooting electrical issues in water treatment equipment.

Troubleshooting electrical issues in water treatment equipment requires a methodical approach, beginning with safety precautions. Always ensure power is disconnected before working on any electrical components. We use appropriate testing equipment, such as multimeters and insulation testers, to diagnose the problem. We systematically check wiring, connections, circuit breakers, and motor starters.

Common problems include faulty motors, blown fuses, wiring shorts, and problems with motor control circuits. For motor problems, we may use a motor analyzer to diagnose issues like winding faults or bearing problems. We carefully inspect wiring harnesses for signs of damage or corrosion. We’re also familiar with using thermal imaging cameras to detect overheating in electrical components which can indicate impending failures.

Troubleshooting electrical systems demands a strong understanding of electrical theory and safety procedures. It often involves tracing wiring diagrams, interpreting fault codes, and performing appropriate repairs. Safety is paramount throughout the process, and proper documentation of findings and repairs is essential for future reference and maintenance planning.

Q 14. How familiar are you with different types of water meters and their maintenance?

I have considerable experience with various water meters, including mechanical, ultrasonic, and electromagnetic flow meters. Mechanical meters, such as positive displacement meters, are relatively simple, but their accuracy can degrade over time due to wear and tear. Maintenance involves periodic inspections for leaks, debris buildup, and gear wear. Regular calibration is also essential.

Ultrasonic meters use sound waves to measure flow, offering high accuracy and minimal pressure drop. Their maintenance is primarily focused on ensuring the sensor is clean and free from obstructions. Electromagnetic meters measure flow by detecting the voltage induced by a conductive fluid passing through a magnetic field. These meters are very accurate but require careful attention to their sensor alignment and proper grounding.

In addition to the above, I’m familiar with maintaining various types of level sensors – float switches, pressure sensors, ultrasonic level sensors – integral to accurate metering operations. Regular calibration and cleaning are key to maintaining the accuracy and reliability of all water meters, ensuring accurate billing and efficient water management.

Q 15. Explain your experience with maintaining chlorination systems.

Maintaining chlorination systems involves ensuring consistent disinfection while adhering to safety regulations. My experience encompasses handling various chlorination methods, including gaseous chlorine, hypochlorite solutions (liquid or granular), and even emerging technologies like electrochlorination. This includes regular monitoring of chlorine residual levels using colorimetric or electronic methods to maintain optimal disinfection throughout the water treatment process.

For example, in my previous role, we experienced a sudden drop in chlorine residuals. Through systematic troubleshooting, we identified a leak in the chlorine feed line. Immediate action was taken to isolate the leak, repair it safely, and recalibrate the feed system. This highlights the importance of regular inspections, preventative maintenance (checking for corrosion, leaks, and proper operation of the system), and accurate data logging to prevent such incidents and maintain effective disinfection. We also conducted regular safety training for staff to handle chlorine safely and minimize risks.

Beyond routine checks, I’m proficient in calibrating chlorine feed pumps, replacing worn parts (like injectors or control valves), and managing chemical storage and handling in compliance with all relevant safety protocols. Furthermore, I have experience optimizing chlorination systems for energy efficiency and cost savings by adjusting feed rates based on flow and demand variations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform a backwash procedure on a filter system?

The backwash procedure is crucial for maintaining the efficiency of filter systems by removing accumulated solids and restoring their filtration capacity. It’s essentially a controlled reverse flow of water through the filter media.

The process typically involves these steps:

- Isolation: Isolate the filter unit from the treatment train by closing inlet and outlet valves.

- Backwash Initiation: Initiate the backwash pump, creating a reverse flow of water through the filter media. The flow rate and duration are crucial and depend on the filter type and size; these parameters are often pre-programmed into the control system.

- Air Scouring (Optional): Some systems incorporate an air scouring phase before the water backwash. This step helps to loosen the accumulated material.

- Water Backwash: The reverse flow of water lifts and removes the accumulated solids. This often results in a cloudy effluent that’s discharged to waste. The duration is critical to ensure proper cleaning without causing damage to the media.

- Slow Rinse: Once the backwash is complete, a slow rinse helps to settle the filter media and remove any remaining suspended solids before resuming normal operation.

- Fast Rinse: This step flushes out remaining debris before resuming filtration.

- Return to Service: After the filter media has settled, the filter is brought back online by slowly opening the outlet valve.

Monitoring the turbidity of the backwash water can indicate the effectiveness of the cleaning process. If necessary, adjustments to the backwash cycle may need to be made, such as increasing duration or adjusting the flow rate. Regular inspection of the filter media is also essential to assess its condition and determine if replacement or regeneration is required.

Q 17. Describe your experience with different types of water storage tanks and their maintenance.

My experience encompasses maintaining various water storage tanks, including elevated tanks, ground storage reservoirs, and clearwells. Each type presents unique maintenance challenges.

Elevated Tanks: These require regular inspections of the tank structure for corrosion, leaks, and structural integrity. Access for inspection and maintenance is often challenging and may require specialized equipment. I’ve been involved in implementing protective coatings and carrying out necessary repairs, as well as ensuring safe access for inspection and maintenance personnel.

Ground Storage Reservoirs: These tanks typically require more frequent cleaning and disinfection to prevent algae growth and bacterial contamination. This often involves draining and cleaning the tank, inspecting for leaks, and then disinfecting using approved methods before refilling. I’ve also monitored water levels and quality within these reservoirs, addressing issues such as stratification and sediment accumulation.

Clearwells: Clearwells, used for sedimentation, need regular cleaning to remove sludge accumulated at the bottom. Maintenance focuses on efficient sludge removal mechanisms, minimizing downtime, and avoiding cross-contamination. The sludge removal process may be manual or automated, requiring regular maintenance of pumps, valves and associated equipment.

In all cases, maintaining accurate records of inspections, cleaning, and repairs is vital for compliance and planning future maintenance activities. Regular water quality monitoring within the tanks is essential for ensuring the stored water is safe and meets required standards.

Q 18. What is your experience with data logging and analysis in water treatment?

Data logging and analysis are crucial for effective water treatment plant management. My experience includes utilizing SCADA (Supervisory Control and Data Acquisition) systems to monitor and record various parameters such as flow rates, pressure, chemical dosages, turbidity, pH, chlorine residual, and other relevant water quality indicators.

I’m proficient in using this data to identify trends, anomalies, and potential problems. For instance, a sudden increase in turbidity might indicate a problem with the filter system, a drop in pH could suggest a malfunction in the chemical feed system, or a decrease in chlorine residual could point to a leak or insufficient dosing.

I use statistical analysis and trend analysis techniques to interpret this data, anticipate potential issues, optimize treatment processes, and improve overall operational efficiency. The analysis may involve using software tools such as spreadsheets, data visualization software, or dedicated water treatment plant management systems. Reporting on these findings to management allows for proactive maintenance and improves the overall efficiency of the water treatment plant. The insights gained from data analysis are also crucial for regulatory compliance reporting.

Q 19. Explain your knowledge of different types of water treatment processes (e.g., coagulation, flocculation, sedimentation).

Water treatment involves several processes to remove impurities and make water safe for consumption. I have experience with various processes:

- Coagulation: This involves adding a coagulant (like alum or ferric chloride) to destabilize suspended particles in the water, causing them to clump together.

- Flocculation: Gentle mixing after coagulation promotes the aggregation of destabilized particles into larger flocs, which are easier to remove.

- Sedimentation: Gravity is used to separate the larger flocs from the water in settling basins or clarifiers.

- Filtration: After sedimentation, water passes through filters (sand, gravel, or membrane filters) to remove remaining suspended solids.

- Disinfection: Chlorination, UV disinfection, or ozonation are used to kill harmful bacteria and viruses.

Understanding the interdependencies of these processes is critical. For example, the effectiveness of coagulation and flocculation directly impacts the efficiency of sedimentation and filtration. Improper coagulation can lead to poor sedimentation, resulting in increased filter loading and shorter filter runs. My experience allows me to optimize the entire treatment train by adjusting parameters in each step to achieve the best possible water quality.

Q 20. How do you interpret water quality test results?

Interpreting water quality test results involves understanding the significance of various parameters and their implications for water quality and treatment processes.

For example, high turbidity indicates excessive suspended solids, potentially necessitating adjustments to the coagulation-flocculation-sedimentation process or filter backwashing. Low pH might indicate the need for adjustment to the chemical feed system, while high levels of specific contaminants would necessitate investigating their source and implementing appropriate treatment measures.

The interpretation also considers the context. Comparing results to regulatory limits and historical data provides a baseline to assess whether values are within acceptable ranges or deviate significantly. A sudden change in a parameter, even if within regulatory limits, may warrant further investigation.

My experience involves using various testing methods and equipment, including analyzing lab reports, understanding the limitations of different testing methods, and communicating findings effectively to both technical and non-technical audiences. This ensures informed decision-making for efficient plant operation and maintenance.

Q 21. How do you identify and address leaks in water treatment systems?

Identifying and addressing leaks is critical to conserve water, maintain system pressure, and prevent potential damage. Techniques I use include:

- Visual Inspection: This involves systematically checking pipes, fittings, valves, and other components for visible signs of leakage, such as wet spots, discoloration, or dripping.

- Pressure Testing: Sections of the system are isolated, and pressure is applied to detect leaks by monitoring pressure drop over time.

- Acoustic Leak Detection: Specialized equipment is used to detect the sound of escaping water, helping to pinpoint leaks even in underground pipes.

- Dye Tracing: Dye is introduced into the system to visually trace the path of escaping water.

- Data Analysis: Analyzing SCADA data on flow rates and pressure can reveal anomalies indicative of leaks.

Once a leak is located, repairing it depends on its nature and location. Small leaks might be repaired using clamps or sealant, while larger or more complex leaks might require excavation, pipe replacement, or other major repairs. Safety is paramount; all work must adhere to relevant safety protocols and regulations, particularly when dealing with pressurized systems. A record of leak locations, causes, and repairs is essential for future maintenance and analysis of system performance and longevity.

Q 22. Describe your experience with maintaining UV disinfection systems.

Maintaining UV disinfection systems involves a multifaceted approach focusing on lamp performance, sensor accuracy, and overall system hygiene. My experience encompasses all aspects, from routine inspections to major repairs. I’ve worked with low-pressure and medium-pressure UV systems, understanding the nuances of each technology.

Routine maintenance includes regularly checking lamp output using a UV radiometer to ensure sufficient disinfection power. A drop in intensity indicates the lamp needs replacement or cleaning. I also inspect the quartz sleeves for fouling; any build-up of minerals or organic matter reduces UV transmission and effectiveness. Cleaning involves careful handling and potentially chemical treatment, always adhering to safety protocols. Further, the sensor monitoring UV intensity and flow rate is regularly calibrated to ensure accurate readings and system efficiency. I have personally tackled issues such as faulty sensors, problematic ballast issues (leading to inconsistent lamp power), and even complete lamp housing replacements.

For example, at my previous role, we noticed a gradual decrease in disinfection efficiency in our larger water treatment plant. By meticulously analyzing the UV intensity readings and conducting a thorough visual inspection, we discovered significant biofouling on the quartz sleeves. A planned shutdown allowed us to effectively clean and restore the system to optimal performance, preventing potential health risks. This highlights the importance of proactive maintenance and regular monitoring.

Q 23. What are the common causes of corrosion in water treatment equipment?

Corrosion in water treatment equipment is a significant concern, primarily driven by the chemical composition of the water itself and the materials used in construction. The most common causes include:

- Low pH (acidity): Highly acidic water aggressively attacks many metals, leading to pitting and general degradation. This is particularly true for steel components.

- Dissolved Oxygen: Oxygen dissolved in water accelerates the corrosion process, particularly in the presence of electrolytes. This is a major factor in both ferrous and non-ferrous metals.

- High concentrations of dissolved salts and minerals: These act as electrolytes, increasing the conductivity of the water and enhancing corrosive reactions. Think of the effect of saltwater on iron.

- Presence of aggressive ions: Chlorides, sulfates, and bicarbonates can significantly contribute to corrosion. Chlorides are particularly problematic.

- Improper material selection: Using materials unsuitable for the specific water chemistry is a major contributing factor. Stainless steels, while often resistant, are still susceptible under harsh conditions.

Understanding these causes allows for proactive measures like implementing cathodic protection, using corrosion-resistant materials, and adjusting the water chemistry (e.g., pH adjustment) to minimize corrosion risks.

Q 24. How do you prevent biofouling in water treatment systems?

Biofouling, the accumulation of biological organisms within a water treatment system, reduces efficiency and can compromise water quality. Prevention strategies encompass both physical and chemical approaches:

- Regular Cleaning and Disinfection: Frequent cleaning of filters, pipes, and tanks is essential. This often involves chemical disinfection using chlorine, ozone, or other suitable biocides.

- Chlorination: Maintaining a residual chlorine level throughout the system is a highly effective method to inhibit microbial growth.

- Ultraviolet (UV) Disinfection: UV light effectively kills bacteria and viruses in the treated water, reducing the risk of biofouling.

- Membrane filtration: Effective in removing a significant portion of microorganisms.

- Proper system design: Designing the system to minimize stagnant areas where biofilm can accumulate is crucial. This includes ensuring proper flow rates and avoiding dead legs in piping.

- Monitoring and control: Regular monitoring of water quality parameters, such as turbidity and bacterial counts, helps in early detection and timely intervention.

Imagine a situation where biofouling severely restricts flow in a filter. This would necessitate emergency shutdown for cleaning, impacting water supply and potentially causing costly delays. By employing a preventative maintenance program that incorporates the strategies above, we drastically reduce the risk of such occurrences.

Q 25. What is your experience with maintaining ion exchange systems?

My experience with ion exchange systems spans several years, covering both maintenance and troubleshooting. I’m proficient in managing both cation and anion exchange resins, understanding their regeneration cycles and the critical role they play in water purification.

Maintenance activities include monitoring resin bed performance (measuring pressure drop and flow rate), conducting regular backwashing to remove suspended solids, and periodically regenerating the resins using appropriate chemicals (typically strong acids or bases). I’m adept at identifying signs of resin exhaustion, such as a gradual increase in the treated water’s ion concentration. This requires careful analysis of effluent quality using conductivity meters and specific ion analyzers. When regeneration is ineffective, it often points to resin degradation or contamination, requiring replacement or more extensive cleaning processes. I have successfully managed situations of resin channeling (where water flows preferentially through certain parts of the bed), which significantly decreases efficiency. This typically involves careful bed expansion and re-stratification procedures.

In one instance, a significant increase in treated water sodium levels indicated resin exhaustion in the cation exchange unit of a pharmaceutical plant. By quickly performing a regeneration cycle, followed by a thorough analysis of the resin’s performance, we prevented a production halt and ensured the plant continued operating safely. This illustrates the importance of monitoring effluent water quality and prompt intervention.

Q 26. Describe your troubleshooting process when a water treatment system fails.

My troubleshooting approach follows a systematic and logical process, starting with observation and data collection, followed by targeted investigation and repair. It involves:

- Initial Assessment: Carefully observe the symptoms of the system failure. What exactly is malfunctioning? Are there any alarms or error messages?

- Data Collection: Gather relevant data, including flow rates, pressure readings, chemical concentrations (e.g., chlorine levels, pH), and water quality parameters (turbidity, conductivity).

- System Checklists: Use standardized checklists for different components to identify potential causes of failure. This speeds up the diagnosis and ensures thoroughness.

- Component Inspection: Visually inspect relevant components, such as pumps, valves, sensors, filters, and piping for any obvious problems (leakages, blockages, physical damage).

- Testing and Analysis: If the problem is not immediately apparent, conduct further testing, possibly using specialized equipment (e.g., flow meters, pressure gauges, spectrometers). Water samples might be sent to a lab for detailed analysis.

- Repair and Restoration: Once the root cause is identified, carry out the necessary repairs or replacements, always documenting the work performed.

- System Re-Commissioning: After repair, rigorously test the system to verify its proper functioning before returning it to normal operation.

For example, a sudden drop in water pressure in a filtration system could be due to a clogged filter, a malfunctioning pump, or a leaking pipe. By systematically checking each component, I can quickly pinpoint the source of the problem and implement the appropriate solution.

Q 27. How do you ensure the proper disposal of hazardous waste from water treatment?

Ensuring proper disposal of hazardous waste from water treatment is crucial for environmental protection and worker safety. This involves adhering to all relevant local, state, and federal regulations. The process typically includes:

- Waste Characterization: Accurate identification of the hazardous components present in the waste (e.g., spent resins, used chemicals, contaminated filters) is the first step. This often requires laboratory analysis.

- Proper Containment: Hazardous wastes should be stored in designated containers, labeled appropriately, and kept securely to prevent leaks or spills.

- Treatment and Neutralization: Some hazardous wastes might require pre-treatment, such as neutralization of acids or bases, before disposal.

- Selection of Licensed Disposer: Disposal should only be done through licensed waste disposal companies that have the appropriate permits and infrastructure for handling the specific type of hazardous waste.

- Record Keeping: Detailed records of all waste generated, treated, and disposed of must be maintained. This is crucial for compliance and auditing purposes.

- Compliance with Regulations: Strict adherence to all environmental regulations is paramount. Regular audits help ensure compliance.

Failing to comply with proper hazardous waste disposal procedures can result in severe environmental damage, hefty fines, and potential legal repercussions. Therefore, meticulous adherence to protocols is not only environmentally responsible but also legally necessary.

Key Topics to Learn for Maintaining Water Treatment Equipment Interview

- Water Chemistry Fundamentals: Understanding pH levels, alkalinity, hardness, chlorine residuals, and other key water quality parameters. This includes knowing how these parameters affect treatment processes and equipment performance.

- Membrane Technology: Practical knowledge of reverse osmosis (RO), ultrafiltration (UF), and microfiltration (MF) systems – including operation, maintenance, troubleshooting, and cleaning procedures. Be prepared to discuss common membrane failures and remediation strategies.

- Filtration Systems: Understanding different types of filters (sand, carbon, multimedia) and their applications. This includes the ability to diagnose filter performance issues, such as pressure drops and clogging, and perform appropriate maintenance tasks.

- Disinfection Processes: Knowledge of various disinfection methods (chlorination, UV disinfection, ozonation) and their effectiveness against different types of microorganisms. Be ready to discuss safety protocols and regulatory compliance related to disinfection.

- Pump and Valve Systems: Familiarize yourself with the operation, maintenance, and troubleshooting of various types of pumps and valves commonly used in water treatment plants. This includes understanding pressure gauges, flow meters, and other monitoring equipment.

- Instrumentation and Control Systems: Understanding the role of sensors, controllers, and data acquisition systems in monitoring and controlling water treatment processes. This might involve PLC programming knowledge depending on the specific role.

- Safety and Regulatory Compliance: Demonstrate a thorough understanding of OSHA regulations, safety procedures, and emergency response protocols relevant to water treatment equipment maintenance.

- Troubleshooting and Problem-Solving: Practice describing your approach to diagnosing equipment malfunctions, identifying root causes, and implementing effective solutions. Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Preventive Maintenance Schedules: Understanding the importance of regular maintenance and the development and implementation of effective preventive maintenance programs.

Next Steps

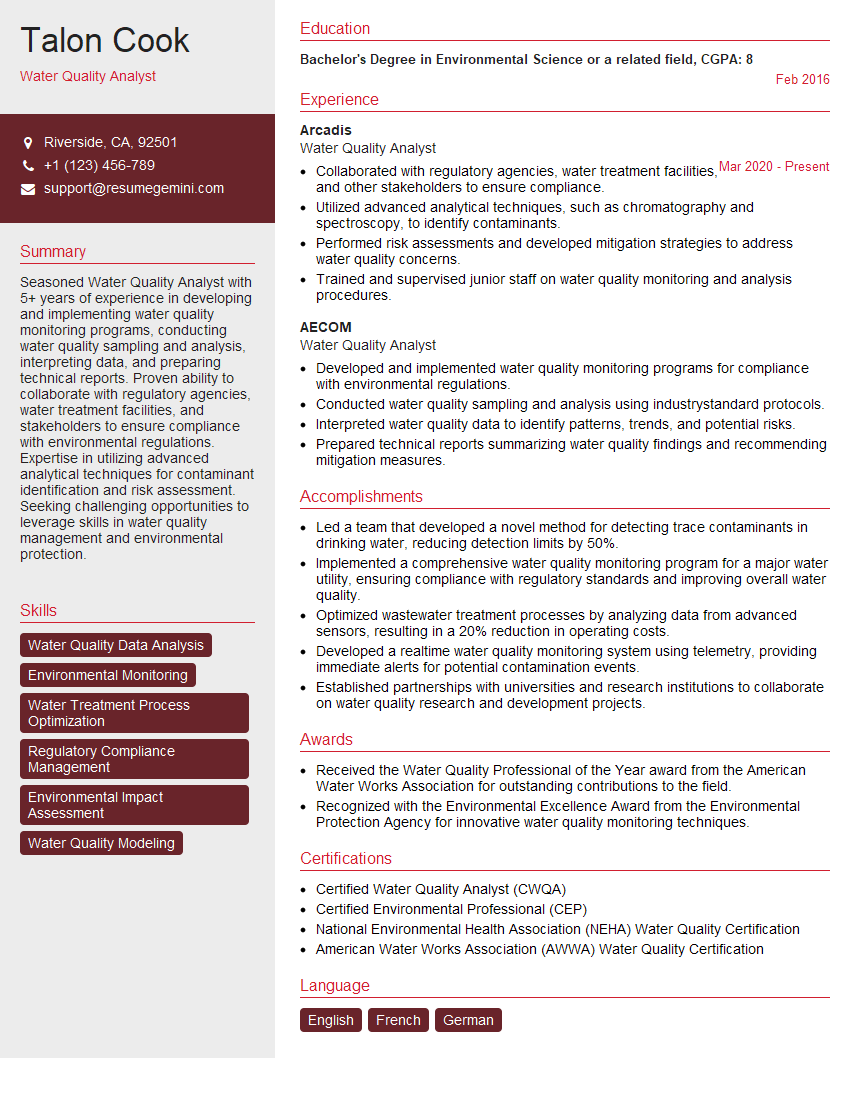

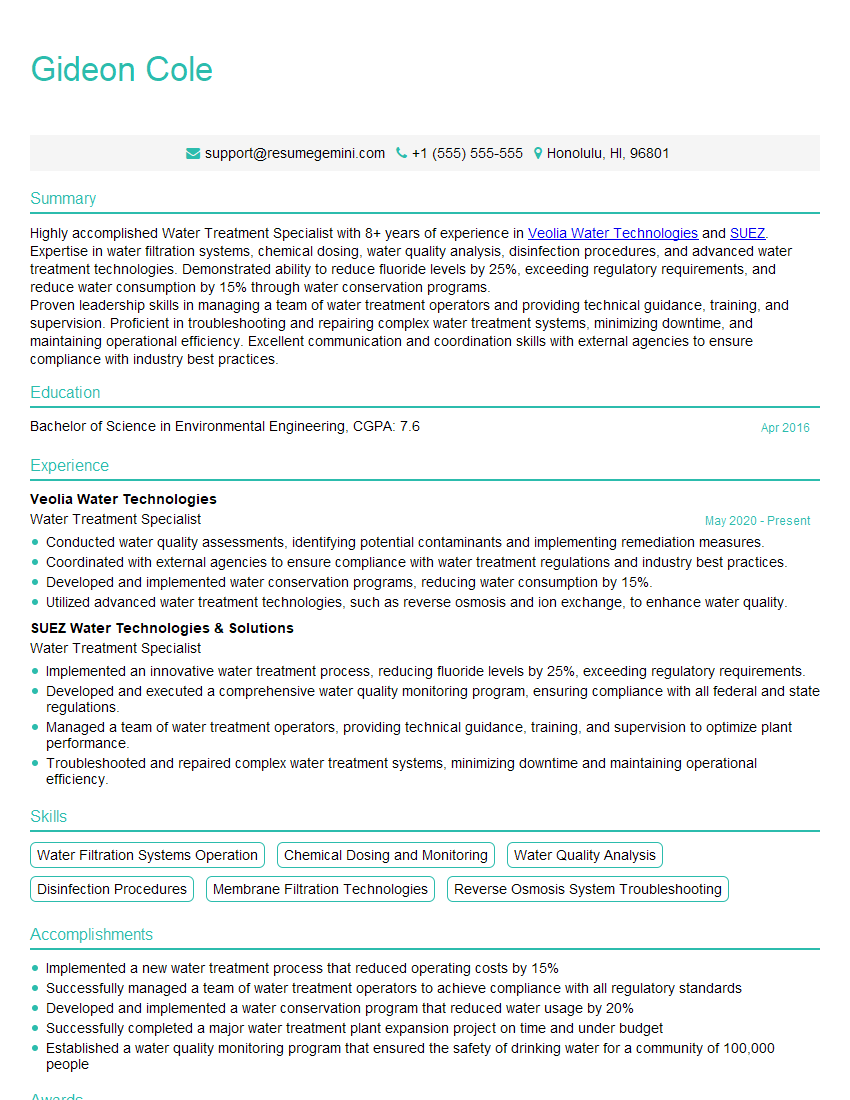

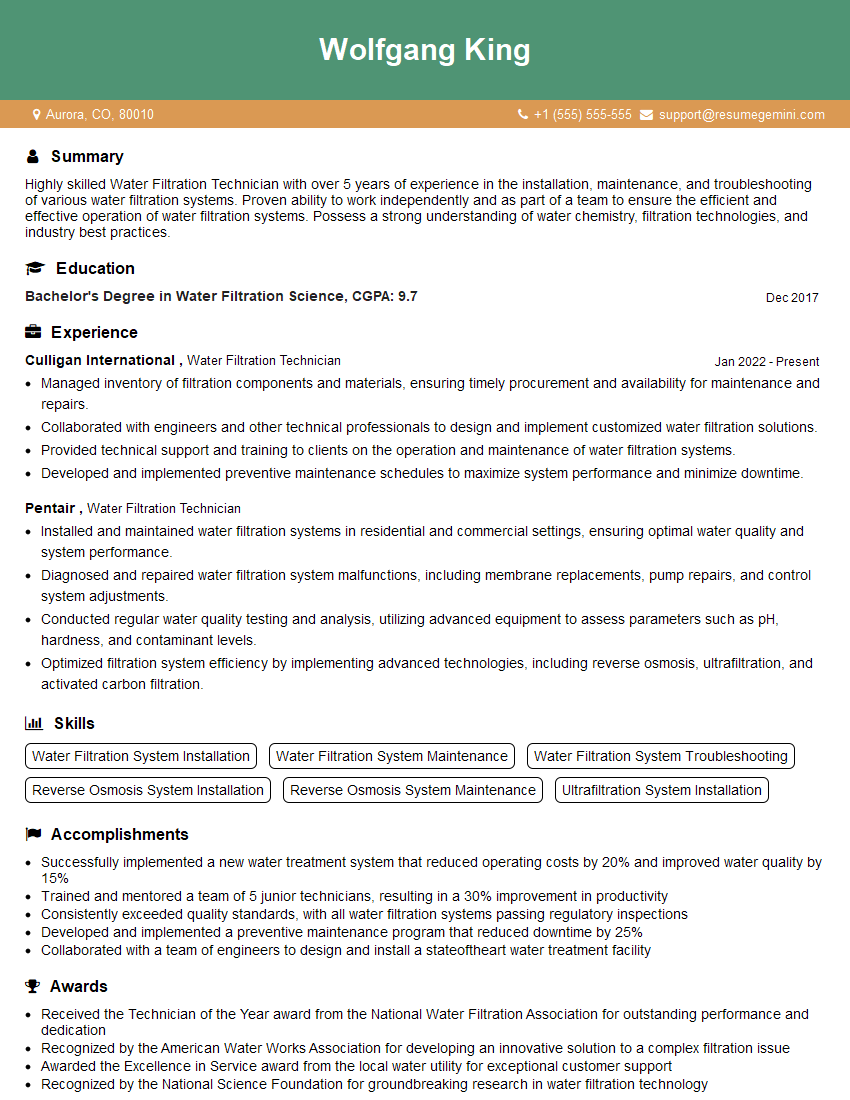

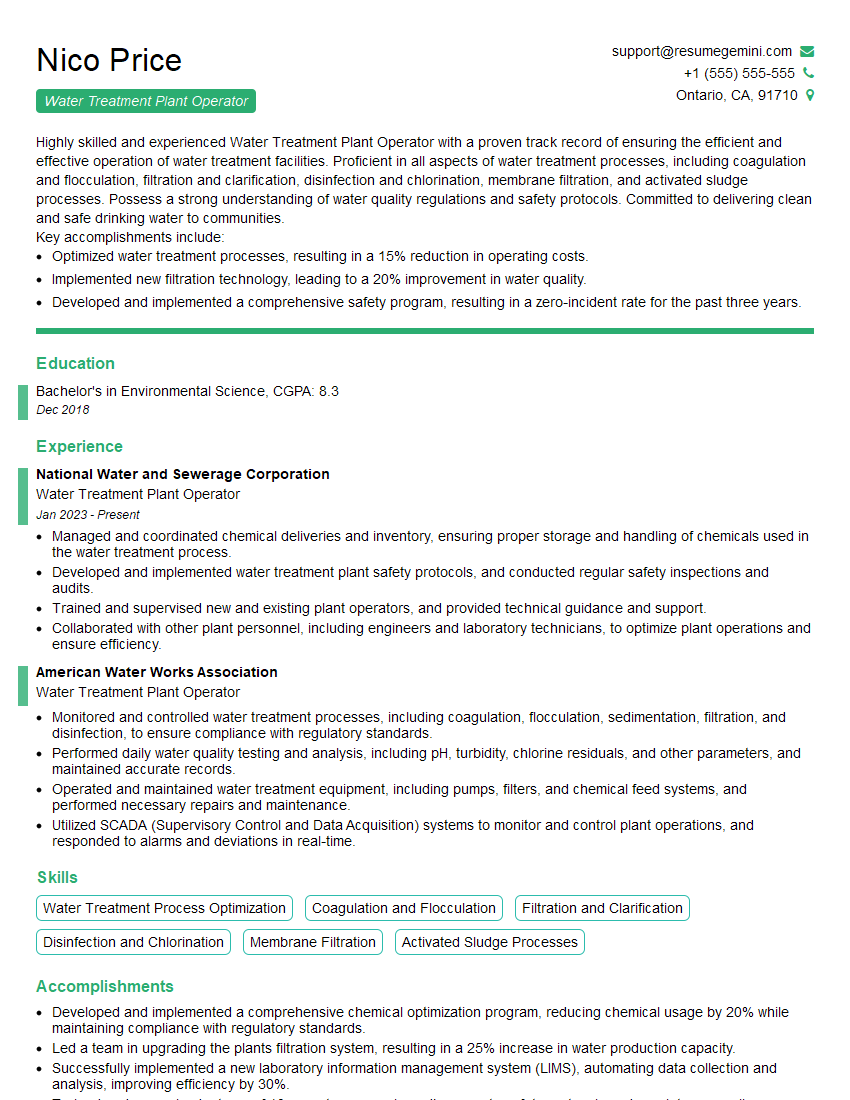

Mastering the maintenance of water treatment equipment opens doors to a rewarding career with excellent growth potential. This expertise is highly sought after, and demonstrating your knowledge through a well-crafted resume is crucial. An ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Maintaining Water Treatment Equipment to help you craft the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?