Are you ready to stand out in your next interview? Understanding and preparing for Maintenance and Repair Services interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Maintenance and Repair Services Interview

Q 1. Describe your experience with preventative maintenance.

Preventative maintenance (PM) is the cornerstone of ensuring equipment longevity and minimizing downtime. It involves proactively inspecting, cleaning, lubricating, and making minor repairs to equipment before significant failures occur. Think of it like regular check-ups for your car – much cheaper and less disruptive than waiting for a major breakdown.

In my previous role at Acme Manufacturing, I implemented a comprehensive PM program for our assembly line robots. This involved creating a detailed schedule based on manufacturer recommendations and usage patterns. Tasks included checking hydraulic fluid levels, lubricating moving parts, inspecting wiring for damage, and running diagnostic software. This resulted in a 30% reduction in unplanned downtime over a six-month period.

- Scheduled Inspections: Regular visual inspections for wear and tear, loose connections, or unusual noises.

- Lubrication: Applying lubricants to moving parts to reduce friction and extend component life.

- Calibration: Ensuring accuracy through regular calibration of measuring instruments and control systems.

- Software Updates: Implementing the latest software patches to improve performance and address known vulnerabilities.

Q 2. Explain your troubleshooting process for malfunctioning equipment.

My troubleshooting process is systematic and follows a logical sequence. I always begin by prioritizing safety, ensuring the equipment is powered down and locked out if necessary. Then I employ a five-step process:

- Gather Information: I start by gathering as much information as possible about the malfunction. This includes talking to operators, reviewing error logs, and visually inspecting the equipment.

- Identify Potential Causes: Based on the gathered information, I create a list of potential causes. This often involves referring to technical manuals, schematics, and troubleshooting guides.

- Test Hypotheses: I systematically test each hypothesis, one by one, using appropriate diagnostic tools and techniques. This might involve checking voltage levels, testing sensors, or running diagnostics software.

- Implement Solution: Once the root cause is identified, I implement the appropriate solution. This could involve replacing a faulty component, adjusting settings, or performing a more extensive repair.

- Verify Solution & Document Findings: Finally, I verify that the solution has resolved the problem and document all steps taken, including the cause of the failure, the solution implemented, and any preventative measures taken.

For example, when a packaging machine suddenly stopped working, I systematically checked the power supply, sensor inputs, and motor operation. I discovered a jammed sensor, cleared the jam, and the machine was back online in under an hour.

Q 3. What safety protocols do you follow during maintenance and repair?

Safety is my paramount concern. I strictly adhere to all relevant safety regulations and company policies. My safety protocols include:

- Lockout/Tagout (LOTO): Always using LOTO procedures before performing any maintenance on energized equipment to prevent accidental startup.

- Personal Protective Equipment (PPE): Consistent use of appropriate PPE, including safety glasses, gloves, hearing protection, and steel-toe boots, depending on the task.

- Risk Assessment: Conducting a thorough risk assessment before starting any maintenance task to identify potential hazards and develop mitigation strategies.

- Proper Handling of Materials: Following safe handling procedures for chemicals, lubricants, and other hazardous materials.

- Emergency Procedures: Familiarity with emergency procedures and knowing how to respond to accidents or incidents.

I never compromise on safety, even under pressure to complete a task quickly. Safety is non-negotiable.

Q 4. How do you prioritize maintenance tasks in a busy environment?

In a busy environment, prioritizing maintenance tasks is crucial. I utilize a combination of techniques:

- CMMS (Computerized Maintenance Management System): Using a CMMS to schedule and track maintenance tasks, assign priorities, and monitor equipment performance. This allows for efficient planning and resource allocation.

- Criticality Analysis: Prioritizing tasks based on the criticality of the equipment. Equipment vital to production receives higher priority.

- Failure Mode and Effects Analysis (FMEA): Using FMEA to identify potential failure modes and their impact, allowing for proactive maintenance to prevent critical failures.

- Urgency & Impact Matrix: This matrix helps prioritize tasks based on urgency (how quickly it needs to be done) and impact (how severe the consequences would be if not addressed). Urgent and high-impact tasks get immediate attention.

For instance, a malfunctioning compressor in a refrigeration unit would be prioritized over routine lubrication of a conveyor belt because of its greater impact on production and potential for significant financial loss.

Q 5. What experience do you have with specific tools and equipment?

I’m proficient with a wide range of tools and equipment, including:

- Hand Tools: Wrenches, screwdrivers, pliers, multimeters, etc.

- Power Tools: Drills, grinders, impact wrenches, saws, etc.

- Specialized Tools: Depending on the equipment being maintained, I’m experienced with specialized tools such as hydraulic presses, diagnostic scanners, and thermal imaging cameras.

- Testing Equipment: Oscilloscopes, clamp meters, and other electrical testing devices.

- Welding Equipment: MIG and TIG welding experience for fabrication and repair.

My experience extends to working with different types of machinery, including industrial robots, CNC machines, HVAC systems, and various types of packaging equipment. I’m always eager to learn new techniques and gain proficiency with new tools as technology advances.

Q 6. Describe your experience with diagnosing and repairing electrical systems.

I have extensive experience diagnosing and repairing electrical systems. This includes troubleshooting problems in control circuits, motor drives, power distribution systems, and instrumentation. My approach involves:

- Safety First: Always ensuring the system is de-energized before working on it.

- Schematic Review: Carefully reviewing electrical schematics to understand the system’s layout and component relationships.

- Testing and Measurement: Using multimeters, oscilloscopes, and other test equipment to measure voltage, current, resistance, and other parameters.

- Component Identification & Testing: Identifying and testing individual components such as relays, contactors, sensors, and circuit boards.

- Wiring Diagrams & Tracing: Carefully tracing wires to locate shorts, open circuits, or other faults.

For example, I once successfully diagnosed a faulty relay in a complex control system that was causing intermittent shutdowns of a critical production line. Through careful testing and tracing, I identified the faulty relay, replaced it, and restored the system to full functionality, avoiding significant production losses.

Q 7. How do you handle unexpected equipment failures?

Unexpected equipment failures require a rapid and effective response. My approach involves:

- Immediate Assessment: Quickly assess the situation to determine the severity of the failure and its impact on operations.

- Safety Precautions: Take immediate safety precautions to secure the area and prevent further damage or injury.

- Emergency Repairs: If possible, perform temporary repairs to restore limited functionality while awaiting further assistance or parts.

- Root Cause Analysis: Once the immediate situation is stabilized, begin a thorough investigation to determine the root cause of the failure.

- Communication: Maintain clear and consistent communication with relevant stakeholders, keeping them informed of progress and anticipated downtime.

- Preventative Measures: Implement preventative measures to avoid similar failures in the future.

In one instance, a critical pump failed unexpectedly during a night shift. I immediately isolated the system, initiated emergency procedures, and managed to implement a temporary workaround using a backup pump. This minimized downtime and prevented significant production losses while the faulty pump was repaired.

Q 8. What is your experience with hydraulic and pneumatic systems?

My experience with hydraulic and pneumatic systems spans over 10 years, encompassing both preventative maintenance and troubleshooting complex failures. I’m proficient in diagnosing leaks, identifying faulty components like pumps, cylinders, and valves, and performing repairs or replacements. I understand the principles of fluid power, including Pascal’s Law and the differences between open and closed-center systems. For instance, in a recent project involving a large industrial press, I diagnosed a pressure drop by meticulously checking for leaks using a pressure gauge and soapy water, tracing the leak to a faulty O-ring seal on a hydraulic cylinder. Replacing the seal restored the press to full functionality. Similarly, with pneumatic systems, I have experience with air compressors, pneumatic tools, and automated systems, troubleshooting issues like air leaks, pressure regulation problems, and component malfunctions. My experience extends to understanding various types of actuators, such as linear and rotary actuators, and their applications.

I’m familiar with various hydraulic fluids and their properties, and I understand the importance of proper fluid selection and maintenance for optimal system performance and longevity. My work also includes understanding and applying safety procedures while working with high-pressure systems.

Q 9. Describe your experience with HVAC systems maintenance and repair.

My HVAC experience involves a broad range of tasks, from routine inspections and preventative maintenance to diagnosing and repairing complex malfunctions. I’m proficient in handling various systems, including chillers, air handlers, boilers, and rooftop units. Think of it like this: an HVAC system is like the circulatory system of a building, and my job is to keep it healthy and efficient. My work includes cleaning and replacing air filters, checking refrigerant levels, inspecting coils for leaks and cleaning them, balancing airflow, and troubleshooting electrical issues. I’m adept at using various diagnostic tools, such as multimeters, pressure gauges, and temperature sensors. For example, I once identified a faulty capacitor in a rooftop unit’s compressor motor by meticulously checking voltage and amperage readings. This prevented a costly system failure and kept the building climate controlled. I also possess experience in working with building automation systems (BAS) for monitoring and controlling HVAC equipment.

Q 10. Explain your experience with plumbing systems maintenance and repair.

My plumbing experience covers a wide spectrum of tasks, from routine maintenance to complex repairs. This includes working with various materials like copper, PVC, and PEX piping. I’m skilled in diagnosing and repairing leaks, clogs, and other plumbing issues. I’m familiar with different types of fixtures, such as faucets, toilets, and showers, and I can troubleshoot and replace them efficiently. My knowledge extends to water heaters, both gas and electric, and I’m capable of performing maintenance and repairs, including anode rod replacements and thermostat adjustments. For example, I recently resolved a low water pressure issue in a multi-unit building by identifying a partially closed valve in the main water line. Think of it like unclogging an artery; a small blockage can have a huge impact on the overall system.

Furthermore, I am experienced in working with backflow preventers and understand their importance in protecting the water supply from contamination. My experience also includes working with drain cleaning equipment such as snakes and sewer augers to clear clogs in drain lines.

Q 11. How do you maintain accurate records of maintenance activities?

Maintaining accurate records is crucial for effective maintenance management. I utilize a computerized maintenance management system (CMMS) to document all maintenance activities. This system allows for the precise recording of each task, including the date, time, equipment involved, work performed, materials used, and the technician responsible. I also include detailed descriptions of any problems encountered, solutions implemented, and any recommendations for future maintenance. This system provides easy access to historical data, making it straightforward to track maintenance trends, predict potential failures, and plan preventative maintenance schedules. It also helps us meet compliance requirements and streamline reporting. Think of it as a detailed medical chart for the building’s systems; it’s essential for proactive care.

Q 12. How do you ensure compliance with safety regulations?

Safety is my top priority. I adhere strictly to all relevant Occupational Safety and Health Administration (OSHA) regulations and company safety policies. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection, depending on the task. Before starting any work, I conduct thorough risk assessments to identify potential hazards and implement appropriate control measures. Lockout/Tagout procedures are religiously followed when working on energized equipment to prevent accidental starts. I participate regularly in safety training sessions to stay updated on the latest regulations and best practices. This proactive approach ensures a safe working environment for myself and others.

Q 13. What is your experience with reading and interpreting technical manuals?

Reading and interpreting technical manuals is a fundamental aspect of my job. I’m proficient in understanding schematics, diagrams, and other technical documentation to diagnose and repair equipment. I’m accustomed to working with various types of manuals, including manufacturer’s specifications, troubleshooting guides, and parts lists. I can quickly identify relevant information, understand technical jargon, and use the information to efficiently resolve problems. This skill is like having a detailed instruction manual for every piece of equipment I work on; it’s essential for effective problem-solving.

Q 14. Describe a time you had to work under pressure to fix a critical equipment failure.

During a severe winter storm, a critical heating system failure occurred in a large office building. The temperature inside was rapidly dropping, posing a significant risk to occupants and potential damage to the building. Under immense pressure to restore heating before working hours, I quickly assembled a team, and we systematically assessed the system. Using our expertise and the building’s blueprints, we isolated the malfunctioning component – a failed boiler pump – within an hour. We had to work quickly and efficiently in cold conditions. We replaced the pump, purged the system of air, and restored heating within two hours. This rapid response prevented significant damage and ensured the building was safe and habitable for employees. This situation highlighted the importance of teamwork, quick thinking, and a thorough understanding of the system under pressure.

Q 15. How do you stay up-to-date with the latest maintenance and repair techniques?

Staying current in the dynamic field of maintenance and repair requires a multi-pronged approach. It’s not enough to rely solely on past experience; continuous learning is paramount.

- Industry Publications and Journals: I regularly subscribe to and read publications like Plant Engineering and Maintenance Technology to stay abreast of the latest advancements in techniques, technologies, and best practices. These publications often feature case studies and in-depth analyses of maintenance strategies.

- Manufacturer Training and Webinars: Equipment manufacturers frequently offer training programs and webinars on the maintenance and repair of their specific products. Participating in these sessions allows me to gain hands-on experience and learn directly from the experts who designed the equipment.

- Professional Development Courses and Conferences: I actively seek out opportunities to attend professional development courses and conferences, such as those offered by organizations like the Society for Maintenance & Reliability Professionals (SMRP). This provides networking opportunities and exposure to broader industry trends.

- Online Resources and Communities: Online forums, communities, and knowledge bases (like those found on manufacturer websites) provide a valuable source of information and peer-to-peer learning. Discussions on troubleshooting specific problems or sharing best practices can be incredibly helpful.

For example, I recently attended a webinar on predictive maintenance using vibration analysis, which significantly enhanced my ability to diagnose equipment problems early and prevent costly failures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or systems are you proficient with for maintenance management?

My proficiency spans several software and systems crucial for efficient maintenance management. I’m experienced with Computerized Maintenance Management Systems (CMMS) like SAP PM, IBM Maximo, and Fiix. These systems allow for streamlined work order management, inventory tracking, and preventive maintenance scheduling. I also possess strong skills in using data analysis software such as Microsoft Excel and Tableau to track key performance indicators (KPIs) and identify areas for improvement in maintenance operations.

For instance, using SAP PM, I’ve successfully implemented a preventive maintenance program that reduced downtime by 15% in a previous role. This involved meticulously scheduling routine inspections and repairs based on manufacturer recommendations and historical equipment data. Furthermore, using Excel, I’ve created dashboards to visualize equipment performance and maintenance costs, enabling data-driven decision-making.

Q 17. How do you handle conflict with other technicians or staff?

Conflict resolution is a crucial skill in any team environment, particularly in maintenance where collaborative problem-solving is essential. My approach emphasizes open communication, mutual respect, and finding collaborative solutions.

- Active Listening: I begin by actively listening to understand the other person’s perspective, even if I don’t initially agree with it. This shows respect and helps build rapport.

- Clear and Respectful Communication: I express my own viewpoint clearly and respectfully, focusing on the issue at hand rather than resorting to personal attacks.

- Collaborative Problem-Solving: I believe in collaborative problem-solving, working together to identify the root cause of the conflict and find a mutually acceptable solution. This might involve brainstorming potential solutions or compromising on certain points.

- Escalation (if necessary): If the conflict cannot be resolved at a team level, I’m comfortable escalating it to a supervisor or manager, but I prefer to exhaust all internal resolution methods first.

For example, I once had a disagreement with a colleague about the best approach to repairing a complex piece of machinery. Instead of arguing, we sat down, reviewed the relevant technical documentation together, and collaboratively determined the optimal solution.

Q 18. Describe your experience with welding and fabrication.

My welding and fabrication experience encompasses various processes, including MIG, TIG, and stick welding. I’m proficient in working with different metals, such as steel, aluminum, and stainless steel. My fabrication skills involve blueprint reading, material selection, and the use of various tools and machinery, including cutting torches, grinders, and shears. I’ve been involved in projects ranging from simple repairs to more complex custom fabrication tasks.

In a previous role, I was responsible for fabricating custom brackets for a specialized piece of industrial equipment. This involved creating detailed drawings based on the engineer’s specifications, selecting appropriate materials, performing the necessary welding and finishing work, and ensuring the final product met the required tolerances and safety standards. I’m comfortable working independently and as part of a team on fabrication projects.

Q 19. What is your experience with industrial machinery repair?

I have extensive experience repairing various types of industrial machinery, including conveyors, pumps, compressors, and hydraulic systems. My experience extends to diagnosing mechanical, electrical, and hydraulic failures, performing repairs, and conducting preventative maintenance. I’m familiar with safety regulations and procedures related to industrial machinery maintenance and repair.

For instance, I once successfully diagnosed and repaired a malfunctioning hydraulic press in a manufacturing facility, preventing significant production downtime. The malfunction was traced to a leak in the hydraulic system. I located the leak, replaced the damaged components, and performed a thorough system test to ensure its proper functioning before resuming operations.

Q 20. How do you manage your workload and prioritize tasks?

Effective workload management and prioritization are critical for efficient maintenance operations. My approach is rooted in a combination of planning, organization, and effective time management techniques.

- Prioritization Matrix: I often employ a prioritization matrix, categorizing tasks based on urgency and importance (e.g., using a Eisenhower Matrix). This ensures that critical tasks receive immediate attention while less urgent tasks are scheduled appropriately.

- Task Scheduling and Time Blocking: I use task scheduling tools and time blocking techniques to allocate specific time slots for different tasks, promoting focus and preventing task switching.

- Regular Review and Adjustment: I regularly review my schedule and adjust it as needed, adapting to changing priorities and unforeseen circumstances. This ensures that I remain flexible and responsive.

- Delegation (when appropriate): If possible, I delegate tasks that can be effectively handled by other team members, freeing up my time to focus on higher-priority items.

For example, when facing multiple urgent repair requests, I prioritize those that directly impact production, ensuring minimal downtime. I then schedule the remaining tasks based on their urgency and impact on overall operations.

Q 21. What is your experience with root cause analysis of equipment failures?

Root cause analysis (RCA) is a systematic process to identify the underlying causes of equipment failures, preventing recurrence. My approach typically follows a structured methodology, often using a combination of techniques such as the ‘5 Whys’ and fault tree analysis.

- Data Collection: I start by gathering all relevant data, including maintenance logs, operating records, and witness statements. This provides a comprehensive understanding of the failure event.

- ‘5 Whys’: This simple yet effective technique involves repeatedly asking ‘why’ to uncover the root cause. By progressively drilling down, we move beyond superficial symptoms to the underlying issues.

- Fault Tree Analysis (FTA): For more complex failures, I may use FTA to graphically represent the various factors that contributed to the event, identifying the most likely root causes.

- Corrective Actions: Once the root cause is identified, I work to implement effective corrective actions to prevent similar failures in the future. This may include design modifications, improved maintenance procedures, or operator training.

In one instance, a recurring pump failure was initially attributed to simple wear and tear. By using the ‘5 Whys’ methodology, we discovered the root cause was inadequate lubrication due to a faulty oil pump, a far more significant and easily rectifiable issue.

Q 22. How do you communicate effectively with clients or supervisors?

Effective communication is the cornerstone of successful maintenance and repair. I prioritize clear, concise, and respectful communication with both clients and supervisors. With clients, I focus on actively listening to understand their needs, explaining technical details in plain language, and providing realistic timelines and cost estimates. I use visual aids like diagrams or photos when helpful. For example, if a client is unsure about the cause of a malfunctioning HVAC system, I’ll show them a clear diagram of the system and explain the problem step-by-step, rather than just stating a technical term like ‘compressor failure’. With supervisors, I maintain open communication channels, promptly reporting progress, challenges, and any potential issues that might affect project timelines or budgets. I also actively seek feedback and incorporate it to improve my performance.

- Active Listening: I ensure I fully understand the issue before offering solutions.

- Plain Language: I avoid jargon and use simple terms to explain complex concepts.

- Visual Aids: Diagrams, photos, and demonstrations are key to clear communication.

- Proactive Reporting: I keep supervisors informed of progress, challenges, and potential problems.

Q 23. What is your understanding of different types of lubricants and their applications?

Lubricants are crucial for reducing friction, wear, and heat in machinery. My understanding encompasses various types, including:

- Mineral Oils: Derived from crude oil, these are cost-effective and suitable for many applications. I’ve used these extensively in routine maintenance on older machinery.

- Synthetic Oils: Engineered oils offering superior performance at extreme temperatures and pressures. They are ideal for high-performance engines or equipment operating in harsh conditions. For example, I used a synthetic grease in the bearings of a high-speed centrifuge to ensure longevity and prevent premature wear.

- Greases: Semi-solid lubricants providing long-lasting lubrication in enclosed systems. Their viscosity and additives vary based on the application, like the type of bearing or operating temperature. I’ve selected greases for specific applications based on manufacturer recommendations.

- Specialty Lubricants: This broad category includes things like lithium-based greases for high-temperature applications, molybdenum disulfide greases for extreme-pressure situations, and food-grade lubricants for machinery used in food processing. The selection of this type of lubricant is critical to ensure safe operation and regulatory compliance.

Selecting the right lubricant is vital for optimal equipment performance and longevity. The choice depends on factors like the type of equipment, operating conditions (temperature, pressure, speed), and manufacturer recommendations. Failure to select the appropriate lubricant can lead to premature wear, equipment failure, and increased maintenance costs.

Q 24. Describe your experience with preventative maintenance scheduling and planning.

Preventative maintenance scheduling and planning are essential for minimizing downtime and extending equipment lifespan. My approach involves a combination of:

- CMMS (Computerized Maintenance Management System) utilization: I’m proficient in using CMMS software to track equipment, schedule preventative maintenance tasks, manage work orders, and generate reports. This system helps streamline the entire process and eliminates scheduling conflicts.

- Equipment History Review: Analyzing past maintenance records to identify trends, common failure points, and areas requiring more frequent attention. For example, if a specific pump consistently requires repair after 6 months, I’d recommend adjusting its preventative maintenance schedule to address this.

- Manufacturer Recommendations: Following manufacturer guidelines for recommended maintenance intervals and procedures. This is critical for warranty compliance and optimal equipment performance.

- Risk Assessment: Prioritizing preventative maintenance based on criticality analysis – identifying equipment that, if it fails, would cause significant downtime or safety risks.

I create detailed schedules that consider factors like equipment age, usage intensity, and potential environmental impacts. A well-planned preventative maintenance schedule helps avoid costly breakdowns and ensures smooth operations.

Q 25. How do you ensure the efficient use of maintenance resources?

Efficient resource use is critical for cost-effectiveness and improved productivity. My strategies include:

- Optimized Scheduling: Careful planning to minimize idle time for technicians and equipment. This might involve grouping similar tasks together or scheduling multiple maintenance activities on the same piece of equipment.

- Inventory Management: Maintaining optimal levels of spare parts to prevent delays caused by part shortages, while avoiding excessive inventory costs. This includes working closely with procurement.

- Proper Tool Selection and Maintenance: Ensuring technicians have the right tools for the job and that tools are in good working order to prevent delays and ensure safety.

- Cross-Training: Developing a skilled and versatile team capable of handling a variety of maintenance tasks. This reduces the need for specialized technicians for every job.

- Data Analysis: Tracking maintenance costs, downtime, and resource utilization to identify areas for improvement. This allows for data-driven decisions to optimize resource allocation.

For example, I once noticed a pattern of wasted time searching for specific tools. By implementing a centralized tool storage system and a better tool tracking system, we reduced downtime and improved technician productivity.

Q 26. What is your experience with inventory management of maintenance parts?

Effective inventory management of maintenance parts is essential for minimizing downtime and optimizing costs. My experience includes:

- ABC Analysis: Categorizing parts based on their value and usage frequency to prioritize inventory control efforts. High-value, frequently used parts receive closer monitoring.

- Min-Max Levels: Establishing minimum and maximum stock levels for each part to ensure sufficient supply while avoiding excessive inventory. I’ve used this method to prevent delays caused by parts shortages and reduce storage costs.

- Regular Stock Audits: Conducting periodic physical checks to verify inventory accuracy and identify discrepancies. This helps prevent errors in stock counts and keeps track of obsolete parts.

- Vendor Management: Building strong relationships with reliable vendors to ensure timely delivery of parts and negotiate favorable pricing agreements.

- Using Inventory Management Software: Utilizing software to track inventory levels, generate re-order points, and manage purchasing processes. This allows for better tracking of parts and efficient ordering.

For instance, by implementing a just-in-time inventory system for frequently used parts, we significantly reduced storage costs while ensuring minimal downtime from part shortages.

Q 27. Describe your experience with training junior technicians.

Training junior technicians is a vital aspect of my role. My approach combines:

- On-the-Job Training: Mentoring junior technicians by guiding them through various maintenance tasks, providing hands-on experience, and offering feedback on their performance. This is done in a safe and controlled environment.

- Classroom Training: Conducting formal training sessions to cover essential safety procedures, maintenance techniques, and troubleshooting strategies. The use of visual aids and practical exercises is essential here.

- Documentation and Standard Operating Procedures: Ensuring junior technicians have access to clear, concise documentation, and standard operating procedures for various maintenance tasks. This aids understanding and consistency across the team.

- Performance Monitoring and Feedback: Regularly assessing their performance, providing constructive criticism, and celebrating achievements to enhance their skill and confidence. This process includes regular check-ins and setting realistic goals.

- Continuing Education: Encouraging ongoing learning through attending workshops, online courses, and certifications to ensure technicians remain up-to-date with the latest industry practices and technologies.

For example, I developed a training program for new hires that included a combination of classroom learning, on-site mentoring, and simulated maintenance scenarios. This program improved their competence and significantly reduced the time required for them to become productive members of the team.

Q 28. How do you contribute to a safe and productive work environment?

Contributing to a safe and productive work environment is paramount. My approach includes:

- Strict Adherence to Safety Regulations: Always following safety protocols, wearing appropriate personal protective equipment (PPE), and ensuring that all equipment is properly maintained and in safe working condition.

- Hazard Identification and Risk Mitigation: Proactively identifying potential hazards, assessing risks, and implementing measures to minimize or eliminate those risks. This includes regular safety inspections and reporting.

- Safety Training and Education: Participating in and leading safety training sessions for both junior and senior technicians to ensure everyone is aware of and complies with safety regulations.

- Promoting a Culture of Safety: Encouraging open communication about safety concerns, actively reporting near misses, and fostering a team environment where safety is prioritized above all else. This includes leading by example and creating an environment where team members feel empowered to speak up about any safety concerns.

- Maintaining a Clean and Organized Workspace: Keeping the work area clean, organized, and free of clutter to prevent accidents and promote efficient workflow. This is not only about safety but also about productivity.

In one instance, I noticed a potential tripping hazard in the workshop. I immediately reported it to my supervisor, and we implemented a solution to correct the problem, preventing a potential injury to a technician.

Key Topics to Learn for Maintenance and Repair Services Interview

- Preventive Maintenance: Understanding schedules, procedures, and the importance of proactive maintenance to minimize downtime and extend equipment lifespan. Practical application: Explain your experience developing or implementing a preventative maintenance plan.

- Troubleshooting and Diagnostics: Mastering systematic approaches to identifying and resolving equipment malfunctions. Practical application: Describe a situation where you successfully diagnosed and repaired a complex equipment failure.

- Safety Regulations and Procedures: Demonstrating knowledge of OSHA regulations, lockout/tagout procedures, and safe work practices. Practical application: Explain how you ensure a safe working environment while performing maintenance tasks.

- Repair Techniques and Methods: Understanding various repair methods (welding, soldering, machining, etc.) and selecting the appropriate technique for specific situations. Practical application: Describe your experience with different repair techniques and their application.

- Record Keeping and Documentation: Maintaining accurate and detailed records of maintenance activities, repairs, and parts used. Practical application: Explain your experience with computerized maintenance management systems (CMMS).

- Equipment Specific Knowledge: Demonstrating in-depth understanding of the specific equipment and systems you’ll be maintaining (e.g., HVAC, plumbing, electrical systems). Practical application: Detail your experience with specific equipment types and their maintenance requirements.

- Problem-Solving and Critical Thinking: Applying analytical skills to diagnose complex issues and develop effective solutions under pressure. Practical application: Discuss a time you had to think creatively to solve a challenging maintenance problem.

Next Steps

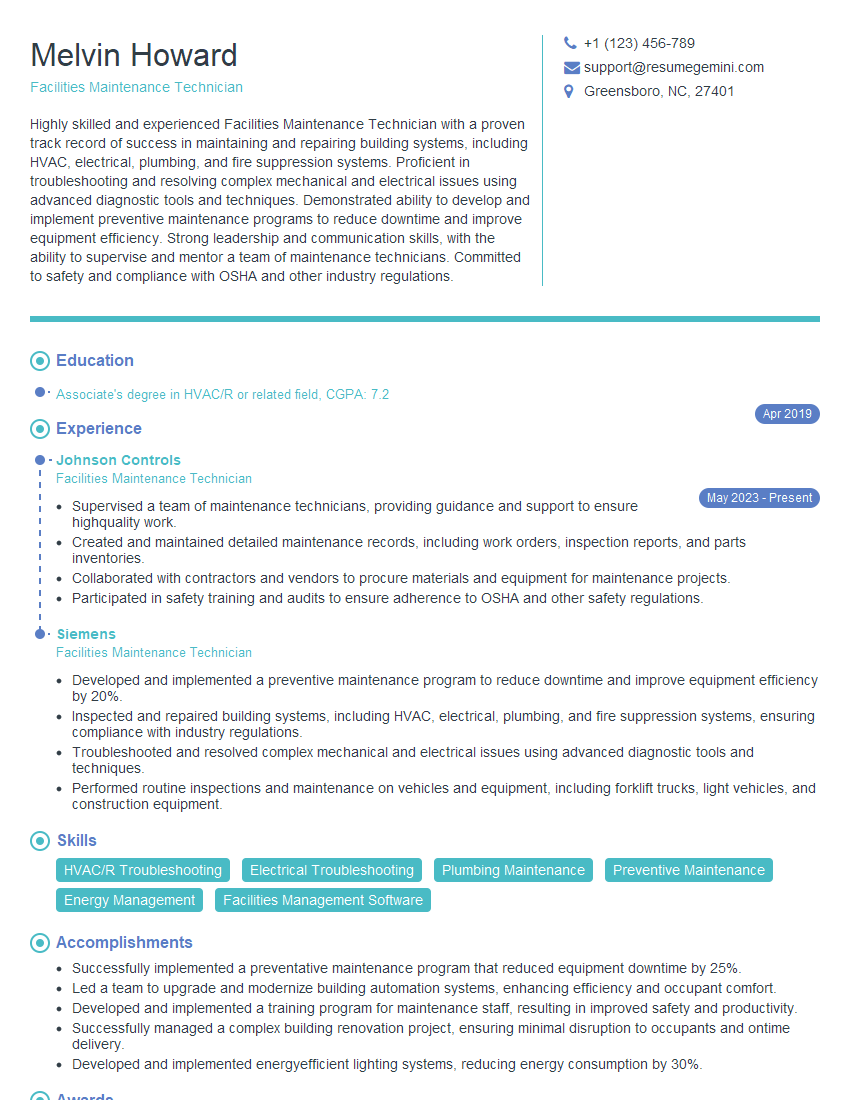

Mastering Maintenance and Repair Services is crucial for career advancement, opening doors to higher-paying roles and increased responsibility. A strong resume is your first impression – make it count! Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. Use ResumeGemini to build a professional and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Maintenance and Repair Services to help you craft the perfect application. Invest time in creating a compelling resume – it’s your key to unlocking your career potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?