Cracking a skill-specific interview, like one for Manual Metal Arc Welding (SMAW), requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Manual Metal Arc Welding (SMAW) Interview

Q 1. Explain the principles of Manual Metal Arc Welding (SMAW).

Manual Metal Arc Welding (SMAW), also known as stick welding, is a widely used arc welding process. Its principle is simple yet effective: an electric arc is created between a consumable electrode and the workpiece. This arc melts both the electrode and the base metal, forming a weld pool. As the electrode melts, it deposits filler metal into the weld pool, creating a strong joint. The process is shielded by a flux coating on the electrode, which protects the weld pool from atmospheric contamination (oxygen and nitrogen), which can cause porosity and weakening.

Think of it like a miniature lightning strike, controlled and harnessed to join metals. The electricity melts the metal, and the flux coating protects the molten metal from spoiling.

Q 2. Describe the different types of SMAW electrodes and their applications.

SMAW electrodes come in a wide variety of types, each designed for specific applications. They are classified based on their chemical composition, coating type, and mechanical properties. Here are some common examples:

- E6010: A low-hydrogen electrode known for its deep penetration and ability to weld in all positions, even overhead. Excellent for vertical welding on pipes and structural steel.

- E6011: Similar to E6010 but designed for welding in all positions on rusty or dirty metal. Ideal for field work where surface preparation might be limited.

- E7018: A low-hydrogen electrode offering excellent mechanical properties and high strength. Commonly used for critical applications where high quality is paramount, such as pressure vessels.

- E6013: A versatile electrode suitable for all positions, offering good weldability on clean or mildly rusty steel. Often chosen for its ease of use.

The electrode designation (e.g., E6010) provides valuable information about its properties. The ‘E’ indicates it’s an electrode, ’60’ denotes the minimum tensile strength (60,000 psi), and the following numbers indicate the electrode’s characteristics, such as its position-welding capabilities and the type of coating.

Q 3. What are the safety precautions you take while performing SMAW?

Safety is paramount in SMAW. The process involves intense heat, ultraviolet radiation, and spatter, all posing potential hazards. My safety precautions include:

- Personal Protective Equipment (PPE): Always wearing a welding helmet with a suitable shade lens, welding gloves, flame-resistant clothing, and safety shoes.

- Proper Ventilation: Ensuring adequate ventilation to prevent the inhalation of welding fumes. This often involves working in a well-ventilated area or using fume extraction systems.

- Fire Safety: Maintaining a fire watch and having a fire extinguisher readily available, especially when welding near flammable materials.

- Eye and Skin Protection: Protecting eyes and skin from ultraviolet radiation and spatter. Regularly checking equipment to ensure it is working properly.

- Grounding: Ensuring proper grounding of the welding machine and workpiece to prevent electrical shocks.

- Awareness of surroundings: Paying attention to my surroundings and avoiding interference from other workers or equipment.

I always follow the safety procedures outlined by my employer and adhere to all relevant safety regulations. A comprehensive safety briefing before any welding operation is crucial.

Q 4. How do you select the correct electrode for a specific welding job?

Selecting the right electrode is crucial for achieving a quality weld. The choice depends on several factors:

- Base Metal: The type of steel being welded (e.g., mild steel, stainless steel).

- Joint Design: The type of joint and its thickness.

- Welding Position: Whether the welding will be done in the flat, vertical, horizontal, or overhead position.

- Required Weld Properties: The strength, toughness, and ductility required of the weld.

- Environmental Conditions: Whether the welding is taking place indoors or outdoors and the presence of moisture or other contaminants.

For example, if I’m welding thick mild steel plates in the flat position and high strength is required, I might choose an E7018 electrode. But for welding thin sheet metal in all positions, a low-amperage electrode like E6013 might be more suitable. The welding data sheet for the electrode should always be consulted.

Q 5. Explain the importance of proper joint preparation in SMAW.

Proper joint preparation is essential for creating strong, reliable welds. Poor joint preparation can lead to incomplete fusion, porosity, and other weld defects that compromise the integrity of the weld. Key aspects of joint preparation include:

- Cleanliness: Removing all rust, paint, oil, grease, and other contaminants from the joint surfaces using appropriate cleaning methods (grinding, wire brushing, etc.).

- Edge Preparation: Shaping the edges of the joint to achieve the desired joint geometry (e.g., beveling, chamfering). This ensures proper penetration and prevents undercut.

- Joint Fit-up: Ensuring that the joint components are properly aligned and spaced to provide consistent gap width for proper weld penetration.

Imagine trying to glue two pieces of wood together without cleaning them first – the glue wouldn’t stick properly. Similarly, a poorly prepared joint in SMAW will result in a weak and unreliable weld. The preparation steps might vary depending on the type of joint and thickness of the material, and this should be clearly defined in the welding procedures.

Q 6. Describe the different types of welding joints and their suitability for SMAW.

SMAW can be used to create various types of welding joints, each with its own characteristics and suitability. Some common joint types include:

- Butt Joint: Two pieces of metal butted together end-to-end. Suitable for SMAW with proper edge preparation.

- Lap Joint: One piece of metal overlapping another. Easy to weld with SMAW, suitable for thinner materials.

- T-Joint: One piece of metal intersecting another at a right angle. Can be challenging with SMAW, requiring careful attention to penetration.

- Corner Joint: Two pieces of metal joined at a corner. Often used with fillets welds and relatively straightforward with SMAW.

- Edge Joint: Two pieces of metal joined edge-to-edge. Requires edge preparation for full penetration and is often used with SMAW.

The choice of joint type is influenced by factors such as the thickness of the materials, the required strength, and the ease of fabrication. For example, a butt joint is suitable for high-strength applications where a large surface area is required, while a lap joint is suitable for simpler applications where less strength is required.

Q 7. How do you control weld bead size and shape in SMAW?

Controlling the weld bead size and shape is crucial for producing a high-quality weld. Several factors influence the bead appearance and properties:

- Welding Current: A higher current results in a wider bead, while a lower current results in a narrower bead.

- Travel Speed: Slower travel speeds produce wider, thicker beads; faster speeds produce narrower, thinner beads.

- Electrode Angle: The angle at which the electrode is held affects the penetration and bead shape. Typically a 15-30 degree angle to the workpiece is used.

Technique: A smooth, consistent motion is crucial for producing a uniform bead. An erratic motion can lead to an irregular bead profile and potentially create defects. Practicing different techniques can improve the overall control.

Practicing on scrap material and observing the changes in the bead size and shape based on adjustments to these parameters is key to developing skill and consistency. It’s like learning to paint – mastering control and technique results in refined and professional outcomes.

Q 8. What are the common welding defects in SMAW and how are they prevented?

Common welding defects in SMAW, or Stick welding, significantly impact the structural integrity and aesthetic appeal of the weld. Understanding these defects and their prevention is crucial for producing high-quality welds. Let’s explore some of the most prevalent ones:

- Porosity: This refers to small holes or voids within the weld metal, often caused by trapped gases (hydrogen, nitrogen, oxygen) during the welding process. Prevention involves ensuring proper electrode storage to prevent moisture absorption, using clean materials, and maintaining a stable arc to minimize gas entrapment. Imagine blowing bubbles into a glass of water – you don’t want those bubbles in your weld!

- Incomplete Fusion: This happens when the weld metal doesn’t properly fuse with the base metal, leading to a weak joint. The cause can be insufficient heat input, incorrect welding parameters, or contamination on the base metal. Prevention requires appropriate preheating (if necessary), proper electrode selection, and meticulous cleaning of the weld joint.

- Undercutting: A groove melted into the base metal at the edge of the weld, weakening the joint. This often occurs due to excessive current, improper travel speed, or an excessively long arc. The solution is to reduce current, adjust travel speed, and maintain a consistent short arc length.

- Slag Inclusions: Pieces of slag (the solidified molten flux from the electrode coating) trapped within the weld metal. This reduces the weld’s strength and ductility. Proper cleaning of the slag between weld passes is essential to prevent this.

- Cracking: This can be caused by various factors like rapid cooling, hydrogen embrittlement, or inadequate preheating. Choosing the right electrode for the base metal, controlling the cooling rate, and preheating when necessary prevents cracking.

Consistent practice, meticulous preparation, and adherence to proper welding procedures are key to minimizing these defects and producing high-quality, reliable welds.

Q 9. Explain the process of setting up a SMAW welding machine.

Setting up an SMAW welding machine is straightforward but requires attention to detail. Here’s a step-by-step guide:

- Check the power supply: Ensure the power source is correctly connected to the welding machine and that the voltage matches the machine’s specifications.

- Select the correct electrode: Choose the electrode based on the base metal’s type and thickness, the desired weld properties, and the welding position. The electrode’s diameter will influence the current setting.

- Set the current: Adjust the amperage on the welding machine according to the electrode diameter and the base metal’s thickness. A lower current is generally used for thinner metals, while a higher current is needed for thicker metals. This is crucial for achieving proper penetration and preventing defects.

- Connect the ground clamp: Securely attach the ground clamp to a clean, unpainted area of the base metal. A good ground connection is essential for a stable arc and proper current flow. Poor grounding can lead to arc instability or even a lack of fusion.

- Connect the electrode holder: Insert the electrode into the electrode holder, making sure it’s firmly clamped.

- Strike the arc: Touch the electrode to the base metal to initiate the arc, then quickly separate them to a short distance. This short distance is critical to avoid excessive spatter and maintain a stable arc.

- Test the weld: Before beginning the actual weld, conduct a short test weld to ensure the parameters are correct and the arc is stable.

Remember to always wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and clothing, to protect yourself from the intense heat and ultraviolet radiation generated during welding.

Q 10. How do you troubleshoot common SMAW welding problems?

Troubleshooting SMAW welding problems often involves systematic investigation. Here’s a structured approach:

- Poor arc stability: This can be caused by a dirty electrode, improper ground connection, or incorrect current setting. Clean the electrode, check the ground connection, and adjust the current as needed.

- Excessive spatter: This often results from an excessively long arc, too high a current, or improper electrode angle. Shorten the arc, reduce the current, and refine your electrode angle.

- Lack of penetration: This is typically due to insufficient current, improper electrode angle, or incorrect travel speed. Increase the current, adjust the electrode angle, and control the travel speed.

- Excessive penetration: This occurs when the current is too high, the travel speed is too slow, or the electrode angle is incorrect. Reduce the current, increase the travel speed, and adjust the electrode angle.

- Porosity or slag inclusions: This points to moisture in the electrode, dirty base metal, or improper arc control. Ensure the electrode is dry, clean the base metal thoroughly, and maintain a stable arc.

Systematic troubleshooting involves checking each parameter individually, isolating the problematic element, and addressing it methodically. Sometimes, a simple adjustment makes all the difference.

Remember to always refer to the manufacturer’s guidelines for your specific welding machine and electrode type.

Q 11. What are the different types of shielding gases used in SMAW?

SMAW, or Shielded Metal Arc Welding, doesn’t use shielding gases in the traditional sense like Gas Metal Arc Welding (GMAW) or Gas Tungsten Arc Welding (GTAW). The shielding is provided by the electrode’s coating. The coating melts and creates a gaseous shield that protects the molten weld pool from atmospheric contamination (oxygen and nitrogen) which could lead to porosity or other defects. Thus, there aren’t ‘types’ of shielding gases used with SMAW like in other processes. The composition of the electrode coating determines its shielding capabilities and the type of weld it produces.

Q 12. How do you interpret welding symbols?

Welding symbols are a standardized way of communicating welding requirements on engineering drawings. They provide concise information about the type of weld, its dimensions, the welding process, and other crucial details. The symbol itself is usually located on a reference line, and its various elements indicate the following:

- Reference Line: A line indicating the location of the weld.

- Arrow Side: The side of the joint where the weld is located (indicated by the arrow pointing to the side of the joint).

- Basic Weld Symbol: Indicates the type of weld (e.g., fillet weld, groove weld).

- Dimension Indicators: Give the size and length of the weld.

- Process Indicator: Indicates the welding process to be used (in this case, SMAW will be indicated by a specific symbol).

- Other Symbols: May include symbols for weld finishing, backing, or special requirements.

Understanding welding symbols is fundamental for welders to interpret and execute engineering designs correctly. Misinterpreting these symbols can lead to incorrect welds and potentially dangerous structures. Training and experience are crucial for accurate interpretation.

Q 13. Describe your experience with different SMAW techniques (e.g., stringer bead, weave bead).

My experience with SMAW encompasses various techniques, tailored to the specific application’s demands. Two prominent examples are stringer bead and weave bead welding:

- Stringer Bead Welding: This technique involves moving the electrode consistently along the weld joint, creating a continuous, linear bead. It’s suitable for thin materials or when deep penetration isn’t required. It’s efficient for fast welds in simple joints. Think of it like drawing a straight line – controlled and precise.

- Weave Bead Welding: This technique involves moving the electrode in a rhythmic pattern, oscillating back and forth across the weld joint. This pattern produces a wider, more uniform weld bead, providing better coverage and penetration than a stringer bead. It’s more suited for thicker materials and situations where a broader weld is needed. It’s like painting a broad brushstroke – distributing the weld material over a larger area.

The choice between these techniques depends on factors like the base material thickness, the desired weld strength, the welding position, and the joint design. Over the years, I’ve developed proficiency in selecting and executing the optimal technique for each specific scenario. I’m also experienced with other techniques such as vertical, overhead, and horizontal welding, always adapting to the job’s unique challenges.

Q 14. What is the importance of preheating and post-heating in SMAW?

Preheating and post-heating in SMAW play crucial roles in enhancing the quality and preventing defects in welds, particularly in thicker materials and those prone to cracking. Let’s look at each:

- Preheating: This involves heating the base metal to a specific temperature before welding. This reduces the cooling rate after welding, minimizing residual stresses and the risk of cracking, particularly in materials susceptible to hydrogen embrittlement. Think of it like warming up before exercise – it prepares the material to handle the stress of the welding process.

- Post-heating: This involves heating the weldment after welding to a controlled temperature for a specific time. It helps relieve residual stresses that develop during welding, reducing the likelihood of cracking and improving the overall toughness of the weld. It’s like a cool-down after exercise – allowing the material to relax and solidify without stress.

The specific preheating and post-heating temperatures and durations depend on factors such as the base metal type, thickness, and the welding procedure. Improper preheating or post-heating can lead to various defects, including cracking, distortion, and reduced weld strength. In my experience, I’ve found that proper preheating and post-heating procedures significantly contribute to the production of stronger and more reliable welds, crucial in critical applications.

Q 15. Explain the concept of weld penetration and its importance.

Weld penetration refers to the depth to which the weld has fused with the base metal. Imagine it like a knife cutting into butter – the depth of the cut represents the penetration. A good weld needs sufficient penetration to create a strong, reliable joint. Insufficient penetration leads to weak points and potential failure. Conversely, excessive penetration can cause burn-through and weaken the base metal.

Its importance is paramount because insufficient penetration leads to incomplete fusion, making the weld susceptible to cracking under stress. This is a serious safety concern, particularly in structural applications. On the other hand, excessive penetration weakens the base material itself, again reducing the joint strength and causing it to be unreliable.

For example, in a pressure vessel weld, insufficient penetration could lead to a catastrophic leak under pressure. Conversely, too deep a weld could weaken the vessel and risk a failure under lower than expected pressure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality of your SMAW welds?

Ensuring SMAW weld quality involves a multi-faceted approach starting from preparation to post-weld inspection. It’s a process, not a single action.

- Proper Preparation: This includes meticulous cleaning of the base metal to remove any contaminants (oil, rust, paint) that would hinder fusion. The joint design also plays a crucial role; a well-prepared joint makes a strong weld much easier to achieve.

- Correct Welding Parameters: Choosing the right electrode type, diameter, and amperage is crucial. This is dependent on the base material and joint design. I always tailor these parameters to the specific job. For example, a larger diameter electrode might be suitable for thicker materials while lower amperage is beneficial when welding thinner materials to avoid burn through.

- Consistent Technique: Maintaining a steady travel speed and electrode angle is critical for consistent weld bead geometry and penetration. My experience allows me to instinctively adapt to different materials and situations.

- Visual Inspection: After welding, I always thoroughly inspect the weld for any visual defects, such as cracks, undercuts, or porosity. This is a crucial step in assessing the quality of the weld. If any defects are found, they are usually addressed by grinding or re-welding.

- Non-Destructive Testing (NDT): For critical applications, NDT methods like radiographic testing (RT) or ultrasonic testing (UT) may be employed to detect internal defects that may not be visible on the surface.

I approach each weld with the understanding that it’s a critical component in a larger structure or application. My attention to detail reflects this understanding.

Q 17. Describe your experience with different types of base metals.

My experience encompasses a wide range of base metals commonly used in SMAW applications. I’m comfortable welding various grades of steel (mild steel, stainless steel, high-strength low-alloy steel), aluminum, and cast iron. Each material requires specific electrode selection and welding parameters, as well as careful consideration of preheating and post-weld heat treatments.

For instance, welding stainless steel requires electrodes specifically designed for this purpose to prevent issues like sensitization or cracking. Working with aluminum necessitates proper cleaning techniques and specialized electrodes due to its high thermal conductivity. Cast iron presents unique challenges due to its brittle nature; preheating is often necessary to avoid cracking.

In each case, understanding the material properties is crucial for successful welding. Over the years, I’ve built up a detailed knowledge of the different welding parameters required for each material, allowing me to efficiently and safely complete diverse projects.

Q 18. How do you maintain your welding equipment?

Maintaining welding equipment is essential for safety and consistent performance. My routine includes:

- Cable Inspection: Regularly inspecting welding cables for damage, wear, and proper insulation. Damaged cables can create a safety hazard and compromise weld quality.

- Electrode Holder Maintenance: Keeping the electrode holder clean and ensuring good electrical contact. A loose connection reduces efficiency and can cause arc instability.

- Cleaning the Welding Machine: After every use, I clean the welding machine of any spatter or slag. This prevents build-up, and damage to the machine.

- Regular Servicing: Scheduled professional maintenance checks for the welding machine are critical to detect any mechanical problems before they escalate.

Proactive maintenance prevents unexpected downtime and ensures the equipment operates at peak efficiency and safety.

Q 19. What are your experience levels with different amperage ranges?

My experience spans a wide range of amperage settings, from low amperage for thin sheet metal welding (e.g., less than 50 amps) to high amperage for thicker materials (e.g., exceeding 200 amps). The selection of amperage is dictated by the thickness of the base metal, electrode diameter, and the desired weld penetration.

In a real-world example, I might use a low amperage setting when welding thin-gauge stainless steel, aiming for a shallow penetration to avoid burn-through. Conversely, when welding thick steel plates, a considerably higher amperage will be required to achieve the necessary fusion depth. I always prioritize safety by using appropriate personal protective equipment regardless of the amperage.

My skill is in not only setting the amperage correctly, but in knowing when to adjust it based on the changing conditions of the weld and material. This experience prevents many issues, and produces consistently high-quality welds.

Q 20. Explain the concept of travel speed in SMAW.

Travel speed in SMAW refers to the rate at which the electrode moves along the weld joint. This speed significantly influences the weld bead shape, penetration, and overall quality. Think of it like painting a wall: too fast, and the paint is thin and uneven; too slow, and it’s thick and potentially runs.

A slow travel speed leads to a wider, deeper weld bead with increased penetration, but it can also result in excessive heat input, potentially causing burn-through, distortion, and even cracking. A fast travel speed produces a narrower bead with shallower penetration, potentially leading to insufficient fusion and weak welds. Optimum travel speed is a balance, depending heavily on material thickness, electrode diameter, and amperage.

My experience allows me to judge the optimal travel speed for the specific job. I regularly adjust it based on my observations of the weld pool and bead formation, ensuring a consistently high-quality weld.

Q 21. How do you ensure the correct polarity settings for your electrode?

Correct polarity in SMAW is crucial for optimal weld quality and electrode performance. There are two main types: Direct Current Electrode Negative (DCEN) and Direct Current Electrode Positive (DCEP).

DCEN (also known as straight polarity) provides more heat to the base metal, leading to deeper penetration and better fusion. It’s commonly used for welding most metals. Think of the electrode as a heat sink, drawing heat away from the electrode and into the base metal.

DCEP (also known as reverse polarity) concentrates heat on the electrode, increasing the electrode’s melting rate, producing a flatter, wider weld bead. It’s often preferred for welding thinner materials and some specific applications to minimize heat input to the base metal. Here, the electrode gets hotter than the base metal.

Ensuring the correct polarity is achieved by checking the polarity settings on my welding machine and correctly connecting the electrode cable to the designated terminals. Incorrect polarity results in inconsistent welds and even equipment damage. I always double-check the connections before beginning any weld to avoid such problems.

Q 22. What are the limitations of SMAW?

SMAW, while versatile and relatively inexpensive, has several limitations. One key limitation is its lower deposition rate compared to other welding processes like GMAW (Gas Metal Arc Welding) or submerged arc welding. This means it takes longer to complete a project. Another significant drawback is the susceptibility to atmospheric contamination, especially hydrogen, which can lead to porosity (small holes) in the weld. The process also generates a significant amount of spatter, requiring extra cleaning time and potentially affecting weld quality. Furthermore, SMAW’s relatively poor control over the arc length and penetration depth necessitates a higher skill level from the welder to achieve consistent results. Finally, the process is generally less suitable for welding in all positions, especially overhead, due to the difficulty in controlling the molten weld pool.

Think of it like painting a wall: SMAW is like using a brush – precise but slower – while GMAW is like using a paint sprayer – faster but requiring more setup and skill for fine details. Each process has its strengths and weaknesses.

Q 23. How do you address undercut, porosity, or slag inclusion in your welds?

Addressing weld defects like undercut, porosity, and slag inclusions requires a multi-pronged approach, starting with preventative measures. Undercut, a groove at the weld toe, often results from excessive current, incorrect travel speed, or improper electrode angle. To prevent it, I carefully adjust amperage and travel speed for the base material and electrode type. Porosity, caused by trapped gas, necessitates checking for moisture in the electrode and ensuring proper shielding gas coverage (for certain applications where shielding gas is used in conjunction with SMAW, such as with flux-cored wire). Slag inclusion, often caused by insufficient cleaning between weld passes, requires meticulous slag removal using a chipping hammer and wire brush after each pass.

If defects do occur, corrective measures might include grinding out the defect and rewelding the area, ensuring proper preparation and technique are followed this time. Visual inspection and, if necessary, non-destructive testing (NDT) methods like radiographic testing (RT) will verify the integrity of the repair.

Q 24. What are your preferred methods for cleaning weld spatter?

Cleaning weld spatter efficiently depends on the type and amount of spatter. For light spatter, a stiff wire brush is often sufficient. For heavier spatter, I find a chipping hammer effective for initial removal, followed by a wire brush to refine the surface. In cases of extensive spatter or access issues, a specialized spatter removal tool, either pneumatic or electric, can greatly expedite the process. Finally, for delicate areas, I’ll use a grinder with a fine grit wheel to remove spatter and blend the weld seam. Safety glasses and appropriate respiratory protection are crucial during all spatter removal operations to prevent eye injury and inhalation of metal particles.

I select the method based on the accessibility of the weld, the type of spatter, and the desired finish of the weldment.

Q 25. Describe a challenging SMAW welding project you’ve worked on and how you overcame the challenges.

One particularly challenging project involved welding a complex stainless steel framework for a chemical processing plant. The challenge stemmed from the stringent requirements for weld quality and the intricate geometry of the structure. The tight tolerances and the need for consistent penetration without burning through the thin sections required precise control of amperage, arc length, and travel speed. Furthermore, the stainless steel’s susceptibility to intergranular corrosion demanded meticulous cleaning and preparation before welding.

To overcome these challenges, I employed a phased approach. First, I conducted extensive pre-weld preparation, meticulously cleaning the stainless steel components and verifying the fit-up. Then, I used a smaller diameter electrode and carefully adjusted the welding parameters to achieve consistent penetration. Frequent visual inspections ensured that no defects were developing. Finally, I thoroughly documented the welding process, including parameters and inspection results, to ensure compliance with project specifications.

Q 26. Describe your experience with non-destructive testing (NDT) methods for welds.

My experience with NDT methods for weld inspection includes visual inspection, magnetic particle testing (MT), and dye penetrant testing (PT). Visual inspection is a fundamental part of any welding process and involves checking for surface defects. MT is used for detecting subsurface flaws in ferromagnetic materials, by applying a magnetic field and then iron particles which accumulate at discontinuities. PT is employed to detect surface-breaking flaws in any material, by applying a dye to the surface and then a developer, causing discontinuities to appear as a color contrast. I’m familiar with interpreting the results of these tests and know when to recommend further inspection, such as radiographic testing (RT) or ultrasonic testing (UT), which I have observed being done by certified inspectors, for deeper or more complex flaw detection.

Q 27. What are your salary expectations?

Based on my experience and skills, my salary expectations are between $X and $Y per year. This range reflects my expertise in SMAW, my experience on complex projects, and the demand for skilled welders in the current market. I’m open to discussing this further and tailoring my expectations to the specifics of the role and your company’s compensation structure.

Q 28. What are your long-term career goals in welding?

My long-term career goals involve progressing to a supervisory role within the welding field. I’m interested in developing my skills in advanced welding techniques and in becoming a certified welding inspector. Eventually, I hope to leverage my experience and knowledge to contribute to the training and development of the next generation of welders, ensuring safety and quality standards are maintained throughout the industry.

Key Topics to Learn for Manual Metal Arc Welding (SMAW) Interview

- Welding Processes: Understanding the SMAW process itself – electrode selection, arc initiation, and control, bead formation, and different welding positions (flat, horizontal, vertical, overhead).

- Safety Procedures: Knowledge of all relevant safety regulations, PPE requirements (personal protective equipment), and emergency procedures for SMAW. This includes fire safety and handling of hazardous materials.

- Joint Design and Preparation: Familiarity with various joint types (butt, lap, tee, corner) and the importance of proper joint preparation (beveling, cleaning) for strong and sound welds.

- Electrode Selection: Understanding the different types of electrodes (E6010, E7018, etc.), their characteristics, and how to select the appropriate electrode for different materials and applications. Be prepared to discuss factors like tensile strength and weldability.

- Welding Parameters: Knowledge of how factors like current, voltage, and travel speed affect the weld quality. Be able to explain the importance of adjusting these parameters for different materials and thicknesses.

- Weld Defects and Remedies: Ability to identify common weld defects (porosity, cracking, slag inclusions) and explain their causes and possible remedies. This demonstrates problem-solving skills.

- Welding Codes and Standards: Familiarity with relevant welding codes and standards (e.g., AWS D1.1) and their importance in ensuring consistent weld quality and safety.

- Practical Experience and Troubleshooting: Being able to articulate your hands-on experience, including any challenges encountered and how they were overcome. Showcasing problem-solving abilities is crucial.

Next Steps

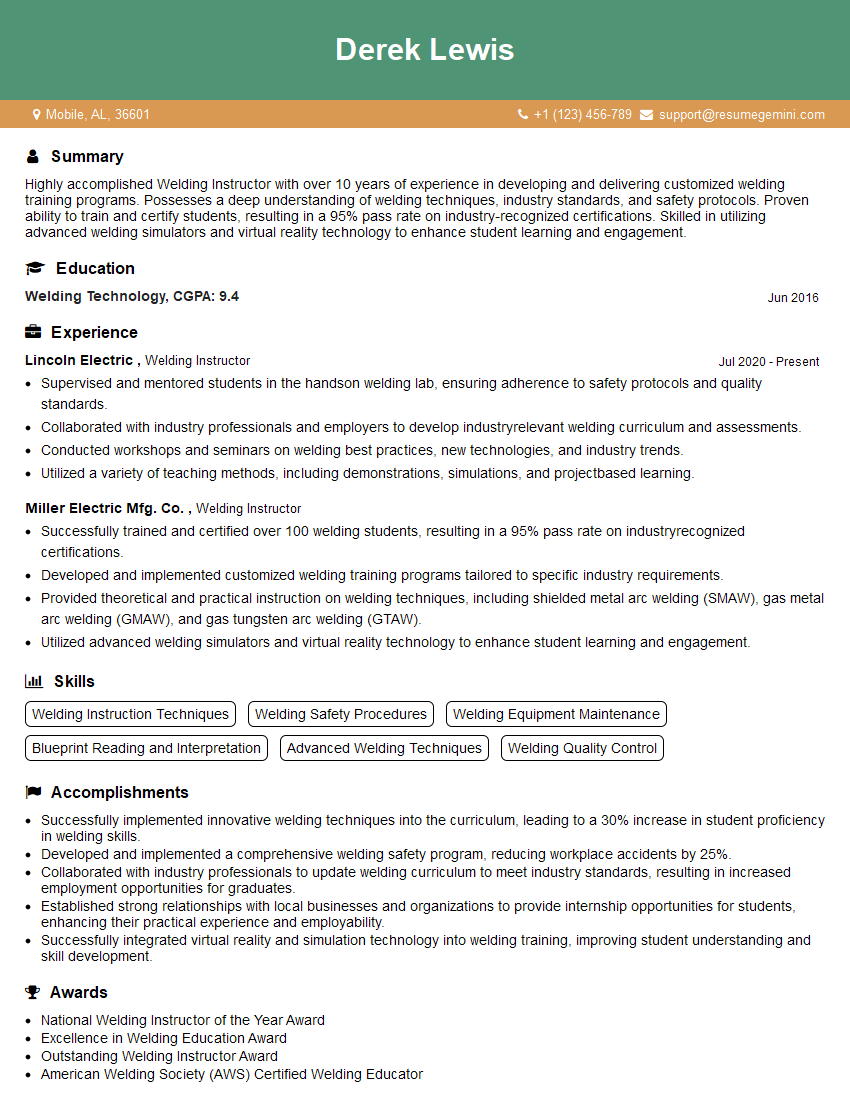

Mastering Manual Metal Arc Welding (SMAW) opens doors to diverse and rewarding career opportunities in various industries. A strong understanding of the theoretical concepts and practical applications discussed above will significantly increase your chances of landing your dream job. To further enhance your job prospects, creating a compelling and ATS-friendly resume is vital. We highly recommend using ResumeGemini, a trusted resource for building professional resumes that stand out to recruiters. ResumeGemini provides examples of resumes tailored to Manual Metal Arc Welding (SMAW) to help you get started. Take the next step towards your successful career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?