Unlock your full potential by mastering the most common Material Handling and Placement interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Material Handling and Placement Interview

Q 1. Describe your experience with various material handling equipment (e.g., forklifts, conveyors, automated systems).

My experience with material handling equipment spans a wide range, encompassing both traditional and automated systems. I’ve extensively used forklifts, from counterbalanced to reach trucks, mastering safe operation and optimizing load handling for different applications. For example, in a previous role, I implemented a training program resulting in a 15% reduction in forklift-related incidents. My experience with conveyors includes designing and implementing systems, from simple roller conveyors to complex automated guided vehicle (AGV) systems that integrated with warehouse management systems (WMS) for seamless order fulfillment. I’m also proficient with automated storage and retrieval systems (AS/RS), utilizing their high-density storage capacity to maximize space utilization. I understand the nuances of various equipment types, their maintenance requirements, and their optimal applications within different warehouse environments.

- Forklifts: Counterbalanced, Reach Trucks, Order Pickers

- Conveyors: Roller, Belt, Chain, AGV

- Automated Systems: AS/RS, Robotic Picking Systems

Q 2. Explain your understanding of warehouse layout optimization for efficient material flow.

Warehouse layout optimization is crucial for efficient material flow. It’s about strategically placing equipment and inventory to minimize travel time and maximize throughput. My approach involves analyzing the warehouse’s unique characteristics – including product volume, order frequency, storage methods, and receiving/shipping processes – to create a tailored layout. This involves applying principles of lean manufacturing and material flow analysis to eliminate bottlenecks. For instance, I once redesigned a warehouse layout by implementing a U-shaped flow pattern for order picking, which resulted in a 20% increase in picking efficiency. Key considerations include proximity to loading docks for inbound and outbound materials, efficient organization of storage areas for fast-moving versus slow-moving inventory, and ergonomic considerations for workers. Software tools like AutoCAD and specialized warehouse design software are integral to this process.

Think of it like designing a well-oiled machine: each part needs to be in the right place, working in harmony with the others to achieve peak performance.

Q 3. How do you ensure workplace safety in a material handling environment?

Workplace safety is paramount in material handling. My approach involves a multi-layered strategy incorporating proactive measures, training, and compliance. This begins with thorough risk assessments, identifying potential hazards and implementing control measures. This could include implementing proper forklift safety protocols, utilizing appropriate personal protective equipment (PPE), establishing clear traffic management systems within the warehouse, and regular equipment maintenance. Providing comprehensive safety training to all employees is crucial, regularly reinforcing safe work practices and addressing any concerns. I’m familiar with relevant OSHA regulations and industry best practices. Regular safety audits and incident reporting help identify areas needing improvement. A culture of safety, where employees feel empowered to report hazards, is essential.

- Risk Assessments

- Safety Training

- PPE Enforcement

- Regular Equipment Maintenance

- Clear Traffic Management

Q 4. What inventory management systems are you familiar with (e.g., WMS, ERP)?

I’m proficient with various inventory management systems, including Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. I have experience implementing and optimizing both, leveraging their features to track inventory levels, manage order fulfillment, and analyze operational data. I’m familiar with software like SAP, Oracle, and various WMS platforms. My experience goes beyond simply using these systems; I understand how to integrate them effectively with other warehouse systems, such as automated material handling equipment, to create a seamless workflow. For instance, I successfully integrated a new WMS into a client’s operation, streamlining the order-to-shipment process and reducing errors by 10%.

WMS systems provide granular control over inventory, tracking everything from location to lot numbers, whereas ERP systems provide a broader overview of the entire business, allowing for better integration of financial and logistical data.

Q 5. Describe your experience with different storage methods (e.g., racking, shelving, bulk storage).

My experience encompasses a broad range of storage methods. I’ve worked with various racking systems – selective pallet racking, cantilever racking, drive-in racking – choosing the optimal system based on the specific needs of the warehouse and the characteristics of the stored goods. Shelving systems are ideal for smaller items, and I’ve used these effectively in various settings. Bulk storage, such as floor stacking or utilizing specialized bulk storage containers, is employed where appropriate, ensuring proper safety and accessibility. The choice of storage method significantly impacts space utilization, efficiency, and worker safety. I consider factors like product size, weight, fragility, and frequency of access when selecting the most appropriate system. For example, in one project, I optimized storage space by 15% by implementing a new high-density racking system.

- Pallet Racking

- Shelving

- Bulk Storage

- Cantilever Racking

- Drive-In Racking

Q 6. How do you handle discrepancies in inventory counts?

Inventory discrepancies are inevitable, but a systematic approach is crucial to address them effectively. My approach starts with identifying the source of the discrepancy through a thorough investigation. This involves checking the accuracy of receiving processes, verifying picking and putaway procedures, and analyzing data from the WMS. Cycle counting, a regular inventory check of a smaller subset of inventory, helps detect minor discrepancies before they escalate. If a significant discrepancy is found, a full physical count might be necessary, meticulously comparing physical inventory against the system records. Root cause analysis is crucial to prevent future occurrences. Process improvements, such as improved scanning practices, better training, and enhanced data validation within the WMS, are implemented to address underlying issues. Documentation of all findings and corrective actions is essential.

Q 7. Explain your approach to managing peak periods or high-volume order fulfillment.

Managing peak periods requires proactive planning and flexibility. My approach involves forecasting demand to anticipate high-volume periods, allowing for appropriate staffing and resource allocation. This includes evaluating current resources and identifying potential bottlenecks. Strategies for handling peak demand include: leveraging overtime, temporary staffing, optimizing existing equipment usage, and streamlining processes to improve efficiency. Involving all stakeholders in the planning process, from operations to customer service, is critical to effective management. Effective communication is key to keep everyone informed and aligned during high-pressure situations. Post-peak review and analysis are important to learn from the experience and refine strategies for future high-volume periods. This might involve identifying operational improvements or investing in additional capacity to support future growth.

Imagine a rush hour on a highway: proper planning, communication, and resource allocation are essential for smooth traffic flow.

Q 8. How do you prioritize tasks in a fast-paced warehouse environment?

Prioritizing tasks in a fast-paced warehouse hinges on a blend of urgency, importance, and resource availability. I utilize a combination of methods to ensure efficiency. First, I leverage a robust Warehouse Management System (WMS) that prioritizes orders based on factors like delivery deadlines, order size, and product location. This system often employs algorithms to dynamically adjust priorities in real-time, responding to changing demands. For example, expedited orders with tight delivery windows automatically jump to the top of the queue. Secondly, I employ visual management techniques like Kanban boards to track order progress and identify potential bottlenecks. This allows me to quickly re-allocate resources – like personnel or equipment – to address emerging issues. Finally, I regularly communicate with the team, ensuring everyone is aware of priorities and potential challenges. This proactive communication fosters collaboration and prevents misunderstandings that can lead to delays.

Think of it like conducting an orchestra; the WMS is the conductor’s score, visual management is the stage layout, and communication is the conductor’s cues to the musicians. Each element is critical for a harmonious and efficient operation.

Q 9. Describe your experience with order picking and fulfillment processes.

My experience with order picking and fulfillment spans over ten years, encompassing various methodologies like batch picking, zone picking, and wave picking. I’ve worked with both manual and automated systems, including voice-directed picking and pick-to-light technologies. In a previous role, I streamlined our order picking process by implementing zone picking, dividing the warehouse into designated areas based on product category. This reduced travel time for pickers, increasing their efficiency by 15%. I’m also proficient in various inventory management techniques, ensuring accurate stock levels and minimizing picking errors. Furthermore, I’m experienced in integrating order fulfillment processes with shipping and receiving to ensure a seamless workflow. This involves understanding and managing various shipping carriers, generating shipping labels, and tracking packages from dispatch to delivery. I’m adept at troubleshooting challenges related to order accuracy, fulfillment speed, and inventory discrepancies.

For instance, I once identified a recurring issue with inaccurate picking in a specific zone. By analyzing pick lists and conducting on-site observation, I pinpointed the problem to unclear labeling. Implementing a new, standardized labeling system immediately resolved the issue, improving accuracy and reducing returns.

Q 10. What metrics do you use to measure the efficiency of material handling operations?

Measuring the efficiency of material handling operations requires a multi-faceted approach, focusing on both quantitative and qualitative metrics. Key quantitative metrics include:

- Order fulfillment rate: Percentage of orders fulfilled accurately and on time.

- Inventory accuracy: The degree to which recorded inventory matches physical inventory.

- Throughput: The number of units or orders processed per unit of time.

- Order cycle time: The time elapsed between order placement and shipment.

- Cost per unit handled: The total cost of material handling operations divided by the number of units handled.

Qualitative metrics, equally important, assess aspects like employee satisfaction, safety performance, and process adherence. Regularly monitoring these metrics, analyzing trends, and implementing corrective actions are crucial for continuous improvement. For example, a consistently low order fulfillment rate might point to inefficiencies in the picking process, prompting a review of procedures and training.

Q 11. How familiar are you with Lean principles and their application to material handling?

I’m highly familiar with Lean principles and their application in material handling. Lean methodologies, focused on eliminating waste and maximizing value, are fundamental to optimizing warehouse operations. I’ve successfully implemented several Lean initiatives, including 5S (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace organization and reduce search times. Also, I’ve utilized Value Stream Mapping to visualize and analyze the entire material flow within a warehouse, identifying bottlenecks and areas for improvement. By eliminating unnecessary steps and movements, we can significantly boost efficiency and reduce costs. Techniques like Kaizen (continuous improvement) and Kanban are also integral parts of my approach. For example, implementing a Kanban system for replenishing picking areas reduced stockouts and improved order fulfillment times.

The core of Lean is waste reduction. Identifying and eliminating Muda (waste) in all its forms — transportation, inventory, motion, waiting, overproduction, over-processing, and defects — is paramount to a successful Lean implementation.

Q 12. Describe your experience with implementing or improving warehouse processes.

In a previous role, I spearheaded a project to improve warehouse layout and picking processes. Through Value Stream Mapping, we identified that long travel distances were significantly impacting picking efficiency. By reorganizing the warehouse based on product popularity and frequency of picking, we reduced travel time by 30%, leading to a substantial increase in throughput. I also implemented a new training program for pickers, focusing on proper techniques and best practices. This resulted in a noticeable decrease in picking errors and improved overall accuracy. Another project involved implementing a new WMS, transitioning from a manual system to an automated one. This improved order tracking, inventory control, and reporting capabilities, leading to better decision-making and increased overall efficiency. Each improvement was meticulously measured using key performance indicators (KPIs) to ensure effectiveness.

The key to successful implementation is a phased approach, involving detailed planning, pilot testing, and regular monitoring of results. Effective communication and employee engagement are crucial for buy-in and successful adoption.

Q 13. How do you handle damaged or defective goods?

Handling damaged or defective goods requires a systematic approach to minimize losses and ensure compliance. First, I ensure the damage is documented meticulously, including photos, descriptions, and the cause if possible. Then, depending on the nature of the damage and the product’s value, we might initiate a return to the supplier, initiate a repair process if feasible, or dispose of the goods responsibly. For returns, I ensure all necessary paperwork is completed and sent to the supplier for processing. For disposal, we adhere to all relevant environmental regulations. A robust system for tracking damaged goods is vital, allowing us to identify trends and implement preventative measures. For example, consistently damaged goods from a specific supplier might prompt a review of their packaging and shipping practices.

The goal is to minimize waste, comply with regulations, and prevent future occurrences of damage. This often involves collaborating with suppliers and implementing better handling and storage procedures.

Q 14. Explain your experience with shipping and receiving procedures.

My experience with shipping and receiving encompasses all aspects of the process, from verifying incoming shipments against purchase orders to preparing outgoing shipments and managing carrier relations. I’m proficient in using various shipping software and tracking systems to manage shipments effectively and ensure timely delivery. I’ve implemented procedures to minimize errors in receiving and shipping, including double-checking quantities and inspecting goods for damage. I’m also familiar with various shipping regulations and documentation requirements, ensuring compliance and minimizing potential delays. My experience includes negotiating rates with carriers, selecting optimal shipping methods, and managing logistics to optimize cost and delivery times. For instance, I once renegotiated our shipping contracts with a major carrier, resulting in a 10% reduction in shipping costs without compromising delivery times.

Efficient shipping and receiving is essential for maintaining smooth supply chains and meeting customer expectations. This often requires effective communication and collaboration with suppliers and carriers.

Q 15. How do you ensure the accuracy and timeliness of order fulfillment?

Ensuring accurate and timely order fulfillment hinges on a robust system integrating several key components. It’s not just about picking the right items; it’s about the entire process, from receiving the order to its delivery.

Real-time Inventory Management: A WMS (Warehouse Management System) is crucial. It provides accurate stock levels, locations, and order statuses in real-time, minimizing picking errors and delays. Imagine trying to find a specific book in a library without a catalog – chaotic, right? A WMS is our catalog.

Efficient Picking Processes: Methods like batch picking (grouping orders with items in the same location), zone picking (dividing the warehouse into zones with dedicated pickers), and wave picking (releasing orders in waves for efficient processing) optimize picking efficiency. I’ve personally implemented wave picking in a fast-paced e-commerce warehouse, resulting in a 15% increase in order fulfillment speed.

Accurate Order Verification: Multiple checkpoints are crucial. This includes verifying the order details against the picked items, scanning barcodes, and conducting final checks before packaging. Think of it like double-checking a surgical procedure – precision is paramount.

Optimized Packaging and Labeling: Proper packaging protects goods during transit and clear labeling ensures swift and accurate delivery. This includes clear addresses, tracking numbers, and any relevant handling instructions.

Streamlined Shipping Process: Integrating with shipping carriers and utilizing shipping software enables automated label generation, tracking updates, and proactive communication with customers. This ensures customers are informed every step of the way.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for preventing workplace accidents related to material handling?

Preventing workplace accidents in material handling requires a multi-faceted approach focusing on proactive measures, employee training, and a strong safety culture.

Proper Training: Thorough training on safe lifting techniques, operating machinery (forklifts, conveyors, etc.), and using personal protective equipment (PPE) is fundamental. I’ve developed and implemented training programs that included hands-on practice and regular safety quizzes, significantly reducing near-miss incidents.

Equipment Maintenance: Regular inspection and maintenance of all equipment are critical. Malfunctioning equipment can lead to serious accidents. We establish a preventative maintenance schedule and record all inspections meticulously.

Ergonomic Design: Workspaces should be designed ergonomically to minimize strain and injuries. This includes proper lighting, appropriate work heights, and the use of ergonomic tools and equipment. For example, implementing adjustable height workstations significantly reduced back injuries in a previous role.

Safe Work Practices: Clear procedures and guidelines for material handling, including proper stacking, storage, and movement of goods, must be in place and followed strictly. We use visual aids, such as floor markings and signage, to reinforce safety procedures.

Regular Safety Audits: Conducting regular safety audits and inspections helps identify potential hazards and address them proactively. This involves checking for potential trip hazards, ensuring proper storage, and assessing the effectiveness of safety measures.

Q 17. Describe your experience with different types of packaging and labeling.

My experience encompasses a wide range of packaging and labeling methods, tailored to the specific needs of the product and shipping requirements.

Packaging Types: I’ve worked with various materials including corrugated cardboard boxes, plastic containers, pallets, shrink wrap, and specialized packaging for fragile or temperature-sensitive goods. The choice depends on product fragility, size, weight, and environmental conditions during transit.

Labeling: Experience includes applying barcodes (EAN, UPC), RFID tags, and custom printed labels with product information, shipping addresses, and handling instructions. Accurate and clear labeling is crucial for efficient inventory management and delivery.

Sustainable Packaging: I am familiar with sustainable packaging options such as recycled cardboard, biodegradable materials, and minimal packaging to reduce environmental impact. In a previous role, we transitioned to using recycled cardboard boxes, reducing our carbon footprint by 10%.

Hazardous Materials Packaging: I have experience handling and packaging hazardous materials according to relevant regulations (e.g., DOT, IATA), ensuring safe transportation and compliance with all legal requirements.

Q 18. How do you manage inventory levels to minimize storage costs and prevent stockouts?

Effective inventory management is a delicate balance between minimizing storage costs and preventing stockouts. It requires a combination of forecasting, data analysis, and efficient processes.

Demand Forecasting: Accurate demand forecasting using historical data, seasonal trends, and market analysis helps predict future needs. This allows for optimal ordering quantities and prevents overstocking or shortages.

Inventory Tracking: Real-time inventory tracking via a WMS provides accurate stock levels, enabling timely reordering and preventing stockouts. A well-implemented system can provide alerts when stock levels fall below a predetermined threshold.

ABC Analysis: Categorizing inventory items into A (high value), B (medium value), and C (low value) categories allows for focused management efforts on high-value items. More rigorous tracking and control measures are implemented for A items.

Just-in-Time (JIT) Inventory: For certain items, a JIT approach can minimize storage costs by receiving materials only when needed. This requires a strong and reliable supply chain.

Regular Stock Audits: Conducting regular physical stock audits verifies inventory accuracy and identifies discrepancies. This ensures the data in the WMS reflects the actual inventory levels.

Q 19. What are your skills in using warehouse management systems (WMS)?

I possess extensive experience using various Warehouse Management Systems (WMS), including Manhattan Associates, Blue Yonder, and Oracle WMS. My skills encompass all aspects of WMS functionality, from configuration and customization to data analysis and reporting.

System Configuration: I can configure WMS parameters to align with specific business needs, including defining warehouse layouts, setting up inventory tracking rules, and configuring picking strategies.

Data Analysis and Reporting: I proficiently extract data from WMS to generate reports on key performance indicators (KPIs) such as order fulfillment rate, inventory turnover, and storage costs. This data informs decision-making and process improvements.

Integration with Other Systems: I have experience integrating WMS with other enterprise resource planning (ERP) systems, transportation management systems (TMS), and e-commerce platforms, creating a seamless flow of information across the supply chain.

Troubleshooting and Maintenance: I can troubleshoot WMS issues, resolve system errors, and perform routine maintenance to ensure system uptime and optimal performance. I’ve successfully resolved several critical system failures, minimizing disruption to warehouse operations.

Q 20. How would you handle a situation where equipment malfunctions during peak operations?

Equipment malfunction during peak operations requires a swift and organized response to minimize disruption. My approach involves a structured, multi-step process.

Immediate Assessment: First, I’d assess the situation to determine the extent of the malfunction and its impact on operations. Is it a minor issue or a major breakdown requiring extensive repair?

Safety First: Ensure the safety of personnel. If the malfunction poses a safety risk, immediate action is required to isolate the equipment and prevent further incidents.

Emergency Procedures: Activate pre-defined emergency procedures, potentially involving backup equipment or alternative workflows. We regularly rehearse these procedures during training exercises.

Problem Diagnosis and Repair: If possible, attempt to diagnose the problem and initiate repair. This may involve contacting maintenance personnel or the equipment vendor. In some cases, a temporary fix might be necessary to restore partial functionality.

Communication and Coordination: Maintain clear communication with all relevant personnel, including warehouse staff, management, and potentially customers, providing updates on the situation and estimated time of resolution. Transparency is crucial.

Post-Incident Analysis: After the equipment is repaired, conduct a thorough post-incident analysis to identify the root cause of the malfunction and implement preventive measures to avoid future recurrences.

Q 21. Describe your experience with different types of warehouse layout designs.

My experience encompasses several warehouse layout designs, each optimized for different operational needs and product characteristics.

U-Shaped Layout: Efficient for processes involving multiple steps, minimizing movement between workstations. This is great for assembly operations or when multiple tasks need to be performed in sequence.

I-Shaped Layout: Simple and straightforward, suitable for smaller warehouses or those with linear workflows. It’s easy to understand and implement but might not be as efficient for larger operations.

L-Shaped Layout: Offers flexibility and adaptability, suitable for warehouses with varying operational needs or when space is limited. It’s a good compromise between efficiency and flexibility.

Random Storage: Utilizes high-density storage systems, suitable for warehouses with a large number of SKUs (Stock Keeping Units) and relatively low turnover. This maximizes space utilization but requires a sophisticated WMS for efficient retrieval.

Dedicated Storage: Allocates specific areas for specific product categories, facilitating order picking and reducing travel time. This design is suitable when specific products have high demand or require special handling.

The optimal layout depends on factors such as the volume of goods, the number of SKUs, order frequency, picking methods, and available space. I always consider these factors to recommend the most efficient design.

Q 22. Explain your understanding of ergonomics and its importance in material handling.

Ergonomics is the science of designing the workplace to fit the worker, not the other way around. In material handling, this means optimizing tasks, equipment, and the environment to minimize risk of musculoskeletal disorders (MSDs) and injuries. It’s crucial because MSDs are a leading cause of workplace injuries, leading to lost productivity, increased healthcare costs, and employee dissatisfaction.

For example, improper lifting techniques can strain backs and shoulders. Ergonomic principles would involve using lifting aids like forklifts or pallet jacks, adjusting work surfaces to proper heights, and providing training on safe lifting mechanics. Implementing ergonomic principles reduces injuries, boosts morale, and improves overall efficiency.

- Proper lifting techniques: Training employees on bending at the knees, keeping the load close to the body, and using leg muscles instead of back muscles.

- Optimized workstation design: Ensuring that workstations are set up to minimize repetitive motions, awkward postures, and excessive force.

- Use of assistive devices: Providing employees with appropriate equipment, such as hand trucks, dollies, and conveyor systems, to reduce manual handling.

Q 23. How do you ensure compliance with relevant safety regulations and industry standards?

Compliance with safety regulations is paramount. This involves staying abreast of OSHA (Occupational Safety and Health Administration) regulations, ANSI (American National Standards Institute) standards, and any other relevant industry-specific guidelines. This isn’t just about avoiding penalties; it’s about creating a safe and productive work environment.

My approach involves regular audits of our material handling processes, equipment inspections, and thorough documentation of all safety procedures. We utilize a combination of checklists, safety meetings, and training sessions to ensure that everyone understands and adheres to the regulations. For example, we rigorously maintain detailed records of equipment maintenance and inspections, ensuring that any potential hazards are identified and mitigated promptly. This proactive approach minimizes risk and fosters a culture of safety.

Q 24. How do you train new employees on safe material handling practices?

Training is an ongoing process, not a one-time event. For new employees, we begin with a comprehensive safety orientation, covering general workplace safety and specific material handling procedures. This involves both classroom instruction and hands-on training in a controlled setting.

We use a combination of methods, including videos, demonstrations, and interactive exercises to ensure understanding. We emphasize the practical application of safe lifting techniques, proper use of equipment, and the importance of reporting any unsafe conditions. Post-training assessments are essential to verify comprehension and identify areas needing further clarification. We also implement a buddy system where experienced employees mentor new hires, further reinforcing safe practices.

Q 25. What are your problem-solving skills when dealing with material handling challenges?

My approach to problem-solving is systematic and data-driven. When faced with material handling challenges, I follow these steps:

- Identify the problem: Clearly define the issue, gathering data through observation, interviews, and analysis of existing data.

- Analyze root causes: Use tools like fishbone diagrams (Ishikawa diagrams) to pinpoint the underlying causes of the problem.

- Develop solutions: Brainstorm potential solutions, considering factors like cost, feasibility, and impact on safety.

- Implement and evaluate: Select the best solution, implement it, and monitor its effectiveness. Make adjustments as necessary.

- Document findings: Record the problem, solution, and outcomes to improve future processes.

For example, if we’re experiencing excessive damage to goods during transport, I would investigate potential causes such as improper packing, inadequate equipment, or deficient training. Then, I’d develop solutions like improved packaging techniques, equipment upgrades, or additional employee training. Following the implementation, I’d track the rate of damaged goods to measure the solution’s effectiveness.

Q 26. Describe your experience with different material handling technologies (e.g., RFID, barcode scanners).

I have extensive experience with various material handling technologies. Barcode scanners are fundamental for tracking inventory and ensuring accurate order fulfillment. RFID (Radio-Frequency Identification) provides a more robust and automated tracking solution, allowing real-time monitoring of goods throughout the entire supply chain. This minimizes human error and increases efficiency.

In one project, we implemented an RFID system to track high-value components in a manufacturing setting. This improved inventory accuracy, reduced theft, and streamlined the production process. I’m also familiar with WMS (Warehouse Management Systems) software, which integrates these technologies to optimize warehouse operations.

Q 27. How would you improve efficiency in a warehouse with bottlenecks in material flow?

Improving warehouse efficiency with bottlenecks requires a systematic approach. First, I’d identify the bottlenecks using data analysis. This might involve analyzing throughput times, identifying congestion points, and interviewing warehouse staff to understand workflow challenges.

Once the bottlenecks are identified, potential solutions might include:

- Re-designing warehouse layout: Optimizing the flow of goods to reduce travel distances and congestion.

- Implementing lean principles: Reducing waste and improving overall process efficiency.

- Upgrading equipment: Investing in more efficient material handling equipment, such as automated guided vehicles (AGVs) or conveyor systems.

- Optimizing staffing levels: Ensuring adequate staffing during peak periods to handle the workload.

- Improving technology integration: Utilizing WMS software to automate tasks and improve visibility across the entire operation.

The specific solution depends on the nature of the bottleneck and the available resources. A combination of solutions might be necessary for a comprehensive improvement.

Q 28. Describe your experience with implementing and managing a warehouse safety program.

Implementing and managing a warehouse safety program is an iterative process. It starts with a thorough risk assessment to identify potential hazards. This involves walking through the facility, observing processes, and interviewing employees to understand potential risks. The findings from this assessment inform the development of a comprehensive safety plan.

Key components of the plan would include:

- Safety training programs: Regular training for all employees on safe handling procedures, emergency response, and hazard identification.

- Regular inspections: Scheduled inspections to identify and correct unsafe conditions.

- Emergency response plan: A documented plan outlining procedures in case of accidents or emergencies.

- Personal protective equipment (PPE): Providing and enforcing the use of appropriate PPE, such as safety shoes, gloves, and eye protection.

- Accident reporting and investigation: A system for reporting and investigating all accidents to identify root causes and prevent recurrence.

Continuous monitoring and evaluation are essential to ensure the program’s effectiveness. Regular safety meetings and feedback from employees are crucial for adapting and improving the program over time.

Key Topics to Learn for Material Handling and Placement Interview

- Warehouse Layout and Design: Understanding efficient warehouse design principles, including slotting optimization, flow patterns, and the impact on productivity.

- Material Handling Equipment: Familiarity with various equipment types (forklifts, conveyors, automated guided vehicles, etc.), their applications, safety protocols, and maintenance requirements. Practical application: Describe experiences optimizing equipment usage or troubleshooting malfunctions.

- Inventory Management Techniques: Knowledge of inventory control systems (FIFO, LIFO, etc.), cycle counting, and the impact of accurate inventory data on warehouse operations. Practical application: Explain how you’ve improved inventory accuracy or reduced stockouts.

- Safety Regulations and Procedures: Understanding and adherence to OSHA (or relevant regional) safety standards, including hazard identification, risk mitigation, and accident prevention in material handling environments. Practical application: Describe your experience implementing safety protocols or conducting safety training.

- Supply Chain Optimization: Knowledge of how material handling impacts the broader supply chain, including inbound and outbound logistics, transportation management, and order fulfillment processes. Practical application: Explain how streamlining material handling improved overall supply chain efficiency.

- Warehouse Management Systems (WMS): Familiarity with WMS software and its role in managing inventory, tracking shipments, and optimizing warehouse operations. Practical application: Describe your experience using or implementing a WMS, highlighting any improvements achieved.

- Lean Principles and Kaizen: Understanding and applying lean methodologies to eliminate waste and improve efficiency in material handling processes. Practical application: Detail experiences implementing lean principles to optimize warehouse operations.

- Ergonomics and Workplace Safety: Understanding ergonomic principles to minimize risk of musculoskeletal injuries and promote a safe working environment. Practical application: Describe your experience in implementing ergonomic improvements in a warehouse setting.

Next Steps

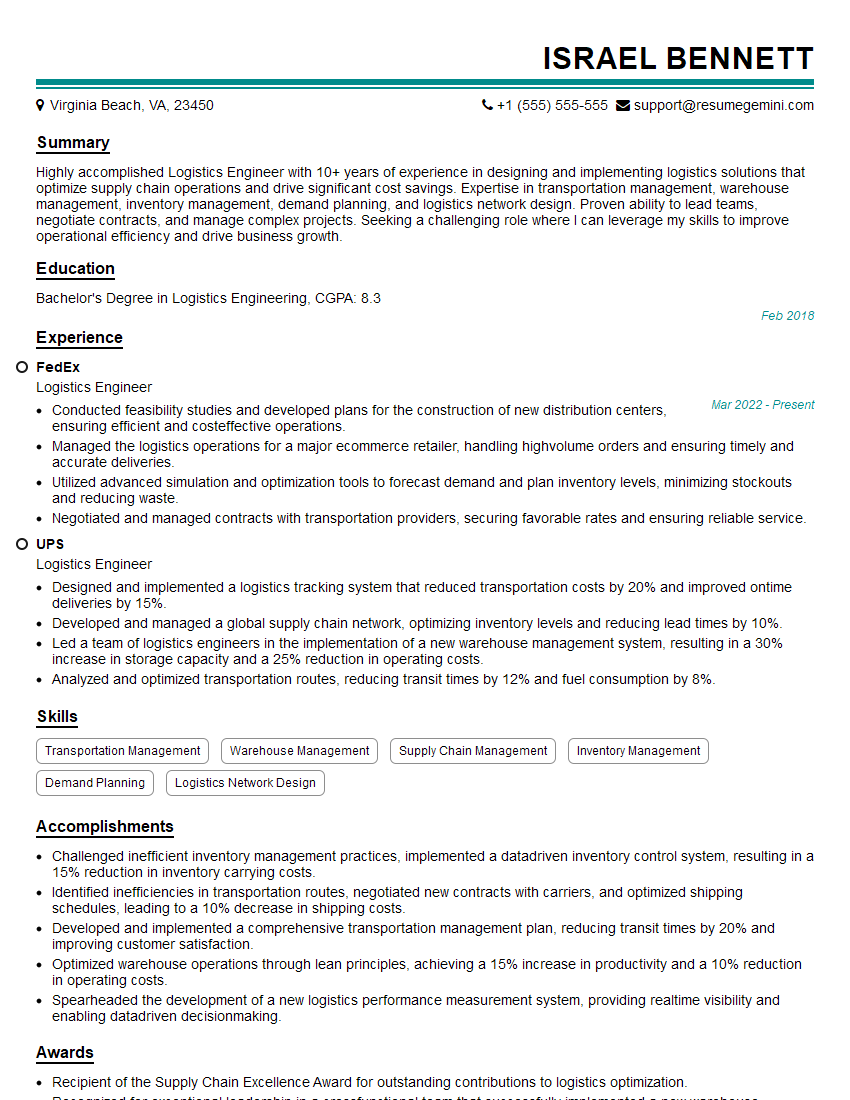

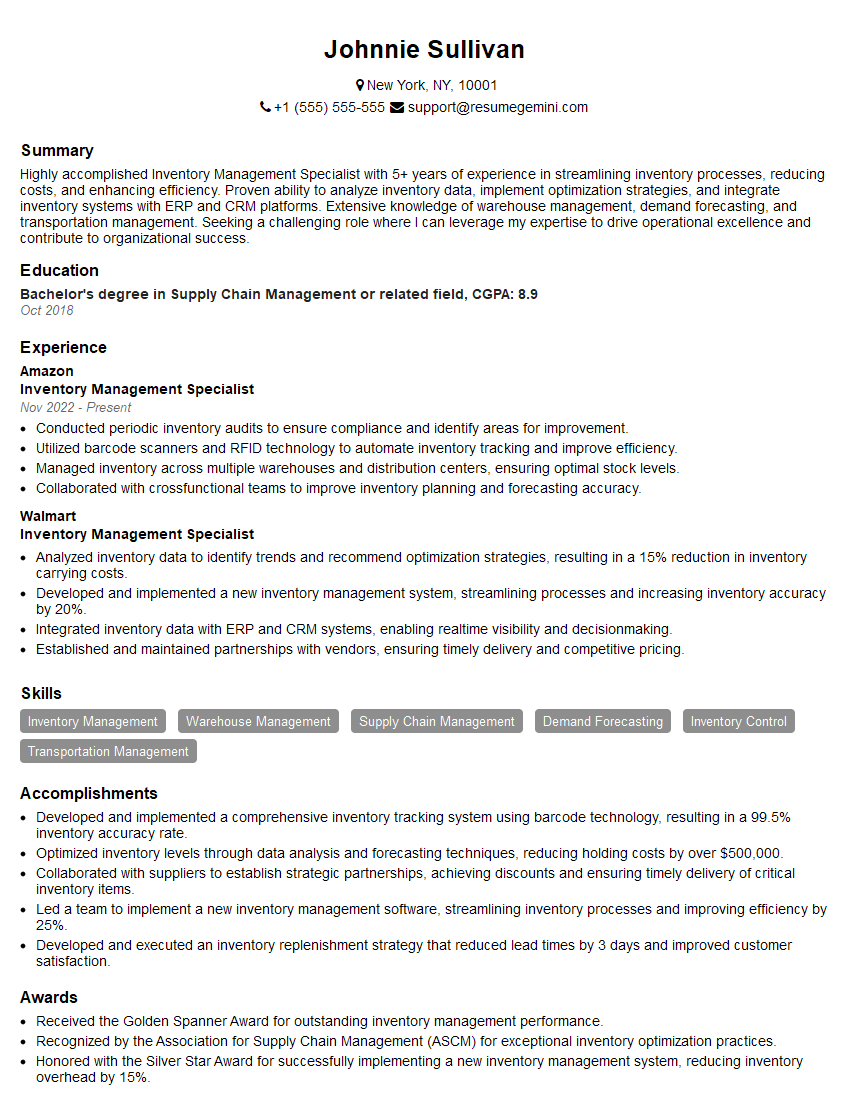

Mastering Material Handling and Placement principles is crucial for career advancement in logistics, warehousing, and supply chain management. These skills are highly sought after, leading to increased job opportunities and higher earning potential. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your qualifications. We strongly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to Material Handling and Placement to help you showcase your expertise effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?