Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential OFS (Optical Fiber Splicing) interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in OFS (Optical Fiber Splicing) Interview

Q 1. Explain the difference between fusion splicing and mechanical splicing.

Fusion splicing and mechanical splicing are two primary methods for joining optical fibers. The key difference lies in how the fibers are joined. Fusion splicing uses heat and pressure to melt and fuse the fiber ends together, creating a permanent, strong, and highly transparent connection. Think of it like welding two metal pieces together – creating a seamless joint. Mechanical splicing, on the other hand, uses precision-engineered connectors to align and clamp the fiber ends. This method is faster and requires less specialized equipment, but the connection is not as strong or low-loss as a fusion splice. It’s more like using a strong adhesive to join two pieces – a reliable connection, but not as seamless.

Fusion Splicing Advantages: Higher strength, lower attenuation (signal loss), longer lifespan, superior performance in harsh environments.

Mechanical Splicing Advantages: Faster connection time, simpler equipment, less expensive (initially), suitable for temporary applications or where speed is prioritized.

In practice, you would choose fusion splicing for high-performance networks (like long-haul telecommunications) where low signal loss and reliability are paramount. Mechanical splicing is often preferred for temporary fixes or applications where cost and speed are more important than ultimate performance.

Q 2. What are the common causes of fiber optic cable damage?

Fiber optic cable damage can stem from a variety of causes, both during installation and throughout its operational life. Common culprits include:

- Excessive bending radius: Bending the fiber beyond its minimum bend radius can fracture the glass core, leading to signal loss or complete breakage. Imagine bending a drinking straw too sharply – it cracks!

- Crushing or compression: Applying external pressure can crush the fiber, compromising its integrity and causing signal attenuation.

- Sharp objects: Anything sharp, from construction tools to carelessly placed debris, can easily cut or damage the fiber.

- Rodent damage: Rodents often gnaw on cables, leading to complete fiber breaks. This is a significant concern in outdoor installations.

- Improper handling during installation: Dropping the cable, pulling too forcefully, or failing to properly secure the cable during deployment can cause significant damage.

- Environmental factors: Extreme temperatures, humidity, and ultraviolet radiation can degrade the fiber’s protective coating and weaken the fiber itself over time.

- Microbending: Small, continuous bends within the cable, often caused by cable movement or vibrations, can create many small areas of high loss, resulting in a gradual performance degradation.

Preventing damage requires careful handling, proper installation techniques, and the use of protective conduit or jackets where appropriate.

Q 3. Describe the steps involved in preparing fiber ends for fusion splicing.

Preparing fiber ends for fusion splicing is a critical step that directly impacts the quality and reliability of the splice. The process usually involves these steps:

- Cutting: A precision fiber cleaver is used to create a perfectly perpendicular cleave on both fiber ends. A bad cleave introduces loss, so a clean, smooth cut is essential.

- Cleaning: Any dirt, dust, or oil on the fiber end can prevent proper fusion. Cleaning is done using specialized cleaning wipes or pens, ensuring the fiber is pristine.

- Inspection: Before splicing, the cleaved ends are inspected using a microscope to verify the quality of the cleave. Checks are made for chipping, scratches, or other imperfections.

- Stripping (if necessary): If the fiber’s protective coating needs to be removed, a stripping tool is used to remove only the necessary amount of coating without damaging the fiber itself.

Example: A poorly cleaved fiber end will result in significant light loss after splicing, degrading the overall signal quality. Careful attention to these steps ensures a high-quality splice.

Q 4. How do you test fiber optic continuity and attenuation?

Testing fiber optic continuity and attenuation is crucial for ensuring proper network performance. These tests are usually performed with an Optical Time Domain Reflectometer (OTDR).

Continuity Testing: An OTDR sends a light pulse down the fiber and measures the backscatter. If a continuous trace is visible, the fiber is continuous. If a significant drop or absence of signal is detected, it suggests a break or fault in the fiber path. A visual fault locator (VFL) can also be used for simpler continuity checks but won’t provide data on attenuation.

Attenuation Testing: The OTDR also measures the signal loss (attenuation) along the fiber. The OTDR displays the attenuation in dB/km (decibels per kilometer). High attenuation indicates excess signal loss, potentially due to poor splices, bends, or other impairments.

Example: An OTDR trace showing a sudden high attenuation at a specific point may indicate a bad splice or a fiber break. Further investigation using a VFL may pinpoint the exact location of the fault.

Q 5. What are the different types of fiber optic connectors and their applications?

Many types of fiber optic connectors exist, each designed for specific applications. Some common types include:

- SC (Subscriber Connector): A push-pull connector, widely used in telecommunications and data centers for its simplicity and reliability.

- FC (Ferrule Connector): A threaded connector offering a very secure and precise connection, often used in high-precision applications and laboratory settings.

- LC (Lucent Connector): A small form-factor connector that saves space, commonly found in dense fiber deployments.

- ST (Straight Tip): A bayonet-type connector that’s becoming less common but can still be found in older installations.

- MT-RJ (Mechanical Transfer-Registered Jack): A connector designed for high-density applications, often used in LAN environments.

Applications: The choice of connector depends on several factors, including the required bandwidth, environmental conditions, cost, and the density of the fiber deployment. For example, LC connectors are preferred in high-density data centers due to their small size, while SC connectors are more prevalent in telecommunication networks for their reliability and ease of use.

Q 6. What safety precautions should be taken when working with fiber optic cables?

Working with fiber optic cables necessitates strict adherence to safety precautions due to potential hazards. Key precautions include:

- Eye protection: Never look directly into the end of a fiber optic cable while a laser light source is active. Strong light sources can cause permanent eye damage. Safety eyewear is required.

- Protective clothing: Wear protective clothing such as gloves and safety glasses to prevent cuts or abrasions from the fiber or related tools.

- Proper grounding: Ensure proper grounding to prevent electrostatic discharge (ESD), which can damage the fiber.

- Laser safety training: Personnel working with lasers should be trained on proper laser safety procedures.

- Cleanliness: Maintain a clean work environment to prevent contamination of the fiber ends.

- Proper tools: Use the appropriate tools for cutting, stripping, and cleaning fibers to prevent damage.

Example: Always use safety glasses when working with fiber, and ensure all equipment is properly grounded to avoid electrostatic damage to the fiber.

Q 7. How do you identify and troubleshoot common fiber optic faults?

Troubleshooting fiber optic faults requires a systematic approach. Common faults and troubleshooting steps include:

- Visual Inspection: Begin by visually inspecting the cables and connections for obvious damage, such as cuts, bends, or loose connectors.

- OTDR Testing: Use an OTDR to identify the location and type of fault. High attenuation or reflections usually indicate problems like bad splices, microbends or breaks.

- Power Meter and Light Source: To locate faults in optical power budget (signal strength), check power levels at various points in the system.

- Connector Inspection: Carefully inspect connectors for dirt, damage, or improper alignment. Clean connectors using appropriate methods.

- Splice Inspection: Inspect splices for cracking, gaps, or other damage that could be causing signal loss.

Example: If an OTDR trace shows high attenuation at a particular location, use a visual fault locator to pinpoint the problem area. This might reveal a damaged splice or a bend in the fiber.

A systematic approach, combining visual inspection with advanced testing equipment like an OTDR, is key to effective fiber optic fault identification and repair.

Q 8. What is the importance of proper fiber cleaving?

Proper fiber cleaving is crucial for achieving low optical loss and a reliable fiber optic connection. A clean, perpendicular cleave ensures the fiber ends meet with minimal air gaps or surface imperfections. Think of it like trying to connect two perfectly smooth pieces of glass; any irregularity will prevent a perfect join, leading to signal loss. An improperly cleaved fiber will have a rough, uneven surface, causing light to scatter and reducing the signal strength reaching its destination. This can lead to significant signal degradation, especially over long distances.

The cleave angle should be precisely 90 degrees. Even a slight deviation can introduce significant losses. Specialized cleavers, using a variety of scoring mechanisms, are used to achieve these precise cleaves consistently.

Q 9. Explain the concept of Optical Return Loss (ORL).

Optical Return Loss (ORL) measures the amount of light reflected back towards the source in a fiber optic system. It’s expressed in decibels (dB) and indicates the quality of a fiber optic connection. A high ORL indicates significant light reflection, signaling a problem such as a poor connection or a bend in the fiber. This reflected light can interfere with the transmitted signal, degrading performance. Imagine shining a flashlight into a mirror; a clean mirror reflects most of the light (low ORL), while a cracked mirror reflects less light and scatters it (high ORL).

A low ORL is desirable, generally below -50dB, indicating a good quality connection with minimal reflections. ORL measurements are essential during installation and troubleshooting to identify and fix faulty connections or components before significant issues arise. It helps identify things like poor splices, connector contamination, or even bends in the fiber.

Q 10. Describe the different types of fiber optic cable.

Fiber optic cables come in various types, primarily categorized by their fiber type and application. The most common types include:

- Single-mode fiber (SMF): Uses a very small core diameter, allowing for long-distance transmission with minimal signal dispersion. Think of it as a single lane highway for light; all the light travels down a very thin, focused path. Ideal for long-haul telecommunications networks.

- Multi-mode fiber (MMF): Has a larger core diameter, allowing for multiple light paths to travel simultaneously. Like a multi-lane highway, different light signals can travel at slightly different speeds and paths. Used for shorter distances, commonly in building infrastructure and local area networks (LANs).

- Loose tube fiber cable: Fibers are housed individually within a loose tube, allowing for easy handling and protection. This design provides flexibility and protects the fibers from bending stress.

- Tight buffered fiber cable: Each fiber is coated with a tight buffer, offering compactness and protection. This is a simpler, more cost-effective design, often used in shorter-reach applications.

The choice of fiber type depends on the specific application. Long-distance high-bandwidth applications benefit from SMF, while shorter-distance applications with less stringent bandwidth requirements may utilize MMF. Cable construction also varies based on the environment and application requirements.

Q 11. What is chromatic dispersion and how does it affect signal transmission?

Chromatic dispersion is a phenomenon in fiber optics where different wavelengths of light travel at slightly different speeds through the fiber. This difference in speed causes the signal to spread out or broaden over long distances, leading to signal distortion and ultimately reduced data transmission rates. Imagine a group of runners in a race; some runners are faster than others (different wavelengths), so the group stretches out over time, making it harder to stay together (signal distortion).

This affects signal transmission by reducing the bandwidth available for data transmission and increasing bit error rates. Over long distances, chromatic dispersion can severely limit the data rate and necessitate the use of dispersion-compensating techniques, such as the use of specialized fibers or electronic compensation.

Q 12. Explain the use of a power meter and OTDR in fiber optic testing.

Power meter: A power meter measures the optical power level of a light signal at a specific point in a fiber optic system. It’s used to verify the signal strength at different points along the fiber to identify potential losses due to attenuation or faulty components. Think of it as a voltmeter for light signals; it tells you the strength of the light signal.

Optical Time Domain Reflectometer (OTDR): An OTDR is a sophisticated instrument that sends pulses of light into a fiber and measures the amount of light reflected back at different points along the fiber. By analyzing the reflections, the OTDR can detect faults, measure fiber length, and identify areas with high attenuation. It essentially creates a ‘map’ of the fiber, highlighting any issues along its length, much like an ultrasound for a fiber optic cable. It is crucial for troubleshooting problems and planning network expansion.

Q 13. What are the advantages and disadvantages of fusion splicing versus mechanical splicing?

Both fusion splicing and mechanical splicing connect fiber optic cables, but they differ significantly in their methods and results:

- Fusion splicing: Uses heat to melt and fuse the fiber ends together, creating a permanent, strong, and low-loss connection. It’s like welding two pieces of metal together; the result is a homogenous join. Advantages include low loss, high reliability, and a permanent connection. Disadvantages involve higher initial cost due to specialized equipment and slower splice time.

- Mechanical splicing: Uses precision alignment and a sleeve to physically connect the fiber ends. This is a quicker, less expensive method, similar to using a connector on an electrical cable. Advantages include lower initial cost and faster splicing. Disadvantages include higher insertion loss, lower reliability compared to fusion splicing, and the connection is not as robust and durable.

The choice between the two depends on the specific application. Fusion splicing is preferred for critical applications requiring low loss and high reliability, such as long-haul telecommunications. Mechanical splicing is suitable for less demanding applications where speed and cost are primary considerations.

Q 14. How do you manage fiber optic cable slack?

Managing fiber optic cable slack is critical to prevent stress on the fibers, which can lead to signal degradation or even fiber breakage. Excess slack should be carefully coiled and secured to avoid creating sharp bends or kinks. Think of it like managing a garden hose; sharp bends can kink the hose and restrict water flow. Similarly, sharp bends in fiber optic cables can severely impact signal transmission.

Methods for managing slack include using slack loops, properly sized cable trays, and appropriate cable management techniques. Slack loops are specifically designed to accommodate fiber movement and expansion/contraction due to temperature changes. Cable trays should be large enough to allow for easy coiling without causing excessive pressure. Proper labeling and documentation of slack loop locations are crucial for maintenance and troubleshooting.

Q 15. How do you handle different types of fiber optic connectors (e.g., SC, FC, LC)?

Handling different fiber optic connectors like SC, FC, and LC involves understanding their specific mechanisms and ensuring proper cleaning and mating. Each connector type has a unique ferrule size and end-face design. For example, SC connectors use a push-pull mechanism, while FC connectors use a screw-on mechanism for coupling. LC connectors are smaller and more compact, ideal for high-density applications. Before connecting any fiber, meticulous cleaning of both connector end faces is crucial to prevent signal loss due to contamination. I always use a high-quality cleaning pen or wipes specifically designed for fiber optic connectors, ensuring I follow the manufacturer’s instructions to prevent scratching. Proper insertion and alignment are equally important to avoid damage and ensure a reliable connection. In a recent project involving a large-scale fiber optic network deployment, having a deep understanding of these connector types saved us valuable time and avoided potential network outages by ensuring compatible and correctly connected equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of splice closure in protecting fiber optic splices?

A splice closure is a critical component in protecting fiber optic splices from environmental damage, ensuring signal integrity and longevity of the network. These enclosures safeguard the delicate splices from water, dust, rodents, and physical damage, which can lead to signal attenuation, breaks, or complete failure of the optical link. They come in various designs—from simple single-splice closures to large capacity units that house numerous splices. Effective splice closures are usually weatherproof, sealed tightly, and often incorporate strain relief mechanisms to protect against accidental pulling or bending of the fibers. Think of a splice closure like a well-protected vault, keeping the valuable fiber optic connections safe from the elements and ensuring the uninterrupted flow of data. During my work on an underwater fiber optic cable installation, the use of highly robust and waterproof splice closures was essential to guarantee the cable’s reliability under harsh marine conditions.

Q 17. How do you document your fiber optic splicing work?

Thorough documentation of fiber optic splicing work is paramount for network maintainability and troubleshooting. My approach combines digital and physical records. I use a detailed spreadsheet or database to record information such as splice location, date, time, fiber type, splice loss values (measured using an OTDR), connector types, and any relevant notes about the work. This information is often geographically referenced using maps or diagrams. Additionally, I create clear and labeled diagrams showing the fiber optic cable routing, splice locations, and equipment connectivity. These diagrams often include photographs of the physical splice points and installed splice closures. Physical labeling of the cables and splice enclosures with clear markings is also crucial. Proper documentation enables swift troubleshooting, future maintenance, and easy network expansion. In one instance, a detailed splice map was instrumental in quickly locating and resolving a fault in a 100km long fiber optic line, saving significant time and cost.

Q 18. Describe your experience with different fusion splicing machines.

My experience encompasses various fusion splicing machines from leading manufacturers. I’ve worked extensively with machines featuring both arc discharge and electric arc methods, understanding the differences in their precision and speed. Some machines offer automated functions, such as fiber alignment and cleaving, enhancing efficiency and minimizing human error. For example, I’ve used the Furukawa Fusion Splicer, known for its precise alignment and user-friendly interface, and the Sumitomo Splicer, appreciated for its robust design suitable for field use in challenging environments. Different machines have varying capabilities in terms of fiber types (single-mode, multi-mode) and core sizes. The choice of machine depends on the specific job requirements, including fiber type, budget, and the level of automation needed. I’m adept at troubleshooting common issues in fusion splicing machines, including arc problems and cleaning issues. This expertise has helped me maintain consistent uptime and excellent splice quality throughout various projects.

Q 19. What are the different types of fiber optic losses?

Several types of fiber optic losses can degrade signal strength. These can be broadly categorized as connection losses and in-line losses. Connection losses occur at the interfaces between fibers, connectors, or other components. They include:

- Fresnel Reflection Loss: This occurs due to the refractive index difference between the fiber and air at connector interfaces.

- Misalignment Loss: This is caused by improper alignment of the fiber ends, leading to light leakage.

- Contamination Loss: Dust, oil, or other contaminants on the fiber ends can cause significant losses.

In-line losses occur along the fiber itself. They include:

- Attenuation Loss: This is inherent to the fiber and increases with distance and wavelength.

- Bending Loss: Excessive bending of the fiber can cause light to escape the core.

- Macrobending Loss: Large radius bends create this type of loss.

- Microbending Loss: Tiny, irregular bends (e.g., due to cabling imperfections) also introduce losses.

Understanding and minimizing these losses is crucial for ensuring efficient optical transmission.

Q 20. How do you interpret OTDR test results?

Interpreting OTDR (Optical Time-Domain Reflectometer) test results requires careful analysis. The OTDR displays a trace showing the power reflected back to the instrument at different points along the fiber. This trace shows several key features:

- Events: These represent abrupt changes in the optical signal, such as splices, connectors, or breaks. The location and magnitude of these events are crucial.

- Attenuation: The gradual decrease in the signal level indicates attenuation loss, allowing us to determine the fiber’s quality and length.

- Reflections: Large reflections can indicate breaks or other significant impairments in the fiber.

By analyzing the trace, I can identify the location and magnitude of losses, determine the overall quality of the fiber, pinpoint potential problems (e.g., high-loss splices, fiber breaks), and ultimately assess the integrity of the entire fiber optic link. Experience is crucial in accurately interpreting subtle variations on the trace and distinguishing between different types of losses. In a recent project, OTDR analysis helped me pinpoint a faulty splice several kilometers away from the main station, enabling focused repair and avoiding unnecessary disruption to the network.

Q 21. How do you ensure the cleanliness of fiber optic connectors?

Maintaining the cleanliness of fiber optic connectors is essential for minimizing optical loss and ensuring a reliable connection. I always follow a strict cleaning procedure. This begins with visual inspection under magnification to check for visible contamination. I then use fiber optic cleaning tools appropriate for the connector type, such as cleaning pens or wipes. These are designed with specialized materials that won’t scratch the delicate fiber end faces. The cleaning process typically involves a series of wipes with a clean tool, ensuring all debris is removed. A final visual inspection confirms cleanliness. It’s crucial to use only high-quality cleaning tools and solutions designed specifically for fiber optics, as improper cleaning can introduce contaminants or damage the connector. Ignoring this step is a common cause of signal loss and network performance issues. In my experience, a well-maintained cleaning process is critical in maintaining a consistent and optimal network performance, reducing the need for costly repairs and replacements.

Q 22. Explain the concept of polarization-mode dispersion (PMD).

Polarization-Mode Dispersion (PMD) is a phenomenon in optical fibers where the two polarization states of light travel at slightly different speeds. Imagine sending two identical light signals down a fiber, but one is polarized horizontally and the other vertically; they won’t arrive at the destination simultaneously due to the fiber’s imperfections. This difference in arrival time causes signal distortion and limits the bandwidth of the fiber.

These imperfections can stem from various sources: stress applied during manufacturing or installation, fiber geometry variations, and even temperature fluctuations. PMD isn’t constant; it varies with temperature and wavelength. This means a perfectly spliced fiber at one temperature may exhibit significant PMD at another.

In practice, PMD impacts high-speed data transmission. The greater the PMD, the more severe the distortion, limiting the bit rate achievable. This is a critical factor in designing long-haul fiber optic systems where the cumulative effect of PMD along the entire link can be substantial. Mitigation strategies involve using polarization-maintaining fibers or advanced digital signal processing techniques.

Q 23. What is the significance of splice loss in a fiber optic network?

Splice loss is the signal power loss that occurs when two optical fibers are joined together. Think of it like connecting two water pipes—some water will be lost at the joint due to imperfect alignment or other factors. In fiber optics, light is lost due to imperfect coupling between the cores of the fibers. This can result from misalignment, air gaps, or variations in refractive index at the splice.

High splice loss is detrimental because it reduces the overall signal strength, necessitating optical amplifiers or higher power transmitters. This increases operating costs and can even lead to signal failure in longer spans. It also directly reduces the network’s reach and potentially its reliability.

Minimizing splice loss is a key concern during installation and maintenance. Proper splicing techniques, using high-quality fusion splicers and connectors, are crucial. Regular monitoring of splice loss using an Optical Time-Domain Reflectometer (OTDR) is essential for proactive maintenance.

Q 24. How do you troubleshoot a fiber optic cable break?

Troubleshooting a fiber optic cable break requires a systematic approach. The first step is identifying the suspected location of the break. This often involves using an OTDR (Optical Time-Domain Reflectometer). The OTDR sends light pulses down the fiber and measures the time it takes for the light to return. A significant drop in the trace indicates a break or a major fault. Think of it like sonar—it uses reflected signals to map the fiber.

Once the location is identified, visual inspection of the fiber at the suspected point is necessary. This may involve accessing underground or aerial cable routes and carefully excavating or inspecting the cable to identify the break point. After locating the break, the damaged section of the fiber needs to be carefully removed and properly spliced using a fusion splicer or other appropriate method to re-establish the connection. In certain circumstances, the connector needs to be repaired or replaced. It’s crucial to utilize proper safety protocols and to follow the safety procedures and guidelines. Protective clothing should always be worn.

If the break is in a difficult-to-access location, specialized equipment and expertise may be required. In some situations, bypassing the damaged section may be a more feasible and cost-effective solution depending on the location and infrastructure. Thorough testing after repair is critical to ensure the connection is reliable and loss is minimal.

Q 25. How do you manage the storage and handling of fiber optic cable?

Proper storage and handling of fiber optic cable is essential to prevent damage and maintain its performance. Fiber is surprisingly delicate. The cable should be stored in a dry, cool environment, away from direct sunlight and extreme temperature fluctuations. Avoid storing it near strong magnetic fields or sharp objects. The cable needs to be stored on reels to prevent kinks or bends, which can weaken the fiber. Before storing, inspect the cables for any signs of damage.

During handling, care should be taken to avoid sharp bends or excessive tension. When working with the fiber itself, always use clean gloves to prevent contamination and fiber damage. Protective coatings, particularly of the cable’s outer jacket, should be handled with care to avoid abrasions which could compromise its strength and long-term reliability.

In addition, meticulous record-keeping of cable storage locations and identification numbers is crucial for efficient inventory management and easy retrieval. Regular inspection of the stored cables is vital to identify and address any potential issues early. A proactive approach can prevent more severe and expensive problems later.

Q 26. Describe your experience with different types of fiber optic terminations.

My experience encompasses a range of fiber optic terminations, including fusion splicing, mechanical splicing, and various connector types like SC, LC, ST, and FC connectors. Fusion splicing offers the lowest loss and highest reliability, creating a permanent bond between fibers using heat. It’s the gold standard for long-haul networks and any situation requiring high bandwidth. Mechanical splicing involves aligning fibers within a precision sleeve; it’s faster but offers higher loss.

Different connector types serve distinct purposes. SC connectors are prevalent in older installations; LC connectors are more compact and increasingly popular due to their smaller size and better density in equipment. ST connectors use a bayonet-style locking mechanism and FC connectors are known for their higher precision and better performance in harsh environments. The selection of the termination method and connector type depends on factors such as application, cost, and performance requirements. For example, a high-speed data center may prioritize low-loss LC connectors, while a short-haul installation might use the readily available SC connectors.

I’ve also worked with field-installable connectors, offering flexibility in situations where splicing isn’t feasible. These are valuable in emergency repairs, cable extensions, and certain structured cabling scenarios where the connector is installed on-site during deployment. However, these connectors typically exhibit higher insertion loss compared to fusion or even mechanical splices. The choice of termination method ultimately hinges on a balance of cost, practicality, and performance in a given network scenario.

Q 27. How do you ensure the long-term reliability of fiber optic splices?

Ensuring the long-term reliability of fiber optic splices involves several critical steps. Proper splicing technique is paramount, using appropriate equipment like a high-quality fusion splicer and performing thorough optical inspection after splicing. Minimizing splice loss is also critical for long-term reliability.

Environmental protection is essential; splices should be protected from moisture, temperature fluctuations, and mechanical stress. Using properly sealed splice closures is crucial for outdoor applications or in areas with harsh environmental conditions. Regular monitoring using an OTDR helps detect any degradation or increases in loss over time.

Proper documentation of splice locations, loss measurements, and dates is crucial for proactive maintenance and troubleshooting. A well-maintained database enables technicians to quickly identify and address potential issues before they escalate. Moreover, following best practices, using high-quality materials, and maintaining a well-organized database greatly contributes to the long-term reliability of any network.

Q 28. What are your experiences in working with different types of fiber optic cable (Single-mode vs. Multi-mode)?

My experience includes extensive work with both single-mode and multi-mode fiber optic cables. Single-mode fiber uses a much smaller core diameter, allowing for longer transmission distances with minimal signal attenuation. It’s the preferred choice for long-haul communication networks and high-bandwidth applications. Imagine it like a narrow water pipe—the water (light) stays more concentrated.

Multi-mode fiber, with its larger core diameter, can support multiple light paths simultaneously. It’s suitable for shorter-distance applications like local area networks (LANs) and building backbones. Think of it as a wider pipe—it can carry more water (light) but with some scattering.

The choice between single-mode and multi-mode depends entirely on the specific application. Single-mode is more expensive but offers superior performance over long distances. Multi-mode is a more cost-effective solution for shorter distances and slower data rates. The splicing techniques are broadly similar but require different precision levels to maximize performance and minimize loss; single-mode splicing requires more meticulous alignment due to the smaller core.

Key Topics to Learn for OFS (Optical Fiber Splicing) Interview

- Fiber Optic Cable Types and Properties: Understand the different types of optical fibers (single-mode, multi-mode), their characteristics, and applications. Be prepared to discuss attenuation, dispersion, and numerical aperture.

- Splicing Techniques: Master various splicing methods, including fusion splicing and mechanical splicing. Know the advantages and disadvantages of each, and be ready to discuss the equipment used.

- Fiber Optic Connectors: Familiarize yourself with common connector types (SC, FC, LC, ST) and their applications. Understand the process of connector termination and testing.

- Optical Time-Domain Reflectometry (OTDR): Learn how to use an OTDR to test fiber optic cables for faults and losses. Understand how to interpret OTDR traces and identify common problems.

- Fiber Optic Testing and Measurement: Be comfortable discussing various testing methods used to ensure the quality of fiber optic connections, including power meters and optical loss test sets.

- Troubleshooting and Problem Solving: Practice identifying and resolving common issues encountered during fiber optic splicing and testing. Be prepared to describe your problem-solving approach in a structured manner.

- Safety Procedures and Regulations: Demonstrate knowledge of safety protocols and regulations related to working with fiber optic cables and equipment.

- Network Topologies and Design: Understand basic network topologies and how fiber optics are used within these architectures. This will demonstrate a broader understanding of the role of OFS in the larger network.

Next Steps

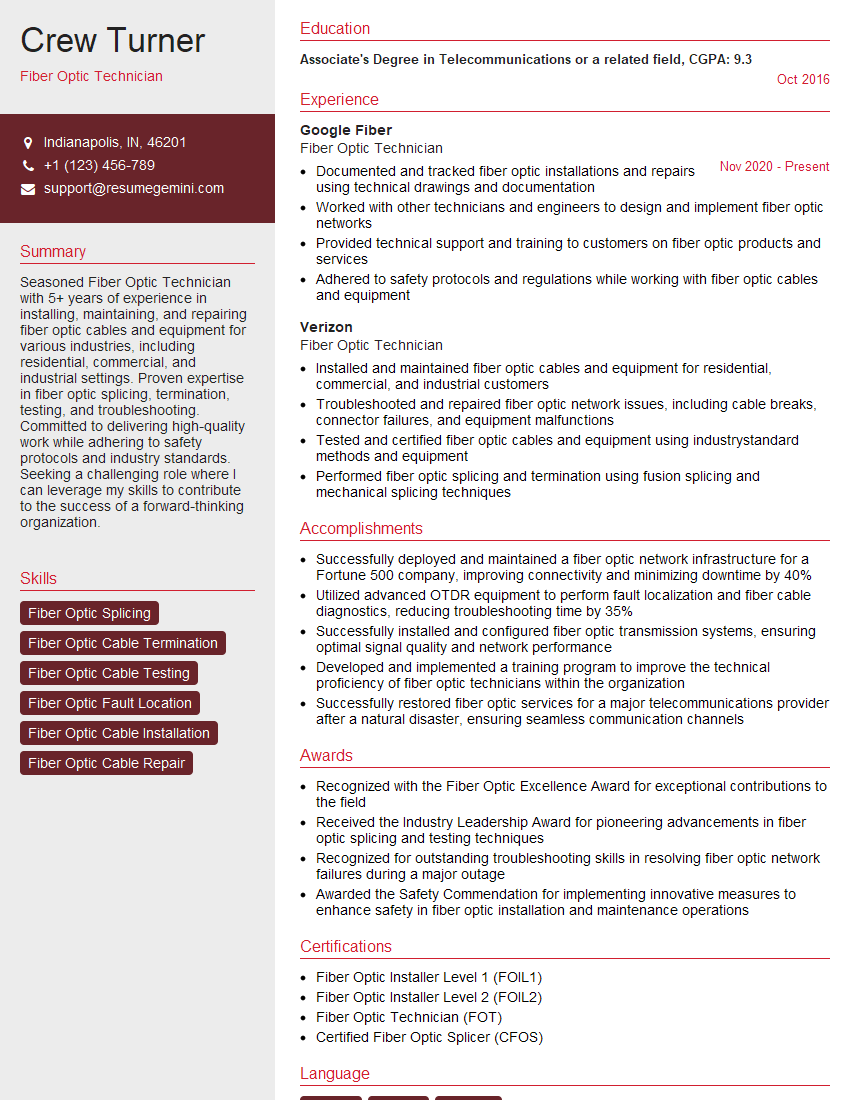

Mastering Optical Fiber Splicing opens doors to exciting career opportunities in telecommunications, data centers, and various other high-tech industries. To maximize your job prospects, it’s crucial to have a strong and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. They offer examples of resumes tailored to OFS (Optical Fiber Splicing) roles, providing you with valuable templates and guidance to present yourself in the best possible light. Take the next step towards your dream career and craft a resume that showcases your expertise!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?