Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top OSH 18001 interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in OSH 18001 Interview

Q 1. Explain the key principles of OSHAS 18001 (or ISO 45001).

OHSAS 18001, now superseded by ISO 45001, is built on several key principles centered around proactively managing occupational health and safety (OH&S). These principles emphasize a holistic approach, moving beyond simple compliance to a culture of continuous improvement.

- Proactive Approach: Instead of reacting to incidents, the standard promotes anticipating and preventing hazards. This involves hazard identification, risk assessment, and implementing control measures before accidents occur. Think of it like preventative medicine – better to prevent illness than cure it.

- Leadership and Worker Participation: Top management commitment is crucial. OH&S should not be delegated but actively championed by leaders at all levels. Equally important is involving workers – they are the ones on the ground and often have the best insights into potential hazards.

- Legal Compliance: The standard requires organizations to identify and comply with all applicable OH&S legislation and regulations. This is the foundation; you can’t build a safe system without it.

- Risk Assessment and Control: This is the core process. Identifying hazards, assessing the associated risks, and implementing control measures to minimize those risks is fundamental to OSHAS 18001/ISO 45001. A simple example: identifying a slippery floor as a hazard, assessing the risk of slips and falls, and implementing a control measure like placing warning signs and ensuring regular cleaning.

- Continual Improvement: The system isn’t static; it requires ongoing monitoring, review, and improvement. Regular audits and management reviews ensure the effectiveness of the system and identify areas for enhancement.

- Communication and Consultation: Open communication and consultation with workers and other stakeholders are essential to building a strong OH&S culture. This fosters a sense of shared responsibility and ownership.

Q 2. Describe the process of conducting a risk assessment.

Conducting a thorough risk assessment is vital. It’s a systematic process to identify hazards, analyze their risks, and determine appropriate control measures. I typically follow a five-step process:

- Hazard Identification: This involves systematically identifying potential hazards within the workplace. Methods include workplace inspections, job safety analysis, checklists, and incident/near-miss reports. For example, identifying unguarded machinery, exposed electrical wiring, or hazardous chemicals.

- Risk Analysis: Once hazards are identified, we analyze the likelihood of an incident occurring and the severity of the potential consequences. This often involves using a risk matrix that combines likelihood and severity to classify risks as low, medium, high, or critical. Qualitative and quantitative methods can be used.

- Risk Evaluation: We evaluate the identified risks based on their severity and likelihood. This prioritizes risks, allowing us to focus our resources where they are most needed.

- Risk Control: Based on the risk evaluation, we implement control measures to eliminate or reduce the risks. This follows a hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE). For example, replacing a hazardous chemical with a less hazardous one (substitution) or installing guards on machinery (engineering controls).

- Review and Monitoring: The risk assessment is not a one-time exercise. It should be regularly reviewed and updated to reflect changes in the workplace, new technologies, and incident reports. This ensures the effectiveness of the control measures remains adequate.

Q 3. What are the main elements of an effective safety management system?

An effective safety management system (SMS) is the backbone of a safe workplace. It integrates several key elements:

- Leadership and Commitment: Visible and active commitment from top management is non-negotiable. It sets the tone and drives the culture of safety.

- Hazard Identification and Risk Assessment: A robust system for identifying potential hazards and assessing the associated risks as previously described.

- Risk Control: Implementing and maintaining appropriate control measures to eliminate or mitigate identified risks.

- Emergency Preparedness and Response: Having plans and procedures in place for handling emergencies and incidents, including evacuation procedures, first aid, and emergency response teams.

- Training and Competency: Providing appropriate training and ensuring workers have the necessary skills and knowledge to perform their tasks safely.

- Monitoring and Measurement: Regularly monitoring the effectiveness of the SMS through key performance indicators (KPIs), such as incident rates, near-miss reports, and audit findings. This data is crucial for continuous improvement.

- Internal Audits: Regular internal audits to assess the effectiveness of the SMS and identify areas for improvement. Audits can be planned or reactive to an incident.

- Management Review: A formal process for reviewing the performance of the SMS and making necessary changes. This ensures the system remains relevant and effective.

- Communication and Consultation: Open communication and consultation with workers and other stakeholders to promote a culture of safety and shared responsibility.

- Documentation and Records: Maintaining accurate and up-to-date records of all aspects of the SMS, including risk assessments, incident reports, training records, and audit findings. This is crucial for demonstrating compliance and continuous improvement.

Q 4. How do you ensure compliance with legal and regulatory requirements?

Ensuring legal and regulatory compliance is paramount. My approach involves several steps:

- Identifying Applicable Legislation: Thoroughly researching and identifying all relevant OH&S legislation, regulations, and standards applicable to the organization’s operations and location. This might include national laws, industry-specific regulations, and local ordinances.

- Integrating Legal Requirements: Integrating these legal requirements into the SMS. This means incorporating them into risk assessments, control measures, training programs, and emergency procedures.

- Monitoring Changes in Legislation: Continuously monitoring and updating the SMS to reflect any changes in legislation or regulations. This requires staying informed through regular updates, subscriptions to relevant publications, and attendance at industry events.

- Maintaining Records: Maintaining accurate records of all compliance activities, including permits, licenses, inspections, and training records. This demonstrates due diligence and helps in audits.

- Conducting Regular Audits: Regularly auditing the SMS to ensure ongoing compliance. These audits can be internal or external, and may include inspections, document reviews, and interviews with staff.

- Proactive Compliance: Beyond merely meeting minimum legal requirements, I strive for proactive compliance. This means anticipating potential changes and proactively implementing measures to ensure continued compliance.

Q 5. What are your experiences with incident investigation and reporting?

Incident investigation and reporting are critical for learning and preventing future occurrences. My approach is based on a systematic process:

- Immediate Response: Securing the scene, ensuring the safety of involved personnel, and providing necessary first aid.

- Gathering Information: Collecting factual information from witnesses, reviewing records, examining the site, and documenting the events leading up to, during, and after the incident.

- Analyzing the Root Cause: Using techniques such as the ‘5 Whys’ or fault tree analysis to identify the root cause of the incident, not just the immediate cause.

- Developing Corrective Actions: Formulating specific, measurable, achievable, relevant, and time-bound (SMART) corrective actions to prevent similar incidents from occurring.

- Implementing Corrective Actions: Implementing the corrective actions and verifying their effectiveness.

- Reporting: Preparing a comprehensive incident report outlining the incident, root causes, corrective actions, and lessons learned. This report is shared with relevant stakeholders.

- Follow-up: Following up on the implemented corrective actions to ensure their effectiveness and make further improvements if necessary.

For example, in an incident involving a fall from height, the investigation might reveal a lack of proper fall protection as the root cause, leading to corrective actions such as providing adequate fall protection equipment, training on its proper use, and regular inspections.

Q 6. Explain your understanding of hazard identification and control measures.

Hazard identification and control measures are intrinsically linked. Hazard identification is the process of pinpointing potential sources of harm in the workplace, while control measures are actions taken to mitigate or eliminate those hazards.

Hazard Identification: This involves a range of techniques, including workplace inspections, job safety analyses, checklists, near-miss reporting, and hazard and operability studies (HAZOP). For example, a workplace inspection might identify a poorly lit area as a hazard, while a job safety analysis might reveal the risk of repetitive strain injury in a specific task.

Control Measures: Once hazards are identified, control measures are implemented following the hierarchy of controls, prioritizing the most effective measures.

- Elimination: Removing the hazard entirely (e.g., removing a hazardous chemical from the workplace).

- Substitution: Replacing the hazard with a less hazardous alternative (e.g., using a less toxic cleaning agent).

- Engineering Controls: Modifying the workplace or equipment to reduce the hazard (e.g., installing guards on machinery).

- Administrative Controls: Changing work practices or procedures to reduce exposure to the hazard (e.g., rotating employees to reduce repetitive strain injuries).

- Personal Protective Equipment (PPE): Providing workers with personal protective equipment to reduce exposure to hazards (e.g., safety glasses, hard hats, earplugs). PPE should always be a last resort, as it protects the individual but not the source of the hazard.

Q 7. How do you develop and deliver safety training programs?

Developing and delivering effective safety training programs is crucial. My approach involves:

- Needs Assessment: Identifying the specific training needs of employees based on their roles, tasks, and the hazards they face. This is done through job safety analyses, risk assessments, and consultation with employees.

- Learning Objectives: Defining clear and measurable learning objectives for the training program. These objectives specify what participants will be able to do after completing the training.

- Training Content: Developing engaging and relevant training content that covers the identified needs and learning objectives. This may include presentations, videos, hands-on activities, and case studies.

- Training Methods: Choosing appropriate training methods that cater to different learning styles. This might include classroom instruction, online modules, on-the-job training, and simulations.

- Delivery: Delivering the training in a clear, concise, and engaging manner. This involves using effective communication techniques, catering to diverse learning styles, and using interactive activities to enhance learning.

- Evaluation: Evaluating the effectiveness of the training through methods such as pre- and post-training tests, observation, feedback, and monitoring of workplace incidents. This ensures the training is effective and produces positive results.

- Documentation: Maintaining accurate records of training provided to all employees, including attendance records, training materials, and evaluation results.

For instance, when training on the use of forklifts, the program would include theoretical instruction on safety procedures, hands-on training with the equipment, and practical assessments to ensure competency before allowing employees to operate forklifts independently.

Q 8. Describe your experience with auditing OSHAS 18001 or ISO 45001.

My experience with auditing OSHAS 18001 (now superseded by ISO 45001) spans over a decade. I’ve conducted numerous audits across diverse industries, from manufacturing and construction to healthcare and IT. My approach is always based on a thorough understanding of the standard’s requirements, focusing on both the documented system and the practical implementation. I utilize a risk-based approach, identifying potential hazards and evaluating the effectiveness of controls in place. For example, in a recent audit of a manufacturing plant, I assessed their procedures for handling hazardous chemicals, verifying their adherence to safe storage, handling, and disposal protocols. This involved reviewing documentation, conducting on-site observations, and interviewing personnel. I also consider the organization’s context and the effectiveness of its top management commitment to health and safety. A successful audit is not just about finding non-conformances, but also about identifying areas for improvement and fostering a culture of continuous improvement within the organization. My reports provide clear and actionable recommendations, allowing the auditee to enhance their OHSMS effectively.

Q 9. How do you measure the effectiveness of your safety programs?

Measuring the effectiveness of safety programs is crucial for demonstrating their value and ensuring ongoing improvement. We use a multifaceted approach, combining leading and lagging indicators. Lagging indicators, such as the number of lost-time incidents (LTIs) or recordable injuries, reflect past performance. However, they are reactive. Leading indicators provide a more proactive measure of safety performance. Examples include the number of safety observations conducted, participation rates in safety training, and the completion of safety audits. We also track near-miss reports, which are invaluable in identifying potential hazards before they result in an accident. Analyzing trends in these indicators helps us to identify areas requiring attention and measure the effectiveness of implemented improvements. For instance, a decrease in near-miss reports coupled with an increase in safety observation participation suggests a positive impact of our safety awareness campaigns.

Q 10. What are your strategies for improving safety performance?

Improving safety performance requires a strategic and multifaceted approach. My strategies center around three key areas: proactive hazard identification and risk assessment, comprehensive training and communication, and fostering a strong safety culture. We employ various techniques for hazard identification, including job safety analyses (JSAs), workplace inspections, and hazard and operability studies (HAZOPs). Risk assessments are then conducted to determine the level of risk associated with each hazard and to establish appropriate control measures. We develop tailored training programs, ensuring employees are properly equipped to perform their tasks safely. Communication is paramount. We use a range of channels, including toolbox talks, posters, and regular safety meetings to engage employees and keep them informed. Building a strong safety culture requires visible leadership commitment, employee empowerment, and open communication. Regular safety committees and feedback mechanisms provide a platform for employees to voice their concerns and contribute to safety improvements. For example, an employee suggestion led to the implementation of a new ergonomic workstation, significantly reducing the risk of musculoskeletal injuries.

Q 11. How do you manage safety within a budget?

Managing safety within a budget requires prioritizing initiatives and resource allocation effectively. We start by conducting a cost-benefit analysis for each safety initiative. This involves estimating the cost of implementation and comparing it to the potential savings from reduced accidents, injuries, and related costs. We prioritize initiatives that deliver the highest return on investment. For instance, investing in ergonomic equipment might have a higher initial cost but can significantly reduce lost-time injuries and associated costs in the long run. We also explore cost-effective strategies such as implementing better housekeeping practices, leveraging technology for safety monitoring, and utilizing readily available resources. Collaboration with other departments can also help in finding cost-effective solutions. We are also proactive in searching for grants and subsidies that can assist in financing safety programs.

Q 12. How do you handle conflicts related to safety concerns?

Handling conflicts related to safety concerns requires a fair, impartial, and transparent approach. Our process begins with active listening to all parties involved, ensuring everyone feels heard and understood. We strive to identify the root cause of the conflict, which often involves miscommunication or differing interpretations of safety procedures. Mediation is often employed to facilitate a constructive dialogue and find a mutually acceptable solution. We emphasize collaboration and the importance of a shared commitment to safety. If mediation fails to resolve the conflict, we escalate the issue to higher management for resolution. Throughout the process, we maintain thorough documentation of all discussions and actions taken. The objective is not just to resolve the immediate conflict, but also to prevent similar situations from occurring in the future by addressing underlying issues and enhancing safety communication.

Q 13. Explain your experience with emergency response planning.

My experience in emergency response planning involves developing and implementing comprehensive plans for various scenarios, including fires, chemical spills, and medical emergencies. This includes conducting risk assessments to identify potential hazards and vulnerabilities, developing detailed emergency procedures, establishing communication protocols, and providing training to employees on emergency response procedures. We conduct regular drills and exercises to test the effectiveness of the plans and identify areas for improvement. The plans are integrated with local emergency services and include procedures for evacuation, rescue, and post-incident recovery. For example, in one project, we developed a detailed evacuation plan for a high-rise office building, including designated assembly points, emergency exits, and procedures for assisting individuals with disabilities. Regular drills ensure that the plan is effective and that employees are prepared to respond appropriately in an emergency.

Q 14. Describe your proficiency in using safety management software.

I am proficient in using various safety management software, including systems for incident reporting, risk assessment, training management, and document control. My experience includes using software such as [Software Name 1] and [Software Name 2]. I understand the importance of data integrity and the use of software to analyze safety data for identifying trends and predicting potential problems. I’m comfortable with data extraction, report generation, and the use of software for improving the efficiency of safety management processes. For example, I’ve utilized software to track near misses, enabling us to proactively address potential hazards before they result in incidents. This ability to efficiently manage and analyze data improves the effectiveness of our safety program and helps in making evidence-based decisions.

Q 15. How do you promote a positive safety culture within an organization?

Promoting a positive safety culture is paramount for any organization aiming to achieve OHSAS 18001 compliance and beyond. It’s not just about rules and regulations; it’s about fostering a shared belief that safety is everyone’s responsibility. This involves a multi-pronged approach.

- Leadership Commitment: Visible and active leadership support is crucial. Leaders must champion safety, participate in safety initiatives, and hold themselves and others accountable. For example, regular safety meetings led by senior management demonstrate commitment.

- Employee Engagement: Safety should not be a top-down mandate. Regular safety training, open communication channels (suggestion boxes, safety committees), and employee involvement in hazard identification and risk assessment processes empower employees and create ownership. I’ve found that safety suggestion schemes, with proper rewards and recognition, drastically improve safety reporting.

- Communication and Training: Clear, consistent, and engaging communication is key. Training programs should be tailored to the specific needs and roles of employees, incorporating interactive methods like simulations and practical exercises. Regular refresher training keeps safety top of mind.

- Incentives and Recognition: Acknowledging and rewarding safe work practices, positive safety behaviors, and contributions to the safety program reinforces the desired culture. This could include safety awards, public recognition, or even small incentives.

- Continuous Improvement: Regularly reviewing safety performance, conducting incident investigations (root cause analysis), and implementing corrective actions demonstrates a commitment to continuous improvement. Data analysis helps pinpoint areas needing attention.

In essence, creating a positive safety culture is a continuous journey, not a destination. It requires consistent effort, open communication, and a genuine commitment from everyone within the organization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your experiences with contractor management and safety?

Contractor management and safety are critical aspects of OHSAS 18001 implementation. I have extensive experience in ensuring contractors comply with our safety standards. My approach involves:

- Pre-qualification: Thorough vetting of contractors before engagement. This includes verifying their safety records, insurance coverage, and OHSAS 18001 certification (or equivalent). I’ve developed a pre-qualification checklist to ensure consistency and thoroughness.

- Clear Safety Requirements: Providing contractors with detailed safety specifications, including site-specific hazards, risk assessments, and required PPE. We use a documented and approved method statement for all contractor activities.

- Joint Site Inspections: Conducting regular joint site inspections with contractors to monitor adherence to safety protocols. This collaborative approach helps identify and address potential hazards proactively.

- Incident Reporting and Investigation: Establishing a clear process for reporting and investigating any incidents involving contractors. This ensures accountability and informs future safety improvements.

- Communication and Training: Ensuring contractors receive adequate training on site-specific hazards and safety procedures. We often provide toolbox talks and site-specific inductions.

In one instance, I successfully prevented a major incident by identifying a contractor’s lack of proper fall protection during high-rise work during a joint inspection. This led to immediate corrective action and a strengthening of our contractor management procedures.

Q 17. How do you ensure the effectiveness of Personal Protective Equipment (PPE)?

Ensuring the effectiveness of PPE is crucial for protecting workers. My approach involves a multifaceted strategy:

- Proper Selection: Selecting PPE appropriate to the specific hazard. This requires a thorough risk assessment to identify the potential hazards and select the most suitable PPE. For example, different types of gloves are needed for handling chemicals versus handling sharp objects.

- Training and Use: Providing comprehensive training on the correct use, maintenance, and limitations of PPE. Employees must understand when and how to use their PPE properly. Regular refresher training is essential.

- Inspection and Maintenance: Regular inspection of PPE for damage or wear and tear. Damaged PPE must be immediately replaced. Providing clear guidelines on PPE maintenance and storage is crucial.

- Fit Testing: Where applicable, conducting fit testing to ensure a proper and comfortable fit for respiratory protection equipment. This ensures the equipment is effective in protecting the wearer.

- Record Keeping: Maintaining accurate records of PPE issuance, training, inspection, and replacement. This provides auditable evidence of compliance.

I’ve implemented a color-coded system for PPE inspection, making it easy for workers and supervisors to identify PPE requiring replacement. This system has significantly improved our PPE management and reduced the risk of accidents.

Q 18. What are your experiences with implementing and maintaining safety procedures?

Implementing and maintaining safety procedures is a continuous process. My experience involves:

- Risk Assessment: Conducting thorough risk assessments to identify hazards and implement appropriate control measures. I use a hierarchical approach to control measures, prioritizing elimination, substitution, engineering controls, administrative controls, and lastly, PPE.

- Procedure Development: Developing clear, concise, and easily understandable safety procedures, tailored to specific tasks and work areas. These procedures must be reviewed and updated regularly.

- Training and Communication: Providing comprehensive training on all safety procedures. Regular communication keeps employees informed of updates and changes.

- Monitoring and Enforcement: Monitoring adherence to safety procedures through regular inspections, audits, and observations. Addressing any non-compliance promptly and consistently is vital.

- Incident Investigation: Thoroughly investigating all incidents to identify root causes and implement corrective actions. This is a critical element for continuous improvement.

I’ve successfully implemented a new lockout/tagout procedure, reducing near-miss incidents by 40% in the first year. This involved a comprehensive training program and a robust monitoring system.

Q 19. Describe your understanding of legal responsibilities related to workplace safety.

Legal responsibilities related to workplace safety are significant and vary by jurisdiction. However, generally, employers have a legal duty of care to provide a safe and healthy working environment for their employees. This includes:

- Compliance with Legislation: Adhering to all relevant occupational safety and health legislation, regulations, and standards (e.g., OHSAS 18001). Staying updated on changes to legislation is essential.

- Risk Assessment and Control: Conducting thorough risk assessments to identify and control hazards. This is a legal requirement in most jurisdictions.

- Provision of PPE and Training: Providing employees with appropriate PPE and training on its use. Failure to do so can lead to legal repercussions.

- Incident Reporting: Reporting all accidents, incidents, and near misses to the relevant authorities. Timely and accurate reporting is crucial.

- Record Keeping: Maintaining accurate records of safety training, inspections, incident investigations, and risk assessments. This is essential for demonstrating compliance.

Failure to fulfill these responsibilities can lead to significant fines, legal action, reputational damage, and even criminal charges.

Q 20. Explain how you would handle a serious workplace accident.

Handling a serious workplace accident requires a structured and systematic approach, prioritizing the safety and well-being of the injured person(s).

- Emergency Response: Activate emergency response protocols immediately. This includes first aid, calling emergency services, and securing the accident site.

- First Aid and Medical Attention: Provide immediate first aid and ensure the injured person receives prompt medical attention.

- Incident Investigation: Conduct a thorough and impartial investigation to determine the root cause(s) of the accident. This involves gathering evidence, interviewing witnesses, and analyzing the circumstances.

- Reporting: Report the accident to the relevant authorities (e.g., regulatory bodies, insurance company) within the stipulated timeframe.

- Corrective Actions: Implement corrective actions to prevent similar accidents from occurring in the future. This might involve modifying procedures, equipment, or training.

- Support for Injured Person: Provide support and assistance to the injured person and their family, including workers’ compensation claims and return-to-work programs.

Maintaining detailed records throughout the entire process is crucial for legal and insurance purposes. I follow a standardized incident investigation report template to ensure consistency and thoroughness.

Q 21. How do you conduct a workplace inspection?

Conducting a workplace inspection is a vital part of proactive safety management. My approach involves a systematic and thorough process:

- Planning: Develop a plan outlining the scope, objectives, and schedule of the inspection. This plan should identify specific areas to be inspected and the hazards likely to be found.

- Inspection Checklist: Use a comprehensive checklist to ensure all relevant areas and hazards are covered. This helps maintain consistency and reduces the likelihood of overlooking important issues.

- Inspection Team: Form an inspection team with diverse expertise and knowledge of the work areas. This can include safety professionals, supervisors, and even employees.

- Conducting the Inspection: Carry out the inspection systematically, following the established plan and checklist. Take photos or videos to document findings.

- Reporting: Prepare a detailed report documenting all findings, including hazards identified, potential risks, and recommended corrective actions. The report should clearly specify the urgency of the corrective actions.

- Follow-Up: Follow up on corrective actions to ensure they are implemented within a timely manner and are effective. This includes revisiting inspected areas to verify improvements.

I regularly use a digital inspection app that allows for real-time documentation, photo upload, and automated report generation. This streamlines the process and improves efficiency.

Q 22. What are the key performance indicators (KPIs) you use to monitor safety performance?

Monitoring safety performance requires a robust set of Key Performance Indicators (KPIs). These aren’t just numbers; they’re indicators of the effectiveness of our safety management system. We use a balanced scorecard approach, considering lagging and leading indicators.

- Lagging Indicators: These reflect past performance and include things like the number of lost-time injuries (LTIs), recordable injuries, medical treatment cases, and the total incident rate (TIR). A low TIR, for example, suggests a safer work environment. For example, a TIR of 2 means 2 injuries per 100 employees.

- Leading Indicators: These predict future performance by measuring proactive safety measures. Examples include the number of safety observations conducted, near-miss reports submitted, safety training hours completed, the effectiveness of risk assessments, and the completion rate of corrective actions from audits. A high number of near-miss reports, while seemingly negative, actually indicates a positive safety culture where employees feel comfortable reporting potential hazards before they lead to incidents.

We also track KPIs related to safety program participation, such as the percentage of employees trained and the engagement in safety meetings. By regularly reviewing these KPIs, we identify trends, areas for improvement, and the overall health of our safety management system.

Q 23. How familiar are you with different types of risk assessment methodologies?

My familiarity with risk assessment methodologies is extensive. I’m proficient in various approaches, adapting my choice to the specific context and complexity of the hazard. Some of the most common methodologies I employ include:

- HAZOP (Hazard and Operability Study): A systematic and structured approach for identifying hazards in complex processes, particularly in chemical and process industries. It involves a team systematically reviewing the process flow diagram to identify deviations from the intended design and their potential consequences.

- What-If Analysis: A simpler, brainstorming technique where team members ask “What if…?” questions to explore potential hazards and their consequences. This is ideal for less complex situations.

- Failure Mode and Effects Analysis (FMEA): A proactive technique to identify potential failure modes in a system and assess their severity, occurrence, and detectability. It assigns a risk priority number (RPN) to prioritize actions.

- Bow-Tie Analysis: A visual representation that shows the cause-and-effect relationship of hazards, including preventative and mitigating controls. It highlights the importance of both preventing the hazard and mitigating its consequences.

In practice, I often combine these methodologies, depending on the specific project requirements. For instance, I might use a HAZOP for a new chemical plant and a What-If analysis for a minor equipment modification.

Q 24. How do you communicate safety information effectively to employees?

Effective communication is paramount in occupational safety. I utilize a multi-faceted approach tailored to different audiences and learning styles. We believe in the power of ‘talk the talk, walk the walk’ approach where leadership visibly supports and champions safety.

- Toolbox Talks: Short, informal discussions on specific safety topics at the start of shifts or work meetings. These offer quick reminders and address immediate concerns.

- Formal Training Programs: Structured courses and workshops using multimedia, interactive simulations, and hands-on exercises. We regularly update these to meet the evolving workplace demands.

- Visual Communication: We use posters, signs, safety alerts, and videos to convey key messages clearly and concisely. We make use of diverse images and languages to reach our employees efficiently.

- Regular Safety Meetings: Formal meetings with employees to discuss safety performance, incidents, and emerging hazards. We encourage open communication and feedback from all levels.

- Digital Communication: We leverage internal communication platforms, emails, and SMS to quickly share important updates, safety alerts, and reminders.

The key is to ensure communication is clear, concise, relevant, and engaging, using various channels and methods to reach everyone effectively. For example, for a large complex topic like Lockout/Tagout (LOTO) procedures, we utilize both formal training videos and visual posters for quick reminders.

Q 25. What are your experiences with safety audits and corrective actions?

I have extensive experience with safety audits and corrective actions. I approach audits systematically, using a checklist-based approach that is in-line with OHSAS 18001 standards. This involves planning the audit scope, selecting auditors with appropriate expertise, conducting inspections and interviews, documenting findings, and generating an audit report.

The audit report details findings, including non-conformities and observations, with clear descriptions and photographs where applicable. Crucially, we focus on both reactive and proactive measures; identifying hazards and risks before they lead to incidents is a key strength of our audit process. Each non-conformity is assigned a severity level based on potential impact, and corrective and preventive actions (CAPAs) are developed to address them. These actions always address root cause. This isn’t just about fixing the immediate problem; it’s about preventing similar issues in the future. For example, a near-miss incident of a worker slipping on a wet floor could lead to a CAPA that focuses not only on cleaning up the spill but on reviewing and improving our spill response procedures and employee training on hazard recognition.

Following the implementation of CAPAs, we conduct follow-up audits to verify their effectiveness. The process ensures continuous improvement and strengthens our safety management system.

Q 26. How do you integrate safety into the design of new projects or processes?

Integrating safety into the design phase of new projects is crucial; it’s far more cost-effective and efficient to design safety in than to retrofit it later. We employ a proactive approach, applying principles of ‘safety by design’ throughout the entire project lifecycle.

- Hazard Identification and Risk Assessment: We conduct thorough hazard identification and risk assessments early in the design process. This includes considering potential hazards associated with materials, processes, equipment, and the work environment.

- Incorporation of Safety Features: We incorporate safety features into the design, such as emergency shut-off switches, safety guards on machinery, and ergonomic workstations. This might include selecting inherently safer materials or processes.

- Consultation with Stakeholders: We involve all relevant stakeholders in the design process, including employees, contractors, and safety professionals. This ensures that different perspectives and potential hazards are considered.

- Use of Standards and Best Practices: We adhere to relevant safety standards, regulations, and best practices during the design phase. This helps ensure that the design meets or exceeds safety requirements.

For instance, when designing a new factory layout, we’d consider the flow of materials, the placement of equipment to minimize risks of collision, and the provision of adequate space for safe movement. We would also identify potential hazards associated with the process, and design the layout to mitigate those risks.

Q 27. Explain your understanding of the hierarchy of hazard controls.

The hierarchy of hazard controls is a fundamental principle in occupational safety. It prioritizes control measures based on their effectiveness in eliminating or minimizing risks. The order of preference is:

- Elimination: Completely removing the hazard. This is the most effective control measure. For example, replacing a hazardous chemical with a less hazardous alternative.

- Substitution: Replacing a hazard with a less hazardous alternative. For example, substituting a solvent-based cleaner with a water-based one.

- Engineering Controls: Modifying the work environment or equipment to reduce or eliminate the hazard. This might include installing guards on machinery or improving ventilation.

- Administrative Controls: Changing work procedures or practices to minimize the risk. Examples include implementing lockout/tagout procedures, providing training, or using work permits.

- Personal Protective Equipment (PPE): Providing employees with PPE to protect them from hazards. This is the least effective control measure and should only be used as a last resort after other controls have been implemented.

It’s important to note that these controls are not mutually exclusive; we often combine them for comprehensive risk management. For example, we might eliminate a particular hazardous chemical, but if that’s not feasible, we could substitute it with a less hazardous one and then further implement engineering controls (e.g., a local exhaust ventilation system) to further reduce the risk before resorting to PPE.

Q 28. How do you stay current with changes in occupational health and safety legislation?

Staying current with changes in occupational health and safety legislation and best practices is an ongoing process. We utilize several methods to ensure we remain compliant and up-to-date.

- Subscription to Regulatory Updates: We subscribe to relevant newsletters and publications from government agencies and professional organizations to receive regular updates on changes in legislation and standards.

- Attendance at Conferences and Workshops: We regularly attend industry conferences and workshops to learn about best practices and emerging trends in occupational safety.

- Membership in Professional Organizations: Membership in professional organizations provides access to resources, training, and networking opportunities to stay informed about industry developments.

- Internal Training Programs: We conduct regular training programs for our employees to keep them informed of changes in legislation and best practices.

- Regular Review of Safety Management System: Our safety management system is regularly reviewed and updated to reflect changes in legislation, technology, and best practices. We conduct internal reviews and, when appropriate, external audits to ensure our systems meet all required standards.

Staying informed is not simply a matter of compliance; it’s about proactively improving our safety performance and ensuring a safe and healthy work environment for our employees.

Key Topics to Learn for OSH 18001 Interview

Ace your OSHAS 18001 interview by mastering these key areas. Remember, practical application and problem-solving skills are just as crucial as theoretical knowledge.

- Understanding the OSHAS 18001 Standard: Thoroughly grasp the core principles, clauses, and requirements of the standard. Be prepared to discuss its intent and overall framework.

- Hazard Identification and Risk Assessment: Practice identifying potential hazards in various workplace scenarios and demonstrate your proficiency in conducting thorough risk assessments. Understand different risk control hierarchies.

- Emergency Preparedness and Response: Review emergency planning procedures, including evacuation plans, first aid protocols, and crisis management strategies. Be ready to discuss practical application and improvements.

- Legal and Regulatory Compliance: Familiarize yourself with relevant legislation and regulations pertaining to occupational safety and health in your region. Understand how OSHAS 18001 ensures compliance.

- Internal Audits and Management Reviews: Learn about the process of conducting internal audits and participating in management reviews. Understand how these contribute to continual improvement.

- Occupational Health and Safety Management Systems (OHSMS): Demonstrate a comprehensive understanding of how an OHSMS functions, including its implementation, maintenance, and continuous improvement.

- Performance Measurement and Improvement: Be prepared to discuss key performance indicators (KPIs) related to OSHAS 18001 and how to track and improve safety performance.

- Incident Investigation and Reporting: Understand the process of investigating incidents, identifying root causes, and implementing corrective actions to prevent recurrence. Practice presenting a case study.

Next Steps

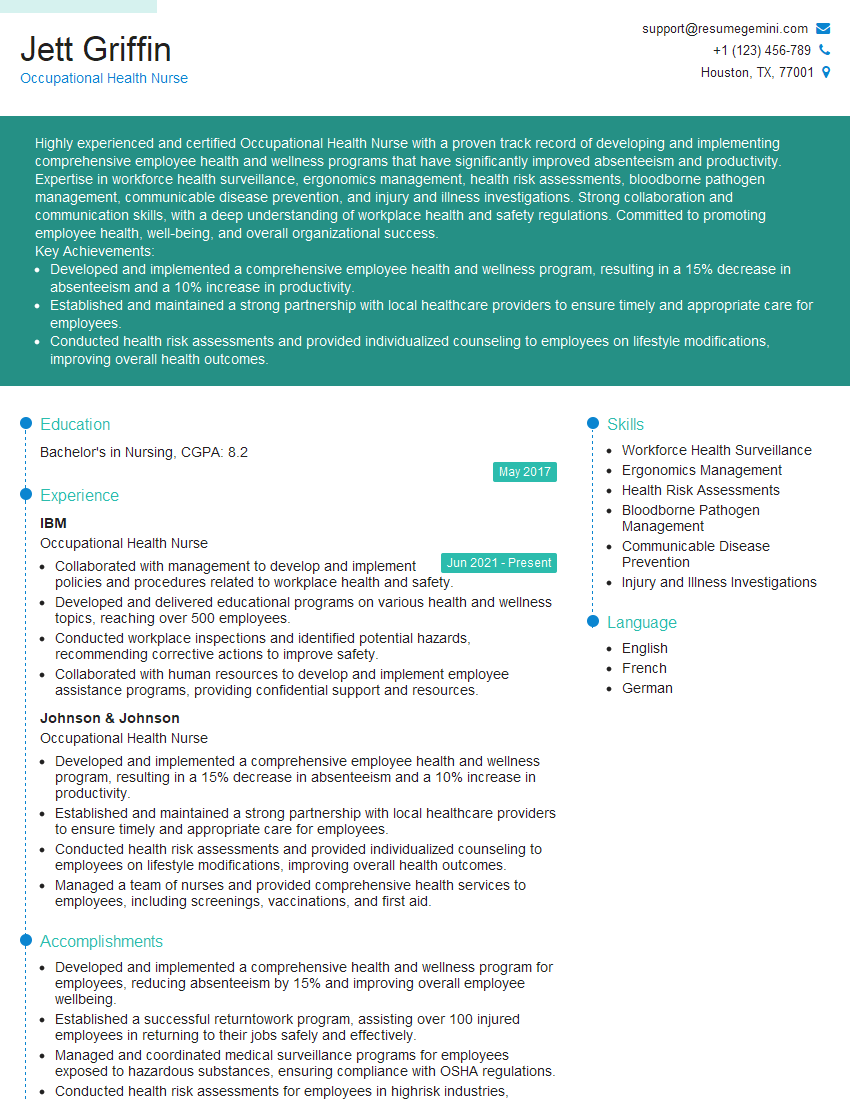

Mastering OSHAS 18001 opens doors to exciting career opportunities and demonstrates your commitment to workplace safety. A well-crafted resume is your key to unlocking these opportunities. Building an ATS-friendly resume is crucial for getting noticed by recruiters.

We recommend using ResumeGemini to create a professional and impactful resume. ResumeGemini provides a streamlined process and offers examples tailored to OSH 18001 roles, helping you present your skills and experience effectively. Invest the time to create a resume that showcases your expertise and boosts your chances of landing your dream job. Take the next step towards your successful career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?