Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important OSHA Safety Regulations and Practices interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in OSHA Safety Regulations and Practices Interview

Q 1. Explain the General Duty Clause of OSHA.

The General Duty Clause of OSHA, found in Section 5(a)(1) of the Occupational Safety and Health Act, is the cornerstone of workplace safety. It essentially states that employers have a general duty to provide a workplace free from recognized hazards that are causing or are likely to cause death or serious physical harm to their employees. This is a catch-all provision, meaning it covers hazards not specifically addressed by other OSHA standards. Think of it as the overarching responsibility that underlies all specific OSHA regulations.

For example, if a new piece of equipment is introduced with an unrecognized hazard (let’s say, a sharp edge that could cause injury), even if there isn’t a specific OSHA standard covering that exact scenario, the General Duty Clause holds employers accountable for identifying and mitigating that hazard. They must take feasible steps to protect their employees. Feasible means achievable; it takes into consideration the size of the business and the resources available.

OSHA enforcement relies on the General Duty Clause when specific standards are lacking. Inspectors will assess whether an employer has taken reasonable steps to identify and control hazards. Failure to comply can result in citations and penalties.

Q 2. Describe the process for reporting a workplace injury or illness.

Reporting a workplace injury or illness is crucial for OSHA recordkeeping and preventing future incidents. The process starts immediately after an incident occurs. First, provide first aid and medical attention as needed. Then, report the incident to your supervisor immediately. Your employer is required to record certain injuries and illnesses on OSHA Form 300, 300A, and 301. These forms track workplace injuries and illnesses, helping identify trends and areas for improvement.

The specific details recorded depend on the severity and nature of the injury. OSHA defines recordable cases, which are those that result in death, days away from work, restricted work, or medical treatment beyond first aid. Employers must also comply with recordkeeping deadlines; usually within 7 days of learning of an injury or illness.

Failure to report can lead to significant penalties from OSHA. It’s vital that employers understand the OSHA recordkeeping requirements and the penalties for non-compliance. Accurate and timely reporting ensures a safer work environment and protects both the employee and the employer.

Q 3. What are the key elements of an effective OSHA safety program?

An effective OSHA safety program is proactive, not reactive. It’s a comprehensive system designed to prevent workplace injuries and illnesses. Key elements include:

- Management Commitment and Employee Involvement: Safety must be a top priority, starting from the leadership down. Employees should actively participate in identifying hazards and developing solutions.

- Hazard Identification and Assessment: Regularly assessing the workplace for potential hazards is fundamental. This involves inspections, employee feedback, and incident investigations.

- Hazard Prevention and Control: Implementing controls to eliminate or reduce hazards, following the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE).

- Training: Providing employees with regular and relevant safety training on hazards specific to their jobs and the proper use of PPE.

- Emergency Action Plan: A detailed plan for responding to emergencies, including evacuation procedures, first aid, and communication protocols.

- Recordkeeping and Reporting: Maintaining accurate records of injuries, illnesses, safety inspections, and training.

- Regular Inspections and Audits: Conducting regular inspections to identify hazards and evaluate the effectiveness of safety programs.

A successful safety program is a culture, not just a set of rules. It requires ongoing commitment, participation from everyone, and continuous improvement based on data and feedback.

Q 4. How do you conduct a workplace hazard assessment?

Conducting a workplace hazard assessment is a systematic process for identifying potential hazards and evaluating their risks. It involves a multi-step approach:

- Walkthrough Inspection: Physically walk through the workplace, observing the work processes, equipment, and environment.

- Job Hazard Analysis (JHA): Break down each job task into steps and identify potential hazards for each step.

- Employee Input: Collect information from employees who perform the tasks. They often have valuable insights into hazards that may be missed by others.

- Review of Incident Reports: Analyze past incidents to identify recurring hazards and near misses.

- Review of OSHA Standards and Regulations: Ensure compliance with all applicable OSHA standards.

- Risk Assessment: Evaluate the likelihood and severity of each identified hazard, determining the overall level of risk.

- Control Measures: Develop and implement control measures to reduce or eliminate hazards, prioritizing the hierarchy of controls.

- Documentation: Thoroughly document all findings, assessments, and control measures.

The goal is to create a comprehensive picture of potential hazards and implement effective control measures to minimize risks and protect employees. Regular reassessments are important to ensure the effectiveness of the controls in place.

Q 5. What are the OSHA requirements for personal protective equipment (PPE)?

OSHA’s requirements for personal protective equipment (PPE) are based on the principle of hazard control. Employers must provide PPE when engineering and administrative controls are insufficient to protect employees from workplace hazards. The key elements are:

- Hazard Assessment: A thorough assessment must identify hazards and the necessary PPE.

- Selection of Appropriate PPE: Employers must choose PPE that is appropriate for the specific hazard. This is often guided by OSHA standards for specific hazards.

- Training: Employees must receive training on how to properly use, maintain, and care for their PPE. This includes understanding the limitations of PPE.

- Proper Use: Employees must correctly use PPE at all times when required.

- Maintenance and Inspection: Employers must provide for regular inspection and maintenance of PPE to ensure its effectiveness.

- Replacement: Damaged or worn-out PPE must be replaced promptly.

For example, if employees are working with chemicals, they may require respirators, gloves, and eye protection. If working at heights, fall protection equipment such as harnesses and lanyards might be necessary. The specific PPE requirements depend heavily on the job tasks and potential hazards.

Q 6. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls is a prioritized approach to managing workplace hazards. The goal is to eliminate hazards whenever possible, and when elimination isn’t feasible, to select controls in decreasing order of effectiveness:

- Elimination: The most effective method is to remove the hazard altogether. For example, replacing a hazardous chemical with a less hazardous alternative.

- Substitution: Substituting a hazardous material or process with a less hazardous one. Replacing a manual material handling task with a mechanical one.

- Engineering Controls: Implementing engineering solutions to control the hazard at the source. This could include installing machine guards, ventilation systems, or improved lighting.

- Administrative Controls: Implementing work practices or procedures to reduce exposure to the hazard. This may involve changing work schedules, providing more training, or implementing stricter safety rules.

- Personal Protective Equipment (PPE): PPE is used as a last resort when other controls are not sufficient. It protects the employee from the hazard, but it does not eliminate the hazard itself.

Think of it like this: elimination is like removing a poisonous plant from your garden; substitution is replacing it with a non-poisonous plant; engineering controls are like building a fence around the poisonous plants; administrative controls are like training children not to touch the poisonous plants; and PPE is like giving the children gloves to handle the plants (but they still shouldn’t touch them).

Q 7. Describe your experience with OSHA recordkeeping requirements.

My experience with OSHA recordkeeping requirements is extensive. I’ve been involved in developing and implementing recordkeeping systems for various organizations, ensuring compliance with all applicable regulations. This involves understanding the different OSHA forms (300, 300A, 301), knowing which injuries and illnesses are recordable, and adhering to strict deadlines for reporting. I have assisted organizations in conducting annual summaries of work-related injuries and illnesses and have ensured that the records are accurately maintained and readily accessible for OSHA inspections.

I’ve also worked with companies to establish procedures for reporting injuries and illnesses, including developing systems for timely reporting to supervisors and the appropriate authorities. I am familiar with the penalties for non-compliance and understand the importance of accurate recordkeeping for both protecting employees and demonstrating a commitment to workplace safety. Additionally, my work has included training employees and managers on proper recordkeeping procedures. This ensures that everyone understands their responsibilities in maintaining accurate and complete records, helping prevent costly fines and demonstrate a commitment to worker safety.

Q 8. How do you ensure compliance with OSHA’s lockout/tagout procedures?

Ensuring compliance with OSHA’s lockout/tagout (LOTO) procedures is paramount to preventing catastrophic accidents involving energized equipment. LOTO is a critical safety procedure designed to isolate energy sources before maintenance or repair work begins. My approach involves a multi-layered strategy:

Comprehensive Training: All employees involved in LOTO procedures receive thorough training covering the standards, specific procedures for our facility’s equipment, and the importance of proper lockout devices. This includes both theoretical knowledge and hands-on practice.

Regular Audits and Inspections: I conduct regular audits to verify that LOTO procedures are being followed correctly. This includes inspecting equipment to ensure proper lockout devices are in place, verifying the effectiveness of energy isolation, and reviewing the documentation associated with each lockout.

Developing and Implementing LOTO Procedures: I work with the team to develop clear, concise, and specific LOTO procedures for each piece of equipment. These procedures are readily available, easy to understand, and tailored to the specific hazards of each machine. We use standardized forms and tags that clearly identify the equipment, the person performing the lockout, and the date and time.

Enforcement and Accountability: Consistent enforcement of LOTO procedures is crucial. Non-compliance is addressed immediately through coaching and disciplinary measures if necessary. Open communication is key to a safety-conscious culture.

Incident Investigation: Any near misses or incidents involving LOTO procedures are thoroughly investigated to identify root causes and implement corrective actions. This helps to prevent similar incidents from occurring in the future.

For example, in a previous role, I implemented a new LOTO program that reduced near-miss incidents by 40% within the first year, demonstrating the effectiveness of a robust and well-maintained program.

Q 9. What is your experience with conducting safety training programs?

I have extensive experience in developing and delivering safety training programs across various industries. My approach is to create engaging, relevant, and interactive training experiences that go beyond simple lecture-based formats.

Needs Assessment: I begin by conducting a thorough needs assessment to identify the specific safety training needs of the workforce. This includes reviewing incident reports, identifying gaps in knowledge and skills, and consulting with supervisors and employees.

Curriculum Development: Based on the needs assessment, I develop comprehensive training curricula that incorporate a variety of learning methods, including interactive exercises, case studies, videos, and hands-on demonstrations. The material is always up-to-date with the latest OSHA regulations and best practices.

Delivery Methods: I adapt training delivery methods to suit the audience and learning styles. I use a combination of classroom training, online modules, and on-the-job training. I regularly assess learning through quizzes and practical assessments.

Documentation and Record Keeping: All training records are meticulously maintained and readily accessible to demonstrate compliance with OSHA requirements and internal policies. This includes tracking employee participation, test scores, and training completion dates.

Evaluation and Continuous Improvement: I regularly evaluate the effectiveness of the training programs by collecting feedback from participants and tracking changes in safety performance. This feedback informs improvements to future training sessions.

For instance, I once developed a specialized fall protection training program that significantly reduced fall-related incidents in a construction project by 65%. This success was due to a combination of engaging training methods and focused practical exercises.

Q 10. How do you handle employee complaints related to safety concerns?

Addressing employee safety concerns promptly and effectively is crucial. My approach emphasizes open communication, thorough investigation, and timely resolution.

Confidential Reporting System: I ensure a confidential system is in place for employees to report safety concerns without fear of retaliation. This could include anonymous reporting mechanisms or designated personnel to receive reports.

Prompt Investigation: All complaints are investigated promptly and thoroughly. This involves interviewing the complainant, witnesses, and relevant supervisors to gather all necessary information.

Corrective Actions: Based on the investigation, appropriate corrective actions are implemented to address the safety concern. This may involve making immediate repairs, implementing new safety procedures, or providing additional training.

Feedback and Follow-up: Employees are kept informed of the investigation’s progress and the actions taken to address their concerns. A follow-up is performed to ensure the issue is resolved and prevent recurrence.

Documentation: All complaints, investigations, and corrective actions are meticulously documented to maintain a record of safety performance and compliance.

For example, I once handled a complaint about inadequate lighting in a warehouse. A prompt investigation led to the immediate replacement of faulty lighting fixtures and improved warehouse safety.

Q 11. Explain your understanding of OSHA’s confined space entry regulations.

OSHA’s confined space entry regulations are designed to protect workers from the hazards associated with entering enclosed or partially enclosed spaces with limited or restricted means of entry and exit. These hazards can include oxygen deficiency, toxic atmospheres, engulfment, and other physical dangers.

Permit-Required Confined Spaces: These spaces have potential atmospheric hazards or other serious safety or health hazards and require a formal entry permit. Before entry, atmospheric testing must be done to ensure it’s safe for entry, appropriate ventilation systems must be in place, and a rescue plan must be developed and tested.

Non-Permit-Required Confined Spaces: These spaces generally do not have the same level of inherent danger and require a less rigorous entry process but still necessitate a thorough assessment of hazards. Simple precautions such as ensuring adequate ventilation before entry are often sufficient.

Entry Procedures: Standard procedures including atmospheric monitoring, proper ventilation, lockout/tagout procedures for equipment, and having designated attendants are essential regardless of the confined space classification.

Rescue Plan: A comprehensive rescue plan is critical for permit-required confined spaces and often necessary for non-permit-required spaces. This plan should detail how to rescue an entrant in the event of an emergency, including the equipment and personnel needed.

Training: All personnel involved in confined space entry must receive thorough training on the hazards, entry procedures, and rescue techniques.

Failure to adhere to these regulations can lead to serious injury or fatality. A well-structured confined space entry program minimizes the risk and protects employees.

Q 12. Describe your experience with fall protection systems.

My experience with fall protection systems encompasses various aspects, from selection and installation to inspection and training. I’ve worked with a wide range of systems in diverse work environments.

System Selection: The selection of a fall protection system depends on the specific work environment and hazards. This involves considering factors such as the height of the work, the type of surface, and the potential for impact. Examples include guardrails, safety nets, personal fall arrest systems (PFAS) and fall restraint systems.

Installation and Inspection: Proper installation and regular inspection of fall protection systems are crucial to ensure their effectiveness. I am proficient in inspecting various systems to identify any damage or defects that could compromise their integrity. This includes inspecting anchors, harnesses, lanyards, and other components.

Training: Providing comprehensive training on the proper use and care of fall protection equipment is a critical component of any fall protection program. I am skilled at instructing workers on how to properly use harnesses, lanyards, and other equipment, emphasizing the importance of proper techniques to prevent falls.

Compliance with OSHA Standards: I am well-versed in OSHA’s fall protection standards (29 CFR 1926 Subpart M), ensuring that all systems are compliant with relevant regulations.

In a previous role, I was responsible for implementing a new fall protection system on a construction site. The system included guardrails, safety nets, and personal fall arrest systems. This resulted in a significant reduction in fall-related incidents and improved overall site safety. This implementation included training all workers on the proper use and care of the equipment and conducting regular inspections.

Q 13. What are the OSHA requirements for hazardous waste management?

OSHA’s requirements for hazardous waste management are extensive and aim to protect human health and the environment from the dangers posed by hazardous waste. Compliance requires a multifaceted approach.

Hazardous Waste Identification: Accurate identification of hazardous waste is the first and most crucial step. This involves understanding the characteristics of hazardous waste, such as ignitability, corrosivity, reactivity, and toxicity.

Storage and Handling: Proper storage and handling of hazardous waste are critical to prevent spills, leaks, and other releases. This includes using appropriate containers, labeling, and storage areas. Secondary containment is often required.

Waste Minimization: OSHA encourages proactive waste minimization techniques to reduce the amount of hazardous waste generated in the first place. This could involve substituting less hazardous materials, recycling, and improving processes.

Disposal and Treatment: Hazardous waste must be disposed of or treated in accordance with applicable regulations. This often involves utilizing licensed disposal facilities and following specific handling procedures.

Emergency Preparedness: A comprehensive emergency plan must be in place to respond to spills or releases of hazardous waste. This includes procedures for containment, cleanup, and employee protection.

Record Keeping: Detailed records of hazardous waste generation, storage, handling, treatment, and disposal must be maintained. These records are subject to audit by OSHA and other regulatory agencies.

Non-compliance with these regulations can result in significant penalties and legal repercussions. A robust hazardous waste management program is essential for any organization that generates or handles hazardous waste.

Q 14. How do you conduct a job safety analysis (JSA)?

A Job Safety Analysis (JSA) is a systematic process for identifying and controlling hazards associated with a specific job task. It’s a proactive approach to safety that helps prevent accidents before they occur. My approach to conducting a JSA typically involves these steps:

Select the Job Task: The first step is to choose the specific job task that will be analyzed. This could be a complex task or even a simple one that presents potential hazards.

Identify the Steps: Break down the job task into a series of sequential steps. This ensures a thorough analysis of each component of the task.

Identify Potential Hazards: For each step, identify all potential hazards. Consider both obvious and less apparent hazards. Think about potential ergonomic hazards, chemical exposures, mechanical hazards and environmental factors.

Identify Control Measures: Develop specific control measures to mitigate each identified hazard. These measures could include engineering controls (e.g., guarding machinery), administrative controls (e.g., work permits), and personal protective equipment (PPE).

Document the JSA: Create a written document that clearly outlines the job task, the steps involved, the potential hazards, and the control measures in place. This should be reviewed and approved by relevant parties.

Train Employees: Once the JSA is completed, ensure that all employees involved in the job task are properly trained on the identified hazards and control measures.

Review and Update: JSAs are not static documents. They must be reviewed and updated regularly to reflect changes in equipment, procedures, or hazards.

For instance, I conducted a JSA for a roofing job which identified potential fall hazards, exposure to sunlight, and the risk of cuts from sharp materials. The resulting JSA included specific requirements for fall protection equipment, the use of sunscreen, and the provision of cut-resistant gloves. This ensured that all workers were aware of the risks and had the necessary protective measures in place.

Q 15. What are the OSHA requirements for respiratory protection?

OSHA’s Respiratory Protection standard (29 CFR 1910.134) mandates a comprehensive approach to protecting workers from airborne hazards. It’s not simply about providing respirators; it’s about a complete program encompassing hazard assessment, respirator selection, fit testing, training, and maintenance.

- Hazard Assessment: Before any respirator is even considered, a thorough assessment must determine if airborne hazards exist and at what concentrations. This might involve air monitoring to quantify the levels of dust, fumes, gases, or vapors.

- Respirator Selection: The right respirator depends entirely on the identified hazard. For example, a simple dust mask might suffice for low-concentration nuisance dust, while a self-contained breathing apparatus (SCBA) is needed for immediately dangerous to life or health (IDLH) situations.

- Fit Testing: Respirators must fit properly to be effective. OSHA mandates fit testing for tight-fitting respirators to ensure a good seal. Different methods exist, such as qualitative fit testing (using a bitter solution) and quantitative fit testing (using a device to measure leakage).

- Training: Workers must be trained on how to properly use, maintain, and care for their respirators. This includes understanding the limitations of the respirator, recognizing signs of respirator malfunction, and knowing when to replace a filter or cartridge.

- Maintenance and Storage: Respirators need regular maintenance and should be stored properly to avoid damage and contamination. A damaged respirator is useless and potentially dangerous.

Example: In a woodworking shop, a hazard assessment might reveal the presence of wood dust. Depending on the concentration, respirators ranging from simple dust masks to more advanced respirators with HEPA filters might be required. Workers would then undergo fit testing and thorough training on their selected respirator before using it.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with emergency response planning and procedures.

My experience with emergency response planning involves developing and implementing comprehensive plans tailored to specific workplace hazards. This includes conducting thorough risk assessments, identifying potential emergencies (fires, chemical spills, medical emergencies), establishing clear communication protocols, and training employees on evacuation procedures and emergency response actions.

I have led teams in developing emergency action plans compliant with OSHA regulations (29 CFR 1910.38) and NFPA standards. This involved:

- Hazard identification and risk assessment: Identifying potential hazards and evaluating their likelihood and severity.

- Emergency response procedures development: Creating detailed procedures for different emergency scenarios, including evacuation routes, assembly points, and emergency contact information.

- Training and drills: Conducting regular training and drills to ensure employees are familiar with the emergency action plan and their roles in an emergency.

- Communication systems: Establishing clear communication systems to ensure rapid and effective communication during an emergency.

- Post-incident analysis and improvement: Conducting thorough post-incident analyses to identify areas for improvement in the emergency response plan.

For instance, during my work at a chemical manufacturing facility, I developed an emergency response plan that included specific procedures for handling chemical spills, including containment, cleanup, and employee evacuation. This plan was regularly reviewed and updated based on new information and incident reports.

Q 17. How do you investigate workplace accidents and incidents?

Investigating workplace accidents and incidents is a systematic process aimed at identifying root causes and implementing corrective actions to prevent recurrence. My approach adheres to OSHA guidelines and emphasizes a thorough, unbiased investigation.

- Secure the scene: The first priority is to ensure the safety of everyone involved and prevent further incidents.

- Gather information: This includes interviewing witnesses, reviewing records (training records, maintenance logs, incident reports), and collecting physical evidence (photos, videos, damaged equipment).

- Analyze the data: This involves identifying contributing factors and root causes, utilizing tools like fault tree analysis or fishbone diagrams.

- Develop corrective actions: Based on the analysis, specific actions are identified to mitigate hazards and prevent future accidents. This might involve modifying equipment, implementing new procedures, or enhancing training.

- Implement and monitor corrective actions: The corrective actions are implemented, and their effectiveness is monitored over time.

- Report the findings: A comprehensive report documenting the investigation, its findings, and recommended corrective actions is prepared and distributed to relevant parties.

Example: If an employee suffered a hand injury while operating a machine, the investigation would examine the machine’s guarding, the employee’s training on safe operating procedures, and the adequacy of personal protective equipment (PPE). The investigation might reveal a lack of proper machine guarding as the root cause, leading to the implementation of improved guarding and retraining of employees.

Q 18. What are your strategies for promoting a safety culture within a workplace?

Promoting a safety culture is not a one-time event, but a continuous process that requires leadership commitment, employee engagement, and a systematic approach. My strategies include:

- Leadership commitment: Safety must be a top priority, clearly communicated and demonstrably supported by leadership at all levels.

- Employee involvement: Workers need to feel empowered to identify and report hazards without fear of retribution. Safety committees or suggestion boxes can foster this involvement.

- Training and communication: Regular safety training, clearly communicating safety policies and procedures, and providing feedback are essential.

- Hazard identification and control: Implementing a robust hazard identification and control program, including regular safety inspections and hazard assessments.

- Incident investigation and reporting: Thorough accident investigations with a focus on root cause analysis and corrective actions.

- Recognition and rewards: Recognizing and rewarding safe behaviors reinforces positive safety attitudes.

- Performance metrics: Tracking safety performance metrics (incident rates, near misses) provides data to guide improvements.

For example, I once implemented a peer-to-peer safety observation program where employees were trained to observe and report unsafe behaviors to their colleagues without judgment. This created a collaborative environment where safety was everyone’s responsibility.

Q 19. Describe your familiarity with OSHA standards related to machine guarding.

OSHA’s machine guarding standards (29 CFR 1910 Subpart O) are crucial for preventing injuries from rotating parts, points of operation, and other hazardous moving machine parts. These standards require safeguarding all hazardous parts of machinery to prevent contact by employees. The specific guarding methods depend on the type of hazard and the machine.

- Guarding types: Common guarding methods include fixed guards, interlocks, presence-sensing devices, and safety distance guarding.

- Point of operation guarding: Special attention must be given to protecting the point of operation, where work is actually performed (e.g., the cutting edge of a saw).

- Maintenance and repair: Safeguards must be maintained in good working order, and procedures for maintenance and repair must ensure that safeguards are restored correctly before operation.

- Lockout/Tagout (LOTO): Before performing any maintenance or repair, lockout/tagout procedures must be implemented to prevent accidental start-up.

Example: A power press would require a point-of-operation guard to prevent the operator’s hand from entering the danger zone. A belt drive might require guarding to prevent contact with the moving belts. Before servicing any of these machines, a rigorous LOTO procedure must be followed to ensure worker safety.

Q 20. Explain your understanding of OSHA’s bloodborne pathogens standard.

OSHA’s Bloodborne Pathogens standard (29 CFR 1910.1030) protects employees from occupational exposure to bloodborne pathogens, such as HIV and Hepatitis B and C viruses. It requires employers to implement a comprehensive plan to minimize the risk of exposure.

- Exposure Control Plan: The core of the standard is a written Exposure Control Plan that identifies tasks and procedures with potential exposure, lists specific engineering and work practice controls, and details personal protective equipment (PPE) requirements.

- Engineering Controls: These are physical changes to the work environment to reduce exposure (e.g., using needleless systems, sharps disposal containers).

- Work Practice Controls: These are changes to how tasks are performed to reduce risk (e.g., proper handwashing, using appropriate techniques for handling contaminated materials).

- Personal Protective Equipment (PPE): PPE such as gloves, gowns, eye protection, and face shields is required when there’s a potential for exposure.

- Hepatitis B Vaccination: Employers must offer free Hepatitis B vaccination to all employees with potential exposure.

- Training: Employees must receive comprehensive training on bloodborne pathogens, the Exposure Control Plan, and proper safety procedures.

- Post-exposure follow-up: A clearly defined plan must be in place for post-exposure follow-up, including medical evaluation and treatment.

Example: In a healthcare setting, the Exposure Control Plan would detail procedures for handling needles and other sharps, cleaning up spills of blood or other bodily fluids, and using appropriate PPE. Employees would receive training on these procedures and be offered the Hepatitis B vaccination.

Q 21. How do you ensure compliance with OSHA’s requirements for hearing conservation?

OSHA’s Hearing Conservation Amendment (29 CFR 1910.95) mandates a comprehensive program to protect workers from noise-induced hearing loss. This involves a multi-pronged approach.

- Noise monitoring: Regular monitoring of noise levels in the workplace is required to identify areas where noise exposures exceed permissible limits.

- Hearing protection: If noise levels exceed permissible limits, hearing protection must be provided, and employees must be trained on how to properly use it. This could range from earplugs to earmuffs.

- Audiometric testing: Baseline audiometric testing (hearing tests) must be conducted for employees exposed to noise above certain levels, followed by periodic testing to monitor changes in hearing.

- Training and education: Employees must receive training on the hazards of noise exposure, the importance of hearing protection, and the results of audiometric testing.

- Recordkeeping: Detailed records of noise monitoring, audiometric testing, and employee training must be maintained.

Example: In a manufacturing plant, noise monitoring might reveal excessive noise levels near certain machinery. This would necessitate providing employees with appropriate hearing protection (e.g., earmuffs) and conducting baseline audiometric testing. Employees would then receive training on the safe use of hearing protection and understand the importance of protecting their hearing.

Q 22. Describe your experience with implementing and managing safety audits.

My experience with implementing and managing safety audits is extensive. I’ve led numerous audits across various industries, from manufacturing to construction. My approach is multi-faceted, starting with a thorough risk assessment to identify potential hazards. This involves reviewing existing safety programs, conducting walkthroughs of facilities, and interviewing employees at all levels to gain a comprehensive understanding of workplace practices.

The audit itself follows a structured methodology, utilizing checklists based on relevant OSHA standards and industry best practices. I meticulously document all findings, including observations of unsafe conditions, non-compliance issues, and near misses. This documentation forms the basis of a detailed report, which includes prioritized recommendations for corrective actions. Crucially, I also focus on the root cause analysis of any identified issues, going beyond simply identifying the problem to understand and address the underlying reasons for its occurrence. Following the audit, I work collaboratively with management to implement corrective actions, track their progress, and verify their effectiveness through follow-up inspections. For example, in a recent audit at a manufacturing plant, I identified a lack of proper lockout/tagout procedures. This led to a comprehensive retraining program and a revised safety protocol, resulting in a significant reduction in near misses.

Q 23. Explain your knowledge of OSHA’s regulations regarding hazardous chemicals.

OSHA’s regulations regarding hazardous chemicals are comprehensive and cover a wide range of aspects, from hazard communication to personal protective equipment (PPE). The cornerstone of these regulations is the Hazard Communication Standard (HCS), which mandates the development and implementation of a written hazard communication program. This program ensures that employees are informed about the hazards associated with the chemicals they handle.

Key components of the HCS include the provision of Safety Data Sheets (SDSs) – detailed documents that provide information on a chemical’s hazards, handling, storage, and emergency procedures – and the proper labeling of containers with hazard pictograms, signal words, and hazard statements. Employers must also train employees on the hazards of the chemicals they use and how to work safely with them. This training should cover topics such as proper handling techniques, emergency response procedures, and the appropriate use of PPE. Failure to comply with the HCS can lead to significant penalties, including fines and legal action. I have extensive experience in developing and implementing compliant HCS programs, ensuring that all necessary documentation is up-to-date and readily accessible to employees. I’ve successfully guided numerous organizations through OSHA inspections concerning hazardous chemicals, ensuring compliance and preventing potential violations.

Q 24. How do you handle inspections from OSHA representatives?

Handling OSHA inspections requires a proactive and organized approach. Preparation is key; this involves ensuring that all safety documentation is up-to-date and readily accessible. This includes safety programs, training records, incident reports, and maintenance logs. I also ensure that all employees are aware of their responsibilities and are prepared to answer questions truthfully and accurately. During the inspection, I maintain a professional and cooperative attitude, providing the inspectors with the necessary information promptly and efficiently.

Transparency is crucial; I openly address any identified issues and explain the steps already taken or planned to rectify them. This collaborative approach builds trust and helps to mitigate potential penalties. I’ve found that proactively identifying and addressing potential compliance issues before an inspection helps to minimize disruptions and maintain a positive working relationship with OSHA. For instance, during one inspection, I anticipated a question on our lockout/tagout procedures. Having all relevant documentation and a trained representative immediately available not only demonstrated our preparedness but also highlighted our commitment to safety.

Q 25. Describe your experience with OSHA’s requirements for ergonomics.

OSHA’s ergonomics requirements focus on preventing work-related musculoskeletal disorders (MSDs) through the design of jobs, workstations, and tools to minimize physical strain on workers. This involves evaluating work tasks to identify potential ergonomic hazards, such as repetitive movements, awkward postures, and forceful exertions. My experience with these requirements includes conducting ergonomic assessments using various methods, including observation, interviews, and physical assessments.

Based on these assessments, I develop and implement strategies for reducing ergonomic risks. This may include changes to work processes, equipment modifications, workstation adjustments, or employee training on proper lifting techniques and body mechanics. For example, in one project I redesigned a workstation to reduce the amount of repetitive reaching required by an employee, effectively reducing their risk of developing carpal tunnel syndrome. The key is to adopt a proactive approach, addressing ergonomic concerns before they develop into MSDs, thereby preventing injuries and improving employee productivity and well-being. Documenting the ergonomic assessments, resulting interventions and their effectiveness is equally important.

Q 26. How do you stay current with changes in OSHA regulations?

Staying current with changes in OSHA regulations is critical for maintaining compliance and ensuring workplace safety. My approach is multi-pronged. I regularly subscribe to OSHA’s publications and newsletters, including the OSHA website and email updates. I also participate in industry conferences and workshops to stay informed about the latest developments and best practices. Furthermore, I maintain professional memberships in safety organizations, accessing their resources and networking with other safety professionals.

Additionally, I utilize online resources and safety-related publications to remain up-to-date on relevant legal and regulatory changes. By actively pursuing this ongoing professional development, I ensure that our safety programs remain current and effective, reflecting the latest safety standards and regulations.

Q 27. What are your strategies for improving safety performance metrics?

Improving safety performance metrics requires a data-driven approach. I start by establishing clear, measurable, achievable, relevant, and time-bound (SMART) goals. This involves identifying key performance indicators (KPIs), such as the number of incidents, lost-time injuries, near misses, and employee participation in safety training. I then collect and analyze data on these KPIs to track progress and identify areas for improvement.

My strategies include implementing proactive safety measures, such as regular safety inspections, hazard assessments, and employee training. I also foster a strong safety culture by encouraging open communication, employee participation in safety initiatives, and recognizing safe work practices. The use of safety management software can greatly assist in this process. Regular review and updates to our safety programs, based on data analysis and insights, allow us to consistently improve our safety performance. For instance, a trend of near misses related to a specific task would lead to a focused intervention, perhaps adding training or modifying the task itself.

Q 28. Explain your experience with using safety management software.

I have extensive experience using safety management software to streamline safety processes and improve data management. The software I’ve used facilitates tasks such as incident reporting, corrective action tracking, training record management, and audit scheduling. These systems provide centralized repositories for all safety-related documentation, making it easy to access and manage.

Moreover, the analytical capabilities of these systems allow for the creation of reports and dashboards to track safety performance metrics and identify trends. This data-driven approach enables us to make informed decisions about resource allocation and prioritize areas requiring improvement. For example, using safety management software, I can quickly identify trends in injuries or near misses, pinpoint root causes, and create targeted training programs to address specific risks. The software also improves compliance auditing as all necessary documents and training records are readily accessible for review, minimizing the time required during an inspection.

Key Topics to Learn for OSHA Safety Regulations and Practices Interview

- OSHA Act of 1970: Understanding the foundational legislation, its purpose, and key provisions. Practical application: Explain how specific sections relate to workplace safety in a given scenario.

- Hazard Identification and Risk Assessment: Methods for identifying potential hazards (e.g., chemical, physical, biological) and assessing associated risks. Practical application: Describe a process for conducting a thorough risk assessment and implementing control measures.

- Personal Protective Equipment (PPE): Selection, use, maintenance, and limitations of various PPE. Practical application: Discuss appropriate PPE for different workplace hazards and explain the importance of proper fit and training.

- Emergency Action Plans (EAPs): Development, implementation, and regular review of EAPs for various emergencies. Practical application: Outline the key components of a comprehensive EAP and explain how to conduct effective drills.

- Lockout/Tagout (LOTO) Procedures: Understanding the principles and procedures for controlling hazardous energy sources during maintenance and repair. Practical application: Describe the steps involved in a LOTO procedure and identify potential pitfalls.

- Incident Investigation and Reporting: Methods for investigating workplace incidents, identifying root causes, and implementing corrective actions. Practical application: Detail the process of conducting a thorough incident investigation and compiling a comprehensive report.

- OSHA Recordkeeping and Reporting Requirements: Understanding the requirements for maintaining OSHA logs and reporting workplace injuries and illnesses. Practical application: Explain the process of completing OSHA 300 logs accurately and timely.

- Specific OSHA Standards (e.g., for Construction, General Industry, Maritime): Familiarity with relevant standards based on your target industry. Practical application: Explain how specific standards apply to your experience and how you ensured compliance.

Next Steps

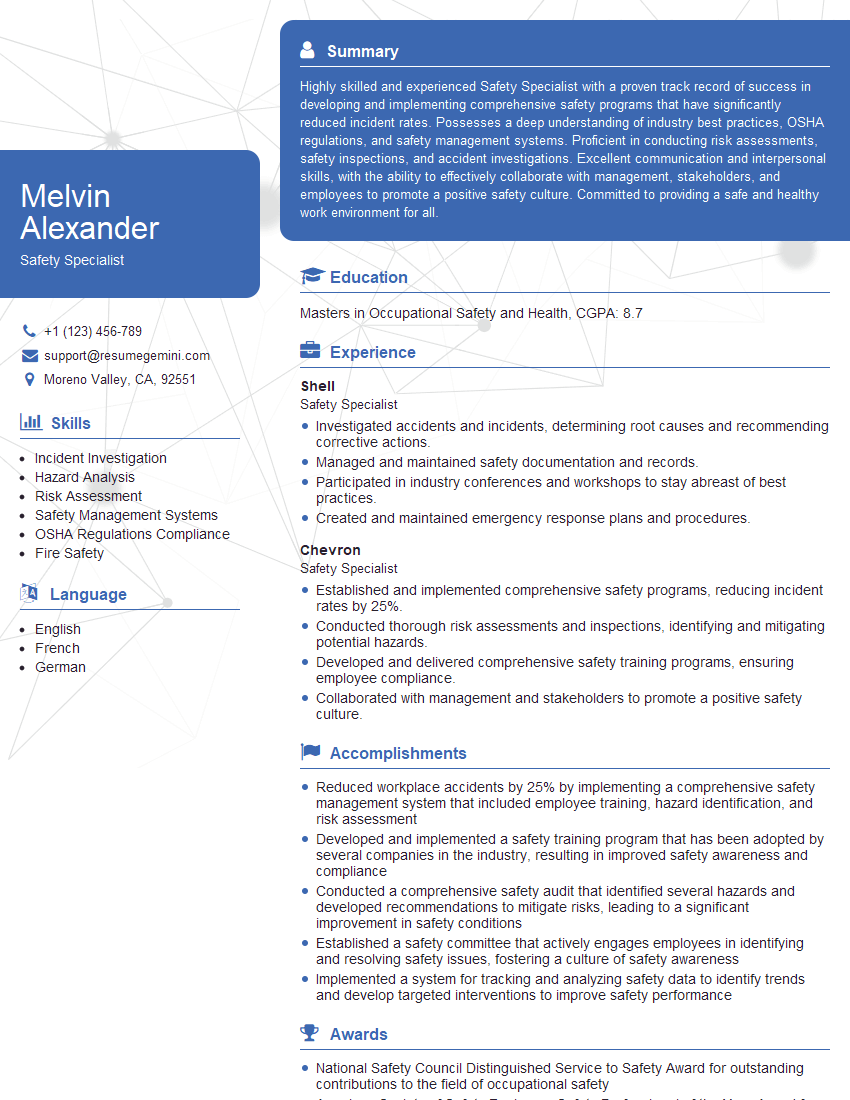

Mastering OSHA Safety Regulations and Practices is crucial for career advancement in any safety-conscious industry. Demonstrating a strong understanding of these regulations will significantly improve your interview performance and job prospects. To maximize your chances, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to OSHA Safety Regulations and Practices to guide you through the process, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?