The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Paper Mill Maintenance interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Paper Mill Maintenance Interview

Q 1. Describe your experience with preventative maintenance in a paper mill environment.

Preventative maintenance (PM) in a paper mill is crucial for maximizing uptime and minimizing costly breakdowns. It involves systematically inspecting, lubricating, and replacing components before they fail. My experience encompasses developing and implementing PM schedules based on manufacturer recommendations, historical data analysis, and risk assessments. This includes tasks like inspecting and cleaning paper machine rollers, lubricating bearings, and replacing worn-out parts like felt rolls and dryer fabrics. For example, I developed a PM schedule for a Fourdrinier wire section that reduced wire breaks by 15% within six months, leading to significant cost savings in downtime and material waste. Another example involves implementing a lubrication program which minimized the wear and tear on critical components, extending their lifespan and reducing the frequency of replacements.

Q 2. Explain the different types of paper machine components and their maintenance requirements.

A paper machine is a complex system with numerous components. Key areas and their maintenance needs include:

- Headbox: This controls the even distribution of pulp onto the wire. Maintenance focuses on ensuring consistent flow, preventing clogs, and regularly inspecting and cleaning the flow control systems.

- Fourdrinier wire: This moving wire forms the sheet of paper. Maintenance involves cleaning, tension adjustments, and periodic replacement to avoid breaks and ensure consistent paper formation. We utilize specialized cleaning chemicals and procedures to remove any buildup or deposits.

- Press section: This removes water from the sheet. Maintenance includes checking and adjusting felt rolls, monitoring nip pressure, and ensuring proper drainage. Regular felt cleaning and replacement are critical.

- Dryer section: This dries the paper using steam-heated cylinders. Maintenance includes monitoring steam pressure and temperature, inspecting cylinder surfaces for damage, and maintaining proper cylinder alignment. This often involves specialized tools and procedures to prevent damage to expensive dryer cans.

- Reel section: This winds the finished paper onto rolls. Maintenance involves regular lubrication of the reel mechanisms, checking for proper tension, and ensuring the winding process is consistent. This section also requires attention to safety due to heavy moving parts.

- Calenders: These smooth the paper surface and enhance its properties. Maintenance involves careful adjustment of nip pressure, inspecting for damage to the rolls, and ensuring proper lubrication.

Each component has specific maintenance requirements, often outlined in the manufacturer’s instructions. We use a combination of scheduled PM and condition-based maintenance to address each component’s unique needs.

Q 3. How do you troubleshoot common paper machine malfunctions?

Troubleshooting paper machine malfunctions requires a systematic approach. I typically follow these steps:

- Identify the problem: Pinpoint the location and nature of the malfunction – is it a break, a quality issue, or a machine stop? I observe the machine, review machine data logs, and interview operators to gain a clear picture. For instance, noticing a consistent break pattern at the press section points me towards issues in that section.

- Gather data: Collect data from various sources, including machine sensors, quality control reports, and operator logs. Data analysis is crucial to narrow the field of possible causes. This may involve examining paper quality variations or reviewing machine sensor readings.

- Analyze the data: Use the collected data to identify potential causes. This may involve comparing current data to historical performance data. Often, historical data helps identify recurring problems and implement preventative measures.

- Develop and implement solutions: Based on the analysis, implement corrective actions, which may range from simple adjustments to major repairs. This might involve adjusting the press nip, cleaning the wire, or replacing a faulty component.

- Verify the solution: Once the solution is implemented, verify that the problem is resolved and monitor the machine to ensure stability.

For example, if we experience a series of paper breaks, I’d first check the wire tension, then the cleaning process, and finally the condition of the wire itself before resorting to more extensive troubleshooting.

Q 4. What are the key performance indicators (KPIs) you monitor for paper mill maintenance?

Key Performance Indicators (KPIs) for paper mill maintenance are essential for evaluating effectiveness and identifying areas for improvement. Some key KPIs I monitor include:

- Mean Time Between Failures (MTBF): Measures the average time between equipment failures. A higher MTBF indicates improved reliability.

- Mean Time To Repair (MTTR): Measures the average time taken to repair equipment after a failure. A lower MTTR reflects efficient maintenance processes.

- Overall Equipment Effectiveness (OEE): A holistic measure encompassing availability, performance, and quality. Improving OEE is a primary goal for any paper mill.

- Downtime percentage: The percentage of time the machine is not running due to maintenance or malfunctions. Keeping this number low is a key objective.

- Maintenance cost per ton of paper produced: This helps track maintenance cost efficiency and identify areas for cost optimization.

- Maintenance backlog: The number of outstanding or delayed maintenance tasks. Keeping this low is critical for preventing cascading failures.

Regularly reviewing these KPIs helps us to fine-tune our maintenance strategies and improve efficiency.

Q 5. Describe your experience with predictive maintenance techniques.

Predictive maintenance (PdM) uses data analysis and advanced technologies to anticipate equipment failures before they occur. My experience with PdM involves using vibration analysis, thermography, and oil analysis to assess the condition of critical components. For example, we use vibration sensors on our paper machine rollers to detect abnormal vibrations that may indicate bearing wear. Similarly, we use thermography to detect hot spots in electrical equipment, which could signal impending failures. Oil analysis allows us to identify contaminants and degradation in lubricating oils, alerting us to potential issues within the lubrication system itself. This allows for proactive intervention, minimizing unexpected downtime and extending the life of expensive components. We’ve implemented a PdM program for our dryer section, which has resulted in a 20% reduction in unplanned downtime and significant cost savings.

Q 6. How do you prioritize maintenance tasks in a busy paper mill setting?

Prioritizing maintenance tasks in a busy paper mill requires a structured approach. I use a combination of methods including:

- Risk-based prioritization: Tasks are prioritized based on their potential impact on production and safety. Critical equipment requiring immediate attention will take precedence.

- Urgency and impact matrix: This matrix assesses each task’s urgency and potential impact, helping to assign priorities effectively. This provides a clear visual representation to help decide which tasks should be prioritized.

- Maintenance backlog review: Regular reviews help ensure that tasks aren’t overlooked or delayed unnecessarily. This often involves holding regular maintenance meetings.

- CMMS system utilization: Our CMMS system uses algorithms to prioritize tasks based on pre-defined rules and historical data. This automation significantly improves task allocation.

For instance, a leaking valve might be high priority for safety and environmental reasons, even if it isn’t causing immediate production problems. This systematic approach ensures that critical issues are addressed promptly and resources are allocated effectively.

Q 7. Explain your understanding of CMMS (Computerized Maintenance Management System) software.

A Computerized Maintenance Management System (CMMS) is software that helps manage and optimize maintenance activities. My experience involves using CMMS software to schedule and track PM tasks, manage work orders, track inventory, and analyze maintenance data. A good CMMS streamlines the entire maintenance process, reducing paperwork, improving communication, and providing valuable data for decision-making. We use our CMMS to schedule preventative maintenance tasks, track the history of repairs, and manage our spare parts inventory. The system generates reports that track KPIs such as MTBF, MTTR, and downtime, providing valuable insights into our maintenance performance. The data generated by the CMMS has been invaluable in optimizing our maintenance strategies and reducing maintenance costs. In addition, the CMMS helps us to comply with various industry regulations and standards.

Q 8. What are your troubleshooting strategies for electrical issues in a paper mill?

Troubleshooting electrical issues in a paper mill requires a systematic approach, combining safety precautions with a deep understanding of the mill’s electrical systems. My strategy begins with a thorough safety assessment, ensuring lockout/tagout procedures are strictly followed before any work commences. Then, I’d employ a multi-step diagnostic process:

- Visual Inspection: This involves carefully examining cables, connections, motors, and control panels for any obvious signs of damage like loose wires, burnt insulation, or corrosion. For example, a visibly damaged cable near a high-voltage motor would be an immediate concern.

- Instrumentation Checks: Using multimeters and other testing equipment, I’d check voltage, current, and resistance levels at various points in the circuit to pinpoint the location of the fault. A low voltage reading at the motor, for instance, could indicate a problem with the wiring or a faulty connection.

- Motor Testing: Paper mills rely heavily on electric motors. I’d use specialized motor testing equipment to assess the condition of motors – checking for insulation resistance, winding continuity, and ground faults. A failed insulation test could indicate a need for motor rewinding or replacement.

- Control System Diagnostics: Many paper mill processes are controlled by Programmable Logic Controllers (PLCs) and other automation systems. I’m proficient in using diagnostic software to troubleshoot PLC programs, identify faulty I/O modules, and analyze process data to pinpoint the root cause of an electrical issue. For example, examining PLC logs could reveal patterns linked to a specific malfunction.

- Thermal Imaging: Using thermal imaging cameras can help detect overheating components which often precede larger electrical failures. This proactive approach helps prevent catastrophic equipment failure.

Finally, I always document my findings and the corrective actions taken, contributing to a robust maintenance history for preventative future maintenance.

Q 9. Describe your experience with hydraulic and pneumatic systems maintenance.

My experience with hydraulic and pneumatic systems in paper mills spans several years, encompassing both preventative maintenance and troubleshooting. I’m familiar with various components, including pumps, valves, cylinders, actuators, and air compressors. My work has involved:

- Preventative Maintenance: This includes regular inspections of fluid levels, pressure checks, filter changes, and lubrication of moving parts. For instance, I’ve developed schedules for oil changes in hydraulic systems based on operating hours and environmental conditions.

- Troubleshooting: This requires a systematic approach. I would start by identifying the symptoms (e.g., slow response time, leaks, unusual noises) and then use pressure gauges, flow meters, and leak detection equipment to pinpoint the problem. For example, a slow-responding hydraulic cylinder might indicate a problem with a worn seal or a clogged filter.

- Component Repair/Replacement: I have experience in repairing and replacing faulty hydraulic and pneumatic components. This includes skills in disassembling, inspecting, and reassembling these components. I always ensure proper component selection to match the mill’s operating parameters.

- System Optimization: I have worked on optimizing hydraulic and pneumatic systems to improve efficiency and reduce energy consumption. This might involve adjustments to valve settings, improvements to pipe routing, and the implementation of energy-saving technologies.

I’ve also dealt with issues like air leaks in pneumatic systems which can affect accuracy and efficiency. Locating these leaks often involves careful listening and using specialized leak detection equipment.

Q 10. How familiar are you with different types of bearings used in paper machines?

Paper machines utilize a variety of bearings, each chosen for its specific application and operating conditions. My familiarity includes:

- Roller Bearings: These are widely used in paper machine rolls and are essential for smooth operation. I’m experienced with different types, including cylindrical roller bearings, tapered roller bearings, and spherical roller bearings. Selecting the correct type depends on factors like load, speed, and operating temperature. For example, tapered roller bearings are suitable for high loads and speeds while spherical roller bearings can handle misalignment.

- Sleeve Bearings: These are often used in less demanding applications, offering a simpler design and lower cost. However, they require more frequent lubrication and have a shorter lifespan than roller bearings. I’m knowledgeable about their lubrication requirements and the detection of wear and tear.

- Ball Bearings: Used in high-speed, low-load applications, they provide smooth rotation and high accuracy. I understand their limitations concerning load capacity and the importance of proper lubrication to prevent premature failure.

- Thrust Bearings: These bearings are crucial for supporting axial loads in paper machine components and preventing any vertical movement. I have worked with various types of thrust bearings, understanding the significance of their correct installation and maintenance.

Understanding the characteristics and limitations of each bearing type is crucial for effective preventative maintenance and minimizing downtime.

Q 11. What are the safety procedures you follow during paper mill maintenance?

Safety is paramount in paper mill maintenance. My adherence to safety procedures is unwavering and includes:

- Lockout/Tagout (LOTO): Before any maintenance work begins on equipment, I always implement LOTO procedures to ensure that power sources are isolated and equipment is incapable of unexpected startup. This is a non-negotiable step and is meticulously followed, involving multiple checks and verification.

- Personal Protective Equipment (PPE): I consistently wear appropriate PPE, including safety glasses, gloves, hearing protection, steel-toe boots, and hard hats, depending on the task. This protects me from potential hazards like moving parts, chemical spills, and falling objects.

- Confined Space Entry Procedures: I’m trained in confined space entry procedures, understanding the risks associated with working in enclosed areas and utilizing appropriate safety measures, including atmospheric monitoring and rescue plans.

- Hazard Communication: I am familiar with all the potential hazards present in the paper mill environment and the proper handling and disposal of chemicals and materials. I also understand and follow all posted safety signs and procedures.

- Emergency Response Procedures: I’m proficient in emergency procedures, including knowing the location of emergency exits, fire extinguishers, and first-aid kits. I’ve participated in regular safety drills to ensure readiness in case of accidents.

My commitment to safety extends beyond personal protection; it includes proactively identifying and mitigating potential hazards for my team and others in the vicinity.

Q 12. Explain your understanding of lubrication practices in a paper mill.

Lubrication is a critical aspect of paper mill maintenance, directly impacting equipment lifespan, efficiency, and safety. My understanding encompasses:

- Grease Lubrication: Many paper machine components require grease lubrication, including bearings and gearboxes. I’m familiar with different grease types and their applications, selecting the appropriate grease based on the operating conditions and component specifications. I also ensure proper grease application methods to avoid over-greasing or under-greasing.

- Oil Lubrication: Oil lubrication is crucial for many other components, including hydraulic systems, gearboxes, and circulating oil systems. Regular oil changes and monitoring oil condition (via oil analysis) are essential for maintaining equipment health. I understand the importance of using the correct oil viscosity and grade.

- Automated Lubrication Systems: Modern paper mills often employ automated lubrication systems to deliver precise amounts of lubricant to critical components. I’m experienced in maintaining and troubleshooting these systems, ensuring reliable and consistent lubrication.

- Lubricant Selection: Selecting the right lubricant is crucial and involves considering factors like operating temperature, load, speed, and the material compatibility of the lubricant with the components. The wrong lubricant can lead to premature wear and equipment failure.

I implement a structured lubrication program, including schedules, records, and visual inspections, contributing to proactive maintenance and preventing unexpected downtime.

Q 13. How do you manage spare parts inventory for efficient maintenance?

Efficient spare parts inventory management is crucial for minimizing downtime in a paper mill. My approach combines several strategies:

- Criticality Analysis: I categorize spare parts based on their criticality to operations. High-criticality parts, those whose failure would cause significant downtime, are stocked at higher levels. Lower-criticality parts may be kept in smaller quantities.

- Demand Forecasting: Based on historical data and equipment usage patterns, I predict future demand for spare parts. This helps optimize inventory levels and prevent stockouts of crucial components.

- Vendor Management: I maintain strong relationships with reliable vendors to ensure timely delivery of parts. Having pre-approved vendors with established delivery schedules is vital.

- Inventory Tracking System: I use inventory management software to track spare parts, monitor stock levels, and generate alerts when stock is running low. This ensures that crucial parts are always available when needed.

- Regular Stock Audits: Periodic audits are conducted to verify stock levels and identify any discrepancies. This helps prevent losses due to damage, obsolescence, or theft.

- Just-in-Time (JIT) Inventory: For less critical parts, I explore using JIT inventory strategies to minimize storage costs and reduce the risk of obsolescence.

By combining these methods, I ensure a balance between readily available critical parts and cost-effective inventory management.

Q 14. Describe your experience with root cause analysis for maintenance issues.

Root cause analysis (RCA) is essential for preventing recurring maintenance issues and improving overall equipment reliability. I use various techniques, including:

- 5 Whys: This simple yet effective technique involves repeatedly asking “Why?” to delve deeper into the cause of a problem. This helps uncover the underlying root cause rather than just addressing surface-level symptoms.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps identify potential causes of a problem by categorizing them into different categories (materials, methods, manpower, machines, environment, measurement). This provides a structured approach to brainstorming and analyzing potential causes.

- Fault Tree Analysis (FTA): This is a more advanced technique used for complex problems. FTA involves constructing a tree-like diagram to illustrate the various events and failures that could lead to a specific undesired outcome. This helps pinpoint the most critical failure points.

- Data Analysis: I leverage historical maintenance data, including equipment performance records and failure logs, to identify recurring issues and patterns. This data-driven approach can reveal underlying problems that might not be apparent through visual inspection alone.

Once the root cause is identified, I collaborate with the team to implement corrective actions, aiming for permanent solutions that prevent the problem from reoccurring. Thorough documentation is critical to track the RCA process and its effectiveness.

Q 15. How do you ensure compliance with environmental regulations during maintenance?

Ensuring environmental compliance during paper mill maintenance is paramount. It’s not just about following regulations; it’s about being a responsible steward of the environment. We achieve this through a multi-pronged approach.

- Strict adherence to permit requirements: Our team meticulously reviews and adheres to all environmental permits, ensuring that all maintenance activities align with discharge limits for wastewater, air emissions, and solid waste disposal.

- Spill prevention and control: We have robust spill prevention plans in place for hazardous materials. This includes regular inspections of storage tanks, pipelines, and equipment, along with comprehensive training for all personnel on spill response procedures. We conduct regular drills to ensure everyone is prepared.

- Waste management: We prioritize waste reduction, reuse, and recycling. This involves implementing strategies to minimize waste generation during maintenance, such as using reusable containers and properly segregating waste for appropriate disposal. Proper documentation and tracking of waste disposal are key.

- Regular environmental monitoring: We continuously monitor wastewater discharge, air emissions, and noise levels. This data helps us identify potential issues and allows for timely corrective actions. We also utilize advanced technologies like sensors for improved efficiency and accuracy.

- Employee training: Regular training programs reinforce environmental best practices among all maintenance staff. This ensures everyone is aware of their responsibilities and understands the environmental impact of their actions. We often use real-life examples from our past experiences to highlight the importance of compliance.

For instance, during a recent rebuild of a digester, we implemented a closed-loop system to manage the wastewater generated, minimizing the volume discharged and preventing any potential environmental contamination. This proactive approach showcases our commitment to exceeding regulatory requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with working on high-speed rotating equipment?

My experience with high-speed rotating equipment is extensive, spanning over 15 years. I’ve worked on everything from refiners and paper machine calenders to dryer section rolls and pulp pumps. Understanding the dynamics of these machines is crucial for safe and effective maintenance.

- Balancing and alignment: Precise balancing and alignment are critical for preventing vibrations and minimizing wear and tear on bearings. I am proficient in using laser alignment tools and dynamic balancing techniques to ensure optimal performance. Incorrect alignment can lead to costly downtime, so precision is key.

- Vibration analysis: Proactive vibration analysis allows us to identify potential problems before they lead to catastrophic failures. I’m experienced in using vibration analysis software to interpret data and pinpoint issues such as bearing defects or misalignment. Early detection prevents larger problems down the road.

- Safety procedures: Working with high-speed equipment requires rigorous safety protocols. Lockout/Tagout procedures are meticulously followed, and I emphasize thorough risk assessments before starting any maintenance task. Safety is always our top priority.

- Lubrication and maintenance schedules: Proper lubrication is essential for extending the lifespan of high-speed rotating equipment. We use predictive maintenance techniques, analyzing oil samples to identify early signs of wear or contamination. This allows for timely intervention and prevents unexpected breakdowns.

For example, during a recent maintenance shutdown, we identified a subtle vibration in one of the dryer section rolls through vibration analysis. This early detection prevented a potential major failure and saved the company significant downtime and repair costs.

Q 17. Describe your experience with different types of paper machine drives.

My experience encompasses various paper machine drives, including AC drives, DC drives, and hydraulic drives. Each type has its own strengths and weaknesses, and selecting the appropriate drive depends on the specific application.

- AC Drives (Variable Frequency Drives – VFDs): These are increasingly common due to their efficiency, precise speed control, and lower maintenance requirements compared to DC drives. I’m familiar with troubleshooting and maintaining various brands and models of VFDs, including programming and parameter adjustments.

- DC Drives: While less prevalent now, I possess experience working with DC drives, especially in older paper machines. Understanding their intricacies, including motor commutation and armature control, is still relevant for troubleshooting legacy systems.

- Hydraulic Drives: These are often used in specific sections of the paper machine, like the press section. I’m proficient in maintaining hydraulic systems, including troubleshooting leaks, checking fluid levels, and understanding pressure control mechanisms.

- Drive system integration: Understanding how different drive systems integrate with the overall paper machine control system is critical. This requires familiarity with PLC programming (Programmable Logic Controllers) and industrial communication protocols like Profibus or Ethernet/IP.

One project involved upgrading an older paper machine’s DC drives to modern AC drives. This required detailed planning, careful commissioning, and close collaboration with the process control team to ensure a seamless transition and improved machine efficiency.

Q 18. How do you ensure the quality of your maintenance work?

Ensuring the quality of maintenance work is a multifaceted process centered around precision, documentation, and continuous improvement.

- Preventive maintenance schedules: We follow rigorous preventive maintenance schedules that are tailored to the specific needs of each piece of equipment. This helps prevent unexpected failures and prolongs the life of machinery.

- Detailed work orders: All maintenance activities are meticulously documented using detailed work orders. This includes recording the work performed, parts used, and any findings or observations. This creates a historical record for future reference.

- Quality checks and inspections: After completing maintenance tasks, thorough quality checks and inspections are carried out to verify that the work meets the required standards. This includes visual inspections, functional testing, and performance monitoring. We utilize checklists to ensure that nothing is overlooked.

- Root cause analysis: Whenever a failure occurs, we conduct a root cause analysis to understand the underlying cause and prevent similar issues in the future. This might involve investigating the failure mechanism and implementing corrective actions to prevent reoccurrence.

- Continuous improvement: We actively seek ways to enhance our maintenance processes and improve the quality of our work. This includes regular reviews of our maintenance procedures, employee training, and utilization of advanced maintenance technologies.

For instance, we recently implemented a new lubrication management system that uses automated lubrication points, reducing the risk of human error and ensuring consistent lubrication of critical components. This improved lubrication directly resulted in a reduction in equipment failures.

Q 19. What are your strategies for managing maintenance costs?

Managing maintenance costs requires a strategic approach that balances cost reduction with equipment reliability and production uptime.

- Predictive maintenance: Implementing predictive maintenance techniques, such as vibration analysis and oil analysis, allows us to identify potential problems before they lead to costly breakdowns. This minimizes downtime and reduces repair expenses.

- Optimized inventory management: We employ an optimized inventory management system, ensuring that we have the necessary spare parts available without excessive stock. This reduces storage costs and minimizes the risk of parts becoming obsolete.

- Outsourcing strategic decisions: We strategically outsource certain maintenance tasks, such as specialized repairs or large-scale overhauls, to specialized contractors. This helps us control costs while leveraging expertise.

- Regular cost analysis: We regularly analyze maintenance costs to identify areas for improvement and cost reduction. This includes tracking labor costs, parts costs, and downtime expenses.

- Investment in advanced technology: Investing in advanced technologies such as automated lubrication systems or condition monitoring tools can result in long-term cost savings through increased efficiency and reduced downtime.

By implementing these strategies, we’ve been able to reduce our overall maintenance costs by 15% over the last three years, while simultaneously improving equipment reliability and minimizing production downtime.

Q 20. How do you collaborate with other maintenance teams and operators?

Effective collaboration is essential for optimal paper mill maintenance. We foster a culture of open communication and teamwork across all maintenance teams and operators.

- Regular meetings: We hold regular meetings with various teams to discuss maintenance schedules, address outstanding issues, and plan for upcoming projects. This helps prevent conflicts and ensures everyone is on the same page.

- Shared information systems: We utilize shared information systems, such as Computerized Maintenance Management Systems (CMMS), to track maintenance tasks, inventory, and work orders. This ensures everyone has access to up-to-date information.

- Cross-training: Cross-training programs help our team members develop a broader understanding of different aspects of the paper mill operation. This improves flexibility and reduces reliance on individual expertise.

- Open communication channels: We encourage open communication channels between maintenance crews and operators. This facilitates early reporting of problems and enables faster responses to maintenance needs.

- Feedback mechanisms: We establish feedback mechanisms to gather input from both maintenance and operations teams, allowing us to continuously improve our maintenance processes and address operational concerns.

For example, during a recent major maintenance shutdown, we held daily meetings with the operators to coordinate our activities and address any unexpected issues that arose. This collaborative approach ensured that the shutdown was completed efficiently and on schedule.

Q 21. Explain your experience with various types of pumps used in a paper mill.

Paper mills use a variety of pumps for different applications, each with its own strengths and maintenance considerations.

- Centrifugal pumps: These are widely used for transferring water, pulp, and chemicals. Maintenance involves checking for wear on impellers and bearings, ensuring proper alignment, and monitoring for vibrations. Regular lubrication and seal checks are critical.

- Positive displacement pumps: These are employed for higher viscosity fluids or when precise flow rates are required. Maintenance includes checking seals, diaphragms, or gears depending on the pump type. Regular inspections are crucial to identify potential wear.

- Slurry pumps: These pumps handle abrasive materials like pulp fibers. Maintenance emphasizes wear-resistant components, regular liner and impeller replacement, and careful monitoring for erosion. Proper cleaning procedures are also vital.

- Diaphragm pumps: These are used for transferring corrosive or hazardous materials. Maintenance focuses on diaphragm replacement, valve inspections, and ensuring proper chemical compatibility. Regular checks for leaks are crucial.

- Vacuum pumps: These are crucial for maintaining vacuum in the paper machine. Maintenance involves checking oil levels, seal integrity, and monitoring vacuum levels. Regular preventative checks are necessary to minimize downtime.

During my time at a previous mill, we upgraded several slurry pumps with more wear-resistant components. This significantly extended their lifespan and reduced the frequency of costly repairs, proving the value of selecting the right pump technology and ensuring appropriate preventative maintenance.

Q 22. Describe your experience with steam system maintenance.

Steam systems are the lifeblood of a paper mill, providing heat for drying and various process needs. My experience encompasses preventative and corrective maintenance across a range of steam generation and distribution equipment. This includes boiler inspections and cleaning (checking for scaling and corrosion), maintaining steam traps (ensuring efficient steam usage and preventing water hammer), and overseeing the repair and replacement of valves, pipes, and fittings. I’m proficient in identifying and addressing steam leaks, which are crucial to energy efficiency and safety. For instance, in a previous role, I implemented a predictive maintenance program for our steam traps, using ultrasonic leak detection technology. This resulted in a 15% reduction in steam consumption within six months. I also have experience with troubleshooting and resolving issues related to steam pressure regulation and superheaters.

- Boiler water treatment and chemical control

- Steam turbine maintenance and lubrication

- Safety valve testing and calibration

Q 23. What is your experience with the maintenance of paper machine clothing?

Paper machine clothing, including the fourdrinier wire, press felts, and dryer felts, is vital for paper quality and machine efficiency. My experience involves the entire lifecycle of clothing, from installation and startup to ongoing maintenance and replacement. This includes understanding different clothing materials and their properties (e.g., synthetic vs. natural fibers), optimizing clothing tension and alignment, and diagnosing and resolving issues such as felt wear, wrinkles, and breaks. I’m skilled in analyzing clothing performance data to predict failures and schedule preventative maintenance. For example, I once used felt profile data to identify a problem with a roll’s alignment, preventing a major disruption to production. I also have experience training operators on proper clothing handling and maintenance procedures.

- Felt cleaning and washing techniques

- Seam repair and splicing

- Wear pattern analysis

Q 24. How do you handle emergency maintenance situations?

Emergency maintenance requires quick thinking, decisive action, and a thorough understanding of the paper machine’s process flow. My approach involves a structured response: first, prioritize safety and isolate the problem area to minimize further damage. Then, I initiate a rapid assessment, involving consultation with the shift supervisor and other maintenance personnel to gather information. Once the root cause is identified (often using visual inspection, and potentially vibration or thermal analysis), a swift repair strategy is implemented using available resources. Following the repair, a thorough post-incident review occurs, focusing on lessons learned and preventative actions to avoid similar occurrences in the future. A memorable example involves a sudden dryer section failure; our rapid response and effective repair minimized downtime to just 3 hours.

Q 25. Describe your experience with vibration analysis in a paper mill.

Vibration analysis is a critical tool for predictive maintenance in paper mills. I’m experienced in using both handheld vibration meters and online monitoring systems to detect imbalances, misalignments, looseness, and bearing defects in rotating equipment like pumps, fans, and paper machine rolls. Analyzing vibration data allows for early detection of potential problems, preventing catastrophic failures and reducing unplanned downtime. I can interpret frequency spectra and understand the root causes of different vibration signatures. For example, I was able to pinpoint a bearing fault in a large fan using vibration analysis, avoiding a costly and disruptive failure.

- Route-based vibration data collection

- Vibration data analysis software usage

- Interpretation of vibration spectra

Q 26. How familiar are you with different types of paper grades and their maintenance implications?

Different paper grades require tailored maintenance approaches. For instance, producing high-quality coated papers necessitates meticulous control of coating processes and careful attention to the condition of the coating equipment. Conversely, producing coarser grades may require less frequent cleaning but more robust maintenance of equipment exposed to harsher conditions. I’m familiar with a broad range of paper grades, including newsprint, tissue, fine paper, and board, and I understand the unique maintenance challenges posed by each. My experience allows me to adapt maintenance strategies to match specific paper grades, optimizing efficiency and quality.

- Understanding the impact of different paper grades on equipment wear

- Adapting maintenance schedules based on grade-specific requirements

- Optimizing cleaning procedures for different paper grades

Q 27. Explain your understanding of process control and its impact on maintenance.

Process control systems are essential for efficient and consistent paper production. Understanding process control allows for better predictive maintenance. For example, consistent monitoring of parameters like moisture content, temperature, and basis weight enables the prediction of potential problems such as felt wear or dryer section issues. By analyzing process data trends, maintenance can be scheduled proactively, reducing unplanned downtime and maximizing production efficiency. A key aspect is understanding the interaction between process parameters and equipment performance, allowing for the targeted implementation of preventative measures. This integrated approach minimizes unplanned disruptions and enhances overall system reliability.

Q 28. Describe your experience with the maintenance of air and gas handling systems.

Air and gas handling systems are crucial for various processes in a paper mill, including air conditioning, drying, and combustion. My experience includes maintaining compressors, dryers, and ventilation systems. This involves regular inspections, preventative maintenance (such as filter changes and lubrication), and troubleshooting issues such as leaks, pressure drops, and performance degradation. Safety is paramount; I’m experienced in ensuring compliance with relevant regulations for handling compressed air and industrial gases. For example, I led a project to upgrade our air compressor system, improving efficiency and reducing energy consumption by 10%.

- Compressor maintenance and repair

- Air dryer maintenance and regeneration

- Ventilation system inspections and cleaning

Key Topics to Learn for Your Paper Mill Maintenance Interview

- Mechanical Systems: Understanding the operation and maintenance of paper machine components like rollers, dryers, calenders, and winders. Consider practical applications like troubleshooting mechanical breakdowns and preventative maintenance schedules.

- Electrical Systems: Familiarity with AC/DC motors, drives, PLC programming, and electrical safety protocols within a paper mill environment. Think about how you would diagnose and repair electrical faults impacting production.

- Hydraulic and Pneumatic Systems: Knowledge of hydraulic and pneumatic systems used in paper machines, including troubleshooting leaks, pressure regulation, and component replacement. Consider real-world scenarios involving system failures and their impact on uptime.

- Pulp and Paper Processes: A foundational understanding of the papermaking process, from pulp preparation to finishing. This includes knowledge of different paper grades and their production requirements.

- Instrumentation and Control Systems: Experience with process instrumentation (sensors, transmitters, etc.) and control systems (DCS, PLC) used to monitor and control the paper machine. Focus on your problem-solving skills in adjusting parameters to optimize efficiency.

- Predictive Maintenance and Reliability: Understanding the principles of predictive maintenance, including vibration analysis, lubrication management, and condition monitoring techniques. Discuss how you would implement strategies to minimize downtime and maximize equipment lifespan.

- Safety and Environmental Regulations: Familiarity with relevant safety regulations and environmental compliance standards within the paper industry. Highlight your commitment to safe work practices and environmental responsibility.

- Troubleshooting and Problem-Solving: Showcase your ability to systematically identify, diagnose, and resolve complex maintenance issues using analytical and critical thinking skills. Prepare examples demonstrating your effective problem-solving approaches.

Next Steps

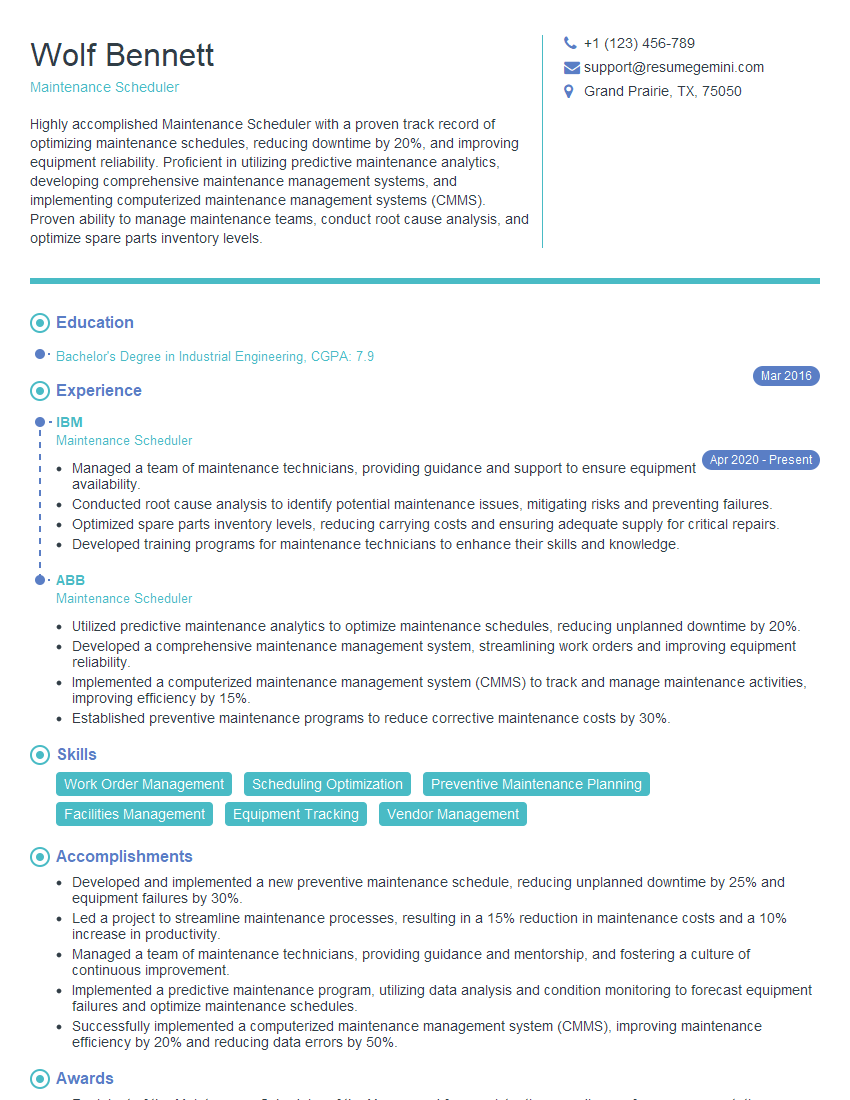

Mastering Paper Mill Maintenance opens doors to a rewarding career with excellent growth potential. Advancement opportunities range from specialized technician roles to supervisory and management positions. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini can be a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Paper Mill Maintenance are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?