Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Power Trowel Operation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Power Trowel Operation Interview

Q 1. What types of power trowels are you familiar with?

Power trowels come in various types, primarily categorized by their power source and size. I’m experienced with both ride-on and walk-behind models. Ride-on trowels are larger, more powerful machines ideal for extensive concrete slabs, offering greater efficiency and smoother finishes. They typically use a gasoline engine. Walk-behind trowels, on the other hand, are more maneuverable and suitable for smaller areas or intricate work. These can be powered by gasoline, propane, or even electric motors. Within each category, there’s variation in blade size and configuration, impacting the final surface texture. For example, a smaller walk-behind with a single blade is perfect for detailed finishing touches, while a ride-on with multiple blades is best for achieving a very smooth, polished finish on a large warehouse floor.

- Ride-on Trowels: Ideal for large areas, high power, efficient.

- Walk-behind Trowels: Manueverable, suitable for smaller areas and detailed work.

- Different Blade Configurations: Single blades for finer control, multiple blades for wider coverage and a smoother finish.

Q 2. Describe the process of preparing a concrete slab for troweling.

Preparing a concrete slab for troweling is crucial for a high-quality finish. It’s a multi-step process that begins even before the concrete is poured. First, the subgrade must be properly compacted to prevent settling. Next, the forms need to be straight, level, and securely braced to ensure the slab’s evenness. After pouring, the concrete must be consolidated to eliminate air pockets and ensure uniform density; this is usually done with a vibrating screed. Then, the initial floating process starts, using a bull float to create a smooth, level surface. This removes excess water and helps to even out the concrete. Once the bleed water has evaporated to a suitable point (the concrete is firm enough not to be easily marred), then the troweling process can begin. Any high spots or low spots will be addressed at this stage by floating again and screeding as needed.

- Proper Subgrade Compaction: Prevents settling and cracking.

- Level and Secure Forms: Ensures even slab thickness.

- Concrete Consolidation (Vibration): Eliminates air pockets.

- Initial Floating: Creates a smooth, even surface.

- Allowing Bleed Water to Evaporate: Ensure the concrete is firm before troweling.

Q 3. Explain the different troweling techniques used for achieving various surface finishes.

Different troweling techniques are employed to achieve specific surface finishes. The initial pass is usually done with a relatively high blade setting for leveling and smoothing. Subsequent passes gradually reduce the blade setting, resulting in increasingly smoother and more polished surfaces.

For example, a ‘smooth’ finish will have a lower blade setting and multiple passes, creating a almost glossy look. A ‘broomed’ finish is achieved by using a broom to create a textured surface. And a ‘exposed aggregate’ finish is achieved by washing away cement from the top layer to expose the aggregate stones. The speed and pressure also play a role. Slower speeds with more pressure are ideal for polishing and achieving a very smooth look. Quick passes with lighter pressure are better for texturing.

- Smooth Finish: Multiple passes, low blade setting.

- Broom Finish: Using a broom during the troweling process.

- Exposed Aggregate Finish: Washing away cement to expose stones.

Q 4. How do you determine the appropriate speed and blade setting for different concrete conditions?

Determining the appropriate speed and blade setting depends heavily on the concrete’s condition. Factors such as the concrete’s water content, temperature, and type of mix all influence the optimal settings. Wetter concrete requires a higher blade setting and slower speed to avoid splashing. Colder concrete requires slower speeds to prevent damage to the trowel blades. A richer concrete mix, with higher cement content, might require a more aggressive approach to achieve the desired finish. Experience and judgment play a large role; I constantly monitor the surface and adjust accordingly. Too high a speed might result in a blotchy or uneven finish, while too low a speed could cause the trowel to drag or even damage the surface. The ideal setting is one that allows for the smooth and even movement of the trowel, removing excess water and creating a level surface.

Q 5. What safety precautions do you take when operating a power trowel?

Safety is paramount. Before operating a power trowel, I always ensure I’m wearing appropriate personal protective equipment (PPE), including safety glasses, hearing protection, sturdy work boots with steel toes, and gloves. I also make sure the area is clear of obstacles and that there’s adequate lighting. The power trowel itself is inspected carefully for any signs of damage or loose parts. I never operate the machine if I’m tired or under the influence of drugs or alcohol. I also maintain a safe distance from the rotating blades, and I’m always aware of my surroundings. Finally, I never operate the machine without understanding the proper operation techniques.

- PPE: Safety glasses, hearing protection, steel-toed boots, gloves.

- Machine Inspection: Check for damage or loose parts.

- Clear Workspace: Ensure no obstacles are present.

- Safe Distance from Blades: Maintain awareness of the blades rotation.

Q 6. How do you identify and address common problems encountered during troweling, such as cracking or pitting?

Cracking and pitting are common problems that can arise during troweling. Cracking often indicates rapid drying, improper concrete mix, or insufficient curing. To address cracking, careful curing is essential; this might involve using curing compounds or covering the slab with plastic sheeting. Pitting often happens because of the presence of aggregate that has risen to the surface; this is less easy to address after the fact and points to issues with the mix design, consistency, or placement. Other issues may include uneven surfaces due to improper floating or inadequate consolidation. In such cases, the process might need to be repeated, or adjustments to the troweling technique might be necessary. Early detection of problems is key for fixing them effectively.

Q 7. Describe your experience with different types of concrete mixes and their impact on troweling.

My experience includes working with various concrete mixes, each impacting the troweling process differently. High-strength concrete mixes, for example, can be more challenging to trowel due to their increased viscosity. They often require more passes and slower speeds to achieve a smooth finish. Ready-mix concrete from different suppliers may also have slight variations in water content and consistency, impacting the troweling method. Leaner mixes might lack the consistency required for a smooth finish, while richer mixes may be harder to work with due to greater cohesion. Understanding the properties of the specific concrete mix being used is crucial for determining the optimal troweling technique and achieving the desired results. For example, I’ve had instances where a high-strength concrete required a substantial increase in passes with the trowel blades set to reduce the pressure on the freshly laid concrete.

Q 8. How do you maintain and perform routine maintenance on a power trowel?

Maintaining a power trowel involves a systematic approach focusing on both the mechanical aspects and the operator’s safety. Regular maintenance prevents costly repairs and ensures a smooth, efficient operation. Think of it like servicing your car – regular checkups prevent major breakdowns.

Daily Inspection: Before each use, inspect the blades for damage, wear, and proper alignment. Check all bolts and nuts for tightness. Make sure the engine oil level is correct and the fuel tank is adequately filled. A quick visual check can prevent significant issues.

Blade Cleaning: After each use, thoroughly clean the blades with a wire brush to remove any hardened concrete or debris. This prevents build-up and ensures the blades’ sharpness for subsequent jobs. Imagine it’s like cleaning your kitchen knives after a big meal – essential for continued performance.

Lubrication: Regularly lubricate moving parts according to the manufacturer’s instructions. This minimizes friction and extends the lifespan of the machine. It’s akin to lubricating your bike chain – keeps everything moving smoothly.

Engine Maintenance: Follow the manufacturer’s schedule for engine oil changes, air filter replacements, and spark plug checks (for gasoline-powered models). Neglecting this is like neglecting your car’s engine – disaster waiting to happen!

Storage: Store the power trowel in a dry, secure location to prevent corrosion and damage. Cover it to protect it from dust and the elements.

Q 9. What is the proper way to shut down and secure a power trowel after use?

Proper shutdown and securing of a power trowel is critical for safety and machine longevity. It’s a multi-step process that should become second nature to any operator.

Bring the Trowel to a Complete Stop: Allow the machine to slow down naturally; don’t abruptly shut it off. This prevents damage to the engine.

Turn Off the Engine: Turn the ignition off completely.

Disengage Blades (if applicable): Some trowels have a mechanism to disengage the blades, making them safe to handle. Utilize this feature if available.

Clean the Trowel: Remove any excess concrete or debris from the blades and machine body. A clean machine is a safe machine.

Secure the Trowel: Store the trowel in a safe and secure location, ideally covered to protect it from the elements.

Q 10. Explain your experience with different types of concrete curing methods.

Concrete curing is essential for achieving the desired strength and durability. I have extensive experience with several methods, each suited to different project needs and environmental factors.

Water Curing: This is the most common method, involving keeping the concrete surface consistently moist for a specified period. This can be achieved using ponding (creating a shallow pool of water), spraying, or covering with wet burlap. I’ve successfully used water curing on numerous large-scale projects, ensuring consistent hydration and preventing premature drying.

Membrane Curing: This involves applying a liquid membrane to the concrete surface, creating a vapor barrier that retains moisture. Membrane curing is especially beneficial in hot and windy conditions where water evaporation is a concern. I’ve found this method particularly effective in maintaining consistent moisture levels during summer months.

Curing Compounds: These are topical chemical treatments applied to the concrete surface to reduce moisture loss. Different compounds offer varying degrees of protection and are suitable for a range of weather conditions. Selecting the appropriate curing compound depends on the project’s demands; I have experience tailoring my selection based on factors like temperature, humidity, and project timeline.

Q 11. How do you ensure the flatness and levelness of a finished concrete surface?

Achieving a flat and level concrete surface requires skill and precision. It’s a combination of proper preparation, skillful troweling techniques, and using appropriate tools.

Proper Subgrade Preparation: A level and compacted sub-base is fundamental. Any imperfections in the subgrade will show up in the finished surface. This involves careful grading and compaction before concrete placement.

Skilled Troweling: The operator’s skill is paramount. Starting with a bull float to level the surface, followed by careful use of the power trowel to achieve a smooth finish, requires experience and attention to detail. Varying the speed and angle of the power trowel blade is key to achieving a consistent surface.

Using a Laser Screed: For large-scale projects, employing a laser screed can significantly improve flatness and levelness. A laser screed provides precise grading and leveling during concrete placement, giving the operator a better starting point for finishing. It streamlines the process and significantly improves accuracy.

Checking with a Level: Regular checks throughout the process using a level ensure consistent progress and allow for adjustments as needed.

Q 12. What are the signs of a poorly finished concrete surface?

Several signs indicate a poorly finished concrete surface. Recognizing these flaws is crucial for ensuring quality control and client satisfaction.

Uneven Surface: Obvious dips, bumps, or high and low spots demonstrate poor leveling or troweling technique.

Cracking: Cracks can indicate issues with the concrete mix, improper curing, or insufficient compaction of the subgrade.

Dusting: A powdery surface suggests poor consolidation or inadequate curing, leading to a weak surface that will wear down quickly.

Scaling/Spalling: These are signs of a poorly finished surface prone to premature deterioration and damage.

Poor Finish: Roughness, pitting, or an overall lack of smoothness points to errors in troweling technique or insufficient attention to detail.

Q 13. Describe your experience working with different types of concrete additives and their impact on the finishing process.

Concrete additives significantly impact the finishing process, altering properties like workability, strength, and durability. Understanding their effects is crucial for achieving the desired outcome.

Superplasticizers: These increase the workability of the concrete mix, allowing for easier placement and finishing. They’re beneficial in achieving a smooth, even surface, especially in challenging conditions. I’ve used superplasticizers on several projects to improve flow and reduce segregation.

Air-Entraining Agents: These incorporate air bubbles into the mix, improving the concrete’s resistance to freeze-thaw cycles. This is particularly important in colder climates. In projects with anticipated freeze-thaw exposures, I consistently specify air-entraining agents.

Accelerators/Retarders: These additives control the setting time of the concrete, adjusting it to suit weather conditions or project schedules. I adjust the dosage based on the temperature, ensuring proper setting times.

Selecting and properly using these additives requires experience and understanding of their interaction with the mix design and environmental conditions. Misuse can lead to significant problems.

Q 14. How do you handle challenging weather conditions during troweling?

Weather conditions can significantly impact the concrete finishing process. Adapting techniques and adjusting materials is crucial for success.

Extreme Heat: In hot conditions, concrete dries quickly, leading to cracking and reduced workability. I’ve addressed this by using retarders to slow down the setting time, ensuring enough time for proper finishing, and frequently applying water to prevent premature drying.

Cold Weather: In freezing conditions, concrete can freeze before it sets properly, reducing its strength and leading to cracking. I’ve countered this by using accelerators to speed up the setting process, and ensuring proper insulation and protection once the concrete is placed, sometimes using heated enclosures.

Wind: Strong winds can accelerate evaporation, leading to rapid drying and cracking. I’ve dealt with this by using windbreaks, applying curing compounds promptly, and adjusting the pace of work to keep up with drying.

Rain: Rain can wash away the surface finish and dilute the concrete mix. Protecting the concrete with tarps is the immediate solution; I’ve found this approach necessary on many occasions to prevent significant damage.

Q 15. How do you manage your workload and prioritize tasks in a fast-paced construction environment?

In the fast-paced world of construction, effective workload management is crucial. I prioritize tasks using a combination of techniques. First, I always begin by reviewing the project blueprints and specifications thoroughly to understand the scope of work and identify potential challenges. Then, I break down the overall job into smaller, manageable tasks. I utilize a daily checklist, noting the concrete area to be troweled, the type of finish required, and estimated time for completion. I always account for potential delays, like unexpected material shortages or weather interruptions. This proactive approach ensures that I can effectively manage my time and resources, even amidst unforeseen circumstances. For example, if I’m working on a large project with multiple phases, I might focus on completing the foundational concrete pours first, ensuring a solid base before moving on to more complex surface finishes. This staged approach not only optimizes efficiency but also minimizes potential rework.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key differences between riding and walk-behind power trowels?

The main difference between riding and walk-behind power trowels lies in their size, power, and intended use. Walk-behind trowels are smaller, more maneuverable, and ideal for smaller projects or areas with limited access. They are easier to learn, requiring less training and experience. Riding trowels, on the other hand, are significantly larger and more powerful, designed for large-scale projects and covering extensive areas rapidly. They require more operator skill and experience due to their size and speed. Think of it like this: a walk-behind trowel is like a powerful lawnmower – perfect for a small yard; a riding trowel is like a large agricultural tractor – necessary for vast fields. The choice depends entirely on the scale and requirements of the job. For instance, finishing the floor of a small garage would call for a walk-behind trowel, while a large warehouse floor would necessitate a riding trowel.

Q 17. How do you calculate the appropriate amount of concrete needed for a given job?

Calculating the concrete quantity for a job requires accurate measurements and a good understanding of concrete’s properties. The process begins with precisely determining the area to be poured – length multiplied by width, considering the thickness of the concrete slab (usually specified in the project plans). Once the volume (length x width x thickness) is known, it needs to be converted into cubic yards (or cubic meters, depending on the region). A cubic yard is approximately 27 cubic feet. This volume is then multiplied by a factor to account for waste and overage, typically ranging from 5% to 10%, depending on the complexity of the pour and desired level of precision. For example, a 10ft x 20ft area with a 4-inch thick slab (1/3 of a foot) would require (10 x 20 x 1/3) = 66.67 cubic feet, approximately 2.47 cubic yards. Adding a 10% overage would yield a concrete order of around 2.72 cubic yards.

Q 18. Explain your knowledge of relevant safety regulations and standards related to concrete finishing.

Safety is paramount in concrete finishing. My knowledge encompasses OSHA (Occupational Safety and Health Administration) regulations and industry best practices. This includes proper use of Personal Protective Equipment (PPE), such as safety glasses, gloves, steel-toed boots, and hearing protection. I am well-versed in the safe operation of power trowels, understanding the importance of regular maintenance checks, preventing falls, and being aware of potential hazards like electrical shock and tripping hazards from cords and uneven surfaces. I’m also familiar with procedures for handling concrete spills and ensuring a clean and organized worksite. Regular training and adherence to safety protocols are critical to preventing accidents. For example, I always ensure the power trowel’s blades are sharp and correctly aligned to prevent vibrations and ensure a smooth finish, reducing the risk of equipment malfunction and injury.

Q 19. How do you work effectively as part of a team in a construction environment?

Effective teamwork is essential in construction. On a concrete finishing crew, communication and coordination are key. I always participate actively in pre-job briefings, ensuring I understand my role and the overall workflow. I maintain open communication with fellow workers, relaying information efficiently, whether it’s signaling changes in concrete consistency or alerting others to potential hazards. I’m always willing to assist others where needed, contributing to a collaborative and productive environment. For instance, if my teammate is struggling with a particularly difficult section, I’ll offer assistance or guidance. A successful team dynamic hinges on mutual respect, clear communication, and a shared commitment to quality workmanship.

Q 20. Describe your problem-solving skills in relation to unexpected issues during troweling.

Problem-solving is a daily occurrence in concrete finishing. Unexpected issues, like inconsistent concrete mix, surface imperfections, or equipment malfunctions, require immediate attention. My approach is systematic. First, I identify the root cause of the problem – is it the concrete’s consistency, the trowel’s settings, or an external factor? Then, I assess the impact on the overall project. A minor imperfection might just need some localized attention; a significant issue may require adjusting the mix or using alternative techniques. For instance, if I encounter excessive bleeding (water separation) in the concrete, I might adjust the troweling technique, wait for the surface to firm up slightly, and then proceed cautiously. I always prioritize finding solutions that ensure quality and safety while maintaining efficiency.

Q 21. What is your experience with using laser screeds or other leveling tools?

I have considerable experience working with laser screeds and other leveling tools. Laser screeds provide unparalleled precision in achieving a perfectly level concrete surface, especially in large-scale projects. They significantly reduce labor and improve consistency compared to manual leveling. My proficiency includes setting up and operating the laser screed, understanding its parameters, and adjusting its settings based on the desired slab thickness and surface finish. I’m also familiar with troubleshooting common issues, such as calibration problems or alignment discrepancies. Integrating laser screeds into the workflow often results in a more efficient and precise concrete placement process, leading to a superior finished product with reduced labor costs and less material waste. Using these technologies isn’t just about efficiency, it’s about producing a higher-quality end product.

Q 22. How do you ensure the consistency of the finished surface across a large area?

Achieving a consistent finished surface across a large area with a power trowel requires meticulous planning and execution. It’s not just about the troweling technique itself, but about managing all aspects of the concrete pour and finishing process.

- Consistent Concrete Mix: The first step is ensuring the concrete mix itself is uniform in terms of water-cement ratio, aggregate size, and slump. Inconsistent mix design will directly translate to variations in the surface finish. I always verify the mix design with the batch plant before the pour begins.

- Proper Placement and Consolidation: The concrete needs to be placed evenly and consolidated thoroughly to remove air pockets. This prevents surface imperfections later on. Vibrating the concrete properly helps to achieve this.

- Staging and Overlapping Passes: When power troweling, I work in stages, overlapping each pass by approximately one-third to avoid leaving any untreated areas. This systematic approach ensures a smooth transition between sections.

- Maintaining Blade Height and Speed: The power trowel’s blade height and speed need to be consistent throughout. Varying these will result in uneven surface texture. Experience helps develop a feel for the optimal settings for different concrete conditions.

- Environmental Factors: Temperature, humidity, and wind all impact the setting time of concrete and can affect the final finish. I closely monitor these conditions and adjust the troweling schedule and technique accordingly. For example, I might avoid troweling in direct sunlight on a hot day to prevent rapid drying and cracking.

For example, on a recent large warehouse floor, we meticulously measured and controlled the concrete mix, ensuring a consistent slump across the entire area. By staging the work and meticulously overlapping passes, we achieved a uniform finish, meeting the client’s high standards for flatness and smoothness.

Q 23. Describe your experience with different types of concrete sealers and their applications.

My experience with concrete sealers is extensive, encompassing a wide range of products tailored to various applications and substrates. I’m familiar with both penetrating and film-forming sealers, each offering unique advantages.

- Penetrating Sealers: These sealers soak into the concrete, enhancing its durability and resistance to staining. They are ideal for porous concrete, allowing moisture vapor to escape while preventing liquid penetration. I often specify these for exterior applications to protect against weathering.

- Film-Forming Sealers: These sealers create a protective layer on the concrete’s surface, offering enhanced protection against abrasion and chemicals. They can be found in gloss, satin, and matte finishes, allowing for aesthetic customization. These are suitable for high-traffic areas like industrial floors or parking garages.

- Specific Examples: I’ve worked with various acrylic, epoxy, and polyurethane sealers, each having specific pros and cons depending on the project’s demands. For instance, epoxy sealers are excellent for chemical resistance, while acrylic sealers offer better breathability.

Selecting the right sealer depends critically on factors such as the type of concrete, intended use, and aesthetic preferences. I always conduct thorough research and assess the project requirements before recommending a particular sealer.

Q 24. How do you handle difficult or uncooperative team members?

Handling difficult team members requires a proactive and diplomatic approach. Open communication is key. I believe in addressing issues directly but respectfully, focusing on behaviors rather than making personal attacks.

- Understanding the Root Cause: Before confronting the issue, I try to understand the underlying reasons for the uncooperative behavior. Is it a skill gap? A communication problem? Or personal issues?

- Open Dialogue: I initiate a private conversation with the individual, expressing my concerns clearly and calmly. I use “I” statements to avoid accusatory language.

- Collaborative Problem-Solving: I work with the individual to find solutions that are mutually acceptable. This fosters a sense of ownership and responsibility.

- Seeking Support When Necessary: If the situation persists despite my efforts, I don’t hesitate to seek guidance from supervisors or project managers. Sometimes a third party can mediate more effectively.

In one instance, a team member was consistently behind schedule. By talking to him, we discovered he lacked proper training on a specific piece of equipment. Providing additional training resolved the issue, and he became a valuable contributor to the team.

Q 25. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and in line with the industry standards for a power trowel operator with my level of expertise. I’m open to discussing a competitive compensation package that reflects my value to the company. I’m more interested in a fair and appropriate salary relative to the job requirements and my contributions, than focusing on a fixed number.

Q 26. What are your career goals?

My career goals involve becoming a highly skilled and respected concrete finishing specialist. I’m eager to continually improve my expertise, including potentially pursuing certifications in concrete finishing techniques and project management. My long-term ambition is to lead a team and take on more responsibility in overseeing projects.

Q 27. Why are you interested in this position?

I’m interested in this position because it offers a fantastic opportunity to utilize my power troweling skills within a company that values quality and efficiency. The description of the role aligns perfectly with my experience and aspirations. I’m particularly drawn to [Mention something specific about the company or role that appeals to you].

Q 28. What are your strengths and weaknesses?

One of my greatest strengths is my meticulous attention to detail. I take immense pride in creating high-quality, consistent finishes. I’m also a quick learner and readily adapt to new techniques and challenges. A weakness I’m actively working on is delegating tasks more effectively. While I’m capable of handling many aspects of a project myself, I recognize that efficient delegation improves overall productivity and teamwork.

Key Topics to Learn for Power Trowel Operation Interview

- Machine Operation & Safety: Understanding the various controls, safety mechanisms, and proper startup/shutdown procedures of different power trowel models. This includes pre-operational checks and maintenance routines.

- Blade Selection & Adjustment: Knowing how to choose the appropriate blades for different concrete finishes (e.g., smooth, textured), adjusting blade height and pitch for optimal results, and understanding the impact of blade wear.

- Concrete Properties & Finishing Techniques: Understanding the properties of different concrete mixes and their impact on troweling, mastering various troweling techniques (e.g., floating, troweling, edging), and recognizing signs of improper mix or curing.

- Troubleshooting & Maintenance: Identifying common problems like blade vibration, uneven finishing, or engine issues. Knowing basic preventative maintenance procedures and when to seek professional help.

- Reading Plans & Specifications: Interpreting blueprints and specifications to understand the required concrete finish and plan the troweling process accordingly.

- Working Safely with a Team: Understanding and practicing safe working procedures on a construction site, including communication with other workers and adhering to site safety regulations.

- Understanding Environmental Considerations: Awareness of dust control measures and environmental regulations related to concrete finishing.

Next Steps

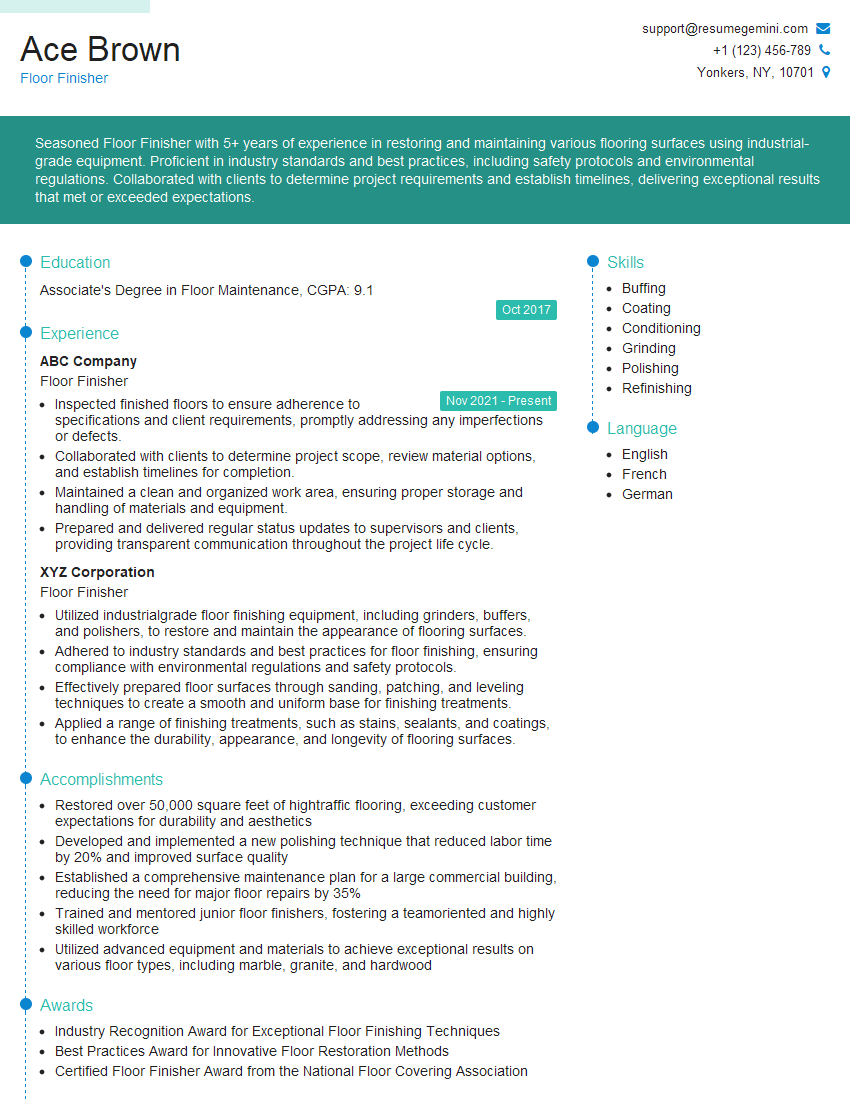

Mastering power trowel operation opens doors to a rewarding career in construction, offering opportunities for advancement and higher earning potential. A strong resume is crucial for showcasing your skills and experience to potential employers. To increase your chances of getting noticed by Applicant Tracking Systems (ATS), focus on creating a clear, concise, and keyword-rich resume. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to the construction industry. Examples of resumes specifically designed for Power Trowel Operators are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?