Cracking a skill-specific interview, like one for Residential Flooring Installation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Residential Flooring Installation Interview

Q 1. What types of flooring materials are you experienced with installing?

My experience encompasses a wide range of residential flooring materials. I’m proficient in installing hardwood flooring (solid and engineered), various types of tile (ceramic, porcelain, natural stone), laminate flooring, luxury vinyl plank (LVP), and vinyl sheet goods. Each material presents unique challenges and requires specialized techniques, and I’ve honed my skills to handle them all effectively. For example, installing engineered hardwood requires a different approach than solid hardwood, considering expansion and contraction rates. Similarly, working with natural stone tiles demands a meticulous approach due to their fragility and variations in size and texture.

Q 2. Describe your experience with subfloor preparation.

Subfloor preparation is the most critical aspect of any flooring installation. A poorly prepared subfloor will inevitably lead to problems down the line, no matter how skilled the installer is. My process begins with a thorough inspection. I check for levelness, moisture content, squeaks, and any damage like cracks or loose boards. For hardwood, I meticulously address any unevenness using self-leveling compound or shims. Moisture is particularly crucial; I use a moisture meter to ensure the subfloor is within acceptable limits for the chosen flooring material, preventing issues like buckling or warping. If necessary, I may recommend and install a moisture barrier. Addressing squeaks involves identifying the source (loose nails, gaps, etc.) and using appropriate methods to fix them, often involving adhesive or additional fasteners. Any damaged areas are repaired before proceeding.

Q 3. What tools and equipment are essential for residential flooring installation?

The tools and equipment vary slightly depending on the flooring type but some essentials include: a measuring tape, chalk line, level (multiple sizes), hand saw, circular saw (with appropriate blades), utility knife, rubber mallet, knee pads, safety glasses, and work gloves. For hardwood, I often use a flooring nailer or stapler, and for tile, a wet saw, grout float, and spacers are crucial. I also use specialized tools for underlayment installation and moisture mitigation, such as moisture meters and vapor barriers. Properly maintaining and using these tools is key for efficient and safe work.

Q 4. How do you measure and calculate the amount of flooring material needed for a job?

Accurate measurement is paramount to avoid material shortages or excessive waste. I start by carefully measuring the length and width of each room to be floored. I then subtract the area of any permanent fixtures like toilets or built-in cabinets. It’s crucial to account for waste, typically adding 5-10% extra for cuts and imperfections, particularly with hardwood. For example, if a room measures 10ft x 12ft, that’s 120 sq ft. Adding 10% waste gives us 132 sq ft. For patterned tiles, I might need even more additional material to accommodate pattern matching. I always double-check my calculations and clearly communicate these measurements to the client.

Q 5. Explain your process for installing hardwood flooring.

Hardwood installation involves several steps: First, acclimating the wood to the room’s temperature and humidity is vital to prevent expansion and contraction issues. Then, I begin laying the flooring, usually starting from the most prominent wall, ensuring proper spacing between boards. I use a flooring nailer to secure the planks to the subfloor, following the manufacturer’s instructions regarding nail placement and spacing. For engineered wood, I might use a combination of nailing and adhesive. I carefully check for levelness throughout the installation process and make any necessary adjustments. Once the main area is laid, I carefully cut and install the border pieces, ensuring a clean and professional finish. Finally, I perform a thorough inspection to ensure all planks are securely fastened and the floor is level and free of gaps.

Q 6. How do you handle uneven subfloors?

Uneven subfloors are a significant challenge, but manageable. Minor unevenness can often be addressed with self-leveling compound, which creates a smooth, level surface. For more severe unevenness, I might use shims to level individual areas before installing the flooring. The type of flooring also influences the solution: hardwood is more sensitive to unevenness than tile. If the unevenness is too extreme, I may recommend subfloor repair or replacement before starting the installation, because ignoring this will lead to problems like floor squeaking, buckling, and premature wear of the installed flooring.

Q 7. What are the different methods for installing tile?

There are two main methods: thin-set and thick-set. Thin-set mortar is used for most tile installations and involves applying a thin layer of mortar to the subfloor before setting the tiles. This method is suitable for most ceramic and porcelain tiles. Thick-set mortar is used for larger format tiles or when a thicker bed is needed to level the subfloor. The choice between methods depends on the type and size of the tile, the subfloor condition, and the project requirements. In either case, I always ensure proper spacing between tiles using spacers to ensure even grout lines and prevent cracking. Once set, I apply grout, carefully cleaning excess grout to maintain a clean finish.

Q 8. Describe your experience with carpet installation, including stretching and seaming.

Carpet installation is a multifaceted process, and my experience encompasses all aspects, from initial measurement and preparation to final finishing. Stretching and seaming are crucial elements ensuring a smooth, wrinkle-free finish. Stretching involves using a power stretcher to firmly attach the carpet to the tack strip around the perimeter of the room. This eliminates wrinkles and ensures a snug fit. Seaming, on the other hand, involves joining two or more carpet pieces seamlessly. This requires precision cutting and the use of seam sealer to prevent unraveling and create a virtually invisible join. I’ve worked with various carpet types, from plush to Berber, and have consistently delivered high-quality installations that meet and exceed client expectations. For instance, I recently installed a custom-patterned carpet in a large living room, requiring careful planning and precise seaming to align the design flawlessly. The client was thrilled with the result, and that’s what truly matters.

Q 9. How do you ensure proper acclimation of flooring materials before installation?

Acclimation is absolutely critical for preventing problems after installation. Think of it like letting a new houseplant adjust to its environment before watering it; flooring materials, particularly hardwood and engineered wood, react to changes in humidity and temperature. Proper acclimation means allowing the materials to sit in the room where they will be installed for at least 48-72 hours, ideally longer, in their original packaging to adjust to the ambient conditions. This prevents shrinking, expanding, or warping after installation. Failure to acclimate properly can lead to significant issues, such as gaps appearing between planks or tiles, cupping, or even buckling. I always emphasize acclimation to clients to avoid costly future repairs.

Q 10. What safety precautions do you take during flooring installation?

Safety is paramount in flooring installation. This involves several key precautions: Always wearing appropriate safety gear, including safety glasses, gloves, and dust masks to protect against airborne particles and potential injuries. Proper use of tools is essential, ensuring that blades are sharp to prevent slipping or extra force which could lead to accidents. Using knee pads and back supports helps prevent strain and fatigue, especially during prolonged work. Maintaining a clean and organized workspace, preventing tripping hazards by removing obstructions, and using caution with electrical equipment are also key aspects of safe work practices. I’ve implemented a strict safety protocol over my years and my work history is free from serious safety incidents. I insist on and model these safety practices with every team member.

Q 11. Explain your experience with moisture mitigation in flooring installation.

Moisture mitigation is crucial, especially when installing wood flooring. Excess moisture in the subfloor can lead to mold, mildew, and damage to the flooring material. Before installation, I always check for moisture levels using a moisture meter. This ensures that the subfloor is sufficiently dry and within acceptable limits for the specific flooring material being installed. If elevated moisture is detected, I will recommend and implement remediation strategies, like utilizing a vapor barrier or addressing any underlying plumbing leaks. Ignoring this step can lead to expensive and frustrating issues down the line. A recent job involved discovering a hidden leak under the existing flooring; timely detection saved the client from extensive water damage and a costly rebuild.

Q 12. Describe your process for installing transition strips and moldings.

Transition strips and moldings are essential for creating a seamless and aesthetically pleasing transition between different flooring types or at doorways. My process starts with precise measurements to ensure a perfect fit. I then use appropriate tools, such as a miter saw, to accurately cut the transition strips and moldings to the required angles. The strips are carefully installed using adhesives or nails, depending on the material and the type of flooring. Proper alignment and finishing touches are crucial to ensure a smooth and professional-looking transition. I pay close attention to detail; a neatly finished transition strip can make all the difference in the final aesthetic appeal of the flooring installation.

Q 13. How do you troubleshoot common problems during installation (e.g., squeaking floors, gaps between tiles)?

Troubleshooting is a significant part of my job. Squeaking floors, for example, can be addressed by identifying the source of the noise (loose subfloor, poorly secured flooring planks, or insufficient underlayment). I’ll typically use screws or adhesive to secure the affected areas and eliminate the squeak. Gaps between tiles can result from improper installation or expansion and contraction of the material. These can often be rectified using grout or caulk to fill the gaps, sometimes requiring the removal and reinstallation of affected tiles. I approach each problem systematically, carefully analyzing the cause before implementing a solution. A methodical approach helps me resolve issues effectively and efficiently.

Q 14. What is your experience with different types of underlayment?

My experience encompasses a range of underlayments, each with specific properties. For example, foam underlayment offers cushioning and sound insulation, while rubber underlayment provides moisture protection. I select the appropriate underlayment based on the type of flooring, the subfloor condition, and the client’s needs. I’ve worked with various materials, from standard foam to high-density rubber and cork underlayment. The choice of underlayment significantly impacts the comfort, durability, and longevity of the flooring installation. I always explain the pros and cons of each type to ensure the client makes an informed decision.

Q 15. Describe your experience with installing vinyl flooring (sheets, planks, tiles).

My experience with vinyl flooring installation encompasses all three formats: sheet, plank, and tile. Sheet vinyl is a classic approach, requiring precise measurements and careful seaming to avoid visible gaps. I’ve worked on numerous projects involving large-scale sheet installations, mastering techniques for achieving seamless transitions and minimizing visible seams. Plank vinyl, with its click-lock or glue-down systems, offers a different set of challenges, focusing on precise alignment and consistent spacing for a visually appealing result. I’m adept at managing the complexities of different plank styles, achieving accurate cuts around obstacles like doorways and pipes. Finally, vinyl tiles offer a more intricate installation, often requiring greater precision in cutting and placement to achieve even grout lines and a clean finish. I have experience with both self-adhesive and traditional adhesive-based vinyl tiles, understanding the nuances of each method.

For example, on one recent project, we used luxury vinyl plank to renovate a high-traffic kitchen. The client wanted a realistic wood-look and opted for a click-lock system. Achieving a perfect alignment across the planks required careful planning, the right tools, and a methodical approach to ensure the final floor was flawless and structurally sound. On another project, I had to repair water damage under a vinyl sheet which involved careful removal and replacement in a way to ensure the flooring integrity was restored perfectly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage your time and resources efficiently on a flooring project?

Efficient time and resource management is paramount in flooring projects. My approach starts with meticulous planning. This involves a detailed site survey to accurately assess the scope of work, identify potential challenges, and create a realistic timeline. I then develop a detailed project schedule, breaking down the process into manageable tasks and assigning specific timeframes. This schedule includes buffer times to account for unforeseen delays, which is very important.

Resource management is equally crucial. I ensure that all necessary materials are ordered well in advance to avoid delays. I also take into consideration the specific needs of each project: the types of tools and equipment, adhesive, underlayment etc., minimizing waste and maximizing the efficient utilization of resources. For example, if I’m installing multiple rooms, the flooring must be brought in and stored so as to not have to carry and manage it in smaller increments.

I utilize technology, such as project management software, to track progress, manage inventory, and communicate effectively with clients and subcontractors. This approach ensures that projects are completed on time and within budget.

Q 17. How do you communicate effectively with homeowners and other contractors?

Effective communication is the cornerstone of a successful flooring project. I maintain open and transparent communication with homeowners from the initial consultation to the final walkthrough. I explain the process clearly, address their questions thoroughly, and provide realistic expectations about timelines and potential challenges. I use a combination of verbal communication, written documentation (including contracts and progress reports), and visual aids (such as samples and design layouts) to ensure clarity and understanding.

When working with other contractors (e.g., electricians or plumbers), I emphasize clear coordination. This involves scheduling meetings to discuss project specifics, establishing clear communication channels, and maintaining a cooperative and respectful work environment. Any conflicts are addressed promptly and professionally to ensure smooth collaboration and avoid project delays.

For example, I once had to coordinate closely with a plumber on a project. There was a potential conflict with the flooring installation and their work, but by scheduling a joint site visit and openly discussing the issue we were able to avoid problems. Clear communication avoided costly mistakes, and led to a successfully completed project.

Q 18. What is your experience with repairing damaged flooring?

Repairing damaged flooring requires careful assessment and a methodical approach. The first step is to identify the cause of the damage (e.g., water damage, impact damage, or wear and tear). Then the damaged area must be evaluated to see if it’s repairable or if a complete replacement is required. Minor damage like scratches or small dents in vinyl flooring can often be repaired using fillers, patching compounds, or specialized repair kits, matched to the flooring color. Larger damaged sections may require more extensive repairs, often involving cutting out the damaged section and carefully replacing it with a matching piece. In the case of sheet vinyl, this involves careful seaming to blend the repair into the surrounding flooring.

I’ve successfully repaired damaged flooring in a variety of situations, from small scratches to significant water damage. For instance, on one project, a homeowner had spilled a significant amount of water on their vinyl flooring, causing a bubble to form. I carefully removed the affected area and used a suitable adhesive to relay the vinyl, eliminating the bubble and restoring the floor’s integrity.

Q 19. How do you maintain quality control throughout the installation process?

Maintaining quality control is an ongoing process throughout the installation. It begins with selecting high-quality materials from reputable suppliers and verifying that the materials meet the project specifications. Throughout the installation process, I pay close attention to detail, ensuring proper substrate preparation, accurate measurements, and meticulous installation techniques. Regular inspections are conducted at various stages—for example, before the adhesive application, after laying sections of flooring, and before final grouting or sealing. This multi-step approach allows for the identification of any issues or defects at an early stage, facilitating timely corrections and preventing major problems.

For instance, before laying vinyl planks, I meticulously check for any inconsistencies in the subfloor, ensuring it is level and free from debris. This prevents problems like uneven flooring surfaces or loose planks. A checklist is used to ensure every stage of the project complies to high quality standards.

Q 20. Describe your experience with different adhesive types.

My experience with different adhesive types is extensive. I’m familiar with various adhesives suitable for different flooring materials and subfloors. For example, I use moisture-cured urethane (MCU) adhesives for their strong bond and excellent durability, especially in high-moisture environments. Pressure-sensitive adhesives (PSA) are used for self-adhesive vinyl tiles, offering a convenient installation method. Water-based adhesives are a good option for environmentally conscious projects, offering low VOC emissions. The choice of adhesive depends on several factors, including the type of flooring, the subfloor material, the environmental conditions, and the project’s specific requirements. I always follow the manufacturer’s recommendations for adhesive selection and application.

Understanding the properties of different adhesives, such as their drying time, open time, and bond strength, is essential for a successful installation. Using the wrong adhesive can lead to problems such as poor adhesion, delamination, or even damage to the flooring or subfloor.

Q 21. What are your preferred methods for cutting and shaping flooring materials?

My preferred methods for cutting and shaping flooring materials involve a combination of tools and techniques. For straight cuts, I use a sharp utility knife or a flooring knife, ensuring a clean and precise cut. For curved cuts or cuts around obstacles, I employ a jigsaw with a fine-toothed blade. This allows for accurate cuts that precisely follow the desired shape. I always use scoring techniques to minimize chipping and tearing when cutting harder materials like ceramic or porcelain tiles.

I also use specialized tools like a scoring wheel for scoring sheet vinyl prior to cutting to make sure the cut is straight. A wet saw is preferred for cutting ceramic tiles to minimize dust and ensure accurate cuts. Safety is always a priority, and I always wear appropriate safety gear, such as gloves and eye protection, while using these tools. Mastering these different cutting methods provides precision and ensures the integrity of the flooring during the installation process.

Q 22. Describe your experience with working with different floor designs and patterns.

My experience encompasses a wide range of floor designs and patterns, from classic hardwood planks in various wood species and finishes to intricate tile mosaics, contemporary engineered wood designs, and the latest in luxury vinyl plank (LVP) styles. I’ve worked with geometric patterns, herringbone, chevron, and basketweave layouts, each requiring precise measurement and meticulous installation techniques. For example, installing a herringbone pattern requires careful planning and cutting to ensure the angles are consistent and the pattern flows seamlessly. With intricate tile designs, I’ve used templates and specialized tools to maintain accuracy and achieve the desired aesthetic. My experience extends to understanding how different patterns affect the visual perception of a space, and I can advise clients on the best options based on their room dimensions and personal style.

I’m proficient in working with various materials and matching patterns across multiple rooms or sections, ensuring a cohesive flow. This includes managing transitions between different flooring types and maintaining consistency in color and grain where necessary. This requires a keen eye for detail and a strong understanding of how different materials interact.

Q 23. How do you handle customer complaints or unexpected issues during a project?

Handling customer complaints or unexpected issues is a crucial part of this profession. My approach is always proactive and solution-oriented. First, I listen carefully to the customer’s concerns, ensuring I understand the issue fully. I then conduct a thorough assessment to identify the root cause of the problem. This might involve checking the subfloor, examining the installed flooring, or reviewing the original project specifications.

Once the cause is determined, I develop a clear and concise plan of action to address the issue. If it’s a minor defect, like a loose tile or a small scratch, I’ll repair it immediately and efficiently. For more significant issues, I discuss potential solutions with the client, outlining the options, costs, and timelines involved. Open and transparent communication is key to maintaining a positive relationship with the client. I always prioritize finding a solution that satisfies the client while adhering to professional standards and industry best practices. I believe in taking ownership of any problems, even if they are outside my direct control, to ensure customer satisfaction.

Q 24. What is your experience with reading and interpreting blueprints or floor plans?

Reading and interpreting blueprints or floor plans is fundamental to my work. I’m highly proficient in deciphering architectural drawings, identifying dimensions, understanding the layout of rooms, and noting the specifications for different flooring materials in various areas. I can accurately measure spaces, calculate material quantities, and identify potential challenges like unusual angles, changes in elevation, or the presence of existing features like fireplaces or built-in units that require careful planning around them.

For example, I’ve worked with complex blueprints that included multiple flooring types, transitions between rooms, and detailed specifications for underlayment and moisture barriers. My ability to accurately interpret these drawings ensures that the installation process is efficient and results in a perfect fit.

Q 25. What are some common mistakes to avoid in flooring installation?

Several common mistakes can significantly impact the quality and longevity of a flooring installation. One major error is inadequate subfloor preparation. A subfloor that’s uneven, damaged, or contains excessive moisture will inevitably lead to problems like squeaking, buckling, or premature flooring failure. Another frequent mistake is improper acclimation of materials. Many flooring types, especially hardwood and engineered wood, require time to adjust to the room’s temperature and humidity before installation to prevent expansion and contraction issues.

Failing to use appropriate adhesives or fasteners for the specific flooring material is another common oversight. This can lead to loose tiles or planks, resulting in an unstable and visually unappealing floor. Incorrect spacing between planks or tiles, improper cutting techniques, and neglecting to use expansion gaps around the perimeter of the room are additional mistakes that can cause problems. Finally, not properly managing moisture levels in the subfloor can lead to mold, mildew and ultimately flooring failure. Addressing these aspects upfront prevents costly repairs and ensures a quality installation.

Q 26. What are your strengths and weaknesses as a flooring installer?

My strengths lie in my meticulous attention to detail, my problem-solving abilities, and my commitment to delivering high-quality workmanship. I’m highly organized and efficient, capable of managing multiple projects simultaneously while maintaining a keen eye for precision. I’m also skilled at communicating effectively with clients, addressing their concerns, and managing their expectations throughout the installation process.

One area I’m actively working to improve is delegation. While I pride myself on attention to detail, I’m learning to delegate certain tasks to others on larger projects to improve efficiency without compromising the quality of the final product. This allows me to focus my energy on the most critical aspects of the installation.

Q 27. How do you stay up-to-date on the latest flooring installation techniques and technologies?

Staying current in this field requires ongoing professional development. I regularly attend industry trade shows and workshops to learn about new products, techniques, and technologies. I subscribe to industry publications and online resources, and I actively participate in professional organizations. I also stay connected with other installers to share best practices and learn from their experiences. This ongoing learning ensures I’m always up-to-date with the latest advancements in flooring installation and can offer my clients the best possible service using the most effective and efficient methods.

Q 28. Describe a challenging flooring installation project and how you overcame the challenges.

One challenging project involved installing wide plank hardwood flooring in a historic home with uneven subfloors and numerous obstacles, including several built-in features and an intricate layout. The existing subfloor was far from level and presented significant challenges. To overcome these difficulties, I first conducted a comprehensive assessment of the subfloor, identifying the areas that required leveling. This involved painstakingly patching and leveling sections of the subfloor using self-leveling compound, a time-consuming process that required multiple applications and precise leveling techniques.

Next, I carefully planned the installation to minimize waste and maximize material efficiency. This involved creating detailed cutting diagrams and meticulously measuring and cutting the planks to fit around the existing features in the room. Throughout the process, careful attention was paid to acclimating the wood to the ambient temperature and humidity to prevent issues with expansion and contraction. The result was a beautiful, perfectly fitted hardwood floor, showcasing the high quality of workmanship and attention to detail that I strive for in every project. Despite the significant challenges presented by the subfloor and layout of the space, I successfully delivered a high-quality result that exceeded the client’s expectations.

Key Topics to Learn for Residential Flooring Installation Interview

- Subfloor Preparation: Understanding different subfloor types (concrete, plywood, etc.), moisture content testing, leveling techniques, and necessary repairs before installation.

- Material Selection & Handling: Knowledge of various flooring materials (hardwood, laminate, tile, vinyl), their properties, installation methods, and proper handling to avoid damage.

- Measurement & Estimation: Accurate room measurement, material calculation, waste factor consideration, and providing precise estimates to clients.

- Installation Techniques: Mastering specific installation methods for each flooring type, including nailing, gluing, floating, and tiling techniques. Understanding expansion gaps and proper acclimation procedures.

- Tools & Equipment: Familiarity with essential tools and equipment (measuring tools, saws, nail guns, tile cutters, etc.) and their safe and efficient use.

- Troubleshooting & Problem Solving: Identifying and resolving common installation issues (uneven surfaces, gaps, damaged materials), demonstrating problem-solving skills and resourcefulness.

- Safety Procedures & Regulations: Adherence to safety protocols, understanding relevant building codes and regulations, and using appropriate personal protective equipment (PPE).

- Finishing & Clean-up: Proper finishing techniques, including trim installation, and efficient clean-up procedures for a professional finish.

- Client Communication & Professionalism: Maintaining clear communication with clients, addressing concerns, and demonstrating professionalism throughout the installation process.

Next Steps

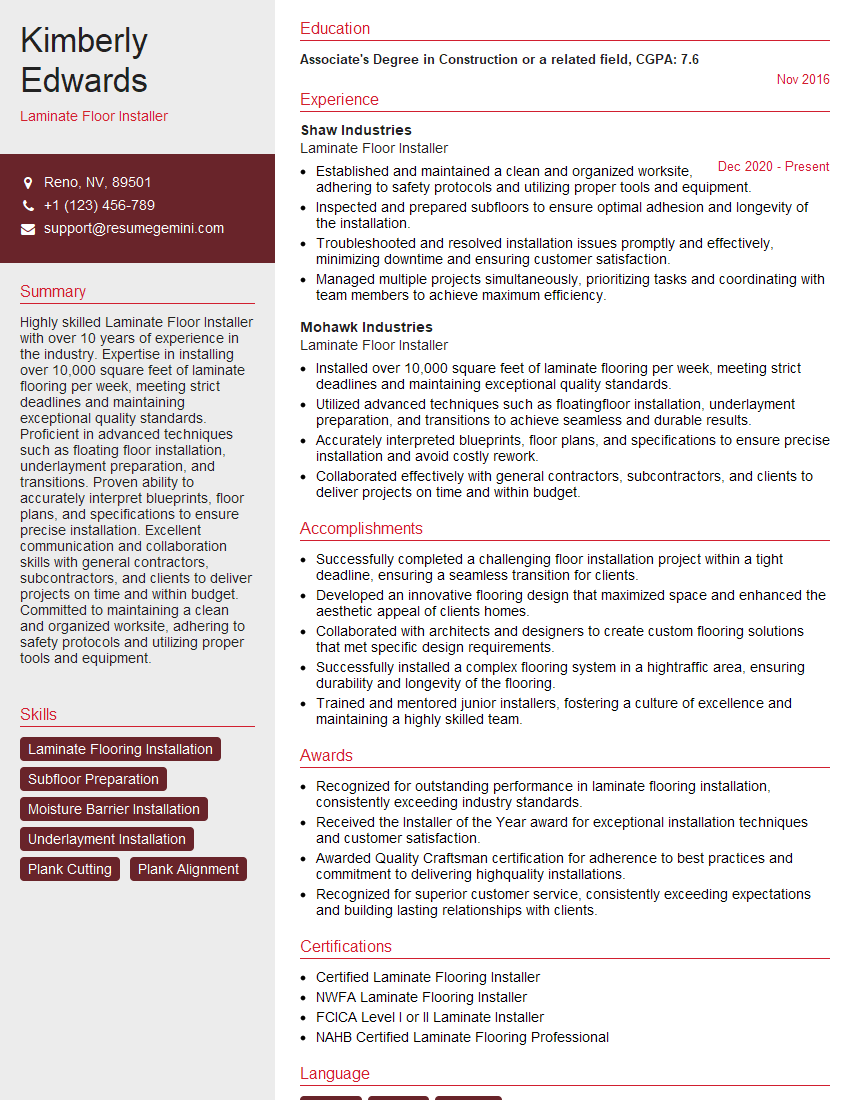

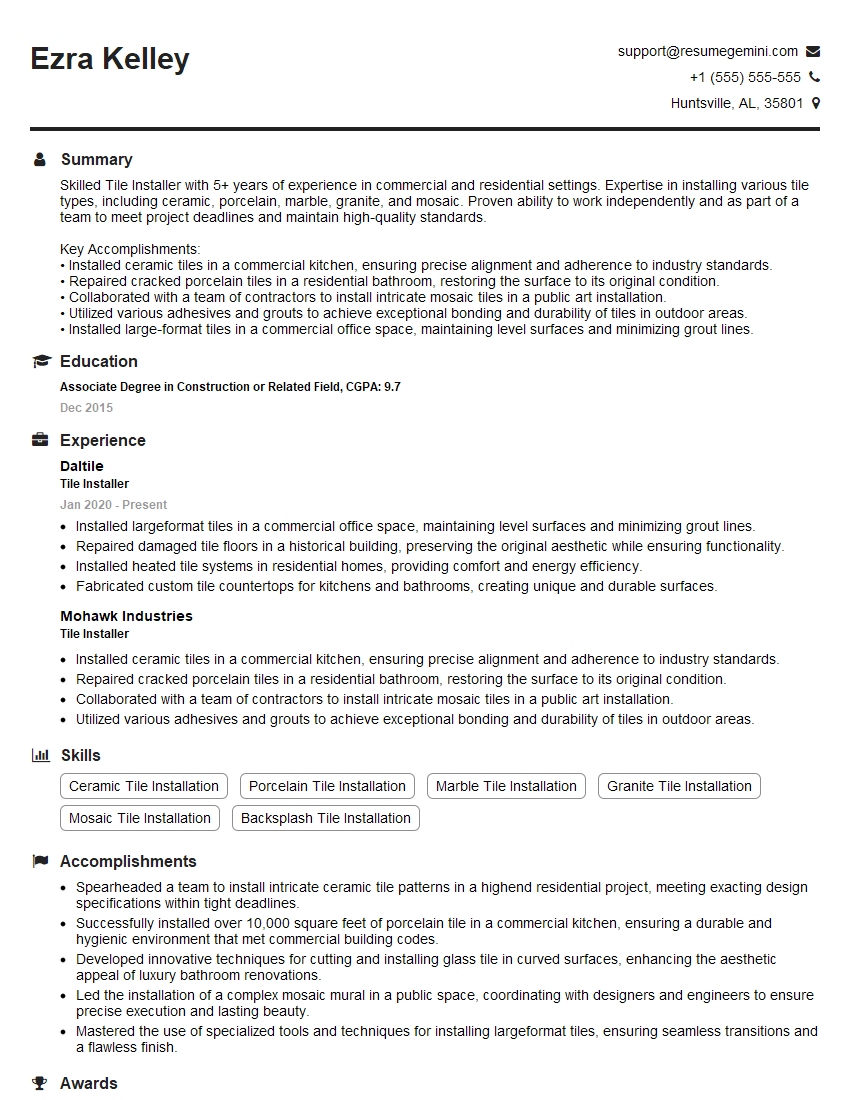

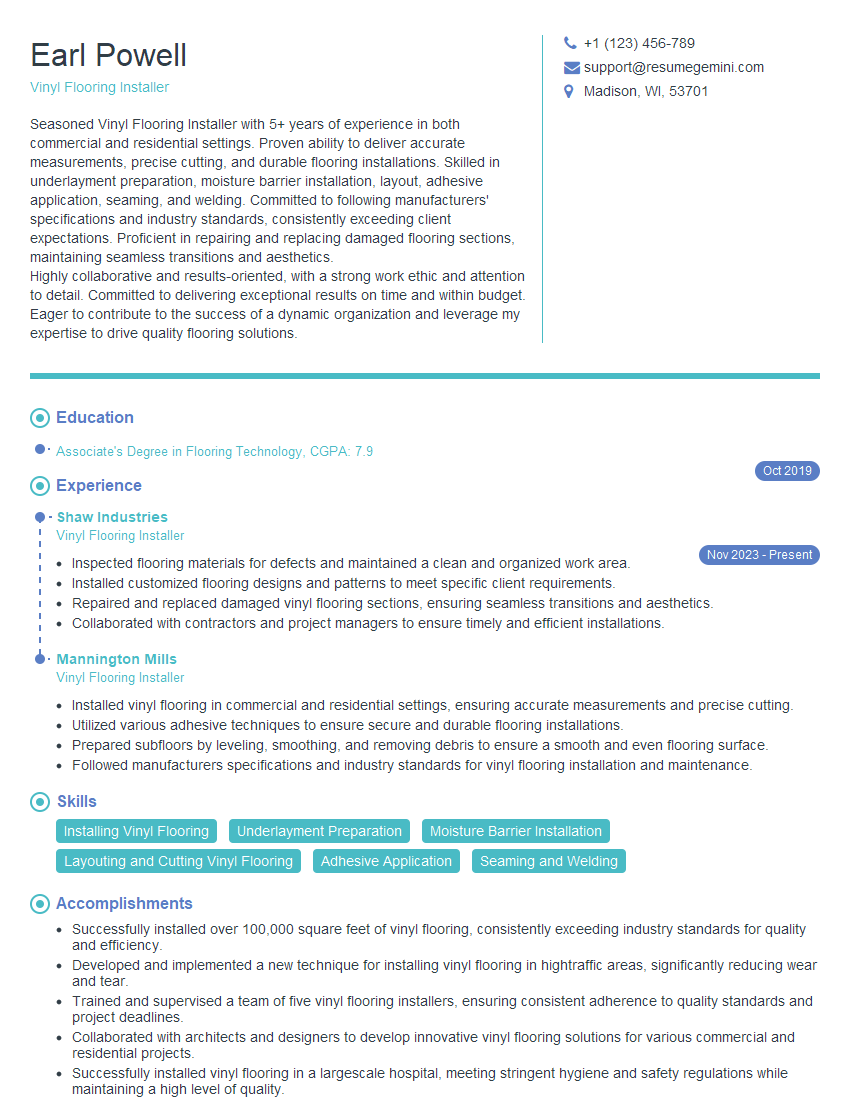

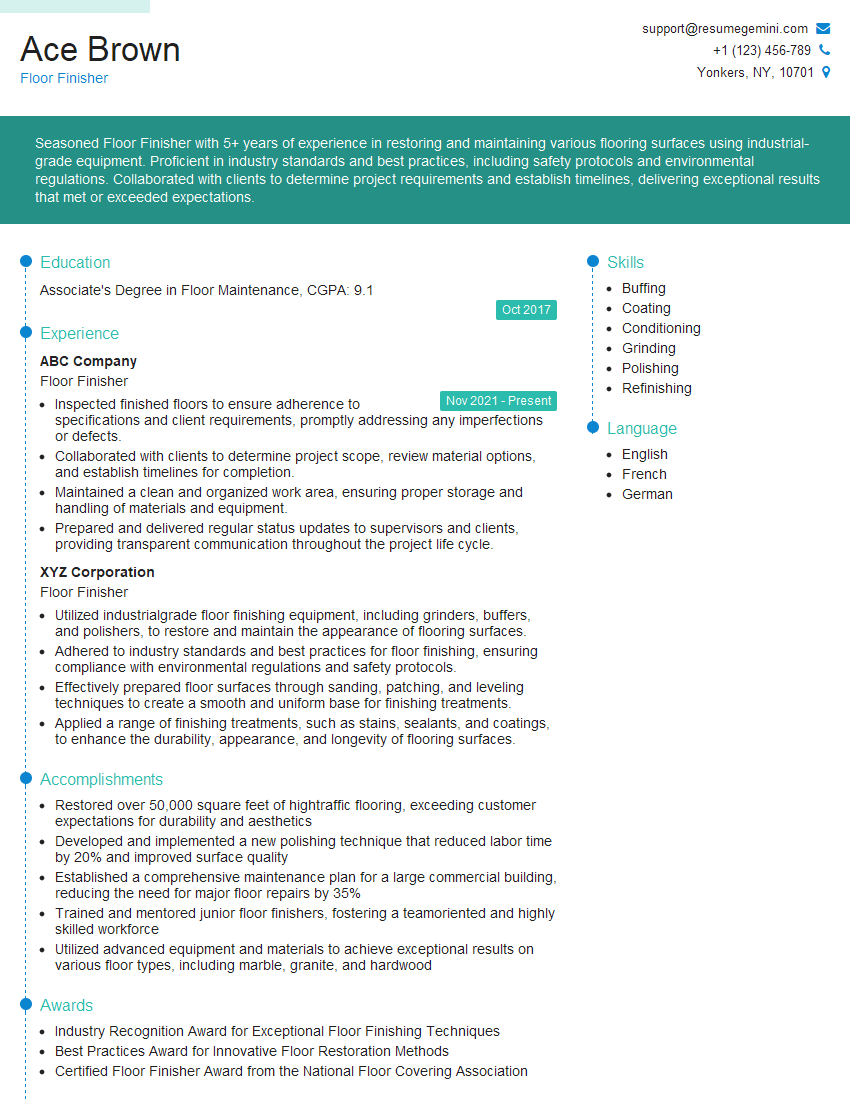

Mastering residential flooring installation opens doors to a rewarding career with excellent growth potential. Demand for skilled installers is consistently high, offering opportunities for advancement and increased earning potential. To maximize your job prospects, creating an ATS-friendly resume is crucial. This ensures your qualifications are effectively highlighted for Applicant Tracking Systems used by many employers. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to Residential Flooring Installation, helping you present your skills and experience in the best possible light. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?