Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Residential Vinyl Flooring Installation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Residential Vinyl Flooring Installation Interview

Q 1. Describe your experience with different types of vinyl flooring (sheet, tile, plank).

My experience spans all major types of residential vinyl flooring: sheet, tile, and plank. Sheet vinyl is a classic choice, offering a seamless, waterproof surface ideal for bathrooms and kitchens. Its installation involves careful measuring and seaming to ensure a smooth, watertight finish. I’ve worked with numerous sheet vinyl options, from basic solid colors to more complex patterns and embossed textures. Vinyl tile offers a more versatile look, allowing for intricate designs and patterns due to its individual tile format. The installation is more time-consuming but provides greater design flexibility compared to sheet vinyl. Finally, luxury vinyl plank (LVP) and luxury vinyl tile (LVT) have become incredibly popular. These products mimic the look of hardwood, stone, or ceramic, often featuring realistic textures and bevelled edges for a high-end appearance. Installing LVP/LVT requires precision and attention to detail, particularly in managing the click-lock or glue-down installation methods. I’ve successfully completed many projects using all three types, adapting my techniques based on the specific material and project requirements.

Q 2. What are the key steps in preparing a subfloor for vinyl installation?

Subfloor preparation is paramount for a successful vinyl flooring installation. Think of it as building a solid foundation for your new floor. A poorly prepared subfloor can lead to unevenness, buckling, and premature failure of the vinyl. The key steps involve:

- Cleaning: Thoroughly remove all debris, dust, and old adhesive residue. A shop-vac is essential here.

- Leveling: Unevenness must be addressed. Minor imperfections can be handled with self-leveling compound, applied thinly and evenly. Larger imperfections often require more extensive subfloor repair, potentially requiring plywood patching.

- Moisture Testing: High moisture content in the subfloor is a major problem for vinyl, leading to bubbling and deterioration. A moisture meter is crucial to ensure the subfloor is sufficiently dry. If moisture levels are too high, delaying the project and employing moisture barriers or allowing for proper drying is necessary.

- Priming (when necessary): Certain subfloors may benefit from a primer to improve adhesion and prevent issues with moisture penetration. Always follow the manufacturer’s instructions on whether priming is required for a specific subfloor and vinyl type.

For example, I once encountered a subfloor with significant dips and unevenness. After careful cleaning, I utilized self-leveling compound to achieve a smooth, level surface before proceeding with the vinyl installation. The result was a flawless, long-lasting floor.

Q 3. Explain the process of measuring and calculating material needs for a vinyl flooring project.

Accurate measurement and material calculation are vital to avoid costly mistakes. I always start by meticulously measuring the length and width of each room, subtracting areas that won’t receive flooring (like built-in cabinets or appliances). I then calculate the total square footage. Next, I add a waste factor, typically 5-10%, to account for cuts, mistakes, and any unforeseen circumstances. For example, a 100 square foot room might require 105-110 square feet of flooring material.

For sheet vinyl, this calculation is straightforward. However, for tile or plank, you also need to consider the size of the individual pieces and account for any pattern matching or cuts required to achieve a desired aesthetic. This might involve using a specialized flooring calculator software or creating detailed diagrams to ensure accurate quantity estimation. Underestimating the amount can lead to noticeable seams in a larger project or necessitate an additional trip to the flooring store for matching material.

Q 4. How do you ensure proper acclimation of vinyl flooring before installation?

Acclimation is crucial, especially for vinyl flooring that is shipped rolled or boxed, as it allows the material to adjust to the temperature and humidity of the installation space. Improper acclimation can lead to expansion and contraction issues after installation, causing buckling or gaps. The specific acclimation time varies depending on the manufacturer’s instructions and the ambient conditions. Generally, it should remain in the room, ideally in its original packaging, for 24-72 hours. I closely monitor the temperature and humidity and ensure that the space is appropriately conditioned to minimize the risk of warping or other installation complications. Failing to acclimate can result in costly rework. I always make sure to emphasize to my clients that it’s a crucial step to guarantee a quality installation.

Q 5. What tools and equipment are essential for efficient vinyl flooring installation?

The right tools are essential for efficient and quality vinyl flooring installation. Here’s a list of essentials:

- Measuring tools: Tape measure, square, chalk line

- Cutting tools: Utility knife with sharp blades, flooring shears (for sheet vinyl), circular saw (for underlayment)

- Installation tools: Putty knife, roller, notched trowel (for adhesive application), knee pads, safety glasses

- Other tools: Hammer, pry bar, safety equipment (gloves, dust mask)

For instance, a sharp utility knife is crucial for making precise cuts in vinyl flooring materials. A notched trowel ensures even adhesive distribution, preventing air bubbles and ensuring proper bonding. Always using sharp blades and maintaining the tools is key to an efficient and safe installation process.

Q 6. Describe your experience with different vinyl flooring adhesives and their applications.

My experience encompasses various vinyl flooring adhesives, each with its own properties and applications. Water-based adhesives are commonly used for their low odor and ease of cleanup. They’re suitable for many types of vinyl flooring, especially in residential settings. However, they often require a longer drying time. Pressure-sensitive adhesives are a more convenient option with quicker drying time, but can be more difficult to work with and may not provide the same level of adhesion as water-based alternatives. I’ve also worked with moisture-cure urethanes which offer exceptional strength and durability, particularly useful in areas prone to moisture. I carefully select the adhesive based on the specific vinyl flooring type, subfloor conditions, and environmental factors. Each adhesive has different application techniques and open times and understanding these is critical to ensure a secure and long-lasting bond.

Q 7. How do you handle transitions between different flooring materials?

Transitions between different flooring materials are a common challenge that requires careful planning and execution. The goal is to create a seamless and aesthetically pleasing transition while maintaining functionality and structural integrity. This often involves using transition strips or reducers. For example, a transition strip might be used to smoothly transition between vinyl flooring and carpet, while a reducer might bridge the gap between vinyl and a taller surface like hardwood flooring. The type of transition strip used is carefully selected based on the height difference between the flooring materials and the overall aesthetic design. Accurate measurements and proper installation are critical to ensure a smooth, safe, and visually appealing transition that blends seamlessly with the surrounding flooring.

Q 8. Explain your method for cutting and fitting vinyl flooring around obstacles (e.g., pipes, doorways).

Cutting and fitting vinyl flooring around obstacles like pipes and doorways requires precision and the right tools. My method begins with careful measurement and marking. I use a utility knife with a sharp blade for precise cuts, ensuring I’m cutting on the underside of the flooring to avoid visible damage on the top surface. For pipes, I trace the pipe onto the flooring, adding a small margin for the adhesive. I then carefully cut out the shape, making sure the cutout is snug but not too tight. For doorways, I’ll measure the doorway’s width and cut a straight line, allowing for a slight overlap to ensure a clean finish and prevent gaps. I use a sharp utility knife and a metal straight edge for straight, clean cuts around doorways. After cutting, I use a heat gun (carefully!) to gently soften the edges of the vinyl around the pipes to achieve a smoother, more seamless fit. Any small gaps are filled with a high-quality vinyl adhesive specifically designed for this purpose. Think of it like creating a custom puzzle piece – each cut needs to be precise for a perfect fit.

Q 9. How do you ensure proper seam sealing for a waterproof vinyl installation?

Proper seam sealing is crucial for a waterproof vinyl floor, especially in bathrooms and kitchens. I use a high-quality, vinyl-specific seam sealer that’s specifically designed for waterproof applications. Before applying the sealer, I ensure both edges of the vinyl seams are clean, dry, and tightly fitted. I then carefully apply the sealer using a caulking gun, creating a smooth, even bead along the seam. The key is to apply enough sealer to completely fill the seam without creating an unsightly overflow. I use a wet finger or a smoothing tool to immediately remove any excess sealer and ensure a clean, professional finish. Allow ample drying time as specified by the manufacturer. I always perform a water test after the sealer has dried completely to ensure the seam is completely waterproof – often spraying a small section of the seam with water to see if there are any leaks.

Q 10. What are the common problems encountered during vinyl flooring installation, and how do you address them?

Common problems during vinyl installation include uneven subfloors, improper acclimation of the vinyl, and poor adhesive application. Uneven subfloors lead to ripples or bumps in the flooring. Addressing this requires leveling the subfloor before installation, using a self-leveling compound if necessary. Improper acclimation means the vinyl hasn’t had enough time to adjust to the room’s temperature and humidity, leading to shrinkage or expansion issues. I always acclimate the vinyl for at least 24-48 hours before installation, following manufacturer’s instructions. Poor adhesive application can result in loose tiles or seams. Using the right amount of adhesive and applying it evenly is crucial to avoid this, ensuring good coverage and proper bonding. I always use the adhesive recommended by the manufacturer for the specific vinyl type and subfloor. In my experience, a methodical approach and attention to detail greatly reduce the likelihood of these issues.

Q 11. Describe your experience with installing vinyl flooring in various room types (e.g., bathrooms, kitchens).

I have extensive experience installing vinyl flooring in various room types. Bathrooms require waterproof vinyl and meticulous sealing around fixtures. Kitchens require durable vinyl that can withstand heavy traffic and spills. In bathrooms, I use specifically designed waterproof vinyl and pay extra attention to sealing around the tub or shower, meticulously cleaning and preparing the surfaces before adhesive application. In kitchens, I often recommend thicker, more durable vinyl to handle potential water damage from spills or cleaning. For bedrooms or living rooms, the choices are more flexible, allowing for varied aesthetics and textures. Each room type presents its own unique set of challenges and considerations, requiring a tailored approach to ensure the finished product is not only aesthetically pleasing but also functional and durable.

Q 12. How do you manage waste material during and after a vinyl flooring installation?

Waste management is an essential part of responsible installation. I start by carefully measuring and cutting the vinyl to minimize waste as much as possible, using the leftover pieces for smaller areas or as templates for more intricate cuts. All waste material is carefully collected and separated for disposal. Depending on the type of vinyl, I sometimes coordinate with local recycling facilities to dispose of it responsibly. Some vinyl can be recycled, and I make sure to adhere to local regulations and responsible disposal practices. This prevents unnecessary environmental impact, ensuring a clean and responsible job completion.

Q 13. Explain your understanding of safety procedures during flooring installation.

Safety is paramount in any installation project. I always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and dust masks to protect myself from sharp objects, adhesives, and dust. I use a utility knife carefully and always cut away from my body. I ensure proper ventilation in the work area, especially when working with adhesives. I also take precautions to prevent slips and falls by keeping the work area clean and free of debris. Before beginning any work, I inspect the worksite for any potential hazards and make the necessary adjustments to ensure a safe working environment. This ensures not only my safety, but also the safety of others present during the installation process.

Q 14. Describe your experience working with different types of underlayments.

My experience with underlayments spans various types, each suited for different needs. Some underlayments provide moisture protection, others enhance sound dampening or thermal insulation. I’ve worked with foam underlayments, cork underlayments, and rubber underlayments, each possessing unique properties. Foam underlayments are cost-effective and offer good cushioning. Cork underlayments add a layer of comfort and insulation. Rubber underlayments are excellent for soundproofing. The choice of underlayment depends on factors such as the subfloor condition, the type of vinyl, and the desired outcome. For example, in a bathroom with a concrete subfloor, I might choose a moisture-resistant underlayment to protect against potential water damage. In a living room, I may choose a cork underlayment to enhance the comfort and insulation of the room.

Q 15. What are your preferred methods for cleaning and maintaining vinyl flooring after installation?

Maintaining vinyl flooring after installation is crucial for its longevity. Think of it like caring for a well-polished car – regular cleaning prevents damage and keeps it looking its best. My preferred method focuses on prevention and regular, gentle cleaning.

Daily Cleaning: A simple sweep or vacuum with a soft-bristled attachment removes loose dirt and debris. This prevents grit from scratching the surface. Imagine it as a quick wipe-down – prevents build-up.

Weekly Cleaning: Damp mopping with a pH-neutral cleaner is recommended. Avoid harsh chemicals, abrasive cleaners, or excessive water, which can damage the vinyl. Think of using a gentle, non-abrasive cleanser like you’d use on fine furniture.

Spot Cleaning: Address spills immediately to prevent staining. Blot (don’t rub!) with a clean cloth. For tougher stains, use a specialized vinyl floor cleaner following the product instructions carefully. Like dealing with a coffee spill – quick action prevents a permanent mark.

Protective Measures: Use doormats at entrances to trap dirt and grit before it reaches the floor. Furniture pads are also crucial under heavy furniture to avoid dents or scratches. Consider this like protecting your car with a cover – preventative measures save on later maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the finished vinyl floor is level and free from imperfections?

Achieving a perfectly level vinyl floor is paramount for both aesthetics and longevity. Unevenness can lead to premature wear and tear, buckling, and an unsightly finish. My process involves several key steps:

Subfloor Preparation: This is the most critical step. The subfloor must be clean, dry, and completely level. Any cracks, gaps, or significant imperfections need to be repaired before installation. I often use self-leveling compound for this, much like preparing a canvas for a painting – a smooth base is essential.

Moisture Testing: Before laying the vinyl, I always conduct a thorough moisture test to ensure the subfloor is dry enough. Excess moisture can lead to issues like buckling and mold growth. This is like checking the humidity before hanging a painting – moisture is the enemy.

Installation Techniques: For sheet vinyl, I pay close attention to proper stretching and seaming to minimize gaps and ensure a flat surface. For tile, proper spacing and consistent adhesive application are key. I use a level throughout the process to check for inconsistencies. This is the artist’s careful hand – ensuring everything is smooth and aligned.

Final Inspection: Once the installation is complete, I conduct a thorough final inspection to look for any high or low spots. Minor imperfections may be addressed with appropriate fillers or by gently working the vinyl.

Q 17. Explain your experience working from blueprints or floor plans.

Working from blueprints or floor plans is a standard procedure for me. I find it invaluable for accurate measurement, material estimation, and efficient project planning. My approach involves:

Detailed Review: I meticulously review the blueprints to understand the room dimensions, any special features (like thresholds or transitions to other flooring types), and any specific installation requirements.

Accurate Measurements: I take my own measurements on-site to verify the blueprint accuracy and account for any minor discrepancies. Measurements are cross-checked to avoid costly mistakes.

Material Calculation: I use the blueprints and my measurements to accurately calculate the amount of vinyl flooring and adhesive needed, minimizing waste and ensuring a smooth project flow.

Pre-installation Planning: Based on the plan, I develop a detailed installation plan including sequencing the work, managing material delivery, and scheduling my team.

For example, a recent project involving a complex multi-level home required careful review of the floor plans to understand transitions between different rooms and flooring types. The detailed plan allowed for efficient material ordering and seamless installation.

Q 18. How do you handle unexpected issues or challenges that arise during a project?

Unexpected issues are a part of any construction project. My approach involves a combination of proactive planning and responsive problem-solving. I’ve faced issues ranging from subfloor inconsistencies to unexpected obstacles concealed beneath existing flooring.

Thorough Assessment: The first step is a careful assessment of the problem to understand its nature and scope. Is it a minor imperfection that can be easily corrected or a more significant issue requiring a change of plan?

Creative Solutions: I brainstorm various solutions, considering their feasibility, cost-effectiveness, and impact on the overall project timeline. This may involve consulting with suppliers or other tradespeople for expert advice.

Client Communication: Keeping the client informed throughout the process is crucial. I always communicate any unexpected issues, potential solutions, and their implications for the schedule and budget.

Documentation: I meticulously document all challenges, solutions implemented, and any changes made to the project scope. This safeguards against future disputes and serves as a valuable learning experience.

For instance, discovering hidden plumbing during a demolition revealed a need to modify the original plan. I communicated this to the client, presented various solutions, and collaboratively selected the best option ensuring minimal disruption.

Q 19. Describe your experience with using a heat gun for vinyl flooring installation.

A heat gun is a valuable tool in vinyl flooring installation, particularly with sheet vinyl. It allows for the precise shaping and smoothing of the material, especially around corners and edges. However, it requires careful and skilled use to avoid damaging the vinyl.

Safe Operation: I always ensure proper ventilation and use heat-resistant gloves and safety glasses to prevent burns. Heat is applied gradually and never directly to the surface of the vinyl itself.

Seaming: Heat guns are essential for creating seamless welds in sheet vinyl installations, ensuring a consistent and smooth finish. The heat softens the vinyl allowing for a tight, secure bond between the edges.

Difficult Areas: In tight corners or around pipes, a heat gun helps stretch and conform the vinyl to the shape, preventing creases or wrinkles. This is an advantage for the aesthetic look.

Temperature Control: Maintaining the correct temperature is critical. Too little heat will be ineffective, too much can damage the vinyl. Experience is key in learning how to judge and maintain the heat to ensure the quality of the result.

Q 20. What is your experience with different types of flooring adhesives (water-based, solvent-based)?

Experience with various flooring adhesives is critical for successful vinyl installations. The choice of adhesive depends on several factors, including the type of vinyl, subfloor, and environmental conditions.

Water-Based Adhesives: These are generally low-VOC (volatile organic compound), making them a more environmentally friendly option. They tend to have a longer open time, providing more time for adjustments. However, they are not suitable for all types of vinyl or subfloors.

Solvent-Based Adhesives: These adhesives are known for their superior strength and faster drying times. However, they have stronger fumes, requiring excellent ventilation during application. Safety equipment and ventilation are crucial while using this type of adhesive.

Choosing the Right Adhesive: I always carefully review the manufacturer’s recommendations for both the vinyl and adhesive to ensure compatibility. This prevents issues like poor adhesion, bubbling, or delamination.

Application Techniques: Regardless of the adhesive type, proper application is paramount. Using the correct trowel size and applying a consistent amount of adhesive prevents inconsistencies in the final floor. Think of this like baking a cake – precise measurements are essential for good results.

Q 21. How do you ensure proper ventilation during the installation process?

Proper ventilation is crucial during vinyl flooring installation, particularly when using solvent-based adhesives. These adhesives release volatile organic compounds (VOCs) which can be harmful if inhaled.

Open Windows and Doors: I always prioritize opening windows and doors to maximize natural ventilation. This helps to remove VOCs and reduce the risk of health problems.

Exhaust Fans: If natural ventilation is insufficient, I’ll use exhaust fans to help circulate air and draw out fumes. This is especially important in smaller or poorly ventilated spaces.

Ventilation Planning: Before starting the installation, I assess the ventilation capabilities of the workspace and plan accordingly. This may involve pre-emptive measures to improve ventilation, like cleaning out air vents, or planning work phases around periods with favorable weather conditions.

Personal Protective Equipment (PPE): In addition to ventilation, I always use appropriate PPE, including respirators, safety glasses, and gloves, to protect myself from harmful fumes and debris.

For example, during a recent basement installation using solvent-based adhesive, I ensured adequate ventilation by opening all available windows and using several exhaust fans to maintain a safe working environment.

Q 22. Describe your experience with installing vinyl flooring in high-traffic areas.

Installing vinyl flooring in high-traffic areas requires a keen understanding of material selection and installation techniques to ensure longevity. I prioritize using commercial-grade vinyl planks or tiles, known for their superior durability and resistance to wear and tear. These typically boast thicker wear layers and enhanced impact resistance compared to residential options.

My approach involves a meticulous subfloor preparation. Any imperfections, like unevenness or moisture, can lead to premature failure. I utilize self-leveling compounds if necessary, ensuring a perfectly smooth base. The planks themselves are installed with extra care, paying close attention to proper expansion gaps and using appropriate adhesives for optimal bonding in high-stress zones, like doorways. Regular checks during and after installation confirm a secure fit and prevent future issues.

For example, in a recent project in a busy restaurant, I used a heavy-duty commercial-grade vinyl with a textured surface to minimize the appearance of scratches. The result was a floor that withstood months of heavy foot traffic with minimal visible wear.

Q 23. What is your approach to quality control throughout the installation process?

Quality control is an integral part of my process, starting from the initial site survey and continuing until the final walk-through with the client. It’s a multi-stage approach.

- Pre-Installation: Thoroughly assessing the subfloor for moisture, levelness, and structural integrity. This includes using a moisture meter and level to identify any potential problems.

- Material Selection: Selecting the appropriate vinyl type based on the client’s needs and the area’s conditions. This includes considering wear layer thickness, embossing, and overall durability.

- Installation Process: Precise cutting, accurate measurements, and the proper use of adhesives to guarantee a seamless and secure installation. This includes regular checks for alignment and ensuring consistent spacing between planks or tiles.

- Post-Installation: A final inspection to ensure there are no gaps, ripples, or other defects. Addressing any minor issues promptly to maintain the highest standard.

This multi-layered approach helps prevent problems down the line and ensures client satisfaction.

Q 24. How do you communicate effectively with clients and other professionals on a project?

Effective communication is crucial for project success. I believe in proactive and transparent communication throughout the entire process. This starts with a detailed initial consultation where I discuss the client’s vision, budget, and any concerns.

I use a combination of methods:

- Regular updates: Keeping clients informed of the progress, any unexpected issues, and potential solutions. This often involves photos and/or video updates.

- Clear explanations: Using simple, non-technical language to explain complex concepts. I also make sure to answer any questions the client may have.

- Professional demeanor: Maintaining a professional and respectful attitude at all times, even when faced with challenges.

- Collaboration with other professionals: Open communication with other tradespeople involved in the project to coordinate schedules and avoid conflicts.

For instance, I recently worked with a contractor who was installing new cabinets. Clear communication ensured we coordinated our work schedules to prevent delays and minimize disruption.

Q 25. Describe your experience working independently and as part of a team.

I’m comfortable working both independently and as part of a team. When working independently, my organizational skills and attention to detail allow me to manage projects efficiently and effectively. I’m adept at planning, scheduling, and executing installations with minimal supervision.

In a team setting, I’m a collaborative team player. I value open communication, shared problem-solving, and the efficient division of tasks. I’ve found that teamwork often leads to more creative solutions and a smoother, faster installation process. For example, on a large-scale project, I worked with a team, where one person focused on subfloor preparation while another handled the installation, leading to a highly efficient and timely completion.

Q 26. What safety precautions do you take to prevent accidents during installation?

Safety is paramount in my work. I adhere to strict safety protocols throughout the entire installation process.

- Proper Personal Protective Equipment (PPE): Consistent use of safety glasses, gloves, dust masks, and appropriate footwear.

- Safe Handling of Materials: Proper lifting techniques and the use of material handling equipment when needed to prevent injuries.

- Clean and Organized Workspace: Maintaining a clean and organized workspace to prevent slips, trips, and falls.

- Adherence to Safety Regulations: Following all relevant safety regulations and guidelines set by OSHA and other relevant authorities.

- Proper Ventilation: Ensuring adequate ventilation when using adhesives or other potentially hazardous materials.

By prioritizing safety, I protect myself and those around me from potential hazards.

Q 27. How do you stay up-to-date on the latest trends and technologies in vinyl flooring installation?

Staying current in the ever-evolving world of vinyl flooring is vital. I utilize several strategies:

- Industry Publications: Regularly reading industry magazines and journals to stay informed on the latest products, techniques, and trends.

- Manufacturer Websites and Training: Accessing manufacturers’ websites for product information, installation guides, and training materials. Many offer online courses and webinars.

- Networking with Other Professionals: Attending industry events, trade shows, and workshops to connect with other professionals and learn about their experiences and best practices.

- Online Resources: Utilizing online forums and communities dedicated to flooring installation to access information and discuss challenges with other professionals.

This continuous learning ensures I’m equipped with the latest knowledge and skills to provide top-quality installations.

Q 28. Describe a time you had to solve a challenging problem during a vinyl flooring installation project.

During a recent installation in an older home, I encountered unexpectedly uneven subflooring that was beyond the capabilities of a standard self-leveling compound. The floor sloped significantly in one area.

My initial approach involved attempting to level the floor with a thick layer of self-leveling compound, but it proved ineffective due to the severity of the unevenness. Instead, I developed a layered approach:

- Assessment: A more thorough assessment of the subfloor using a laser level to map out the exact discrepancies.

- Strategic Build-Up: Using a combination of plywood shims and thinset mortar to create a more level base in the problematic areas, creating a stepped approach rather than relying solely on self-leveling compound.

- Careful Installation: Careful installation of the vinyl planks, adjusting the layers of adhesive and paying close attention to the unevenness as I worked through each plank to ensure a flat, seamless finish.

This multi-faceted solution ensured a successful installation despite the significant subfloor challenges. The client was incredibly pleased with the final result, highlighting the importance of adaptability and problem-solving skills in this profession.

Key Topics to Learn for Residential Vinyl Flooring Installation Interview

- Subfloor Preparation: Understanding different subfloor types (concrete, plywood, etc.), moisture content testing, leveling techniques, and necessary repairs before installation.

- Acclimation and Measurement: Properly acclimating vinyl planks or tiles to the room’s temperature and humidity, accurate room measurement, and efficient material calculation to minimize waste.

- Installation Methods: Mastering various installation techniques including full-spread adhesive, loose-lay, click-lock, and self-adhesive methods, understanding their applications and limitations.

- Cutting and Trimming: Precise cutting techniques for achieving clean cuts around obstacles like doors, pipes, and uneven walls, using appropriate tools safely and efficiently.

- Transitioning and Molding: Properly installing transitions between different flooring types and using various moldings to achieve a professional finish and conceal expansion gaps.

- Tools and Equipment: Demonstrating familiarity with essential tools and equipment used in vinyl flooring installation, including measuring tools, cutting tools, adhesives, and safety gear.

- Troubleshooting and Problem Solving: Identifying and resolving common installation issues such as uneven seams, buckling, lifting edges, and understanding the causes and solutions for such problems.

- Safety Procedures: Highlighting knowledge of relevant safety regulations, the use of personal protective equipment (PPE), and safe handling of tools and materials.

- Code Compliance: Demonstrating awareness of building codes and regulations related to flooring installation in residential settings.

- Clean Up and Final Inspection: Understanding the importance of a thorough cleanup after installation and the final inspection process to ensure a high-quality finished product.

Next Steps

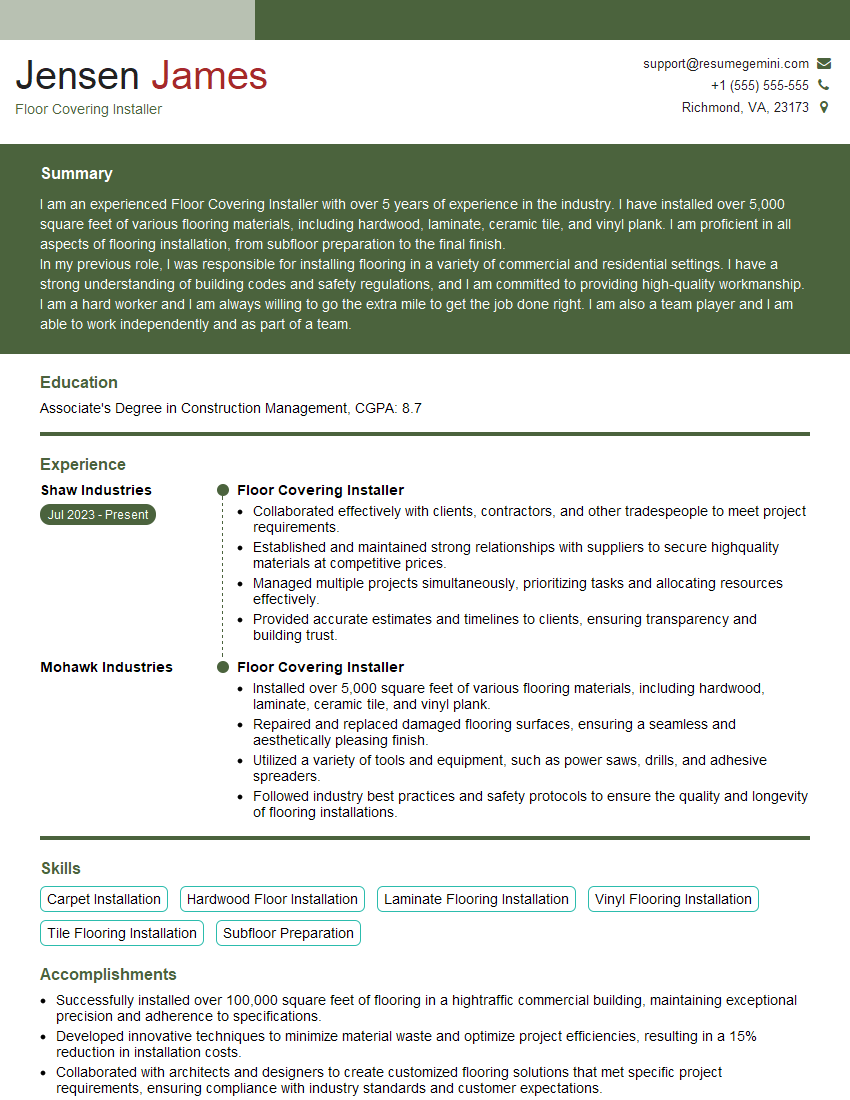

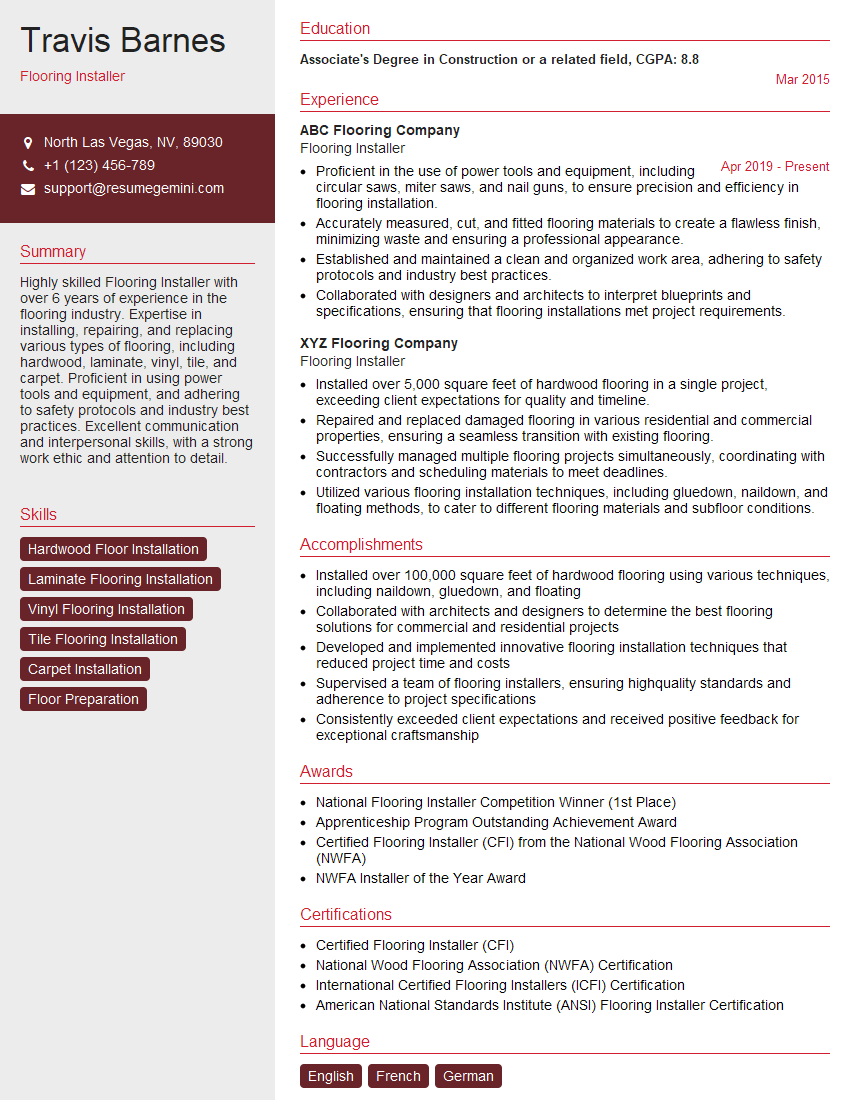

Mastering residential vinyl flooring installation opens doors to a rewarding career with excellent growth potential. Demand for skilled installers is consistently high, offering opportunities for advancement and increased earning capacity. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, designed to get noticed by employers. Examples of resumes tailored specifically to Residential Vinyl Flooring Installation are available to guide you. Invest time in crafting a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?