Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Robotics (FANUC, ABB, etc.) interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Robotics (FANUC, ABB, etc.) Interview

Q 1. Explain the difference between a Cartesian and a SCARA robot.

Cartesian and SCARA robots are both types of robotic arms, but they differ significantly in their structure and range of motion. Think of it like comparing a crane (Cartesian) to a human arm (SCARA).

A Cartesian robot, also known as a gantry robot, moves along three linear axes (X, Y, Z) like a coordinate system. Its movements are straight lines, making it ideal for tasks requiring precise positioning in a large workspace, such as pick-and-place operations with large components or 3D printing.

A SCARA (Selective Compliance Assembly Robot Arm) robot has two parallel rotary joints that provide movement in the horizontal plane (X and Y axes). It also typically has a vertical linear joint (Z axis). SCARA robots excel at applications requiring fast and precise assembly operations, like inserting parts into circuit boards, because of their speed and dexterity in the horizontal plane. Their compliance (ability to give slightly in one direction) helps with inserting parts into tight spaces.

- Cartesian: Three linear axes, large workspace, precise positioning, slower speeds.

- SCARA: Two rotary axes in horizontal plane, one linear Z-axis, high speed and accuracy in assembly tasks, good repeatability.

Q 2. Describe your experience with FANUC’s R-30iB controller.

I have extensive experience with FANUC’s R-30iB controller, having used it in various industrial automation projects. This controller is known for its robust performance and advanced features. I’ve worked extensively on programming complex motion sequences, integrating vision systems, and troubleshooting system errors within this platform.

For example, in one project, we used the R-30iB to control a robotic welding cell. I programmed the robot to perform intricate weld paths with high precision and speed, achieving significant improvements in production efficiency. We also integrated a vision system, using the controller’s advanced capabilities to allow the robot to adapt to variations in part positioning. My experience includes working with the TP (Teach Pendant) for programming, utilizing the Karel programming language for more complex custom routines, and using the controller’s diagnostic tools for efficient troubleshooting.

I am proficient in using the various features including the different modes of operation (automatic, manual, teach), handling of digital I/O signals, and using the various communication protocols like EtherCAT, Profibus, and others for seamless integration with other industrial equipment. I am comfortable using the controller’s monitoring and diagnostic features to swiftly identify and resolve issues.

Q 3. How would you troubleshoot a robot’s communication error with a PLC?

Troubleshooting communication errors between a robot and a PLC involves a systematic approach. Think of it like detective work; we need to systematically eliminate potential causes.

My approach usually starts with verifying the basic connections – checking cables, connectors, and network settings. This often involves verifying IP addresses, subnet masks, and gateway settings on both the robot controller and the PLC. Tools like a network tester are very helpful here.

Next, I’d examine the communication protocol settings on both devices. This might include checking baud rates, parity, and data bits if using serial communication, or verifying the correct EtherCAT or Profinet settings if utilizing these protocols. Inconsistencies in these settings are a common cause of communication failures.

After that, I would check the PLC program to ensure that it is correctly addressing the robot controller. I might look for errors in the PLC’s communication logic, and use the PLC’s diagnostic functions to pinpoint possible communication errors from its end.

If the issue persists, I would consult the relevant manuals for both the robot controller and the PLC to find more specific troubleshooting steps and error codes. I also rely on the robot controller’s diagnostic tools, which often pinpoint the exact source of the communication problem and provide valuable insights.

Finally, a physical inspection of the communication hardware, including the cables and connectors for signs of damage or loose connections, is crucial. Sometimes the most straightforward solutions are the easiest to overlook!

Q 4. What are the common safety considerations when programming industrial robots?

Safety is paramount when programming industrial robots. It’s not just about avoiding accidents; it’s about ensuring a consistently safe working environment. I always prioritize these key considerations:

- Risk Assessment: Thorough risk assessment identifies potential hazards during robot operation, considering both programmed movements and unexpected events. This is crucial before any programming begins. We need to carefully consider the possibility of collisions with humans, falling objects, or unexpected robot movements.

- Safety Zones and Fencing: Establishing physical safety zones and fences around the robot’s workspace restricts access to unauthorized personnel and prevents accidental contact. Light curtains and safety scanners further enhance this protection.

- Emergency Stops: Multiple emergency stop buttons, strategically positioned within easy reach, are essential. Ensuring their proper function and accessibility is critical.

- Speed and Jerk Limiting: Programming the robot to operate at safe speeds and with smooth movements minimizes the risk of collisions and unexpected behavior. Careful consideration must be given to the potential for overshoot or unexpected motion.

- Redundant Safety Systems: Implementing redundant safety systems (e.g., multiple safety relays) creates backups to safeguard against single-point failures. This layered approach significantly enhances safety.

- Robot Programming Guidelines: Following strict programming guidelines and adhering to safety standards (e.g., ISO 10218) is crucial to ensure safety compliance. These guidelines provide a framework for safe robot programming practices.

Q 5. Explain the concept of robot teach pendants and their functionalities.

Robot teach pendants are handheld devices used to program and control industrial robots. Think of them as the robot’s control panel.

Their functionalities include:

- Manual Control: Directly controlling the robot’s movement by manually moving the robot through a sequence of points. This is common during the initial setup and teaching of the robot’s movements.

- Program Editing: Creating, editing, and modifying robot programs. This usually involves selecting commands and setting parameters, and sometimes might include writing custom code.

- Program Execution: Starting, stopping, pausing, and single-stepping robot programs. The teach pendant allows for complete control over the program’s execution.

- Monitoring and Diagnostics: Monitoring the robot’s status, such as position, speed, and error codes, allows for efficient diagnostics.

- I/O Control: Controlling input/output signals from sensors and actuators. This allows for the interaction of the robot with its environment.

The teach pendant is integral to robot programming, allowing for interactive adjustments and fine-tuning of robot movements. It’s a critical tool for ensuring accurate and safe robot operation.

Q 6. Describe your experience with ABB’s RobotStudio software.

My experience with ABB’s RobotStudio software is extensive. I’ve utilized it for both offline programming and simulation of robotic systems. This powerful software significantly streamlines the robot programming process.

I have used RobotStudio to create, simulate and test robot programs virtually before deploying them on actual robots, minimizing downtime and potential errors. The simulation environment allows me to visualize robot movements and identify potential collisions or other issues before they occur in the real-world setting. This is particularly useful when dealing with complex tasks or integrating robots into a complex production line. For example, I once used RobotStudio to simulate the operation of a palletizing robot, optimizing its movements and minimizing cycle time before implementing it on the factory floor.

Furthermore, RobotStudio’s features extend beyond simple simulation. I’ve utilized its capabilities for creating accurate 3D models of work cells, including robots, conveyors, and other equipment. This allows for realistic simulation of the entire production environment, enabling comprehensive testing and optimization of the entire system. This capability has proven invaluable in coordinating the movements of multiple robots in a collaborative cell.

Q 7. How do you perform robot calibration and what are the common methods?

Robot calibration is the process of accurately determining and adjusting the robot’s physical parameters to match its mathematical model. Think of it as regularly tuning up your car’s engine to ensure optimal performance. Without proper calibration, the robot’s movements might be inaccurate, leading to errors in its tasks.

Common calibration methods include:

- Geometric Calibration: This method involves measuring the robot’s physical parameters, such as link lengths and joint angles, to refine its kinematic model. It is typically performed using a laser tracker or other precision measurement devices. The accuracy of these measurements directly impacts the accuracy of the robot’s movements.

- Thermal Calibration: This addresses the effects of temperature changes on the robot’s geometry. As temperatures fluctuate, materials expand and contract, affecting the robot’s accuracy. Thermal calibration compensates for these effects, maintaining accuracy across varying temperatures.

- Kinematic Calibration: This method identifies and corrects errors in the robot’s kinematic model, which defines the relationship between joint angles and the robot’s end-effector position. Inaccurate kinematic parameters can cause significant deviations in the robot’s position and orientation. It’s usually done using a variety of measurement techniques, often in conjunction with special software.

The choice of calibration method depends on the specific requirements of the application and the desired level of accuracy. Regular calibration is essential for maintaining the robot’s accuracy and reliability over time, ensuring consistent performance across different operating conditions. Neglecting calibration can lead to significant errors and reduced productivity.

Q 8. Explain different robot programming languages (RAPID, KRL).

Robot programming languages are crucial for instructing robots to perform specific tasks. Two prominent examples are RAPID (used primarily by ABB robots) and KRL (used by KUKA robots). While they differ syntactically, they share the fundamental goal of defining robot movements, actions, and interactions with the environment.

RAPID is a structured, Pascal-like language. It allows for complex program structures, including functions, procedures, and modules, promoting code reusability and organization. Imagine it like building with LEGOs—you can create intricate structures by combining pre-built blocks (functions/modules) and basic instructions. Example:

MoveL p1, v100, z10, tool0; // Move to point p1 at speed v100, zone z10, using tool0This line moves the robot to a predefined point.

KRL (KUKA Robot Language) is a more text-based language, often compared to a simpler scripting language. It’s known for its relative ease of learning, especially for users with less programming experience. Think of it as giving instructions in a simpler, more direct way. While it can handle complex tasks, it may require more lines of code compared to RAPID for equally complex functions. An example:

PTP HOME; // Moves the robot to the home positionEach language provides a set of commands for movement (linear, circular, point-to-point), I/O control (interfacing with sensors and actuators), and error handling. The choice between them depends on the specific robot manufacturer and the complexity of the application. For example, a large-scale automotive application might prefer RAPID’s advanced features, while a simpler pick-and-place task might utilize KRL’s straightforward syntax.

Q 9. How would you handle a robot collision during operation?

Handling robot collisions requires a multi-faceted approach that prioritizes safety and minimizing damage. The first line of defense is preventative: thorough risk assessment, proper programming, and using safety features built into the robot controller are essential. This is like having a robust seatbelt system in a car—it’s the first thing preventing serious consequences.

If a collision occurs, the immediate action is to stop the robot. Most controllers have emergency stop buttons and safety circuits that automatically halt operation upon detecting a collision. These are like your car’s airbags—they react immediately to an impact.

Following the immediate stop, investigation is critical. Determine the cause of the collision—was it a programming error, sensor malfunction, or unexpected obstacle? Analyzing data logged by the robot controller, such as joint positions and speeds at the moment of impact, is invaluable for identifying the root cause. This data is similar to an accident investigation report—it provides clues to how things went wrong.

After identifying the cause, corrective actions must be taken: this could involve reprogramming the robot, recalibrating sensors, redesigning the work cell layout, or implementing additional safety measures, such as light curtains or safety scanners. This is like fixing the issue that caused the car accident—addressing the root cause to prevent future incidents.

Finally, regular maintenance and operator training are vital in preventing future collisions. Preventative maintenance is like regular car servicing—it reduces the likelihood of mechanical failure contributing to accidents.

Q 10. What are the advantages and disadvantages of using vision systems in robotics?

Vision systems significantly enhance robot capabilities by providing the ‘eyesight’ robots lack. They enable robots to perceive their environment, identify objects, and react accordingly, opening up a wide range of applications beyond pre-programmed tasks.

Advantages:

- Flexibility: Vision systems allow robots to handle variations in object position, orientation, and appearance. Imagine a robot tasked with picking parts from a conveyor belt—a vision system ensures it can pick the correct part even if it’s slightly shifted or rotated.

- Improved Accuracy: Vision-guided robots can achieve higher precision in tasks such as assembly, welding, and inspection, surpassing human capabilities in repetitive tasks. Think of a robotic arm placing tiny components onto a circuit board—vision ensures perfect alignment.

- Automation of Complex Tasks: Vision systems enable robots to perform tasks that would be impossible or extremely difficult without them, such as bin picking (selecting parts from a jumbled bin) or quality inspection of intricate parts.

Disadvantages:

- Cost: Implementing vision systems can be expensive, requiring specialized hardware (cameras, lighting), software, and integration expertise.

- Complexity: Integrating and programming vision systems can be challenging, requiring specialized knowledge in computer vision and image processing. It’s not as simple as plug-and-play.

- Lighting Sensitivity: The performance of vision systems is highly sensitive to lighting conditions, requiring careful planning and control of lighting to ensure reliable operation. Poor lighting can render the vision system ineffective.

- Computational Demands: Processing images and analyzing data in real-time can be computationally intensive, demanding powerful processors.

Overall, the advantages often outweigh the disadvantages, especially in applications requiring high precision, flexibility, and automation of complex tasks. Careful planning, selecting the right hardware and software, and addressing lighting challenges are key to successful integration.

Q 11. Describe your experience with robot end-effectors and their selection process.

End-effectors are the ‘hands’ of a robot, the tools or devices attached to the robot’s wrist to perform specific tasks. Selecting the appropriate end-effector is crucial for efficient and safe operation. My experience spans various types, including grippers, welding torches, and specialized tools.

The selection process begins with a thorough understanding of the task. For example, a delicate assembly task requires a gripper with soft jaws and precise control, whereas a heavy-duty material handling task demands a robust gripper with high gripping force. It’s like choosing the right tool for a job—a screwdriver for screws, a hammer for nails.

Factors to consider include:

- Payload capacity: The weight the end-effector can handle.

- Reach and dexterity: The ability to reach into confined spaces and manipulate objects.

- Gripping force and type: The force needed to securely hold the object and the type of gripping mechanism (e.g., parallel, angular, vacuum).

- Interface compatibility: Ensuring the end-effector is compatible with the robot’s flange and communication protocols.

- Environmental considerations: Factors like temperature, humidity, and corrosive substances.

I’ve worked on projects requiring custom-designed end-effectors to meet specific application needs. For instance, a project involved designing a specialized vacuum gripper for handling fragile glass components. This required careful consideration of suction pressure, nozzle design, and material selection to avoid damaging the components. It was a rewarding experience because we found a solution that optimized both speed and delicate handling.

Q 12. Explain the concept of robot work envelope and its significance.

The robot work envelope defines the three-dimensional space within which a robot can move its end-effector. It’s the robot’s reach, encompassing all points reachable by the end-effector without collisions. Think of it as the robot’s ‘sphere of influence.’

Understanding the work envelope is critical during robot cell design and programming. It determines the robot’s reachable area for tasks and influences factors like:

- Cell layout: The placement of workpieces, fixtures, and other equipment needs to be within the robot’s reach.

- Part accessibility: Ensuring the robot can access all sides and orientations of the workpiece.

- Program feasibility: A program is only feasible if it involves movements within the robot’s work envelope. It’s like planning a journey—you can only reach destinations within your car’s range.

- Safety: Ensuring the work envelope is clear of obstacles and personnel to avoid collisions.

The work envelope varies depending on the robot’s configuration (articulated, SCARA, etc.), arm length, and joint limitations. Software tools and simulations are used to visualize and optimize the work envelope to maximize efficiency and minimize interference. Precise work envelope knowledge reduces errors and improves production efficiency.

Q 13. How do you perform robot path planning and optimization?

Robot path planning and optimization is crucial for efficient and safe operation. It involves determining the sequence of movements required for the robot to accomplish a task while considering factors like speed, accuracy, and avoiding collisions.

The process typically involves:

- Path generation: Defining the desired path using various techniques. This might involve specifying waypoints, using spline interpolation to create smooth curves, or utilizing advanced algorithms that consider obstacle avoidance.

- Collision detection: Verifying that the planned path doesn’t lead to collisions with the robot itself, surrounding equipment, or other obstacles. This often involves using software tools that simulate the robot’s movement in a 3D environment.

- Optimization: Refining the path to improve performance metrics. This could involve minimizing path length, reducing travel time, or optimizing energy consumption. Algorithms exist to minimize these factors.

- Validation: Simulating the optimized path to ensure it functions correctly and meets performance criteria before deploying it on the physical robot.

Several optimization techniques are used, including:

- Shortest path algorithms: Algorithms such as A* search find the shortest path between points, minimizing travel time.

- Smoothing algorithms: Algorithms such as cubic splines smooth out the path, reducing jerky movements and improving accuracy.

- Dynamic path planning: Algorithms that consider robot dynamics, such as inertia and joint limits, to generate paths that are both efficient and feasible.

Software tools often combine these techniques, allowing engineers to visualize and optimize the robot path before deployment. I have used such tools in my work, often finding that optimized paths reduced cycle times by 10-15%, increasing overall productivity.

Q 14. What are the different types of robot sensors and their applications?

Robot sensors provide crucial feedback to the robot controller, allowing it to perceive its environment and react accordingly. Different types of sensors cater to different needs. The choice depends heavily on the application.

Types and Applications:

- Proximity Sensors: Detect the presence of an object without physical contact. Common types include inductive, capacitive, and ultrasonic sensors. These are useful for detecting approaching obstacles or confirming object presence.

- Force/Torque Sensors: Measure forces and torques applied to the robot end-effector. Essential for tasks requiring precise interaction with objects, such as assembly and delicate handling. They help the robot adjust its grip or movement based on feedback.

- Vision Systems (Cameras): Provide visual information about the environment. As discussed earlier, they enable robots to identify, locate, and manipulate objects, and also used for quality inspection.

- Laser Scanners/LIDAR: Create a 3D map of the environment by emitting and detecting laser beams. Used for navigation, obstacle avoidance, and mapping in autonomous robots.

- Encoders (Joint Position Sensors): Measure the position and speed of the robot’s joints, ensuring accurate movement control. They’re foundational for precise motion.

- Tactile Sensors: Detect contact and pressure between the robot and an object. Provide detailed tactile feedback essential for sensitive operations. Think of robotic fingertips.

The selection of sensors is determined by the specific application requirements. A simple pick-and-place operation might only need proximity sensors, whereas a complex assembly task would likely require a combination of force/torque sensors, vision systems, and encoders for precise control. A robotic surgery application might utilize many specialized tactile sensors and extremely high-precision force/torque sensors.

Q 15. Describe your experience with robot maintenance and preventive maintenance schedules.

Robot maintenance is crucial for ensuring operational efficiency, safety, and longevity. My experience encompasses both preventative and corrective maintenance across various FANUC and ABB robots. Preventative maintenance schedules are meticulously planned, typically involving regular lubrication of joints, inspection of cables and wiring for wear and tear, and verification of sensor functionality.

For example, on a FANUC R-2000iB robot used in a welding cell, our preventative schedule included weekly lubrication of all joints, monthly inspection of the welding torch and cable, and quarterly checks of the robot’s safety systems and emergency stops. This involved detailed logging of all maintenance activities, noting any anomalies detected. We also conducted more comprehensive checks every six months, which included thorough visual inspections, torque checks on fasteners, and testing of the robot’s various control functions.

Corrective maintenance, on the other hand, addresses unexpected failures or malfunctions. This typically involves troubleshooting error codes, identifying faulty components, and implementing repairs. My experience includes diagnosing and resolving issues such as servo motor failures, sensor malfunctions, and software glitches. A systematic approach, utilizing the robot’s diagnostic tools and manufacturer’s manuals, is essential for effective troubleshooting. Proper documentation of all corrective actions is crucial for future reference and tracking maintenance history.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain different robot control strategies (e.g., point-to-point, continuous path).

Robot control strategies dictate how a robot moves and performs tasks. Two common types are point-to-point and continuous path control.

- Point-to-Point (PTP): In PTP control, the robot moves from one specified point to another in a rapid, straight-line motion. This is ideal for tasks requiring movement between discrete locations, like pick-and-place operations. Think of a robotic arm picking items off a conveyor belt and placing them in a box—each pick and place is a point, and the robot swiftly moves between these points. The robot’s speed and acceleration are usually programmable, allowing optimization for the task.

- Continuous Path (CP): CP control allows the robot to follow a defined path, often a complex curve or trajectory. This is necessary for tasks requiring smooth, precise movement, like painting, welding, or sealant application. Imagine a robot arm painting a car; it needs to smoothly follow the contours of the car’s body. The path is typically defined using a series of points, but the robot’s movements are interpolated to create a continuous and fluid motion. CP typically utilizes higher-level programming capabilities compared to PTP.

Other strategies include joint interpolation (controlling individual joint movements), and circular interpolation (moving the robot along a circular arc), each suited to different robotic tasks and applications.

Q 17. How would you integrate a new robot into an existing production line?

Integrating a new robot into an existing production line requires careful planning and execution. It’s a multi-stage process that involves:

- Needs Assessment: Define the specific task the robot will perform and the required specifications (reach, payload, speed, accuracy).

- Robot Selection: Choose a robot model that meets the requirements, considering factors such as workspace constraints, available power and communication interfaces, and integration with existing PLC systems.

- Cell Design: Design the robotic cell, including the robot’s base, end-effector (gripper), safety features (light curtains, emergency stops), and any required peripherals (conveyors, vision systems).

- Programming: Develop and test the robot’s program, ensuring smooth integration with other machines and devices in the production line. This may involve utilizing offline programming software for simulating the robot’s actions before deployment.

- Integration: Physically install the robot and connect it to the production line’s control system, ensuring proper communication and data flow.

- Testing and Commissioning: Thoroughly test the integrated system to ensure it functions correctly and meets performance specifications. This typically involves running several test cycles to identify and rectify any glitches.

- Training: Train operators on safe operation and maintenance of the new robotic system.

Throughout this process, collaboration with engineers, technicians, and operators is critical for a successful integration.

Q 18. Describe your experience with robot safety standards (e.g., ISO 10218).

Robot safety is paramount. My experience aligns closely with ISO 10218, which defines safety requirements for industrial robots. This standard outlines crucial aspects like risk assessment, safety design, and safeguarding measures.

Specifically, my experience includes implementing safety features such as light curtains, pressure-sensitive mats, and emergency stop buttons. These features create safeguarded spaces around the robot, ensuring that the robot’s operation is halted if a person enters these zones. I’ve also been involved in designing and implementing interlocks, which ensure that the robot cannot operate unless specific safety conditions are met (like the guarding system being properly in place). Furthermore, I’ve worked with risk assessments to identify potential hazards and determine the appropriate safety measures to mitigate them. This often includes reviewing the robot’s operational parameters (speed, acceleration, payload) to ensure they are within safe limits. Regular safety audits and inspections are also a significant part of my experience to verify the continued efficacy of safety measures and ensure compliance with ISO 10218.

Q 19. Explain your experience with different robot programming techniques (e.g., offline programming).

I’m proficient in various robot programming techniques. Traditional methods involve using the robot’s teach pendant to manually guide the robot through its movements. This approach is suitable for simple tasks but can be time-consuming and less efficient for complex operations.

Offline Programming (OLP): OLP is a powerful technique that allows programmers to create and test robot programs off-line, using simulation software. This eliminates the need to stop production for programming. I’ve extensively used software packages like RoboDK and ABB RobotStudio to simulate robot movements, optimize programs, and detect potential collisions before deployment to the actual robot. This approach significantly reduces downtime and increases overall productivity. For example, I used OLP to program a FANUC robot for a complex part-handling task, simulating the entire process in RoboDK to ensure proper functionality and prevent potential collisions before implementing the program on the actual robot.

Other techniques include using RAPID (ABB) or Karel (FANUC) programming languages for more intricate control and custom functionality.

Q 20. How would you perform a risk assessment for a robotic application?

A risk assessment for a robotic application is a systematic process to identify potential hazards and determine appropriate control measures. It typically follows a structured approach:

- Hazard Identification: Identify all potential hazards associated with the robotic application, including collisions, crushing, entanglement, electrical hazards, and noise. This involves a thorough review of the robotic cell’s design, operation, and environment.

- Risk Analysis: Analyze the likelihood and severity of each identified hazard, considering factors like the frequency of exposure, the potential for injury, and the effectiveness of existing safety measures.

- Risk Evaluation: Evaluate the overall risk level associated with each hazard, typically using a risk matrix. This matrix helps prioritize hazards based on their potential impact.

- Risk Control: Develop and implement control measures to mitigate the identified risks. This could include implementing safety guards, emergency stops, speed limits, interlocks, and worker training programs. The choice of control measures depends on the risk level and the feasibility of implementation.

- Verification and Monitoring: Verify that the implemented control measures are effective and monitor the robotic application’s performance to ensure continued safety.

Documentation of the entire risk assessment process, including hazard identification, risk analysis, risk evaluation, control measures, and verification results, is essential for compliance and future reference.

Q 21. Describe your experience with different types of robotic grippers.

Robotic grippers are end-of-arm tooling that enables robots to grasp and manipulate objects. The choice of gripper depends on the specific application and the characteristics of the object being handled.

My experience includes working with a variety of grippers, including:

- Two-finger grippers: Simple and versatile, suitable for many applications. They can be pneumatic, electric, or hydraulic. I used these extensively for pick-and-place operations in automotive assembly.

- Three-finger grippers: Offer more dexterity and stability compared to two-finger grippers, enabling them to handle objects of various shapes and sizes. These are common in applications requiring precise manipulation.

- Vacuum grippers: Ideal for handling flat or smooth objects. They provide a non-marring grip and are commonly used in applications handling delicate items like printed circuit boards.

- Magnetic grippers: Suitable for handling metallic objects. They are effective for quick and easy picking and placing of ferrous materials.

- Adaptive grippers: These grippers can adjust their shape and grip force to accommodate a wide range of object sizes and shapes. They usually include advanced sensing and control systems.

The selection of a gripper also involves considering factors like gripping force, speed, repeatability, and durability. Proper selection ensures efficient and safe manipulation of objects.

Q 22. Explain the concept of robot kinematics and dynamics.

Robot kinematics and dynamics are fundamental concepts in robotics that describe the robot’s motion. Kinematics deals with the geometry of motion – the position, velocity, and acceleration of the robot’s links and joints without considering the forces and torques causing the motion. Think of it like describing the path a car takes without considering the engine power or brakes. Dynamics, on the other hand, incorporates the forces and torques acting on the robot, considering factors like inertia, gravity, and friction. This is like understanding not just the car’s path but also how the engine, brakes, and other forces influence that path.

In practice, kinematic analysis is crucial for path planning and trajectory generation. We use kinematic equations to determine the joint angles needed to reach a specific target position. Dynamic analysis, however, is essential for accurate control, especially for fast and complex movements. It allows us to predict the robot’s response to external forces and to design control systems that compensate for these effects, preventing instability or collisions. For instance, in a FANUC robot welding application, kinematic calculations determine the precise joint movements for smooth welding, while dynamic models predict the robot’s behavior under the load of the welding torch and its interaction with the workpiece.

- Forward Kinematics: Calculating the end-effector position and orientation given the joint angles.

- Inverse Kinematics: Calculating the required joint angles to achieve a desired end-effector position and orientation.

Q 23. How would you troubleshoot a robot’s servo motor error?

Troubleshooting a robot servo motor error requires a systematic approach. The first step is to identify the specific error code. Each robot manufacturer (like FANUC or ABB) has its own error code system. The code provides valuable clues about the problem’s location. Let’s imagine an ABB robot displays a servo error code indicating a problem with motor 3.

- Check the Error Log: The robot controller will have a detailed log of the error, including timestamp, motor, and possibly the cause. This is the starting point of your investigation.

- Visual Inspection: Examine the motor itself for any obvious physical damage – loose connections, damaged wiring, or unusual heat. Look for anything out of the ordinary.

- Power and Wiring: Verify that the motor is receiving proper power. Check the motor’s connections for tightness and any signs of damage. Sometimes a simple loose wire is the culprit.

- Sensor Check: Many servo motors utilize sensors like encoders for position feedback. These sensors might be malfunctioning, causing the error. This check might involve using a multimeter to test sensor signals.

- Calibration: If the problem is not immediately apparent, recalibrating the servo motor might resolve the issue. This is a procedure specific to the robot model and should be carried out according to the manufacturer’s instructions.

- Advanced Diagnostics: If the basic checks fail, more advanced diagnostic tools might be needed. These tools allow more detailed analysis of motor currents, voltages, and other parameters. Robot manufacturers often provide specific software for these diagnostics.

Remember safety is paramount. Before any physical intervention, always power down the robot and follow lockout/tagout procedures.

Q 24. Describe your experience with robotic simulation software.

I have extensive experience using various robotic simulation software packages, including RoboDK, RobotStudio (ABB), and ROBOGUIDE (FANUC). These tools are invaluable for offline programming, design, and testing of robotic systems.

In my previous role, we used RoboDK to simulate a complex palletizing application. We designed the robot cell virtually, including the robot, conveyor, and pallets. This allowed us to optimize the robot’s movements and ensure collision avoidance before implementing the system on the actual factory floor. The simulation identified several potential bottlenecks, such as insufficient reach and slow cycle times, which were addressed in the design phase saving significant time and resources. The ability to test different robot models and configurations within the simulation environment before physical implementation is a significant advantage. With RobotStudio, we were able to program and test complex welding paths before deploying them to ABB robots on a production line. This reduced downtime significantly and allowed for more efficient programming.

My experience also includes using these simulators for training purposes. Simulating realistic scenarios allows trainees to practice robot programming and troubleshooting in a safe environment, reducing the risk of damage to expensive equipment.

Q 25. Explain the concept of payload capacity in robotics.

Payload capacity refers to the maximum weight a robot can lift and manipulate while maintaining its performance specifications. It’s a critical consideration when selecting a robot for a particular application. Think of it like the maximum weight a truck can carry. Exceeding the payload capacity can lead to inaccurate movements, reduced speed, and even damage to the robot’s mechanical components or the end-effector (the robot’s ‘hand’).

The payload capacity is often specified at a certain reach. The farther the robot extends its arm, the less weight it can handle. This is because the leverage and stress on the joints increase with distance. For example, a robot might have a payload capacity of 10kg at a 1-meter reach but only 5kg at a 2-meter reach. Manufacturers typically provide payload charts that illustrate this relationship between reach and payload.

In selecting a robot, it’s crucial to consider not only the weight of the object being manipulated but also the weight of any tooling attached to the end-effector. For instance, if the robot needs to handle a 5kg part and the welding torch weighs 2kg, you would need a robot with at least a 7kg payload capacity.

Q 26. What are the advantages and disadvantages of using collaborative robots (cobots)?

Collaborative robots, or cobots, are designed to work safely alongside humans without the need for protective cages. This offers several advantages:

- Increased Safety: The inherent safety features minimize the risk of human injury. Cobots usually have sensors that stop their movement upon contact.

- Flexibility and Ease of Programming: They are typically easier to program than traditional industrial robots, often requiring less specialized training.

- Reduced Costs: The absence of safety cages lowers the initial investment and reduces floor space requirements.

- Improved Productivity: Cobots can perform repetitive or dangerous tasks, freeing up human workers to focus on more complex or creative tasks.

However, cobots also have some disadvantages:

- Lower Payload Capacity: Compared to traditional industrial robots, cobots generally have lower payload capacities.

- Slower Speed: Their speed is often limited for safety reasons.

- Limited Reach and Workspace: Their working range might be smaller than that of traditional robots.

- Higher Cost per kg of Payload: While the initial investment is lower, the cost per kilogram of payload can be higher.

The choice between a cobot and a traditional industrial robot depends on the specific application and requirements.

Q 27. How would you design a robotic cell for a specific application?

Designing a robotic cell involves a systematic approach. Let’s consider a robotic cell for a part-picking application from a conveyor:

- Define the Application: Clearly specify the task, including the type of parts, throughput requirements, and accuracy needed.

- Select the Robot: Choose a robot with the appropriate payload capacity, reach, and speed based on the application requirements.

- Design the End-Effector: Design a gripper or other end-effector capable of handling the parts safely and effectively. Consider factors such as part geometry, weight, and material.

- Layout Planning: Arrange the robot, conveyor, parts feeder, and any other necessary equipment in an efficient layout, optimizing for workspace, accessibility, and safety. Simulation software helps significantly at this stage.

- Safety Considerations: Implement safety features such as light curtains, emergency stops, and appropriate guarding to protect human workers.

- Programming: Develop the robot program to control its movements, ensuring accurate part picking and placement. This often involves using robot-specific programming languages.

- Testing and Optimization: Thoroughly test the cell to ensure it meets the performance specifications. Adjust the robot program and cell layout as needed to optimize efficiency.

Throughout this process, collaboration with engineers from various disciplines—mechanical, electrical, and software—is vital to ensure a robust, efficient, and safe robotic cell.

Q 28. Describe your experience with different types of robot joints (e.g., revolute, prismatic).

Robot joints are the articulation points that allow for robot movement. Two primary types are revolute and prismatic:

- Revolute Joints (R): These joints allow for rotational movement, like a human elbow or shoulder. Most industrial robots heavily use revolute joints. Think of the robotic arm’s ability to rotate around its axis.

- Prismatic Joints (P): These joints allow for linear movement, like a drawer sliding in and out. These are less common as primary joints in industrial manipulators but can be found in certain applications requiring linear extension or retraction. Examples include linear actuators used in certain robotic assembly lines.

Other types include spherical joints (allowing rotation about three axes) and screw joints (combining rotation and translation). The combination of different joint types determines the robot’s degrees of freedom (DOF), defining its range of motion. A six-DOF robot, for instance, can move its end-effector to any position and orientation in its workspace. The specific arrangement and types of joints significantly impact the robot’s workspace, dexterity, and ability to reach different points.

My experience spans various robots from FANUC (known for their extensive use of revolute joints in their articulated arms) and ABB (offering robots with varied joint configurations, including both revolute and prismatic joints depending on the robot model and application) showcasing proficiency in working with the diverse kinematic structures prevalent across industrial automation.

Key Topics to Learn for Robotics (FANUC, ABB, etc.) Interview

- Robot Kinematics and Dynamics: Understanding robot arm configurations (e.g., revolute, prismatic), forward and inverse kinematics, Jacobian matrices, and dynamic modeling for accurate control and path planning.

- Robot Programming and Control: Experience with programming languages like RAPID (ABB), Karel (FANUC), or other relevant languages. Understanding control systems, including PID controllers and trajectory generation techniques.

- Robot Sensors and Vision Systems: Familiarity with various sensors (e.g., force/torque sensors, proximity sensors, laser scanners) and their integration with robots. Knowledge of computer vision techniques for object recognition and manipulation.

- Robot Safety and Standards: Understanding safety protocols, risk assessments, and relevant industry standards (e.g., ISO 10218) for safe robot operation and integration.

- Industrial Applications of Robotics: Practical experience or knowledge of robotics applications in various industries (e.g., automotive, manufacturing, logistics). Be prepared to discuss specific case studies or projects.

- Troubleshooting and Maintenance: Understanding common robot malfunctions, diagnostic techniques, and preventative maintenance procedures for minimizing downtime.

- PLC and Integration: Knowledge of Programmable Logic Controllers (PLCs) and how robots integrate with other automation systems within a larger production environment.

- Simulation and Offline Programming: Experience using robot simulation software for offline programming, testing, and optimization of robot programs.

Next Steps

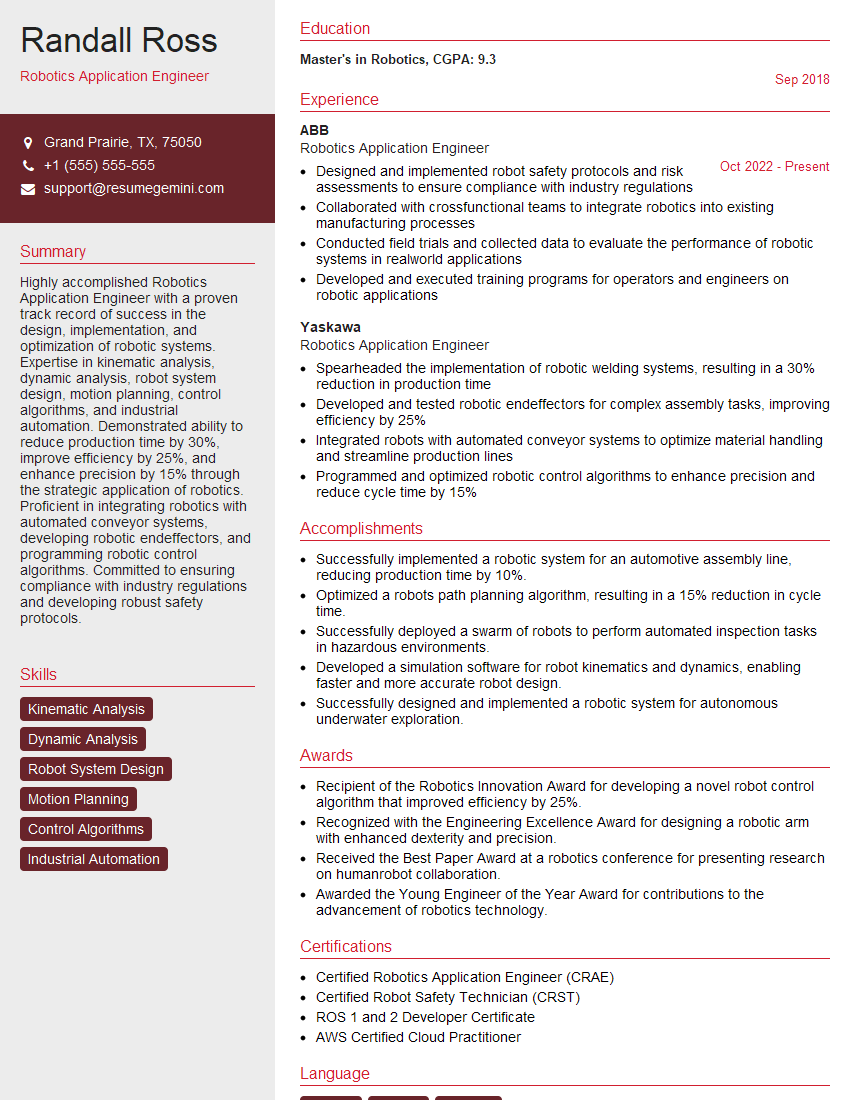

Mastering robotics skills opens doors to exciting and high-demand careers in a rapidly evolving field. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. This ensures your qualifications are effectively communicated to potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your expertise. Examples of resumes tailored to robotics positions with FANUC, ABB, and other leading companies are available to guide you. Take the next step towards your dream career in robotics – build your best resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?