Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Rubber Compounding Optimization interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Rubber Compounding Optimization Interview

Q 1. Explain the role of different fillers in rubber compounding.

Fillers are crucial in rubber compounding, acting as extenders, reinforcing agents, or modifiers of specific properties. They significantly impact the cost, performance, and processability of the final rubber product. Think of them as the ‘secret ingredients’ that tailor the rubber to its intended application.

- Reinforcing Fillers: These increase the strength and stiffness of the rubber. Carbon black is the most common example, providing excellent tensile strength, abrasion resistance, and tear strength.

- Extender Fillers: These reduce the cost by replacing a portion of the more expensive rubber. Examples include calcium carbonate and clay. They typically don’t improve strength but can influence other properties like hardness and processability.

- Speciality Fillers: These are added for specific performance enhancements. Silica, for instance, offers excellent grip in wet conditions and is often used in tire applications. Other examples include talc, which improves processing, and zinc oxide, which acts as an activator for vulcanization.

The choice of filler depends heavily on the desired properties of the final rubber product. For instance, a high-performance tire will use a significant amount of reinforcing filler like carbon black, while a general-purpose rubber part might utilize a blend of extender and reinforcing fillers to achieve a balance of cost and performance.

Q 2. Describe the effects of carbon black on rubber properties.

Carbon black is a ubiquitous reinforcing filler in rubber compounding, profoundly impacting numerous properties. Its effects stem from its high surface area and structure, allowing for strong interactions with the rubber matrix.

- Increased Tensile Strength and Modulus: Carbon black creates a stronger, stiffer rubber due to its interaction with the polymer chains. Imagine it as a reinforcing mesh within the rubber, strengthening its overall structure.

- Enhanced Abrasion Resistance: The tough, carbon black particles protect the rubber surface from wear and tear, extending its lifespan. This is vital for applications like tires and conveyor belts.

- Improved Tear Strength: The strong bonds between carbon black and rubber resist tearing, ensuring durability. Think of it like adding reinforcing fibers to a fabric.

- Increased Hardness: Higher carbon black loadings generally lead to a harder rubber compound.

- Improved Heat Resistance: Carbon black can help dissipate heat, enhancing the rubber’s performance at higher temperatures.

However, excessive carbon black can also negatively affect certain properties. It might increase viscosity, making processing more difficult, and can reduce elasticity and flexibility.

Q 3. What are the key factors influencing the cure characteristics of a rubber compound?

The cure characteristics of a rubber compound, essentially how quickly and completely it vulcanizes (cures), are influenced by several interacting factors. Understanding these is crucial for consistent and optimized production.

- Type and amount of curing agent (vulcanizing agent): Sulfur is the most common, but others like peroxides are used for specific rubber types. The amount directly dictates the cure rate and degree of crosslinking.

- Type and concentration of accelerators: These speed up the vulcanization process. Different accelerators have varying levels of activity and influence the cure kinetics.

- Type and amount of activators: These work in conjunction with accelerators to enhance the curing process. Zinc oxide is a commonly used activator.

- Temperature: Higher temperatures generally accelerate the cure reaction.

- Filler type and loading: Certain fillers can interact with the curing system, either accelerating or retarding the cure.

- Rubber type: Different rubbers have different cure characteristics, requiring adjustments in the compounding recipe.

Think of it like baking a cake: The recipe (compound formulation), oven temperature (cure temperature), and baking time (cure time) all work together to determine the final product’s quality.

Q 4. How do you determine the optimal cure temperature and time for a specific rubber compound?

Determining optimal cure temperature and time involves a combination of laboratory testing and experience. A rheometer is essential here.

- Rheometer Testing: A rheometer measures the torque developed during vulcanization as a function of time and temperature. This provides a cure curve showing the scorch time (onset of cure), optimum cure time (maximum torque), and the post-cure region. These curves are generated at different temperatures.

- Data Analysis: Analyze the cure curves to identify the optimal cure time at various temperatures. Look for the point where the torque reaches a plateau (optimum cure) without significant further increase.

- Selection of Cure Parameters: Based on the rheometer data, select the temperature and time that yield the desired cure characteristics. Consider factors like production speed and the need to avoid premature cure (scorch) during processing.

- Validation: Verify the chosen parameters through physical testing of cured samples. Ensure that the properties (tensile strength, elongation, hardness, etc.) meet the specifications.

The process often involves iterative adjustments based on rheometer data and physical testing until optimal cure parameters are determined. This ensures consistent quality and efficient production.

Q 5. Explain the concept of Mooney viscosity and its importance in rubber compounding.

Mooney viscosity is a measure of the flow resistance of unvulcanized rubber at a specific temperature and rotor speed. It’s analogous to the viscosity of a liquid, but for a more complex viscoelastic material. It’s measured using a Mooney viscometer.

Importance in Rubber Compounding:

- Processability: Mooney viscosity directly affects the ease of processing. Higher viscosity indicates more resistance to flow, making mixing and shaping more challenging. Conversely, lower viscosity can lead to easier processing but might compromise the final product’s properties.

- Quality Control: Mooney viscosity is a key quality control parameter. Consistent Mooney viscosity ensures uniform processing and predictable final product properties. Any deviation indicates a potential problem in the raw materials or the compounding process.

- Compound Design: Rubber compounders use Mooney viscosity as a guide during formulation. Adjusting the filler type and loading can modify the viscosity to optimize processability without sacrificing final properties.

Imagine trying to pour honey (high viscosity) versus water (low viscosity). Similar to the honey, high Mooney viscosity indicates a more difficult processing. Mooney viscosity is a critical parameter that helps rubber compounders to understand the ‘flowability’ of the unvulcanized rubber.

Q 6. Describe different types of rubber testing equipment and their applications.

Various equipment is used to test the properties of rubber compounds. Here are some key examples:

- Mooney Viscometer: Measures the viscosity of unvulcanized rubber, as discussed earlier.

- Rheometer: Measures the cure characteristics (torque vs. time) of the rubber compound to determine optimal cure parameters.

- Tensile Tester: Determines the tensile strength, elongation at break, and modulus of cured rubber. This provides insights into the strength and elasticity of the material.

- Hardness Tester (Shore Durometer): Measures the hardness of cured rubber using a standardized scale (e.g., Shore A, Shore D).

- Abrasion Tester: Measures the resistance of rubber to wear and tear, indicating its durability.

- Tear Strength Tester: Measures the force required to propagate a tear in the rubber, assessing its tear resistance.

- Compression Set Tester: Measures the ability of rubber to recover its original shape after compression, a crucial property for seals and gaskets.

The choice of testing equipment depends on the specific properties being evaluated and the intended application of the rubber product.

Q 7. How do you interpret tensile strength, elongation, and hardness data for rubber compounds?

These three parameters provide a comprehensive assessment of the mechanical properties of a cured rubber compound. Let’s examine each:

- Tensile Strength: This indicates the maximum stress (force per unit area) that the rubber can withstand before breaking. A higher tensile strength indicates a stronger rubber. Think of it as the rubber’s resistance to being pulled apart.

- Elongation at Break: This represents the maximum percentage increase in length the rubber can sustain before failure. High elongation signifies good elasticity or flexibility. Imagine stretching a rubber band; the higher the elongation, the further it stretches before breaking.

- Hardness: This signifies the resistance of the rubber to indentation. Measured using a durometer, hardness provides insights into the stiffness of the rubber. Higher hardness generally indicates a stiffer material.

Interpreting this data requires considering the intended application. For example, a tire needs high tensile strength and abrasion resistance, while a rubber band requires high elongation. Analyzing these three properties together provides a complete picture of the rubber’s suitability for a specific purpose. Inconsistencies can point to potential issues with the compounding process or raw materials.

Q 8. What are the common causes of scorch in rubber compounding and how can they be prevented?

Scorch, in rubber compounding, refers to the premature curing of the rubber mix before it’s actually vulcanized in the mold. Imagine trying to bake a cake before you’ve even fully mixed the ingredients – the result would be disastrous! Similarly, scorch leads to uneven curing, weak points, and ultimately, a faulty rubber product.

- High temperatures: Excessive heat during mixing or storage can accelerate the curing reaction, leading to scorch. Think of leaving the cake batter in a hot car – it’ll start to cook prematurely.

- Improperly balanced formulations: An imbalance in the curing system (e.g., too much accelerator or too little sulfur) can drastically speed up the curing reaction. This is akin to using too much baking powder in your cake recipe; it’ll rise too quickly and unevenly.

- Contamination: Metallic impurities or other contaminants can act as catalysts, speeding up the curing process. It’s like accidentally adding salt instead of sugar – it changes the whole reaction.

- Degradation of antioxidants: Antioxidants help prevent premature curing. If they’re depleted or ineffective, the mix is more susceptible to scorch. This is comparable to a cake’s preservatives wearing off, making it spoil faster.

Prevention involves careful control of mixing temperatures, precise ingredient weighing and compounding, scrupulous cleanliness of equipment, and the use of effective scorch retarders. Regular maintenance of equipment and proper storage of ingredients are crucial.

Q 9. Explain the importance of rheometer testing in rubber compounding.

Rheometer testing is an essential part of rubber compounding. It’s like a doctor’s checkup for your rubber mix, providing insights into its rheological properties (flow behavior) during the curing process. It allows us to predict how the rubber will behave during processing and in its final application.

A rheometer measures the torque (resistance to deformation) of the rubber compound as it’s heated under controlled conditions. This data gives us critical information about:

- Cure characteristics: We can determine the optimal cure time and temperature, ensuring consistent vulcanization. This prevents under-curing (resulting in a weak product) or over-curing (leading to degradation).

- Scorch time: This tells us how long the mix remains processable before it starts to scorch, providing valuable information for adjusting processing parameters.

- Rheological properties: This data reveals how the rubber will flow during molding or extrusion, impacting the final product’s shape and uniformity.

By optimizing the cure parameters based on rheometer data, manufacturers can improve processing efficiency and enhance product quality. This leads to consistent product performance, reduced waste, and improved production yields.

Q 10. Describe different types of rubber processing aids and their functions.

Rubber processing aids are essentially additives that enhance the workability and processability of the rubber compound. They act as helpers to improve various aspects of the manufacturing process.

- Peptizers: These chemicals break down the rubber molecules, making the mix softer and easier to process. Think of them as softening agents that make the dough easier to knead.

- Plasticizers: These reduce the viscosity of the rubber compound, allowing for better flow during mixing and processing. They’re like adding oil to a cake batter to make it smoother and easier to spread.

- Tackifiers: These increase the stickiness or adhesion of the rubber mix, aiding in the bonding of different layers or components. They’re like glue for rubber, allowing layers to stick together firmly.

- Dispersing agents: These aid in the uniform distribution of fillers and other additives within the rubber matrix. Imagine them as emulsifiers, preventing separation in a mixture.

The choice of processing aid depends on the specific rubber type and the desired properties of the final product. For example, a highly filled compound might require a higher dosage of dispersing agents to maintain a uniform dispersion and prevent clumping. Proper selection leads to improved processing efficiency and the desired final product properties.

Q 11. How do you select appropriate antioxidants and antiozonants for a rubber compound?

Antioxidants and antiozonants are crucial for protecting rubber compounds from degradation caused by oxidation and ozone. Oxidation is like rust for rubber, and ozone attacks its structure, causing cracking.

The selection depends on factors like the type of rubber, the intended application, and the anticipated environmental conditions. For example:

- Type of rubber: Different rubbers have different susceptibilities to oxidation and ozone attack. Natural rubber is known to be more susceptible to ozone cracking than many synthetic rubbers.

- Application: Outdoor applications (e.g., tires, hoses) face significant exposure to both oxidation and ozone, requiring stronger and more robust protection than indoor applications.

- Environmental conditions: High temperatures, UV radiation, and high ozone concentrations necessitate the use of more effective antioxidants and antiozonants.

The process often involves testing different combinations to find the optimal balance of protection and cost. Several types of antioxidants and antiozonants exist, including hindered phenols, aromatic amines, and waxes. A well-designed formulation employs a carefully chosen blend for maximum protection.

Q 12. Explain the impact of processing conditions on the properties of a rubber compound.

Processing conditions significantly impact the final properties of a rubber compound. It’s like baking a cake – the oven temperature, baking time, and even the mixing technique all influence the final product’s texture and taste.

Factors like mixing time, temperature, and shear rate affect the dispersion of fillers, the degree of mixing, and the development of the network structure. Improper processing can lead to:

- Poor dispersion of fillers: Resulting in uneven properties and reduced mechanical strength.

- Incomplete mixing: Leading to variations in properties and performance.

- Excessive heat buildup: Causing degradation and scorch.

- Inconsistent cure: Resulting in weak or brittle areas within the final product.

Careful control of these parameters is essential for achieving the desired properties. For example, increasing the mixing time might improve filler dispersion but could also increase heat buildup and lead to scorch. Therefore, optimization is crucial, often involving experimentation and analysis to find the ideal balance.

Q 13. Describe the differences between natural rubber and synthetic rubber.

Natural rubber (NR) and synthetic rubbers differ significantly in their origin, chemical structure, and properties. Imagine comparing a handcrafted, natural material to a precisely engineered synthetic one.

- Origin: NR is harvested from the sap of the Hevea brasiliensis tree. Synthetic rubbers are manufactured from petroleum-based or other chemical sources.

- Chemical structure: NR is primarily cis-1,4-polyisoprene. Synthetic rubbers encompass a wide range of polymers with diverse chemical structures, tailoring their properties to specific applications.

- Properties: NR possesses excellent elasticity, resilience, and tack but is susceptible to degradation from oxidation and ozone. Synthetic rubbers offer a broader range of properties, allowing for customization based on the desired application (e.g., high tensile strength, resistance to chemicals or heat). For example, Styrene-Butadiene Rubber (SBR) offers good abrasion resistance, while Nitrile Rubber (NBR) excels in oil resistance.

The choice between NR and synthetic rubber depends on the specific application and the required properties. NR excels in applications demanding high elasticity and resilience, while synthetic rubbers provide more flexibility in tailoring properties to meet diverse demands.

Q 14. What are the different types of rubber mixing equipment and their capabilities?

Various types of rubber mixing equipment are available, each with specific capabilities and applications. Choosing the right equipment is like selecting the right tool for a specific job.

- Internal mixers (Banbury mixers): These are high-shear mixers used for compounding large batches of rubber. They generate intense heat and shear, promoting efficient mixing and dispersion of fillers. They are ideal for high-volume production.

- External mixers (roll mills): These use two counter-rotating rolls to mix and refine the rubber compound. They are better suited for smaller batches and allow for greater control over mixing parameters. They are often used for refining and finishing operations.

- Kneaders: These are similar to internal mixers but with a more gentle mixing action, suitable for compounds sensitive to high shear forces.

- Extruders: While primarily used for shaping the rubber compound, they also contribute to mixing and homogenization. This is particularly true for continuous compounding processes.

The selection of mixing equipment is based on factors such as batch size, the type of rubber compound, required mixing intensity, and the desired final product properties. Each mixer has its strengths and limitations, and understanding these nuances is essential for efficient and effective rubber compounding.

Q 15. Explain the principles of extrusion and molding in rubber processing.

Rubber processing utilizes several techniques to shape and cure the compound. Extrusion and molding are two primary methods. Extrusion is like squeezing toothpaste from a tube – a continuous process where the rubber compound is forced through a die to create a consistent profile, like hoses or seals. Molding, on the other hand, is a shaping process where the rubber compound is placed into a mold cavity and cured under heat and pressure to conform to the desired shape. Think of making custom rubber parts.

- Extrusion: Involves a screw-fed extruder that melts and homogenizes the rubber compound before forcing it through a precisely engineered die. The die determines the final shape and size of the extruded product. This is a highly efficient method for producing long, continuous profiles.

- Molding: Includes several sub-processes like compression molding (placing the compound in a heated mold and applying pressure), transfer molding (forcing the compound into a closed mold), and injection molding (injecting the compound into a heated mold at high pressure). Molding offers greater design flexibility and is suitable for creating complex shapes.

The choice between extrusion and molding depends heavily on the desired product geometry, production volume, and cost considerations. For instance, producing large quantities of O-rings would lend itself well to compression molding, while producing long lengths of rubber tubing would be best suited for extrusion.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you optimize a rubber compound for specific applications like seals or belts?

Optimizing a rubber compound for specific applications requires a deep understanding of material properties and application demands. For example, seals require excellent elasticity and resistance to compression set (the permanent deformation after compression), while belts need high tensile strength and abrasion resistance. This optimization is done by carefully selecting the right combination of base polymers, fillers, and additives.

- Seals: Here, the focus is on achieving low compression set and good chemical resistance. We might incorporate high-performance polymers like fluoroelastomers (FKM) or silicone rubbers, combined with specific fillers to enhance the desired properties. The curing system would be tailored for optimal heat resistance and durability. The hardness would be adjusted to achieve a perfect balance between sealing ability and ease of installation.

- Belts: For belts, tensile strength and durability are key. We’d likely employ natural or synthetic rubbers reinforced with carbon black to enhance strength and tear resistance. Additives like antioxidants and antiozonants would protect against environmental degradation. The crosslink density (vulcanization) would be optimized for high tensile strength and resistance to fatigue.

The optimization process is iterative, involving multiple rounds of compounding, testing, and fine-tuning to meet the specific performance criteria defined for the application. This often involves using Design of Experiments (DOE) methodology for efficient optimization.

Q 17. What are the key factors affecting the durability and lifespan of a rubber product?

The durability and lifespan of a rubber product are influenced by a complex interplay of factors. Think of it like a house – if one component is weak, it can affect the whole structure.

- Polymer Selection: The choice of base polymer significantly impacts the overall durability. Natural rubber, for instance, is known for its excellent elasticity but poor resistance to ozone. Synthetic polymers offer a wider range of properties that can be tailored to specific needs.

- Compounding Ingredients: Fillers, such as carbon black or silica, influence strength, abrasion resistance, and other properties. Additives like antioxidants and UV stabilizers are essential for protecting against environmental degradation.

- Vulcanization: Proper vulcanization (crosslinking of polymer chains) is crucial for achieving the desired mechanical properties and durability. Insufficient or uneven cure can lead to premature failure.

- Environmental Factors: Exposure to heat, ozone, UV radiation, chemicals, and mechanical stress can degrade the rubber over time, shortening its lifespan. Proper material selection and design can mitigate these effects.

- Manufacturing Process: Inconsistent mixing, improper curing cycles, and defects introduced during processing can all affect the product’s long-term performance.

By carefully considering all these factors, we can create rubber products designed to last.

Q 18. Describe your experience with statistical process control (SPC) in rubber compounding.

Statistical Process Control (SPC) is invaluable in maintaining consistent quality in rubber compounding. We use SPC charts to monitor critical parameters like viscosity, Mooney viscosity, and cure characteristics throughout the entire process. This allows for early detection of variations or trends that might indicate problems.

In my experience, we’ve implemented control charts (X-bar and R charts, for example) for key properties. If a point falls outside the control limits or a pattern emerges (e.g., a consistent drift), it triggers an investigation into the root cause. This might involve examining the raw materials, processing equipment, or even the compounding recipe itself.

SPC isn’t just about detecting problems; it helps prevent them. By establishing baselines and control limits, we can identify variations early on, before they impact the quality of the final product. This results in improved process efficiency, reduced waste, and higher quality products. For instance, we used SPC to identify a variation in the batch-to-batch consistency of a filler material. This led to better supplier management and improved quality control of that ingredient.

Q 19. Explain your knowledge of different vulcanization systems.

Vulcanization is the process of crosslinking polymer chains to transform raw rubber into a more durable and useful material. Different systems achieve this crosslinking using various agents.

- Sulfur Vulcanization: This is the most common method, employing sulfur and accelerators to create crosslinks. It’s relatively inexpensive and provides good control over the curing process. The type and amount of sulfur and accelerators impact the final properties.

- Peroxide Vulcanization: Uses organic peroxides as crosslinking agents. This method is suitable for polymers that are difficult to cure with sulfur, like EPDM (ethylene propylene diene monomer) rubber. It offers good heat resistance but can be more expensive.

- Radiation Vulcanization: Employs ionizing radiation (gamma rays or electron beams) to initiate crosslinking. This offers exceptional control over the cure depth and is used for specific applications requiring high precision.

The choice of vulcanization system depends on the specific requirements of the application and the type of rubber being used. For example, sulfur vulcanization is frequently used for tire manufacturing because of its cost-effectiveness, while peroxide vulcanization is often preferred for products requiring superior heat resistance.

Q 20. How do you troubleshoot problems related to poor mixing or uneven cure in rubber compounding?

Troubleshooting poor mixing or uneven cure in rubber compounding requires a systematic approach.

- Poor Mixing: This can manifest as non-uniform distribution of fillers or additives in the compound. Possible causes include inadequate mixing time, insufficient mixing intensity (low rotor speed or incorrect mixing equipment), or inconsistent addition of ingredients. Troubleshooting involves checking mixing parameters, examining the mixing equipment, and analyzing the ingredient distribution in the final compound. Sometimes, a change in the mixing process or the type of mixer is necessary.

- Uneven Cure: This results in variations in the physical properties of the final product. Potential causes include uneven heat distribution within the mold, incorrect curing time or temperature, or insufficient crosslinking. Troubleshooting includes examining the cure profile, evaluating the heating system in the mold, and checking the curing parameters and adjusting them as needed. Sometimes, additives that control the cure rate could solve this issue.

In both cases, a combination of visual inspection, physical property testing, and potentially microscopic analysis can help identify the root cause. We also sometimes use thermal analysis (DSC or DMA) to check for any abnormalities in the cure process.

For example, I once encountered uneven cure in a compression molding process, which was traced to a malfunctioning heating element in the mold. Replacing the faulty element resolved the problem. In another instance, poor mixing led to uneven color distribution in a final product, solved by increasing the mixing time.

Q 21. Describe your experience with different types of rubber polymers.

My experience encompasses a wide range of rubber polymers, each with unique characteristics suitable for different applications.

- Natural Rubber (NR): Excellent elasticity, low hysteresis, good resilience, but susceptible to ozone and oxidation.

- Styrene-Butadiene Rubber (SBR): Good abrasion resistance, lower cost than NR, versatile and used in many applications.

- Butyl Rubber (IIR): Excellent impermeability to gases, used in inner tubes and seals.

- Ethylene Propylene Diene Monomer (EPDM): Excellent weather resistance and ozone resistance, used in automotive parts and outdoor applications.

- Nitrile Rubber (NBR): Good oil resistance, used in seals and hoses requiring oil resistance.

- Chloroprene Rubber (CR or Neoprene): Good resistance to chemicals and ozone, used in various industrial applications.

- Silicone Rubber (VMQ): Excellent heat and cold resistance, used in high-temperature applications and medical devices.

- Fluoroelastomers (FKM): Exceptional chemical resistance, particularly to fuels and oils, used in demanding environments.

Selecting the right polymer is crucial for meeting the performance requirements of a given application. The choice often involves weighing cost-effectiveness against the necessary durability, resistance to specific chemicals or temperatures, and mechanical properties.

Q 22. How do you ensure the quality and consistency of rubber compounds?

Ensuring the quality and consistency of rubber compounds is paramount for producing reliable and durable products. It’s a multifaceted process involving rigorous control at every stage, from raw material selection to final product testing.

- Raw Material Control: We start by meticulously specifying the quality of our raw materials – polymers (natural rubber, SBR, EPDM, etc.), fillers (carbon black, silica, clay), and additives (antioxidants, vulcanizing agents, etc.). Each batch is tested to ensure it meets predetermined specifications. This often involves analyzing things like particle size distribution, specific gravity, and chemical composition.

- Compounding Process Control: The mixing process itself must be precisely controlled. Factors like mixing time, temperature, and the order in which ingredients are added significantly affect the final product’s properties. We use sophisticated mixing equipment with precise control systems, and regularly monitor parameters like torque and temperature to ensure uniformity.

- Quality Control Testing: Throughout the process, and especially at the end, rigorous quality control testing is essential. This includes physical tests like tensile strength, elongation at break, hardness, and tear resistance; and chemical tests to ensure the correct formulation. Statistical Process Control (SPC) charts help us track parameters and identify deviations from the norm promptly.

- Calibration and Maintenance: Regular calibration of our testing equipment and preventative maintenance of our compounding machinery are crucial for accuracy and consistent performance. A well-maintained system minimizes variability and unexpected issues.

For example, in one project involving a critical automotive part, a slight variation in the silica filler’s particle size distribution resulted in a noticeable change in the compound’s tensile strength. Through careful monitoring and adjustment of the compounding process, we were able to quickly identify and correct the issue, avoiding costly production delays and potential product failures.

Q 23. What are some common industry standards relevant to rubber compounding?

Several industry standards guide rubber compounding, ensuring safety, performance, and consistency across various applications. Some key standards include:

- ASTM (American Society for Testing and Materials): ASTM provides a vast library of standards covering various aspects of rubber testing, including physical properties (ASTM D412 for tensile properties), chemical analysis, and methods for evaluating aging resistance. These standards are widely referenced in the industry and provide a baseline for quality control.

- ISO (International Organization for Standardization): ISO standards offer international guidelines for rubber and related materials. These often overlap with ASTM standards but offer a broader, globally applicable perspective. ISO 14001, for instance, addresses environmental management systems, critical for sustainable practices in rubber compounding.

- SAE (Society of Automotive Engineers): The SAE offers standards specifically tailored to the automotive industry, defining requirements for rubber components used in vehicles. These standards cover aspects like temperature resistance, durability, and safety.

- Industry-Specific Standards: Besides these general standards, specific industries (e.g., aerospace, medical) may have their own stringent requirements for rubber compounds used in their applications. These often build upon the more general ASTM and ISO standards.

Compliance with these standards is vital for ensuring product quality, meeting regulatory requirements, and maintaining credibility in the marketplace.

Q 24. How do you handle and dispose of hazardous materials in a rubber compounding setting?

Handling and disposing of hazardous materials is a critical aspect of responsible rubber compounding. It requires strict adherence to safety regulations and best practices.

- Proper Storage: Hazardous materials are stored in designated areas, clearly labeled and segregated according to their compatibility. We use appropriate containers and follow strict inventory control to prevent accidents and ensure proper usage tracking.

- Personal Protective Equipment (PPE): All personnel involved in handling hazardous materials are required to wear appropriate PPE, such as gloves, respirators, and safety glasses, according to the specific hazards of each material. Regular training ensures proper use and disposal of PPE.

- Spill Response Plan: A comprehensive spill response plan is in place, outlining procedures for handling spills and leaks of hazardous materials. This plan includes detailed steps, emergency contact information, and the use of appropriate cleanup materials.

- Waste Management: Waste materials are disposed of according to local, regional, and national regulations. Hazardous waste is carefully segregated, labeled, and transported by licensed hazardous waste disposal companies. We maintain meticulous records of waste disposal to demonstrate compliance.

- Employee Training: Comprehensive training is provided to all employees handling hazardous materials. Training covers safe handling procedures, emergency response, and regulatory compliance. Refresher training is provided regularly.

For example, we have a detailed procedure for the disposal of spent solvents used in cleaning equipment, ensuring they are handled by a specialized waste disposal contractor with all necessary documentation.

Q 25. Explain your experience with design of experiments (DOE) in optimizing rubber compounds.

Design of Experiments (DOE) is an invaluable tool for optimizing rubber compounds. It allows us to efficiently investigate the effects of multiple variables on the desired properties of the compound, minimizing the number of experiments required.

In my experience, I’ve extensively used DOE methodologies like factorial designs and response surface methodology (RSM) to optimize various compound properties. For instance, in one project, we aimed to maximize the abrasion resistance of a tire tread compound while maintaining acceptable tensile strength. We used a full factorial design to study the effects of four factors: carbon black type, filler loading, processing oil type, and curing temperature. This allowed us to identify optimal combinations of these factors, resulting in a significantly improved abrasion resistance with only a minimal impact on other critical properties.

The use of statistical software packages like Minitab or JMP is crucial in analyzing the results and generating response surfaces or contour plots to visualize the optimal operating region. This data-driven approach significantly reduces reliance on trial-and-error experimentation, saving time and resources. DOE ensures a more scientific and efficient approach to compound development.

Q 26. Describe your experience with developing new rubber compounds to meet specific requirements.

Developing new rubber compounds to meet specific requirements often begins with a thorough understanding of the application. This includes understanding the intended use, operating conditions (temperature, stress, exposure to chemicals), and desired performance characteristics (strength, elasticity, durability, etc.).

I have extensive experience in this area. For example, I led the development of a new rubber compound for use in high-temperature seals in oil and gas applications. The key requirements were superior heat resistance, excellent chemical resistance to various oils and solvents, and adequate compression set resistance. We started by selecting appropriate high-temperature-resistant polymers, adding specialized additives to enhance resistance to oil and solvents. Through iterative testing and refinement of the formulation using DOE methodologies, we successfully developed a compound that far exceeded the initial performance targets.

This process frequently involves detailed material characterization, extensive testing using accelerated aging techniques, and close collaboration with engineers and end-users to validate the performance of the new compound in its intended application.

Q 27. How would you approach the problem of reducing the cost of a rubber compound without compromising performance?

Reducing the cost of a rubber compound without compromising performance requires a strategic approach. It’s not merely about reducing the quantity of expensive ingredients; it’s about finding cost-effective alternatives that maintain the desired properties.

- Material Substitution: Explore less expensive alternatives for fillers, polymers, or additives. This might involve using a different grade of carbon black, substituting some silica with a cheaper filler, or utilizing a less expensive processing oil. Careful evaluation is required to ensure that the substitute maintains the desired compound properties.

- Optimization of Ingredient Ratios: Fine-tuning the ratios of ingredients can sometimes lead to cost reductions without sacrificing performance. This might involve slightly reducing the amount of a relatively expensive additive, but only after conducting thorough tests to ensure its efficacy remains satisfactory.

- Process Optimization: Improving the efficiency of the compounding process can reduce production costs. This could include optimizing mixing parameters (time and temperature), minimizing waste generation, and improving the overall process flow.

- Supplier Negotiation: Negotiating favorable pricing with suppliers is essential. Building strong relationships with reliable suppliers can lead to better deals and ensure consistent supply of high-quality materials.

For example, in one project, we successfully reduced the cost of a compound by 15% by substituting a portion of a premium grade of carbon black with a less expensive grade, while maintaining the desired tensile strength and abrasion resistance through careful optimization of the other ingredients and mixing parameters.

Q 28. What are some emerging trends and technologies in the field of rubber compounding?

Several emerging trends and technologies are shaping the future of rubber compounding:

- Sustainable Materials: Increased focus on using bio-based materials and recycled rubber to reduce environmental impact and enhance sustainability. This includes utilizing natural rubber from sustainable sources and developing effective methods for recycling and reusing rubber waste.

- Smart Compounds: Incorporating sensors and other smart technologies into rubber compounds to provide real-time monitoring of performance and condition. This can lead to improved predictive maintenance and optimized product life.

- Additive Manufacturing (3D Printing): 3D printing of rubber compounds is gaining traction, allowing for the creation of complex shapes and customized components with high precision. This can revolutionize product design and manufacturing processes.

- Digitalization and Data Analytics: Increased use of digital tools and data analytics for process optimization, quality control, and predictive maintenance. This involves the integration of sensors, automated data collection, and advanced analytics to improve efficiency and reduce costs.

- Advanced Simulation and Modeling: Utilizing advanced computational tools to simulate the performance of rubber compounds under various conditions, reducing the need for extensive experimental testing and accelerating the development process.

These advancements are continuously pushing the boundaries of rubber compound technology, leading to the development of innovative materials with enhanced performance and sustainability.

Key Topics to Learn for Rubber Compounding Optimization Interview

- Polymer Chemistry Fundamentals: Understanding the properties of different elastomers (natural rubber, SBR, EPDM, etc.) and their influence on final product performance. This includes knowledge of molecular weight, crosslinking density, and glass transition temperature.

- Filler Technology and Reinforcement: Explore the role of fillers (carbon black, silica, clay) in enhancing mechanical properties like tensile strength, tear resistance, and abrasion resistance. Learn how filler type, loading level, and dispersion affect the overall compound performance.

- Compounding Ingredients and their Interactions: Gain a comprehensive understanding of the function of various additives like processing aids, antioxidants, vulcanization systems, and other specialty chemicals. Analyze how their interactions influence the final product’s properties and processability.

- Rheology and Processing: Master the principles of rubber rheology, understanding how the flow behavior of the compound affects mixing, shaping, and curing processes. Learn about different mixing techniques and their impact on compound uniformity and quality.

- Vulcanization and Curing: Deeply understand the chemical reactions involved in crosslinking rubber molecules, the influence of curing parameters (temperature, time, pressure) on the final product properties, and how to optimize the curing process for desired performance.

- Testing and Quality Control: Familiarize yourself with standard testing methods used to characterize the properties of rubber compounds (e.g., tensile testing, hardness testing, dynamic mechanical analysis). Understand how to interpret test data and use it for optimization.

- Statistical Design of Experiments (DOE): Learn how to design and analyze experiments to efficiently optimize rubber compound formulations. This includes understanding factorial designs, response surface methodology, and other statistical techniques.

- Troubleshooting and Problem-Solving: Develop your ability to identify and resolve common problems encountered during rubber compounding, such as poor dispersion, insufficient cure, or undesirable mechanical properties. This includes root cause analysis and corrective actions.

Next Steps

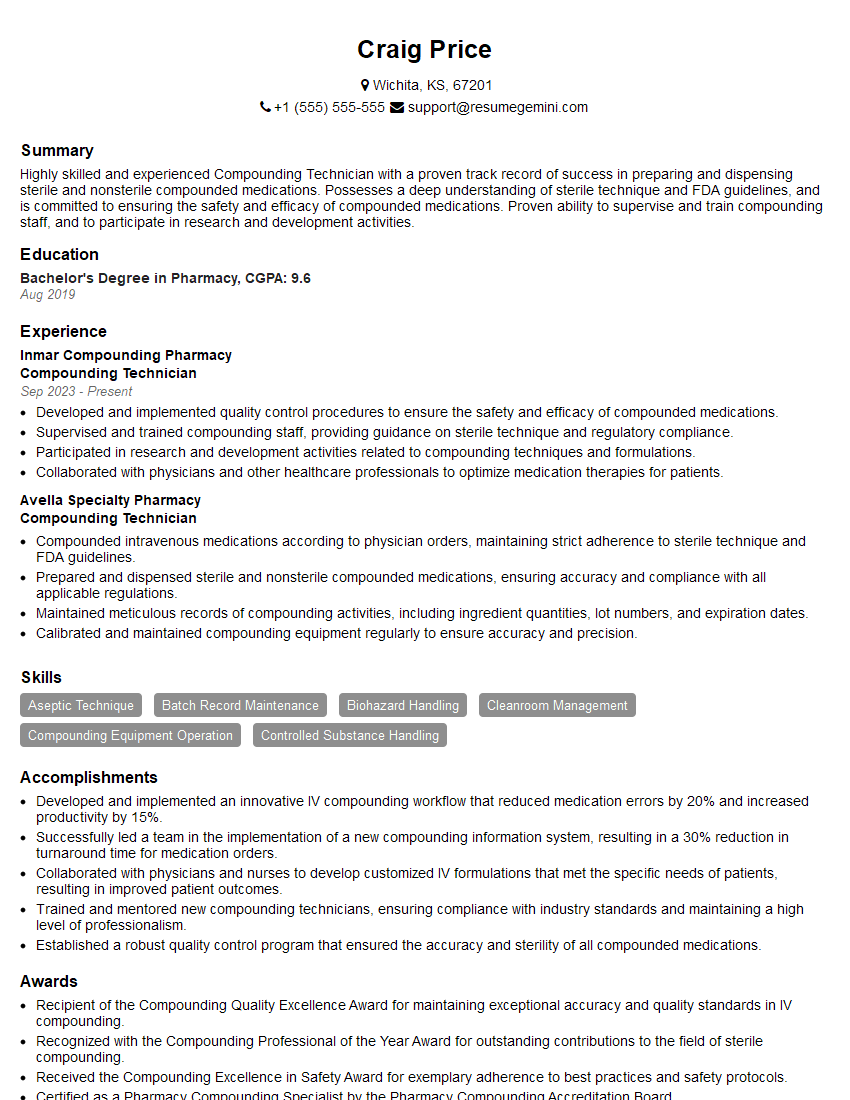

Mastering Rubber Compounding Optimization is crucial for career advancement in the materials science and engineering field, opening doors to specialized roles and leadership positions. Building an ATS-friendly resume is essential to maximizing your job prospects. To create a compelling and effective resume that highlights your skills and experience, we strongly recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored specifically to Rubber Compounding Optimization, helping you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?