Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Shuttleless loom weaving interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Shuttleless loom weaving Interview

Q 1. Describe the different types of shuttleless weaving machines.

Shuttleless weaving machines offer a range of weft insertion methods, each with its own advantages and disadvantages. The most common types include:

- Rapier Weaving Machines: These use one or two flexible metallic arms (rapiers) to carry the weft yarn across the shed. Single rapier machines are simpler, while double rapier machines offer higher speed and efficiency. Think of it like using tongs to carefully place the yarn across the warp threads.

- Projectile Weaving Machines: A small, self-propelled projectile carries the weft yarn across the shed. The projectile is launched across the warp, depositing the yarn, then returns to its starting position. This method is particularly suited for heavier fabrics.

- Air-Jet Weaving Machines: Compressed air is used to propel a stream of weft yarn across the shed. This allows for high weaving speeds and is ideal for producing lightweight fabrics. Imagine a miniature, controlled air blast delivering the weft yarn.

- Water-Jet Weaving Machines: Similar to air-jet, but uses a high-pressure jet of water to carry the weft yarn. This is effective for delicate yarns that might be damaged by air jets.

The choice of machine depends largely on the type of fabric being woven, the desired production speed, and the yarn characteristics.

Q 2. Explain the process of warp preparation in shuttleless weaving.

Warp preparation is crucial for successful shuttleless weaving. It involves several steps aimed at creating a strong, even warp beam ready for weaving:

- Warp Yarn Preparation: This includes sizing the yarn – applying a starch or other size to increase strength and reduce friction – as well as cleaning and inspecting for imperfections. Think of this as preparing your threads for a delicate embroidery project.

- Warp Winding: The sized yarn is wound onto a creel, a frame holding multiple bobbins. This is often done using automatic winding machines to ensure even tension.

- Warp Beaming: The yarn from the creel is then wound onto a warp beam, a large cylindrical device that feeds the yarn into the loom. This step must carefully control tension to avoid breakage and ensure a consistent weft insertion.

- Warp Let-off: The mechanism on the loom that controls the unwinding of the warp beam is crucial for maintaining consistent tension and avoiding problems during weaving.

Precise control at each stage is essential to prevent weaving defects like broken warps and uneven fabric density. A poorly prepared warp is a recipe for disaster on the loom.

Q 3. How do you troubleshoot weft insertion problems in a projectile weaving machine?

Troubleshooting weft insertion problems in a projectile weaving machine requires a systematic approach. Common issues include:

- Projectile Misfires: Check the air pressure, projectile gripper mechanism, and the electrical systems controlling the launching mechanism.

- Weft Yarn Breakages: Inspect the yarn quality, tension, and the path of the yarn through the machine for any snags or points of high friction. A faulty yarn guide or improperly tensioned yarn can cause frequent breakage.

- Projectile Path Obstructions: Examine the projectile’s path for debris, misaligned parts or other obstructions that could prevent smooth operation.

- Inconsistent Weft Density: Check the projectile speed settings, yarn tension, and the shedding mechanism to ensure that the weft yarn is being inserted uniformly.

The process often involves careful inspection, testing individual components, and consulting the machine’s maintenance manual. It’s like detective work, systematically eliminating possible causes until you find the culprit.

Q 4. What are the common causes of warp breakage in shuttleless weaving?

Warp breakage in shuttleless weaving can stem from several factors:

- Excessive Warp Tension: Improperly set let-off mechanisms, or variations in yarn tension during beaming, create stress points and lead to breakage.

- Yarn Defects: Weak or damaged yarn fibers, inconsistent yarn quality, and knots or slubs can all contribute to frequent warp breakage.

- Mechanical Problems: Faulty heald frames, reed damage, or other mechanical issues on the loom can cause undue stress on the warp yarns.

- Improper Sizing: Insufficient sizing or improper sizing agents leave the warps weak and prone to damage.

- Environmental Factors: High humidity or excessively dry conditions can influence warp yarn strength and lead to breakage.

Regular inspection of the warp, the loom’s components, and maintaining appropriate environmental conditions are key preventative measures.

Q 5. Explain the role of the selvedge in shuttleless weaving.

Selvedges are the edges of the woven fabric. In shuttleless weaving, they play a vital role in holding the warp yarns together and preventing unraveling. They provide a neat and finished edge to the fabric.

The selvedge is created by specific mechanisms within the loom which interlock or otherwise secure the outer warp yarns. Different types of shuttleless looms employ different methods to achieve this. The selvedge’s strength is crucial for the overall quality and stability of the woven fabric. A weak or poorly formed selvedge can lead to fabric damage during further processing or handling.

Q 6. How do you adjust the weft density in a rapier weaving machine?

Adjusting weft density in a rapier weaving machine involves altering settings that control the distance between weft insertions. This is achieved primarily through:

- Beat-up mechanism adjustment: This controls how tightly the weft is pushed against the previously inserted weft, altering the fabric’s compactness.

- Reed spacing adjustment: Though less direct, adjusting the reed’s density can indirectly influence the fabric’s compactness, and thus the perceived weft density.

- Rapier speed control: In some machines, the speed of the rapier can subtly affect weft density.

These adjustments are usually made using the machine’s control panel and require careful consideration to avoid fabric defects. It’s important to make incremental changes, observing the results before making significant alterations. Think of it like fine-tuning a musical instrument for the perfect sound.

Q 7. Describe the maintenance procedures for a air-jet weaving machine.

Maintaining an air-jet weaving machine focuses on keeping the air supply system clean and functional, along with regular checks of the mechanical components:

- Air System Maintenance: Regular cleaning of air filters, nozzles, and air lines is crucial to ensure optimal air pressure and prevent blockages. A clogged nozzle can lead to inconsistent weft insertion.

- Nozzle Inspection and Replacement: Worn or damaged nozzles need to be replaced promptly.

- Mechanical Component Lubrication: Regular lubrication of moving parts helps prevent wear and tear and ensures smooth operation.

- Yarn Guide and Tension Control: Regular checks are needed to ensure the correct alignment of the yarn guides and that the yarn tension is optimal.

- Regular Inspections: Regular inspections help identify and address any potential issues before they escalate into major problems. This proactive approach helps ensure the machine’s longevity and optimal performance.

Proper maintenance not only extends the machine’s lifespan but also ensures the consistent production of high-quality fabrics. It’s like regular servicing for a car – prevents major breakdowns down the line.

Q 8. What are the advantages and disadvantages of using different types of weft yarns in shuttleless weaving?

The choice of weft yarn significantly impacts the final fabric properties in shuttleless weaving. Different yarns offer various advantages and disadvantages.

- Advantages of using different weft yarns:

- Fine yarns (e.g., cotton, silk): Produce smooth, high-quality fabrics with excellent drape, suitable for apparel and high-end applications. However, they may require slower weaving speeds and be more prone to breakage.

- Coarse yarns (e.g., jute, wool): Ideal for creating sturdy, durable fabrics like carpets and upholstery. Their robustness makes them less susceptible to breakage but may lead to coarser, less refined surface textures.

- Synthetic yarns (e.g., polyester, nylon): Provide high strength, excellent colorfastness, and are easy to care for. They are versatile and used widely in various applications, but they may sometimes feel less luxurious than natural fibers.

- Blends: Combining different fibers (e.g., cotton/polyester blend) offers a balance of desired properties; improved strength combined with softness, for instance.

- Disadvantages of using different weft yarns:

- Yarn variations: Differences in yarn diameter, twist, and fiber content can cause inconsistencies in the fabric’s appearance and texture, demanding careful yarn selection and tension control.

- Weaving speed limitations: Some yarns, due to their delicate nature or bulkiness, may restrict the maximum weaving speed achievable on the shuttleless loom.

- Cost implications: Different yarn types have varying costs. Utilizing high-end fibers can increase production expenses significantly.

- Specific processing needs: Certain yarns may require specialized handling or pre-treatment before weaving to ensure optimal performance and prevent issues like yarn breakage or uneven weaving.

For example, when weaving a luxurious silk scarf, fine silk yarns would be preferred for their softness and drape. In contrast, a heavy-duty industrial fabric might require coarse, robust yarns for durability. The selection always depends on the intended end use of the fabric.

Q 9. How do you identify and correct fabric defects in shuttleless weaving?

Identifying and correcting fabric defects in shuttleless weaving involves meticulous observation and understanding of the loom’s mechanics. Many defects stem from yarn faults, weaving parameters, or machine malfunctions.

- Identification: Careful inspection of the woven fabric is crucial. Common defects include broken ends, mispicks, floats, holes, slubs, and creases. Using a magnifying glass might be necessary for finer defects. Regular checks during the weaving process help in early detection, reducing waste.

- Correction: The approach depends on the defect’s nature and severity.

- Broken ends: Manually re-threading the broken end is often the solution. Advanced looms have automatic weft insertion systems to alleviate this issue.

- Mispicks: Usually caused by incorrect shedding or weft insertion; often require adjustments to the loom settings or a more thorough yarn preparation.

- Floats: Long floats (uncovered warp yarns) can be corrected by adjusting the weft density or adjusting the loom settings.

- Holes: Caused by missed weft insertions or broken warp yarns. Again, loom adjustments or fixing the yarn are necessary.

- Slubs: Variations in yarn thickness, often difficult to correct during weaving. Better yarn quality control is essential in preventing this.

- Creases: Usually a result of improper fabric handling or tension control. Careful monitoring of loom settings is crucial.

A systematic approach, including regular quality checks and detailed records of adjustments, is essential for efficient defect correction and improved loom productivity.

Q 10. Explain the concept of shedding in shuttleless weaving.

Shedding in shuttleless weaving refers to the process of separating the warp yarns to create a space (the shed) for the weft yarn to pass through. Unlike traditional shuttle looms, shuttleless looms use various mechanical or pneumatic mechanisms to achieve this.

Imagine separating a curtain to allow someone to walk through. In weaving, the warp yarns are the curtain and the weft yarn is the person walking through. The shedding mechanism ‘opens’ the ‘curtain’ to allow the weft insertion mechanism to pass the weft yarn through the shed. Different shuttleless loom types have different shedding mechanisms.

The shedding mechanism is typically controlled by a ‘heald frame’ or ‘harness’ system with heddles (wires or other devices) that lift and lower different groups of warp yarns, creating the desired shed for the weft insertion mechanism. The shedding cycle repeats itself for each weft insertion, building the fabric layer by layer.

Accurate shedding is critical; improper shedding will lead to mispicks or other weaving defects. Therefore, well-maintained shedding systems and careful control over their timing and accuracy are essential for producing high-quality fabric.

Q 11. What are the safety precautions you should take while operating a shuttleless loom?

Operating a shuttleless loom requires adherence to strict safety precautions to prevent accidents and injuries. These include:

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and appropriate clothing that won’t get caught in moving parts. Gloves should also be considered depending on the specific loom type and material being woven.

- Machine Guards: Ensure all machine guards are in place before operation. Never attempt to operate the loom with guards removed or damaged.

- Emergency Stop Button: Familiarize yourself with the location and operation of the emergency stop button and other safety mechanisms on the loom.

- Regular Maintenance: Regular maintenance is crucial for preventing accidents. Report any malfunction or defect immediately to maintenance personnel.

- Proper Training: Only trained and authorized personnel should operate shuttleless looms. Thorough training is vital to understanding the operation and safety procedures.

- Lockout/Tagout Procedures: Before any maintenance or repair work on the loom, always follow lockout/tagout procedures to prevent accidental startup.

- Awareness of Moving Parts: Remain constantly aware of the moving parts of the loom and maintain a safe distance. Never reach into the machine while it is running.

Ignoring safety measures can lead to serious consequences, including injuries or damage to the equipment. Safety should always be the highest priority when operating industrial machinery.

Q 12. How do you calculate the loom efficiency?

Loom efficiency is a crucial metric in textile production, reflecting how effectively the loom produces fabric within a given time. It’s calculated using the following formula:

Loom Efficiency = (Effective Running Time / Total Time) x 100%

Effective Running Time: This is the actual time the loom is producing fabric. It excludes downtime caused by factors like machine breakdowns, yarn changes, maintenance, and cleaning.

Total Time: This includes the entire time the loom was scheduled to operate, encompassing both productive and unproductive periods.

Example: If a loom was scheduled to operate for 8 hours (Total Time) but had 1 hour of downtime (e.g., for yarn changes and minor repairs), the Effective Running Time would be 7 hours. The loom efficiency would be (7/8) x 100% = 87.5%.

Factors influencing loom efficiency include machine condition, operator skill, yarn quality, and the type of fabric being woven. High loom efficiency directly translates to cost savings and increased profitability.

Q 13. Describe the process of setting up a new weaving pattern on a shuttleless loom.

Setting up a new weaving pattern on a shuttleless loom involves several steps, combining mechanical adjustments and software programming (for more advanced looms).

- Pattern Design: The desired pattern is first designed using specialized software or by hand-drawn drafts, defining the warp and weft yarn arrangements.

- Warp Preparation: Warp yarns are prepared according to the pattern, often involving specific dyeing or other pre-treatments. They are then wound onto the loom’s warp beams, ensuring correct tension and alignment.

- Heald Frame Adjustment: The heald frames (harness) are adjusted to lift and lower the appropriate warp yarns, according to the pattern draft, to create the necessary sheds for weft insertion.

- Weft Insertion Setup: The weft insertion mechanism (depending on the loom type – rapier, projectile, air-jet) is set up for the correct yarn type and tension.

- Software Programming (if applicable): Many modern shuttleless looms are controlled by computer software. The pattern design data is input into the loom’s control system, specifying all weaving parameters, including shedding sequences, weft insertion timing, and weft density.

- Test Run and Adjustments: After setup, a test run is conducted to evaluate fabric quality and make necessary adjustments to the machine settings, correcting any deviations from the planned pattern.

- Production Run: Once the pattern is correctly reproduced and quality is verified, the production run can commence.

The complexity of this process varies widely, depending on the loom’s sophistication and the complexity of the desired fabric pattern. Simpler patterns require less complex adjustments compared to intricate designs.

Q 14. Explain the difference between projectile, rapier, and air-jet weaving.

Projectile, rapier, and air-jet weaving are three prominent types of shuttleless weaving, each employing a distinct weft insertion mechanism.

- Projectile Weaving: Uses a small, self-propelled projectile that carries the weft yarn across the shed. The projectile is launched from one selvedge to the other, carrying the yarn and then returning to its starting position. It’s suitable for weaving coarser and heavier fabrics but relatively slower than other methods.

- Rapier Weaving: Employs one or two flexible rapiers (metal or plastic rods) to carry the weft yarn across the shed. The rapiers grip the yarn, pass it through the shed, and release it at the other side. Rapier weaving offers more versatility than projectile weaving, handling a wider range of yarns and producing finer fabrics at higher speeds. Single-rapier weaving is simpler and cheaper but slower, while double-rapier weaving is faster and more versatile.

- Air-Jet Weaving: Utilizes a high-velocity air jet to propel the weft yarn across the shed. The air jet carries a package of yarn and propels it across the shed, making it ideal for high-speed weaving of light to medium-weight fabrics. Air-jet weaving excels at speed and efficiency, particularly for synthetic and light-weight fabrics, but can be challenging with thick or bulky yarns.

The choice of weaving method depends on factors like desired fabric type, yarn characteristics, production speed requirements, and budget considerations. Each technique has its strengths and weaknesses, making it suitable for various applications.

Q 15. How do you manage different types of fabric structures in shuttleless weaving?

Managing different fabric structures in shuttleless weaving relies heavily on understanding the loom’s capabilities and the specific requirements of each structure. Essentially, we’re controlling the interplay between warp and weft yarns to achieve the desired texture and appearance.

- Plain weave: This is the simplest structure, achieved by alternating warp and weft yarns over and under each other. Shuttleless looms handle this easily, often with minimal setup changes.

- Twill weave: Requires a more complex weft insertion pattern to achieve the characteristic diagonal lines. This involves programming the loom’s weft insertion mechanism to follow a specific floating pattern across the warp yarns. We might adjust parameters like the shedding sequence and weft insertion timing.

- Satin weave: Produces a smooth, lustrous fabric. Its long floats (continuous weft yarns running over multiple warp yarns) demand precision in weft insertion to avoid yarn breakage. This often involves careful yarn selection and potentially fine-tuning the loom’s tension settings.

- Jacquard weave: This intricate structure, capable of creating complex designs, needs sophisticated loom control systems. The software controlling the shedding mechanism plays a crucial role, accurately coordinating the raising and lowering of individual warp yarns to create the desired pattern. Careful monitoring and adjustment of yarn tension is critical.

In practice, we use weaving software to define the fabric structure, and the loom’s controls translate that digital information into the physical movement of the yarns. The key is to match the loom’s capabilities to the complexity of the desired structure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of weft yarn breakage in shuttleless weaving?

Weft yarn breakage in shuttleless weaving is a common issue with several potential culprits. It’s often a symptom of a larger problem rather than an isolated incident.

- Insufficient yarn strength: Using yarn that’s too thin or poorly spun is a major cause. We carefully select yarns with appropriate strength for the intended fabric structure and weaving speed.

- Excessive tension: Both the warp and weft tensions must be properly balanced. Over-tensioning can snap the weft yarn, while under-tensioning can lead to poor fabric quality and even breakage.

- Poor yarn preparation: Knots, slubs, and other imperfections in the weft yarn will lead to breakage. Thorough yarn inspection and preparation are essential. We often use advanced yarn clearing systems to detect and remove imperfections before they reach the loom.

- Loom malfunction: Issues with the weft insertion mechanism, such as misaligned grippers or improper timing, can also cause breakage. Regular loom maintenance and timely repairs are crucial.

- Abrasion: Excessive friction between the weft yarn and other loom components can lead to wear and tear, resulting in breakage. Lubrication and regular inspection are important preventative measures.

Troubleshooting often involves systematically checking each of these areas, starting with the simplest solutions like adjusting tension before moving to more complex mechanical issues.

Q 17. How do you address problems related to weft insertion consistency?

Consistent weft insertion is paramount for fabric quality. Inconsistent insertion leads to uneven fabric density, poor appearance, and potential strength issues.

- Regular maintenance of the weft insertion mechanism: This includes cleaning, lubrication, and ensuring proper alignment of all components. Regular preventative maintenance significantly reduces issues.

- Precise control of yarn tension: Consistent weft tension is vital. Advanced looms often incorporate sensors and feedback loops to automatically adjust tension as needed. We regularly check and calibrate these systems.

- Optimal shedding motion: The way the warp yarns are separated to allow weft insertion must be smooth and consistent. Proper shed timing prevents yarn damage and ensures even insertion. We address problems with shedding timing by adjusting loom settings and checking for mechanical obstructions.

- Correct weft insertion speed: The speed of the insertion mechanism must be optimized for the specific yarn and fabric type. Too high a speed increases the risk of breakage; too low a speed decreases production efficiency. This often requires experimentation and fine tuning based on experience and data from the loom.

- Software adjustments: Many modern shuttleless looms utilize sophisticated software for controlling various aspects of the weaving process. Software updates, parameter adjustments, and optimization can significantly improve weft insertion consistency.

Addressing inconsistencies requires a combination of mechanical adjustments, precise parameter settings, and a deep understanding of the weaving process.

Q 18. Describe your experience with different types of weaving software.

My experience encompasses a variety of weaving software packages, both proprietary and open-source. This experience spans from simple loom control interfaces to complex CAD (Computer-Aided Design) systems for fabric design and simulation.

- Proprietary software: I have extensive experience with software packages provided by major loom manufacturers, such as [Manufacturer A’s software] and [Manufacturer B’s software]. These systems typically offer a comprehensive suite of tools for designing, controlling, and monitoring the weaving process. The focus is often on user-friendliness and integration with specific loom models.

- Open-source options: I have also worked with several open-source platforms, primarily for research and development purposes. These platforms are more customizable but may require more technical expertise to operate and maintain. The advantage is adaptability and potential integration with other tools within a larger workflow.

- CAD Software: I am proficient in using several CAD software packages, such as [Specific CAD software], for designing complex fabric structures and simulating the weaving process. This allows for virtual prototyping and early detection of potential issues before production.

My experience allows me to adapt quickly to new software systems and leverage the capabilities of each platform to achieve optimal results. I believe that software fluency is essential for maximizing the potential of modern shuttleless looms.

Q 19. How do you handle quality control issues related to fabric imperfections?

Quality control is critical in shuttleless weaving. Fabric imperfections can stem from various sources. My approach involves a multi-layered strategy.

- In-process monitoring: Regular checks during the weaving process are essential. We utilize sensors and cameras to detect defects like broken ends, mispicks, and other irregularities. This allows for immediate intervention and minimizes waste.

- Statistical Process Control (SPC): We employ SPC techniques to monitor key parameters such as weft density, warp tension, and fabric width. This enables us to identify trends and deviations that could signal developing problems.

- Defect classification and analysis: When defects are detected, we meticulously classify them to identify root causes. This often involves analyzing the weaving process parameters, inspecting the yarn, and examining the loom’s mechanical components.

- Corrective actions: Based on the root cause analysis, we implement corrective actions, which might involve adjusting loom parameters, replacing faulty parts, or improving yarn preparation techniques.

- Post-production inspection: Final inspection involves checking for overall fabric quality, including measurements, appearance, and strength. This helps to ensure that only high-quality products are shipped to customers.

A proactive approach to quality control, combining real-time monitoring with rigorous analysis, ensures the production of high-quality, consistent fabric.

Q 20. What is your experience with different types of shuttleless weaving fabrics?

My experience with shuttleless weaving fabrics is extensive, covering a broad range of fiber types and fabric structures. This includes both conventional and specialized fabrics.

- Cotton fabrics: I have worked extensively with cotton fabrics for apparel, home furnishings, and industrial applications. The focus here is on achieving optimal strength, drape, and comfort.

- Synthetic fabrics: I am proficient in weaving various synthetic fibers, such as polyester, nylon, and acrylic. These fabrics are often used in technical textiles, automotive applications, and sportswear, emphasizing specific properties like water resistance or durability.

- Blended fabrics: I have extensive experience with blended fabrics combining natural and synthetic fibers, such as cotton/polyester blends or wool/nylon blends. These blends often seek to combine the best properties of each fiber type.

- Specialty fabrics: I have also worked with more specialized fabrics, including flame-resistant fabrics, high-tenacity fabrics, and fabrics with specific finishes. These require specialized knowledge of yarn selection, weaving parameters, and finishing techniques.

My ability to adapt to diverse fabric types is a key strength, allowing me to meet a wide range of customer needs and challenges.

Q 21. Explain your experience with troubleshooting loom malfunctions.

Troubleshooting loom malfunctions is a critical aspect of my role. My approach is systematic and data-driven.

- Identifying the problem: The first step is to accurately identify the nature of the malfunction. This involves observing the loom’s operation, analyzing error messages (if any), and listening for unusual sounds.

- Gathering data: I collect data relevant to the problem, such as production logs, sensor readings, and images of the malfunction. This data provides crucial insights into the cause of the issue.

- Systematic troubleshooting: I follow a systematic approach, starting with the simplest potential causes and progressing to more complex issues. This often involves checking for loose connections, worn parts, and software glitches.

- Using diagnostic tools: Modern looms often have built-in diagnostic tools to identify specific problems. I am proficient in using these tools to pinpoint the root cause of the malfunction.

- Implementing solutions: Once the root cause is identified, I implement the appropriate solution, which may involve replacing faulty components, adjusting loom parameters, or even modifying software settings. I always prioritize safety and proper procedures.

- Preventative maintenance: After resolving the issue, I often recommend preventative maintenance procedures to avoid similar problems in the future. This may involve regular inspections, lubrication, and scheduled part replacements.

My experience has taught me that a proactive and methodical approach to loom maintenance is critical for maximizing uptime and minimizing production disruptions.

Q 22. How familiar are you with various weaving parameters (e.g., PPI, EPI)?

Weaving parameters like PPI (picks per inch) and EPI (ends per inch) are fundamental to controlling fabric structure and quality. PPI refers to the number of weft threads packed into one inch of fabric, determining its density and drape. EPI, conversely, represents the number of warp threads per inch, influencing the fabric’s strength and stability. Understanding these parameters is crucial for achieving desired fabric properties.

For instance, a higher PPI will result in a denser, heavier fabric with a potentially smoother surface, while a higher EPI will generally create a stronger, more durable fabric. Imagine trying to weave a fine silk scarf versus a heavy duty canvas. The silk scarf would require a high PPI and possibly a moderate EPI, whereas the canvas would need a much lower PPI but potentially a high EPI for strength. These values are not independent; the ideal combination depends on the desired end product and material used.

In my experience, I’ve used these parameters extensively to create fabrics ranging from delicate chiffons (high PPI, moderate EPI) to robust denim (moderate PPI, high EPI). I’m proficient in calculating and adjusting these parameters based on yarn counts, fabric weight requirements, and the specific shuttleless loom settings.

Q 23. What experience do you have with preventative maintenance on shuttleless looms?

Preventative maintenance on shuttleless looms is paramount for ensuring efficient and consistent production. My experience encompasses a wide range of tasks, including regular lubrication of moving parts such as the grippers, shed formation mechanisms, and take-up rollers. This prevents friction and wear, extending the lifespan of the machinery.

I also meticulously inspect warp beams for any signs of damage or uneven winding, which could lead to fabric defects. Regularly cleaning the loom, including removing lint and debris, is essential for optimal performance and preventing yarn breakage. I am adept at performing these checks and addressing minor adjustments proactively to avoid costly downtime.

Furthermore, I follow a strict schedule for replacing worn parts like selvedge wires, heddles, and reed teeth. I’m also familiar with the specific maintenance schedules for various makes and models of shuttleless looms, optimizing the maintenance strategy for each machine. I believe in a proactive approach to maintenance, preventing small issues from escalating into major problems.

Q 24. Describe a time you had to solve a complex weaving problem.

During a large production run of a high-end upholstery fabric, we encountered a persistent issue with uneven weft insertion, resulting in inconsistent fabric density and noticeable banding across the width. Initially, we suspected the yarn itself, but after thorough inspection, we ruled that out. The problem persisted despite adjustments to the weft insertion parameters.

My systematic troubleshooting approach involved isolating each component in the weft insertion mechanism. We methodically examined the gripper mechanism, checking for wear, misalignment, or any other irregularities. We also reviewed the timing and speed of the weft insertion system. Eventually, we found that the problem wasn’t mechanical but related to a subtle vibration in the loom’s frame, likely caused by the high speed setting we were using for this particular, heavy yarn. We solved this issue by strategically adding dampening supports to the loom frame, eliminating the vibration and resolving the weft insertion inconsistency. The resulting fabric quality significantly improved.

Q 25. How do you ensure consistent fabric quality throughout a production run?

Maintaining consistent fabric quality throughout a production run requires a multi-faceted approach. Firstly, I rigorously monitor yarn quality, ensuring consistency in count, twist, and strength. Any deviation can directly impact the final product.

Secondly, precise control of weaving parameters, including PPI, EPI, and shedding motion, is essential. Regular calibration and adjustment of the loom based on real-time monitoring data are critical. I utilize statistical process control (SPC) techniques to identify and address any deviations from the target values promptly.

Thirdly, preventative maintenance as described earlier plays a vital role in preventing inconsistencies. Consistent loom performance minimizes the chances of fabric defects. Finally, regular quality checks throughout the weaving process, using instruments such as fabric width testers and density meters, are essential for detecting and correcting any anomalies before they escalate.

Q 26. What are your preferred methods for monitoring loom performance?

Monitoring loom performance involves both real-time observation and data analysis. Real-time observation focuses on visual inspection for things like weft misinsertion, broken ends, or abnormal machine sounds. I also look for consistent fabric width and evenness.

In addition to visual checks, I utilize data logging systems that track machine parameters such as weft insertion speed, shedding timing, and take-up speed. This data is analyzed using statistical process control (SPC) charts to identify trends and potential problems early on. This allows for proactive adjustments before significant quality issues arise. Some looms have built-in monitoring systems which provide valuable data. I also use manual checks alongside the digital monitoring.

Q 27. How do you stay updated on the latest advancements in shuttleless weaving technology?

Staying updated on advancements in shuttleless weaving technology is crucial for maintaining my expertise. I regularly attend industry conferences and trade shows, networking with other professionals and learning about the latest innovations in loom design, materials, and software.

I also subscribe to industry publications and journals, keeping abreast of research and development in areas such as high-speed weaving, advanced control systems, and innovative yarn handling techniques. Furthermore, I actively participate in online forums and communities dedicated to weaving technology, allowing me to engage in discussions with experts from around the world and stay informed about best practices.

Finally, I regularly review technical documentation and manuals for various shuttleless loom models to ensure that I’m familiar with the capabilities and maintenance requirements of different equipment.

Key Topics to Learn for Shuttleless Loom Weaving Interview

- Loom Types and Mechanisms: Understanding the different types of shuttleless looms (e.g., projectile, rapier, air-jet) and their operating principles. This includes the intricacies of weft insertion mechanisms.

- Warp Preparation and Beaming: Mastering the process of preparing the warp yarns, including sizing, winding, and beaming onto the loom. Understand the impact of warp tension on fabric quality.

- Weft Insertion Techniques: Detailed knowledge of the specific weft insertion methods used in various shuttleless loom types. Be prepared to discuss the advantages and disadvantages of each technique.

- Fabric Structure and Design: Understanding how different weaving parameters (e.g., warp density, weft density, weave patterns) affect the final fabric structure and properties.

- Troubleshooting and Maintenance: Familiarity with common problems encountered in shuttleless loom operation and the procedures for troubleshooting and maintenance. This includes understanding preventative maintenance schedules.

- Quality Control and Inspection: Knowledge of quality control methods used to ensure consistent fabric quality, including identifying and rectifying defects.

- Safety Procedures and Regulations: Demonstrate awareness of safety protocols and regulations related to operating shuttleless looms.

- Yarn Properties and Selection: Understanding the properties of different yarns and their suitability for various weaving applications. This includes considerations of fiber type, yarn count, and twist.

- Production Optimization and Efficiency: Discuss strategies for optimizing production efficiency and reducing downtime on shuttleless looms.

- Advanced Concepts (if applicable): Depending on the seniority of the role, be prepared to discuss advanced topics such as automation, robotics, and advanced weaving techniques.

Next Steps

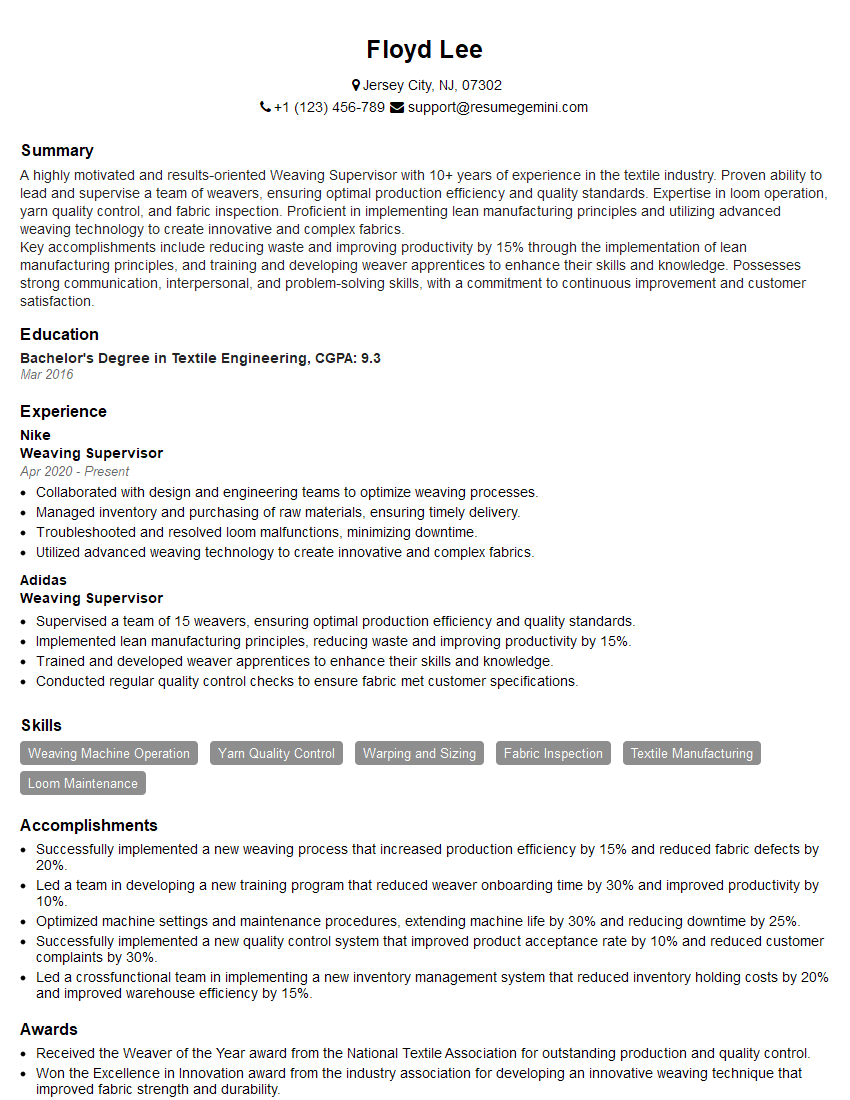

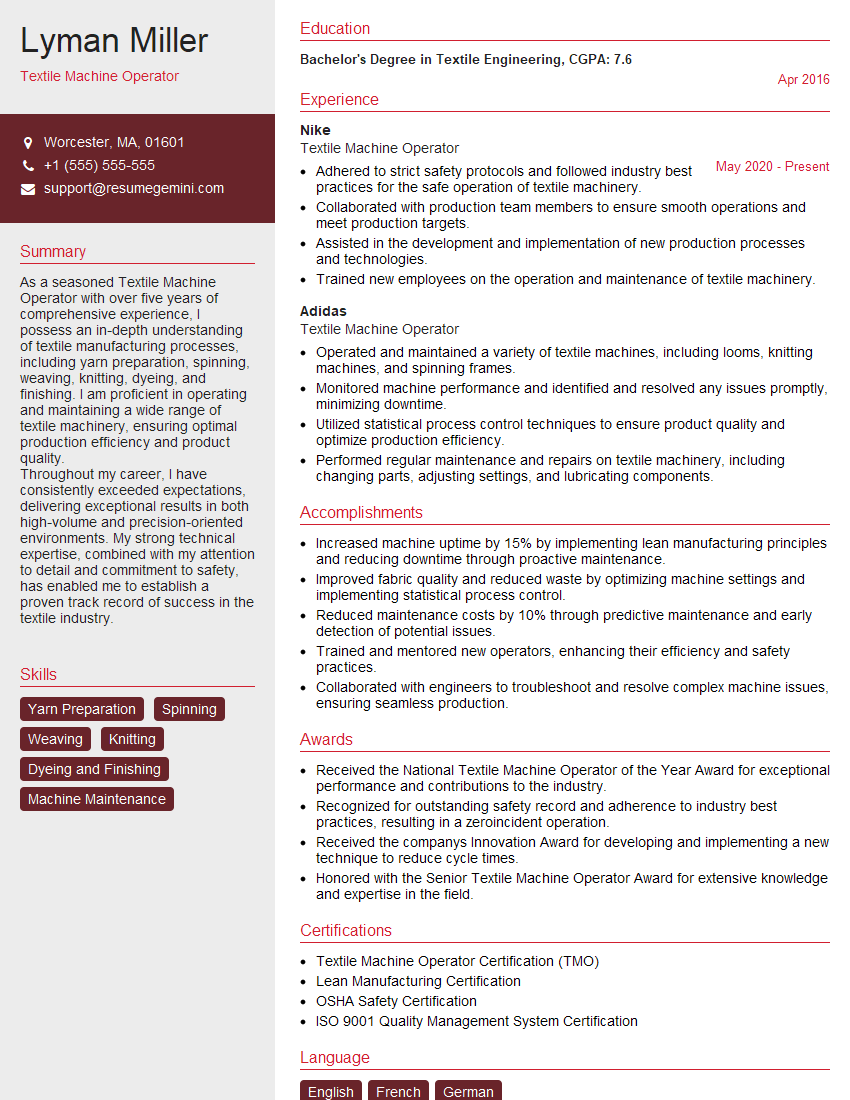

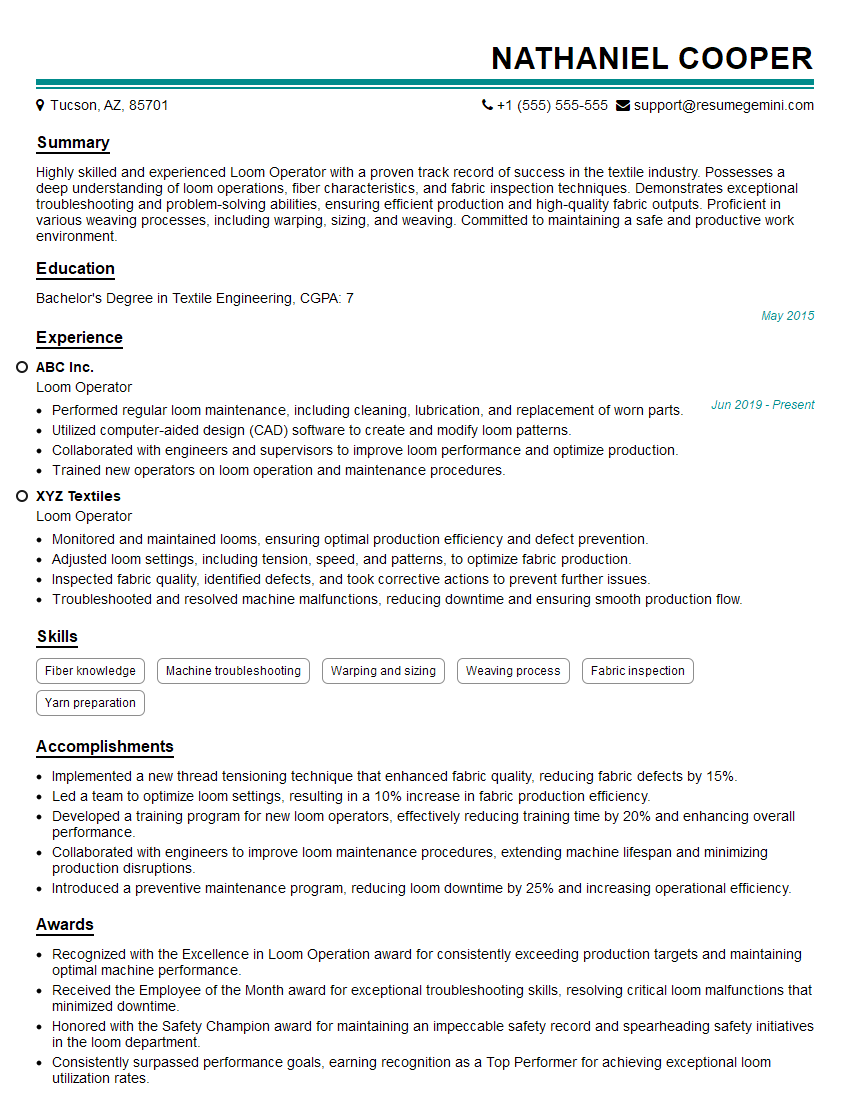

Mastering shuttleless loom weaving opens doors to exciting career opportunities in the textile industry, offering potential for growth and specialization. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to shuttleless loom weaving are available to guide you through the process. Invest time in presenting your qualifications clearly; it’s the key to unlocking your potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?