Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Site Preparation and Maintenance interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Site Preparation and Maintenance Interview

Q 1. Describe your experience with site clearing and grubbing.

Site clearing and grubbing is the initial phase of site preparation, involving the removal of all unwanted vegetation, debris, and other obstacles from a construction site. This includes clearing trees, shrubs, and other plant life, as well as removing stumps, rocks, and other surface obstructions. My experience encompasses a wide range of projects, from small residential lots to large-scale commercial developments. For example, on a recent highway project, we utilized specialized heavy machinery, like excavators equipped with shears and grapple attachments, to efficiently remove hundreds of large trees and clear acres of land, minimizing disruption to surrounding areas. We also carefully managed the disposal of the cleared materials, adhering to all environmental regulations. Another project involved a meticulous hand-clearing operation in a sensitive ecological area, where precision was key to preserve the existing ecosystem. This highlights my adaptability to different site conditions and project requirements.

Q 2. Explain your knowledge of different types of soil and their impact on site preparation.

Understanding soil types is critical for successful site preparation. Different soils possess varying characteristics that significantly impact excavation, foundation design, and overall project feasibility. For instance, sandy soils are well-drained but can be unstable, requiring careful compaction during construction. Clay soils, on the other hand, are cohesive but can retain water, potentially leading to foundation problems unless appropriate drainage solutions are implemented. Silty soils often exhibit intermediate properties. I use soil testing reports to determine the specific soil type on each project. This information guides decisions regarding excavation methods, foundation design, and the need for soil stabilization techniques. For example, on a project with expansive clay soil, we implemented a deep foundation system to mitigate potential settlement issues. The project’s success was largely due to the careful consideration and management of the soil properties.

Q 3. How do you ensure site safety during preparation and maintenance?

Site safety is paramount throughout the preparation and maintenance phases. My approach involves a multi-layered strategy. First, we conduct a thorough site safety analysis before any work commences, identifying potential hazards and developing a comprehensive safety plan. This plan incorporates elements such as designated safe zones, clear signage, and regular safety briefings for all personnel. We enforce the use of appropriate personal protective equipment (PPE), including hard hats, safety glasses, high-visibility vests, and steel-toe boots. All heavy machinery operators are properly trained and certified. Regular inspections are carried out to ensure compliance with safety regulations and address any emerging risks. Think of it like a layered security system, with multiple checks and safeguards in place to prevent accidents. For example, on a large-scale construction site, we implemented a traffic management plan to control the movement of heavy equipment and vehicles, minimizing the risk of collisions.

Q 4. What are your methods for managing waste materials during site preparation?

Waste management is an integral part of environmentally responsible site preparation. We adhere to all local and national environmental regulations regarding waste disposal. Our methods involve sorting materials into different categories – recyclable materials (e.g., scrap metal, wood), non-recyclable materials (e.g., contaminated soil), and potentially hazardous materials (e.g., asbestos). Each category is handled accordingly. Recyclable materials are sent to designated recycling facilities. Non-recyclable materials are typically taken to landfills, and hazardous materials are disposed of according to strict regulations involving specialized contractors. Accurate record-keeping and documentation are crucial, not only for environmental compliance but also for project cost management. For instance, on a recent demolition project, we meticulously sorted and recycled a significant amount of construction debris, reducing the overall waste sent to landfills and demonstrating our commitment to sustainable practices.

Q 5. Describe your experience with earthmoving equipment.

My experience with earthmoving equipment is extensive and includes operating and supervising the use of a wide range of machinery, including excavators, bulldozers, graders, and loaders. I’m proficient in their safe and efficient operation, understanding their capabilities and limitations. I’m also adept at selecting the appropriate equipment for specific tasks, considering factors such as soil conditions, site accessibility, and project requirements. For example, in a tight urban environment, a compact excavator might be preferred over a larger model to minimize disruption to surrounding areas. In contrast, a bulldozer would be the ideal choice for large-scale earthmoving operations. My expertise extends beyond mere operation; I also oversee maintenance and repairs of this equipment, ensuring optimal performance and minimizing downtime. This includes scheduling routine maintenance and troubleshooting any mechanical issues.

Q 6. How do you handle unexpected site challenges or delays?

Unexpected challenges and delays are inherent in site preparation. My approach to handling them involves a proactive and adaptable mindset. First, we establish clear communication channels with all stakeholders, including clients, subcontractors, and regulatory bodies. When unexpected issues arise, such as unforeseen underground utilities or changes in soil conditions, I immediately assess the situation, determine the impact on the project timeline and budget, and develop mitigation strategies. This might involve adjusting the work plan, seeking necessary approvals, or engaging specialized contractors. Detailed documentation of these events and their resolutions is essential for transparency and accountability. For example, discovering unexpected bedrock during excavation required a revision of the foundation design and a slight delay in the project schedule, but through proactive communication and prompt adaptation, we managed to minimize the overall impact.

Q 7. Explain your understanding of grading and leveling techniques.

Grading and leveling are crucial for creating a stable and suitable platform for construction. These techniques involve the controlled removal or addition of earth to achieve the desired elevation and slope. My understanding encompasses various methods, from manual grading for small-scale projects to the use of sophisticated laser-guided grading systems for large-scale developments. Precision is key; slight deviations can lead to drainage problems or foundation instability. Factors such as soil type, drainage requirements, and the planned structure’s foundation influence the grading plan. Careful consideration of erosion control measures is also essential to prevent soil loss and environmental damage. For example, on a large residential development, we used a combination of laser-guided grading and manual fine-tuning to achieve the precise elevations required for the house foundations and drainage systems, ensuring optimal stability and longevity.

Q 8. What are your experience with drainage systems and installation?

My experience with drainage systems encompasses the entire lifecycle, from initial design review and site assessment to installation, testing, and ongoing maintenance. I’m proficient in various drainage methodologies, including French drains, swales, catch basins, and underground piping systems. For example, on a recent project involving a large commercial development, we had to design a complex drainage system to manage heavy rainfall and prevent waterlogging in the parking area. This involved careful topographic analysis, selecting appropriate pipe sizes and materials based on the soil type and anticipated flow rates, and ensuring proper slope gradients for effective water conveyance. The system was rigorously tested post-installation to verify its functionality and prevent future issues. I’m also experienced with different materials such as PVC, HDPE, and corrugated metal pipes, and I understand the implications of choosing one over another for different applications.

Q 9. How do you ensure compliance with environmental regulations during site preparation?

Ensuring environmental compliance is paramount in site preparation. My approach involves a multi-faceted strategy beginning with thorough pre-construction environmental impact assessments. This includes identifying protected species and habitats, assessing potential contamination, and understanding applicable local, state, and federal regulations (like the Clean Water Act or the Endangered Species Act). We then develop a detailed environmental management plan that outlines mitigation strategies for identified risks. For example, if we discover a protected wetland area, we’d implement measures like erosion control, water diversion techniques, and carefully planned construction activities to avoid any adverse impacts. Regular site inspections and documentation are crucial for tracking progress and ensuring ongoing compliance throughout the project. We often engage environmental consultants to provide expert guidance and ensure adherence to stringent regulations.

Q 10. Describe your experience with utility location and protection.

Utility location and protection are critical for safety and project efficiency. My experience includes utilizing various methods for utility locating, such as ‘one-call’ systems, ground-penetrating radar (GPR), and physical probing. Before any excavation, a thorough utility locate is performed to identify the precise location of underground utilities, including water lines, gas lines, electrical cables, and communication lines. This information is then used to establish safe working zones, and I’m experienced with implementing appropriate safety measures, like installing barriers, shoring, and protective covers. For instance, on a highway widening project, accurate utility locating prevented a potentially catastrophic accident by avoiding damage to a high-pressure gas line. Effective communication with utility companies is also key to ensuring accurate information and to coordinate any required adjustments or rerouting during the project.

Q 11. What is your experience with asphalt and concrete work?

I have extensive experience with both asphalt and concrete work, from initial site preparation and base construction to finishing and quality control. My expertise covers various applications, including roadways, parking lots, sidewalks, and building foundations. This includes understanding the specifications for different mixes, proper compaction techniques, and the importance of curing procedures. For example, I’ve overseen projects involving large-scale asphalt paving using various paving methods including slipform pavers and conventional methods. I understand the importance of achieving proper density and smoothness to ensure longevity and performance. With concrete, my experience includes managing formwork, reinforcement placement, and finishing techniques to achieve a high-quality, durable surface. Quality control measures like testing the compressive strength are critical and are consistently employed in my work.

Q 12. How do you develop and manage a site maintenance schedule?

Developing and managing a site maintenance schedule requires a systematic approach. I begin by conducting a thorough site assessment to identify all assets and potential maintenance needs. This typically involves creating a detailed inventory of site features, including landscaping, pavements, drainage systems, and structures. Based on this assessment, a prioritized maintenance schedule is developed, considering factors such as frequency of needed tasks, urgency, and potential impact. This schedule might incorporate preventative maintenance, routine inspections, and reactive repairs. The schedule is then documented and communicated to the maintenance team, and a system for tracking progress and recording completed work is implemented. This could involve using software or spreadsheets to schedule and track tasks. Regular review and adjustments are crucial to keep the schedule relevant and effective. For instance, we might schedule annual weed control, bi-weekly lawn mowing, and monthly inspections of drainage systems. A well-maintained schedule ensures efficiency, prevents significant problems, and enhances the longevity of site assets.

Q 13. What are your experience with preventative maintenance?

Preventative maintenance is critical for minimizing costly repairs and extending the lifespan of site assets. My approach focuses on regular inspections and proactive repairs to address potential issues before they become major problems. This includes routine checks of drainage systems, pavements, landscaping, and structural components. For example, regular cleaning of gutters and downspouts prevents clogging and water damage. Similarly, prompt patching of minor pavement cracks prevents them from worsening and requiring more extensive repairs later. I’m proficient in identifying potential problems by recognizing early warning signs such as cracks, settling, or erosion. A proactive approach ensures site safety and reduces long-term costs. Detailed records of inspections and maintenance activities are kept for tracking and future reference. The specific preventative maintenance tasks are tailored to the unique characteristics and requirements of each site.

Q 14. How do you troubleshoot and repair common site maintenance issues?

Troubleshooting and repairing common site maintenance issues requires a systematic approach. I start by carefully assessing the problem, gathering relevant information, and identifying the root cause. This often involves visual inspection, testing, and potentially utilizing specialized equipment. For example, if a drainage system is malfunctioning, I’d check for blockages, assess pipe gradients, and inspect for leaks. Depending on the nature of the problem, repairs could range from simple tasks like clearing debris to more complex fixes requiring specialized equipment or contractor involvement. Once the repair is completed, I verify its effectiveness and document the process. Effective communication with clients or management is essential to keep them informed about progress and any necessary changes to the schedule or budget. A systematic troubleshooting approach minimizes downtime and ensures that repairs are both effective and cost-efficient.

Q 15. Explain your familiarity with building codes and regulations.

Building codes and regulations are the cornerstone of safe and compliant site preparation and maintenance. My familiarity spans various jurisdictions and encompasses aspects like zoning ordinances, safety regulations (OSHA, local equivalents), environmental protection laws (Clean Water Act, etc.), and accessibility standards (ADA). I understand the importance of these regulations in preventing accidents, protecting the environment, and ensuring projects are legally sound. For example, I’ve worked on projects requiring specific permits for demolition, soil disturbance, and stormwater management, ensuring all documentation was meticulously completed and submitted to the relevant authorities. I’m adept at interpreting complex regulations, staying current with updates, and proactively integrating compliance into all project phases.

Understanding these codes isn’t simply about avoiding fines; it’s about building responsibly and ethically. A thorough grasp of the regulations allows for proactive risk management, preventing costly delays and legal issues down the line. I routinely use online resources, professional journals, and attend industry workshops to keep my knowledge updated and ensure I am well-versed in the latest building codes for any given project location.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage a team during site preparation and maintenance?

Managing a team effectively during site preparation and maintenance requires a blend of leadership, communication, and delegation. I believe in fostering a collaborative environment where each team member feels valued and understands their role in achieving project goals. My approach starts with clearly defined roles and responsibilities, ensuring everyone is aware of their tasks and deadlines. Regular team meetings, both formal and informal, are crucial for open communication, addressing concerns, and sharing updates. I use a combination of verbal and written communication—from daily briefings to detailed task assignments—to maintain transparency and clarity.

Furthermore, I empower my team members by providing opportunities for skill development and professional growth. Delegation is key; I assign tasks based on individual strengths and experience, fostering a sense of ownership and accountability. I also focus on conflict resolution and providing constructive feedback, creating a positive and productive team dynamic. A successful project hinges not just on individual performance, but on the seamless collaboration of the entire team.

Q 17. How do you prioritize tasks during site maintenance?

Prioritizing tasks during site maintenance is crucial for efficient resource allocation and ensuring the smooth operation of the site. I use a combination of methods to prioritize, prioritizing tasks based on urgency, criticality, and impact. Urgency refers to the immediate need for action, such as repairing a leaking pipe to prevent further damage. Criticality refers to the importance of the task to overall site functionality, like maintaining essential equipment. Impact considers the consequences of not completing the task, for instance, neglecting landscaping might lead to safety hazards or negative aesthetics.

I often employ tools like a prioritized task list, categorized by urgency, criticality, and impact (e.g., using a weighted scoring system). This ensures that critical tasks are tackled first, followed by those with high impact and then urgency. This systematic approach minimizes downtime, prevents escalating problems, and optimizes resource utilization. Regularly reviewing and adjusting the priority list based on changing circumstances is key to adapting to unexpected issues and maintaining site efficiency.

Q 18. Describe your experience with budgeting and cost control for site maintenance.

Budgeting and cost control are paramount in site preparation and maintenance. I begin by developing a comprehensive budget that includes all anticipated costs, from materials and labor to equipment rentals and permits. This requires careful estimation and consideration of potential contingencies. Throughout the project, I meticulously track actual expenses against the budgeted amounts, using project management software to monitor progress and identify any discrepancies.

My experience includes implementing cost-saving measures without compromising quality. This involves exploring alternative materials, negotiating favorable contracts with suppliers, optimizing equipment usage, and scheduling work efficiently to minimize overtime. Regular budget reviews with stakeholders help ensure transparency and allow for proactive adjustments as needed. Thorough documentation of all financial transactions is essential for accountability and auditing purposes. A successful cost control strategy is proactive, transparent, and aligned with the overall project objectives.

Q 19. What software or tools do you use to manage site preparation and maintenance?

Managing site preparation and maintenance efficiently requires the right tools. I’m proficient in various software and tools to streamline workflows and ensure accurate record-keeping. For project management, I regularly use software such as MS Project or similar applications for scheduling, task assignment, and progress tracking. For communication, I utilize platforms like Slack or Microsoft Teams for efficient team interaction and updates. For financial tracking, I use accounting software such as QuickBooks or Xero to manage budgets, invoices, and expenses.

In terms of field tools, I am experienced with GPS systems for precise surveying and mapping, mobile devices for data collection, and various software to capture and manage site data such as images, videos, and reports. This technology integration enables better decision making and reduces reliance on manual methods, enhancing both accuracy and efficiency.

Q 20. How do you document and report on site preparation and maintenance activities?

Comprehensive documentation and reporting are fundamental to effective site preparation and maintenance. I maintain detailed records of all activities, including inspections, repairs, maintenance schedules, and material usage. This documentation includes photographs, videos, and detailed written reports, which are stored securely and organized systematically using cloud-based storage and a robust filing system.

Regular reports are generated to keep stakeholders informed about progress, cost management, and any issues encountered. These reports clearly outline completed tasks, ongoing projects, and any future maintenance needs, providing a transparent overview of site activities. The format and content of these reports are tailored to the specific needs and preferences of the stakeholders, ensuring clear and concise communication. This robust documentation process ensures accountability, facilitates problem-solving, and provides a valuable historical record for future reference.

Q 21. Describe your experience with erosion and sediment control.

Erosion and sediment control is a critical aspect of site preparation and maintenance, essential for protecting water quality and preventing environmental damage. My experience encompasses implementing various best management practices (BMPs) to minimize soil erosion and sediment runoff. This includes designing and installing silt fences, sediment basins, and other control measures appropriate for the specific site conditions and local regulations.

I understand the importance of pre-construction planning, selecting appropriate BMPs based on site topography, soil type, and rainfall patterns. Post-construction monitoring is also crucial; I regularly inspect the implemented controls, ensuring their effectiveness and making necessary adjustments or repairs. Compliance with all relevant environmental regulations is a priority, and I work closely with environmental agencies to ensure all activities are conducted in a responsible and sustainable manner. Preventing erosion and sediment control is not just environmentally responsible—it’s a crucial aspect of ensuring a safe and compliant project.

Q 22. How do you conduct regular site inspections?

Regular site inspections are crucial for proactive maintenance and preventing costly repairs. My approach involves a systematic, documented process. First, I develop a detailed checklist tailored to the specific site, encompassing all aspects from landscaping to structural elements. This checklist might include assessing pavement for cracks or potholes, checking for drainage issues, inspecting fencing for damage, and evaluating the overall cleanliness and safety of the site. Then, I conduct inspections at pre-determined intervals – weekly for high-traffic areas, monthly for less frequented spaces, and seasonally for aspects like snow removal preparation. I document all findings with photographs and detailed notes using a dedicated software or app, allowing for easy tracking of issues and trends over time. This allows me to identify potential problems early on, preventing minor issues from escalating into major, and costly, repairs.

For example, during a recent inspection, I noticed a small crack developing in a walkway. By addressing it promptly with sealant, I prevented it from widening and requiring more extensive and expensive repairs later.

Q 23. How do you handle emergency repairs?

Emergency repairs require a swift and efficient response. My procedure begins with a rapid assessment of the situation to ensure safety – securing the area and addressing any immediate hazards. Following this, I prioritize the repairs based on the severity of the problem and the potential risk. For instance, a burst pipe takes precedence over a minor landscaping issue. I then contact necessary contractors or suppliers (plumbers, electricians, etc.) and ensure access for them, often working outside of normal business hours. Thorough documentation of the emergency, repairs undertaken, and associated costs is crucial for insurance purposes and future planning. The entire process emphasizes safety, efficiency and clear communication with relevant stakeholders.

In one instance, a severe storm caused significant damage to a section of fencing. We swiftly addressed the immediate safety concerns – securing loose materials to prevent injury – and then mobilized a contractor for emergency repairs, ensuring the area was secure before nightfall.

Q 24. What is your experience with landscaping and grounds maintenance?

My experience in landscaping and grounds maintenance is extensive. I’m proficient in all aspects, from conceptual design and planting to ongoing maintenance. I understand the principles of plant selection considering local climate and soil conditions. My knowledge encompasses irrigation system management, pest and disease control, fertilization techniques, and pruning methods. I have experience with various hardscaping elements such as patios, walkways, retaining walls, and decorative features. I also understand the importance of sustainable landscaping practices and regularly incorporate environmentally friendly methods into my work.

For example, I’ve led projects involving the complete redesign of commercial property landscaping, resulting in aesthetically pleasing and ecologically conscious environments. This involved selecting drought-tolerant plants to reduce water consumption and implementing a water-wise irrigation system.

Q 25. Describe your experience with snow removal and winter maintenance.

Snow removal and winter maintenance are critical for site safety and accessibility. My experience includes developing and implementing comprehensive snow and ice management plans. This involves assessing the site’s unique characteristics, including slopes, traffic patterns, and potential hazards. I choose appropriate snow removal equipment – snow plows, snow blowers, shovels – depending on the scale of the operation. I also utilize various de-icing products, always selecting environmentally friendly options, and applying them strategically to minimize environmental impact while ensuring effective ice control. Regular monitoring of weather forecasts is crucial for proactive planning and timely deployment of resources.

For example, in a previous role, I managed snow removal for a large shopping center during a significant blizzard. Our proactive planning and efficient use of resources ensured that the site remained accessible and safe throughout the storm.

Q 26. How do you ensure the longevity of site infrastructure?

Ensuring the longevity of site infrastructure requires a preventative approach focusing on regular maintenance, proactive repairs, and strategic planning. This includes establishing a robust maintenance schedule encompassing all systems, from plumbing and electrical to paving and landscaping. Regular inspections are essential to identify potential problems early. Utilizing high-quality materials during initial construction and employing appropriate repair techniques prolongs the lifespan of infrastructure. Furthermore, employing sustainable practices minimizes environmental impact and reduces long-term maintenance costs.

For example, by regularly inspecting and sealing cracks in asphalt paving, we prevent water infiltration which can lead to costly damage in the future.

Q 27. Explain your understanding of different types of paving materials.

Different paving materials offer varying benefits and drawbacks. Asphalt is cost-effective and durable, ideal for large areas like parking lots. Concrete is highly durable and resistant to heavy loads, often used for driveways and walkways. Brick pavers provide aesthetic appeal and are permeable, allowing water to drain through, reducing runoff. Permeable interlocking concrete pavers offer a similar benefit with increased durability. The choice of material depends on factors such as budget, traffic volume, aesthetic preferences, and environmental considerations. Understanding the strengths and limitations of each is crucial for making informed decisions.

For instance, in a project with limited budget but high traffic volume, asphalt would be a practical choice. However, for a pedestrian area needing aesthetic appeal, brick pavers would be preferable.

Q 28. What is your experience with site security measures?

Site security is paramount. My experience encompasses implementing and managing various security measures, including access control systems (gates, keypads, security cameras), perimeter fencing, and lighting. I’m also familiar with alarm systems and their integration with security monitoring services. Regular security patrols, both physical and via remote monitoring systems, are essential for deterring crime and ensuring site safety. Working closely with local law enforcement to report and address any security breaches forms an integral part of the process. Security measures are tailored to the specific site’s needs and risk assessment.

For example, for a construction site, measures would focus on preventing theft of equipment. For a retail center, the focus might shift towards customer and staff safety, and deterring shoplifting. A risk assessment helps define the best approach for each situation.

Key Topics to Learn for Site Preparation and Maintenance Interview

- Site Surveying and Assessment: Understanding the importance of thorough site analysis, including soil conditions, topography, and potential hazards, before commencing any work. Practical application: Describing your experience in identifying and mitigating potential risks during site preparation.

- Clearing and Grubbing: Techniques and equipment used for removing vegetation, debris, and unwanted materials from a construction site. Practical application: Explaining your knowledge of safe and efficient clearing methods and the importance of adhering to environmental regulations.

- Grading and Excavation: Principles of earthmoving, leveling, and excavation, including understanding different soil types and their impact on site preparation. Practical application: Describing your experience operating or overseeing earthmoving equipment and ensuring proper site drainage.

- Erosion and Sediment Control: Implementing measures to prevent soil erosion and runoff during and after site preparation. Practical application: Explaining your knowledge of best practices for erosion control, such as silt fences and vegetation control measures.

- Utilities Management: Identifying and managing underground utilities to prevent damage during site preparation and construction. Practical application: Detailing your experience in locating and protecting underground utilities, working safely with utility companies.

- Site Maintenance and Landscaping: Post-construction site maintenance, including landscaping, cleanup, and waste disposal. Practical application: Describing your experience in maintaining a clean and safe work environment and proper waste disposal techniques.

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety regulations and procedures related to site preparation and maintenance. Practical application: Demonstrating a strong commitment to safety, including your experience in implementing and enforcing safety protocols.

- Problem-solving and Troubleshooting: Analyzing and resolving challenges encountered during site preparation and maintenance. Practical application: Giving examples of how you’ve overcome unexpected issues during site preparation or maintenance projects.

Next Steps

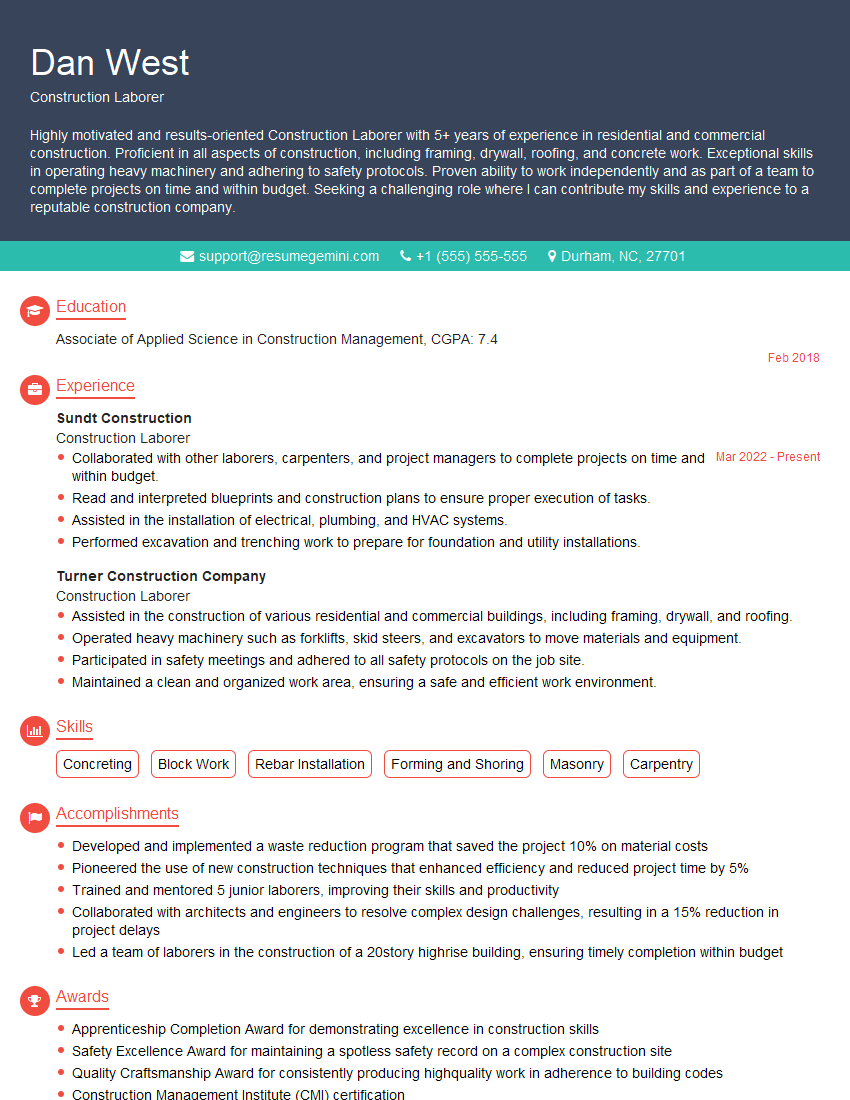

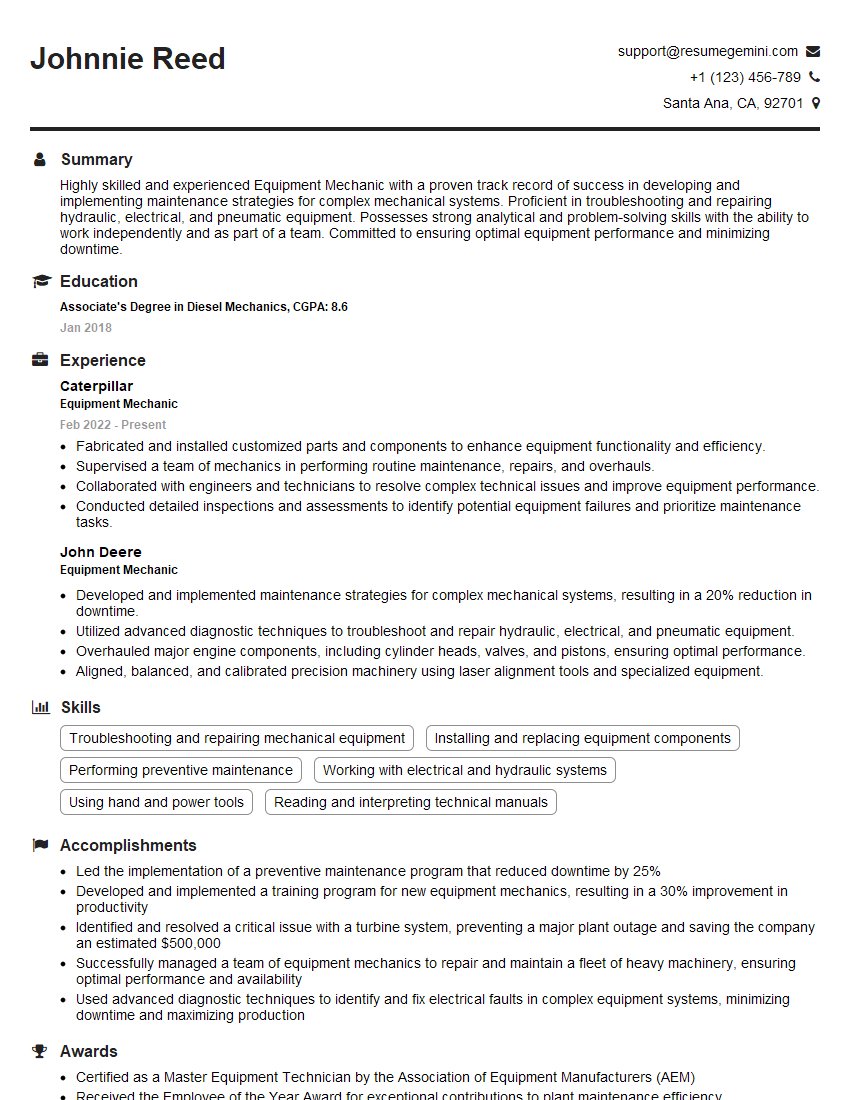

Mastering Site Preparation and Maintenance is crucial for career advancement in the construction and infrastructure industries. A strong understanding of these topics demonstrates valuable skills and experience to potential employers. To significantly enhance your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that will catch the eye of recruiters. We provide examples of resumes tailored to Site Preparation and Maintenance to guide you through the process. Take the next step towards your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456