Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Sludge Digestion interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Sludge Digestion Interview

Q 1. Explain the different types of sludge digestion processes.

Sludge digestion is a crucial wastewater treatment process that breaks down organic solids, reducing volume and producing valuable byproducts. There are primarily two types: aerobic and anaerobic digestion.

- Aerobic Digestion: This process uses oxygen to break down organic matter. It’s faster than anaerobic digestion, but requires significant energy for aeration and produces less biogas. Think of it like composting – you need air (oxygen) for the decomposition to happen efficiently. It’s often used for smaller wastewater treatment plants or as a pre-treatment step before anaerobic digestion.

- Anaerobic Digestion: This process occurs in the absence of oxygen, relying on specialized microorganisms to break down organic matter. It’s slower than aerobic digestion but produces biogas – a mixture of methane and carbon dioxide – which can be used for energy generation. This is much more common for larger wastewater treatment facilities due to the energy recovery potential. There are several variations within anaerobic digestion including: single-stage, two-stage, and high-rate (e.g., using different reactor designs like UASB reactors).

The choice between aerobic and anaerobic digestion depends on factors like the volume of sludge, energy requirements, and the desired end products.

Q 2. Describe the role of microorganisms in anaerobic digestion.

Microorganisms are the workhorses of anaerobic digestion. A complex consortium of bacteria, archaea, and protozoa work synergistically in a carefully orchestrated process to break down organic matter. This process occurs in several stages:

- Hydrolysis: Complex organic polymers (like carbohydrates, proteins, and lipids) are broken down into smaller, soluble molecules.

- Acidogenesis: These smaller molecules are fermented by acidogenic bacteria into volatile fatty acids (VFAs), alcohols, and hydrogen.

- Acetogenesis: VFAs are converted into acetic acid, hydrogen, and carbon dioxide.

- Methanogenesis: Methanogenic archaea convert acetic acid, hydrogen, and carbon dioxide into methane (CH4) and carbon dioxide (CO2).

Each group of microorganisms plays a specific role, and the balance between them is essential for efficient digestion. Think of it like a well-oiled machine, where each part performs its task to produce the final output (biogas and stabilized sludge).

Q 3. What are the key operational parameters to monitor in a sludge digester?

Monitoring key operational parameters ensures efficient and stable digestion. These include:

- Temperature: Optimal temperature ranges vary depending on the type of digester and the microorganisms involved. Consistent temperature is crucial for microbial activity.

- pH: The pH level significantly impacts microbial activity. Maintaining a slightly alkaline pH (around 7-8) is usually ideal.

- Volatile Fatty Acids (VFAs): High VFA concentrations indicate an imbalance in the process and can lead to digester failure. Monitoring VFAs provides early warning signs of problems.

- Alkalinity: Alkalinity is a measure of the digester’s buffering capacity, its ability to resist pH changes. Low alkalinity can be a problem.

- Biogas Production: Monitoring biogas production rate and composition (methane content) assesses the overall efficiency of the process.

- Solids Retention Time (SRT): This refers to the average time that solids spend in the digester, impacting microbial activity and digestion efficiency.

- Total Solids (TS) and Volatile Solids (VS): Monitoring changes in TS and VS indicates the rate of organic matter degradation.

Regular monitoring allows operators to identify potential issues early on and take corrective actions before significant problems arise.

Q 4. How do you control pH levels in a digester?

pH control is vital for optimal anaerobic digestion. Digester pH typically drops when there is an imbalance in the microbial community, leading to an accumulation of volatile fatty acids. Maintaining the optimal pH range (7-8) is achieved through several methods:

- Adding Lime (Ca(OH)2): Lime is a common neutralizing agent to raise pH. The amount added depends on the current pH and alkalinity of the digester.

- Adding Sodium Bicarbonate (NaHCO3): Sodium bicarbonate provides alkalinity buffering, preventing significant pH fluctuations.

- Controlling the Feed Rate and Composition: Avoiding sudden changes in feed composition and rate prevents sudden shifts in pH.

- Process Monitoring and Adjustment: Continuous monitoring of pH and adjusting the addition of neutralizing agents based on real-time measurements is essential.

Careful control of pH is essential to prevent digester failure, which can result in a substantial loss of biogas production and increased operating costs.

Q 5. Explain the process of biogas production in anaerobic digestion.

Biogas production in anaerobic digestion is the result of the methanogenic phase, the final step in the anaerobic process. Methanogenic archaea convert acetic acid, hydrogen, and carbon dioxide into methane (CH4) and carbon dioxide (CO2). The ratio of methane to carbon dioxide varies depending on several factors, including temperature, pH, and the composition of the feedstock.

The overall reaction can be simplified as:

C6H12O6 → 3CH4 + 3CO2(This is a simplified representation; the actual reactions are much more complex). The biogas produced can be captured and used for energy generation (e.g., electricity production, heating), reducing the need for external energy sources and making the process more sustainable.

Q 6. What are the common causes of digester failure?

Digester failure can have several causes, often stemming from a disruption in the delicate balance of the anaerobic process. Common causes include:

- Excessive VFA Accumulation: An imbalance in the microbial community, often due to overloading or changes in feedstock, can lead to a build-up of VFAs, causing a drop in pH and inhibiting methanogens.

- Inhibition of Methanogens: Certain substances, such as heavy metals, antibiotics, and some industrial chemicals, can inhibit the growth and activity of methanogens.

- Temperature Fluctuations: Significant deviations from the optimal temperature range can negatively impact the activity of microorganisms.

- Overloading: Adding too much organic matter to the digester than it can handle can overwhelm the microbial population and lead to process instability.

- Nutrient Deficiencies: A lack of essential nutrients like nitrogen and phosphorus can limit microbial growth and biogas production.

- Foaming: Excessive foaming can interfere with mixing and gas collection, leading to process instability.

Preventing digester failure requires careful monitoring of key operational parameters, proper feed management, and proactive troubleshooting.

Q 7. How do you troubleshoot a digester experiencing foaming?

Foaming in a digester is a common problem that can hinder the efficient operation of the system. It can be caused by several factors, including the presence of certain surfactants or proteins in the feedstock, or an imbalance in the microbial community. Troubleshooting involves a systematic approach:

- Identify the Cause: Determine the cause of foaming by analyzing the feedstock and digester contents. This might involve laboratory tests to identify the specific foaming agents.

- Reduce Foaming Agents: If the cause is identified as a specific compound in the feedstock, it might be possible to reduce the concentration of that compound or pre-treat the feedstock to remove the foaming agents.

- Improve Mixing: Adequate mixing can help break down foam. Check the efficiency of the mixing system and make adjustments if necessary.

- Chemical Foam Control: Anti-foaming agents can be added to the digester, but this should be done cautiously, as some anti-foam agents can be inhibitory to methanogenic activity. A trial and error method with different agents is required to find a suitable one.

- Adjust SRT: Increasing SRT can modify microbial populations and reduce foaming tendency, especially if it is linked to microbial imbalance.

- Adjust Operational Parameters: Optimizing parameters such as pH, temperature, and nutrient balance can help mitigate foaming.

Addressing foaming requires careful analysis and a well-planned strategy to avoid disrupting the overall anaerobic digestion process.

Q 8. Describe the methods used for sludge thickening.

Sludge thickening is a crucial pretreatment step in wastewater treatment, aiming to increase the solids concentration of the sludge before further processing. This reduces the volume needing handling, transportation, and ultimately disposal, resulting in significant cost savings. Several methods are employed:

Gravity Thickening: This is the simplest method, relying on sedimentation. Sludge is placed in a tank, and the solids settle under gravity. It’s cost-effective but slow and less efficient for low-solids sludge.

Flocculation: Chemical flocculants, like polymers, are added to the sludge to enhance the aggregation of smaller particles into larger, heavier flocs, improving settling rates in gravity thickeners. This is a common method to improve the efficiency of gravity thickening.

Centrifugal Thickening: This uses centrifugal force to separate solids from liquids, achieving much higher solids concentrations than gravity thickening. It’s faster and more efficient, particularly for handling high-volume sludge streams, but requires more energy input.

Dissolved Air Flotation (DAF): Air bubbles are introduced into the sludge, attaching to the solids and causing them to float to the surface, forming a concentrated sludge layer. DAF is effective for removing fats, oils, and greases along with suspended solids.

The choice of thickening method depends on factors such as sludge characteristics (e.g., solids content, type of solids), available space, energy costs, and overall treatment objectives. For example, a smaller plant might favor gravity thickening with flocculation, whereas a large municipal plant might opt for centrifugal thickening to handle its high sludge volume.

Q 9. What are the safety precautions associated with sludge handling?

Sludge handling involves significant safety risks due to its potentially hazardous nature. Key precautions include:

Personal Protective Equipment (PPE): Workers must always wear appropriate PPE, including respirators (to avoid inhaling harmful gases or pathogens), gloves, protective clothing, and eye protection. The specific PPE required will vary depending on the sludge’s composition and the task involved. For instance, handling chemically treated sludge necessitates more protective gear than handling raw primary sludge.

Confined Space Entry Procedures: Digesters and other sludge storage areas are often confined spaces with limited oxygen and potentially hazardous atmospheres (e.g., methane, hydrogen sulfide). Entry requires strict adherence to confined space entry procedures, including atmospheric monitoring, ventilation, and a standby rescue team.

Lockout/Tagout Procedures: To prevent accidental start-up of equipment during maintenance or repairs, lockout/tagout procedures are crucial. This ensures that equipment remains safely shut down before personnel enter areas where moving parts or hazardous materials are present.

Proper Training and Supervision: Workers must be adequately trained on safe sludge handling procedures and emergency response. Experienced supervision is critical for ensuring that protocols are followed and risks are mitigated.

Emergency Response Plan: A comprehensive emergency response plan should address potential scenarios like spills, equipment malfunctions, and exposure incidents, providing clear procedures for containment, cleanup, and first aid.

Regular safety inspections, maintenance of equipment, and ongoing employee training are essential for maintaining a safe working environment in a sludge handling facility.

Q 10. Explain the process of sludge dewatering.

Sludge dewatering aims to remove excess water from thickened sludge, reducing its volume and making it easier and cheaper to transport and dispose of or further process. Common dewatering methods include:

Belt Filter Presses: These use a moving belt to transport sludge through a series of filter cloths, squeezing out water under pressure. They are efficient and widely used, handling a range of sludge types.

Centrifuges: These use centrifugal force to separate solids from liquids. Different types of centrifuges are available, suited to different sludge characteristics. High-speed centrifuges can achieve high dryness levels, but require significant energy.

Vacuum Filters: A vacuum is applied to draw water through a filter cloth, leaving behind a dewatered cake. This method is effective but often slower than belt presses or centrifuges.

Pressure Filters: These utilize pressure to force water out of the sludge through filter media. They are effective for difficult-to-dewater sludge but require more energy.

Lagooning (Natural Dewatering): This is a slow, passive method where sludge is allowed to dewater naturally over time in a lagoon or pond. It is cost-effective but requires significant land area and is subject to environmental conditions.

The choice of dewatering method depends on factors such as the sludge’s characteristics, the desired dryness level, the capital and operating costs, and the available space.

Q 11. How do you manage digester supernatant?

Digester supernatant is the liquid fraction separated from the digested sludge in anaerobic digesters. It contains dissolved organic matter, nutrients, and potentially pathogens. Effective management is crucial for environmental protection and process optimization.

Return to the Digester: Part of the supernatant can be recycled back to the digester to maintain optimal conditions and improve digestion efficiency. This reduces the volume requiring further treatment.

Tertiary Treatment: The remaining supernatant typically requires further treatment before discharge to remove remaining pollutants. Common methods include biological treatment, chemical precipitation, or advanced oxidation processes.

Nutrient Recovery: The supernatant is a rich source of nutrients like nitrogen and phosphorus. Technologies are being developed to recover these nutrients for reuse in agriculture, reducing the environmental impact of wastewater treatment.

Land Application (with caution): In some cases, after appropriate treatment, the supernatant might be applied to land for irrigation, provided it meets stringent regulatory requirements to prevent contamination.

Effective supernatant management involves careful monitoring of its composition and appropriate treatment methods to meet regulatory discharge limits and ensure efficient digester operation. For example, regular testing for ammonia, phosphorus, and pathogens is essential for guiding treatment decisions.

Q 12. What are the environmental regulations related to sludge disposal?

Environmental regulations related to sludge disposal vary by jurisdiction but generally aim to protect human health and the environment. Key aspects often covered include:

Pathogen Reduction: Regulations typically stipulate minimum reductions of pathogens (e.g., E. coli) in the sludge to prevent contamination of soil and water.

Vector Attraction Reduction: Measures to minimize the attraction of vectors (e.g., flies, rodents) to sludge are often required. This can involve proper storage, handling, and land application methods.

Pollutant Limits: Limits are set for various pollutants in the sludge, including heavy metals (e.g., lead, cadmium, mercury), organic compounds, and nutrients (nitrogen and phosphorus). These limits often vary based on the intended disposal method.

Land Application Regulations: If land application is used, regulations typically specify the acceptable loading rates of pollutants and the types of soils suitable for sludge application.

Monitoring and Reporting: Facilities are usually required to monitor sludge characteristics, treatment effectiveness, and environmental impacts and submit regular reports to regulatory authorities.

Non-compliance with these regulations can result in penalties and legal actions. Staying abreast of current regulations is crucial for wastewater treatment operators and sludge management professionals.

Q 13. Describe the different methods for sludge disposal.

Sludge disposal methods vary depending on the sludge’s characteristics, local regulations, and economic considerations. Common methods include:

Land Application: Dewatered sludge can be applied to land as a soil amendment, enriching the soil with organic matter and nutrients. However, it’s crucial to ensure that pollutant loading rates remain within regulatory limits.

Incineration: Sludge can be burned at high temperatures, reducing its volume significantly and destroying pathogens and pollutants. Incineration produces ash, which needs careful management.

Landfilling: Sludge can be disposed of in landfills designated for biosolids. This method requires appropriate containment measures to prevent leachate contamination.

Composting: Sludge can be composted with other organic materials, producing a stable, humus-like product suitable for soil amendment. This requires careful management of the composting process to ensure proper decomposition and pathogen reduction.

Ocean Disposal (decreasingly common): In some regions, sludge was historically disposed of in the ocean, but this practice is increasingly restricted due to environmental concerns.

The choice of disposal method requires careful consideration of all aspects, including environmental impact, cost, regulatory compliance, and the overall sustainability of the process. A life-cycle assessment (LCA) can provide a comprehensive evaluation of the environmental impacts associated with each method.

Q 14. What are the benefits of anaerobic digestion compared to aerobic digestion?

Anaerobic digestion and aerobic digestion are two main methods for treating sludge. Both stabilize the sludge, but they differ significantly in their processes and outcomes:

Anaerobic Digestion: This process occurs in the absence of oxygen, using microorganisms to break down organic matter, producing biogas (primarily methane and carbon dioxide) and digestate (a stabilized sludge). The biogas can be captured and used as a renewable energy source, offering economic and environmental benefits. Anaerobic digestion generally produces less sludge volume than aerobic digestion.

Aerobic Digestion: This process utilizes oxygen to break down organic matter, producing carbon dioxide and water. It generally requires more energy input for aeration and produces less biogas. The resulting sludge is more stable than raw sludge but typically requires further dewatering before disposal.

Benefits of Anaerobic Digestion over Aerobic Digestion:

Biogas Production: Anaerobic digestion generates biogas, a valuable renewable energy source.

Reduced Sludge Volume: The volume of sludge produced is often lower than with aerobic digestion.

Lower Energy Consumption: While the initial investment may be higher, less energy is typically required for operation compared to aerobic digestion.

Nutrient Recovery Potential: Digestate can be used as a fertilizer, reducing the need for synthetic fertilizers.

However, anaerobic digestion requires more specialized equipment and operational expertise. The choice between the two methods depends on several factors, including the size of the plant, the sludge characteristics, energy costs, and local regulations. A cost-benefit analysis is usually conducted to determine the most appropriate method for a given situation.

Q 15. How do you calculate the biogas yield from a digester?

Calculating biogas yield from a digester involves understanding the relationship between the volatile solids (VS) added and the biogas produced. It’s not a simple calculation because biogas production depends on many factors including the type of sludge, the digester’s operational parameters (temperature, retention time, mixing), and the efficiency of the anaerobic digestion process. We generally estimate it using a combination of lab-scale tests and empirical data from similar facilities.

One common approach involves determining the biogas potential of the sludge through laboratory-scale batch tests. These tests measure the cumulative biogas production over time from a known amount of sludge. The results are then used to develop a predictive model for the full-scale digester. The model considers factors like the volatile solids concentration in the influent, the solids retention time (SRT), and the digester temperature.

For example, if a lab test shows that 1 kg of VS produces 0.3 cubic meters of biogas, and a full-scale digester receives 1000 kg of VS per day, a rough estimate of the daily biogas production would be 300 cubic meters. However, this is a simplification. In practice, we use more sophisticated models that account for variations and losses in the full-scale process.

Ultimately, regular monitoring of biogas production and VS reduction in the full-scale digester is crucial to fine-tune the predictive model and ensure accurate yield estimations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of volatile solids reduction in sludge digestion.

Volatile solids reduction (VS reduction) in sludge digestion is a key performance indicator (KPI) that measures the efficiency of the anaerobic digestion process. Volatile solids represent the organic matter in the sludge that can be broken down by microorganisms. During anaerobic digestion, these organic compounds are converted into biogas (methane and carbon dioxide) and digested solids (liquor and stabilized sludge). The difference between the VS input and VS output (in the digester effluent) represents the VS reduction.

A high VS reduction indicates efficient digestion, meaning most of the organic matter is being converted into biogas and stabilized solids. Think of it like this: you’re feeding microorganisms a ‘meal’ (the VS). The higher the VS reduction, the better the microorganisms are at ‘eating’ that meal and producing energy (biogas) and a less odorous and easily handled final product.

VS reduction is typically expressed as a percentage:

((VSin - VSout) / VSin) * 100%where VSin is the volatile solids concentration in the influent and VSout is the volatile solids concentration in the effluent. A typical target for VS reduction in well-operated digesters is between 35% and 60%, depending on the sludge type and process conditions.

Q 17. What are the different types of digester configurations?

Sludge digesters come in various configurations, each with its own advantages and disadvantages. The choice depends on factors like sludge characteristics, site constraints, capital cost, and operational requirements. Common configurations include:

- Completely Mixed Digesters (CMD): These are simple, relatively inexpensive, and easy to operate. The sludge is thoroughly mixed, ensuring uniform conditions throughout the digester.

- Completely Mixed Continuous Flow (CMCF): Similar to CMDs, but sludge continuously flows in and out. This provides consistent biogas production.

- Two-Stage Digesters: These involve separate acidogenic and methanogenic stages, optimizing conditions for each stage of the anaerobic digestion process. This often results in higher biogas yields.

- High-rate anaerobic digesters (e.g., UASB, anaerobic filters): These are designed to achieve higher digestion rates per unit volume compared to conventional digesters, often using specialized media or configurations to enhance biomass retention and mixing.

- Anaerobic Lagoons: These are large, open tanks with minimal mixing. They are cost-effective but require large land areas and have slower digestion rates.

Each configuration has its own operational challenges and ideal applications. For instance, a completely mixed digester might be suitable for smaller-scale operations, while a two-stage system might be preferred for large-scale wastewater treatment plants to optimize biogas production and sludge stabilization.

Q 18. How do you optimize digester performance?

Optimizing digester performance involves a multi-faceted approach focused on maintaining optimal conditions for the anaerobic microorganisms. Key strategies include:

- Temperature control: Maintaining the optimal temperature range for the specific microorganisms (mesophilic or thermophilic). Temperature fluctuations can significantly affect digestion efficiency.

- pH control: Anaerobic digestion is sensitive to pH changes. Maintaining a near-neutral pH (around 7) is crucial. This may involve adding alkaline substances to neutralize acidic byproducts.

- Proper mixing: Adequate mixing ensures uniform distribution of substrates, promoting better contact with microorganisms and preventing stratification (settling of solids).

- Solids retention time (SRT): SRT is a critical parameter influencing digester performance. It should be optimized to balance the need for sufficient retention time for complete digestion with the potential for accumulation of excess solids.

- Monitoring and control: Regular monitoring of parameters like pH, temperature, volatile fatty acids (VFAs), biogas production, and VS reduction is essential for detecting any deviations and implementing corrective actions.

- Nutrient balance: Maintaining adequate levels of essential nutrients (e.g., nitrogen, phosphorus) is important for optimal microbial growth.

Regularly reviewing operational data and making informed adjustments based on the feedback from monitoring systems allows for adaptive management and ensures that the digester runs consistently at peak efficiency.

Q 19. Describe the role of temperature in anaerobic digestion.

Temperature plays a crucial role in anaerobic digestion as it dictates the activity and efficiency of the microorganisms involved. Anaerobic digestion processes are broadly categorized into mesophilic (30-40°C) and thermophilic (50-55°C) digestion.

Mesophilic digestion operates at lower temperatures, offering lower energy requirements for heating. However, it may be slower and produce less methane than thermophilic digestion.

Thermophilic digestion, while faster and potentially producing more biogas, demands greater energy input for heating and often requires more robust system designs to withstand high temperatures.

The choice of temperature range is a trade-off. Higher temperatures are beneficial in terms of the kinetics of the reactions and reduce digester volume, but come at a higher cost. Lower temperatures require less energy input but come with a slower reaction rate and therefore a larger digester size.

Maintaining a consistent temperature is also crucial for stable performance. Sudden temperature changes can stress the microorganisms, impacting digestion efficiency and potentially leading to process upsets (e.g., acidification).

Q 20. What are the common instrumentation used in sludge digesters?

Sludge digesters require comprehensive instrumentation to monitor and control various parameters. Common instrumentation includes:

- Temperature sensors: To monitor the digester temperature at multiple points, ensuring uniform temperature distribution.

- pH probes: To measure the pH of the digester contents, helping to maintain optimal conditions for the microorganisms.

- Gas flow meters: To measure the biogas production rate. This data provides insight into digester performance and energy recovery potential.

- Gas composition analyzers: To determine the methane content of the biogas, aiding in optimizing process efficiency and assessing energy value.

- Level sensors: To monitor the sludge level inside the digester, preventing overflow and ensuring sufficient working volume.

- Pressure sensors: To monitor the pressure within the digester, which can indicate potential blockages or other issues.

- VFAs (volatile fatty acids) analyzers: To measure the concentration of VFAs, indicating the presence of potential process issues such as overloading or acidification.

- Data acquisition and control systems (SCADA): To integrate and manage all the sensor data, providing real-time monitoring and process control.

The specific instrumentation selected depends on factors such as the digester size and complexity, the desired level of control, and operational goals.

Q 21. How do you ensure the proper mixing of sludge in a digester?

Ensuring proper mixing of sludge in a digester is crucial for maintaining optimal conditions for anaerobic digestion. Poor mixing leads to stratification, where solids settle at the bottom, creating zones with differing substrate concentrations and microbial populations. This impairs the efficiency of digestion and may lead to process instability.

Mixing strategies vary depending on the digester configuration:

- Mechanical mixing: This is a common method involving impellers or mixers rotating within the digester. This is effective for completely mixed digesters but requires significant energy input.

- Recirculation: Sludge is withdrawn from the bottom and recirculated back to the top. This method is also effective but may require pumps and piping.

- Hydraulic mixing: In some designs, the inflow and outflow patterns contribute to sufficient mixing. This is often seen in high-rate anaerobic digestion systems.

- Gas mixing: The biogas generated itself can provide some degree of mixing, especially in smaller digesters, but it’s often insufficient for large-scale operations.

The choice of mixing method depends on the digester’s size, shape, and desired mixing intensity. Regular maintenance of mixing equipment is vital to ensure consistent and effective mixing throughout the digester’s operating life. Monitoring for dead zones (areas with minimal mixing) is a key aspect of ensuring overall performance.

Q 22. What are the different methods for controlling odors from a digester?

Odor control in sludge digesters is crucial for environmental compliance and community relations. Unpleasant smells arise from the volatile organic compounds (VOCs) produced during anaerobic digestion. Effective odor control strategies employ a multi-pronged approach.

Proper Digester Operation: Maintaining optimal temperature and pH levels minimizes the production of odorous gases. Think of it like controlling a recipe – the right conditions yield the best results (less odor).

Covering the Digester: A properly sealed digester prevents the escape of odorous gases. This is like putting a lid on a pot to prevent smells from escaping.

Gas Collection and Treatment: Collecting biogas and treating it before release significantly reduces odor. This involves processes such as scrubbing with chemicals or biological filtration, essentially ‘cleaning’ the gas before it goes into the atmosphere.

Biofiltration: Passing the biogas through a bed of microorganisms which consume the odorous compounds. This is nature’s way of cleaning up – microorganisms ‘eat’ the smelly components.

Chemical Treatment: Using chemicals like activated carbon or oxidizing agents to neutralize odorous compounds. This is like using a cleaning agent to remove stubborn stains.

Odor Masking: This is generally a less desirable approach. This involves the use of masking agents, that are used to cover up rather than solve the problem, although can be helpful during emergencies or specific operational needs.

Q 23. Describe the process of sludge conditioning.

Sludge conditioning prepares the digested sludge for dewatering, making it easier to handle and dispose of or further process. The goal is to improve the sludge’s dewaterability by altering its physical and chemical properties.

Chemical Conditioning: This involves adding chemicals like polymers, lime, or ferric chloride to alter the sludge’s charge and floc size. Polymers, for example, help the smaller particles clump together (like glue) forming larger, easier-to-filter solids.

Thermal Conditioning: This increases the sludge temperature to improve its dewaterability by changing its viscosity and promoting the release of bound water. Think of it like making mud easier to handle after it’s dried in the sun.

Biological Conditioning: This uses microorganisms to break down the sludge and reduce its water content. This relies on the bacteria and fungi naturally present to improve the sludge properties, a more sustainable method than chemical treatments.

The choice of conditioning method depends on factors such as sludge characteristics, cost, and available resources. A common real-world example is using polymers in a municipal wastewater treatment plant to improve the effectiveness of belt filter presses used to dewater the sludge.

Q 24. How do you manage digester solids buildup?

Digester solids buildup, often manifested as a thickened sludge layer or ‘bottom sludge’, can lead to decreased digester efficiency and operational problems. Managing this requires a proactive approach.

Regular Solids Removal: Implementing a scheduled solids removal program using techniques like pumping and transferring to another location for further treatment prevents buildup.

Maintaining Optimal Digester Loading: Avoid overloading the digester with excessive amounts of raw sludge. Think of it like cooking too much food; the pot overfills and things get messy.

Monitoring Solids Concentration: Regular monitoring of total suspended solids (TSS) and volatile suspended solids (VSS) helps identify potential buildup early on. Regular checks allow the operator to catch issues early and prevent costly future interventions.

Digester Design Considerations: Properly sized digesters with sufficient mixing capabilities are crucial. A well-designed digester has a better chance of preventing issues in the first place.

Ignoring solids buildup can cause operational issues such as reduced gas production and digester failure. Regular maintenance and proactive management prevent costly shutdowns.

Q 25. Explain the importance of proper sludge sampling and analysis.

Proper sludge sampling and analysis is paramount for effective digester operation and process optimization. It provides the data needed to assess performance, identify problems, and make informed decisions.

Representative Sampling: Obtaining a sample that accurately represents the overall digester contents is crucial. This might involve taking samples from multiple locations within the digester.

Parameter Analysis: Analyzing key parameters such as volatile fatty acids (VFAs), pH, alkalinity, ammonia, and solids concentrations helps assess the health and stability of the digestion process.

Microbial Analysis: Evaluating the microbial community can provide insights into digestion efficiency and potential problems. This allows to identify which bacteria or microbes are driving the digestion process and understand if there are issues.

Data Interpretation: Interpreting the results in the context of digester performance allows operators to take action. This might lead to changes in operational parameters such as temperature or the addition of chemicals.

For example, elevated VFAs can indicate overloading or process upsets, prompting adjustments to sludge feed rates. Regular analysis prevents costly long-term problems.

Q 26. What are the challenges associated with managing digester scum?

Digester scum is a floating layer of solids that can hinder gas production and affect digester operation. Managing scum presents several challenges.

Scum Buildup: Excessive scum buildup can reduce gas collection efficiency and create anaerobic conditions within the scum layer, leading to odor problems.

Scum Composition: Scum often consists of fats, oils, greases, and other materials that are difficult to break down, making management challenging.

Scum Removal: Removing scum requires specialized equipment and techniques. It’s not something you do with a standard shovel, and it needs to be done carefully to avoid compromising the digester itself.

Impact on Digester Performance: Scum accumulation can lead to decreased gas production, operational instability, and increased maintenance requirements.

Strategies for scum management include regular scum removal, proper feed management, enhanced mixing, and the use of scum-breaking agents. Effective management requires a proactive and comprehensive approach.

Q 27. How do you handle emergency situations in a sludge digester?

Emergency situations in sludge digesters can include uncontrolled gas release, digester overflow, or equipment failures. A well-defined emergency response plan is essential.

Emergency Shutdown Procedures: Establishing clear procedures for shutting down the digester in case of an emergency is critical. This includes steps for closing valves, turning off equipment, and evacuating personnel.

Gas Release Response: In case of uncontrolled gas release, immediate actions include activating ventilation systems, evacuating personnel, and contacting emergency services.

Overflow Response: Actions taken to deal with overflows include activating backup systems, contacting local authorities, and implementing containment measures.

Equipment Failure Response: A comprehensive response includes determining the nature of the failure, implementing temporary repairs or workarounds, and ensuring safe operation of the remaining equipment.

Regular Drills: Conducting regular drills and training personnel ensures readiness to respond effectively to potential emergency situations.

A well-prepared emergency response plan is crucial to minimizing environmental damage and ensuring personnel safety.

Q 28. What are the future trends in sludge digestion technology?

The future of sludge digestion technology points towards increased efficiency, sustainability, and integration with other renewable energy systems.

Advanced Digester Designs: New digester designs incorporating advanced mixing, temperature control, and solids separation technologies will enhance efficiency.

Integration with Biogas Upgrading: Upgrading biogas to biomethane allows for its injection into natural gas grids, further enhancing its value and reducing reliance on fossil fuels.

Improved Process Monitoring and Control: Advanced sensors and data analytics provide real-time monitoring and control of digestion processes, leading to optimized operations and reduced energy consumption.

Hybrid Digestion Systems: Combining anaerobic digestion with other treatment processes to enhance overall efficiency and reduce waste volume is becoming increasingly common.

Resource Recovery: Focusing on recovering valuable resources from sludge, such as biochar, fertilizers, and other bioproducts, is a major trend.

These advancements aim to make sludge digestion a more sustainable and resource-efficient process, contributing to a circular economy approach to waste management.

Key Topics to Learn for Sludge Digestion Interview

- Anaerobic Digestion Processes: Understand the different types of anaerobic digestion (e.g., mesophilic, thermophilic) and their respective advantages and disadvantages. Explore the microbial communities involved and their roles in the process.

- Process Control and Optimization: Learn about monitoring parameters like pH, temperature, volatile fatty acids (VFAs), and biogas production. Understand how to troubleshoot common operational issues and optimize digestion efficiency.

- Biogas Utilization and Treatment: Explore methods for capturing, cleaning, and utilizing biogas for energy generation (e.g., combined heat and power). Familiarize yourself with biogas upgrading technologies.

- Sludge Characteristics and Pretreatment: Understand how the characteristics of the influent sludge (e.g., solids content, composition) affect the digestion process. Explore various pretreatment techniques to improve digestibility.

- Digester Design and Operation: Learn about different digester types (e.g., completely mixed, plug flow) and their design considerations. Understand the principles of digester operation, including loading rates and hydraulic retention times.

- Safety and Environmental Considerations: Familiarize yourself with safety protocols associated with handling biogas and digester operation. Understand environmental regulations and best practices for managing digester effluent.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and resolve common issues in sludge digestion, such as foaming, acidification, and reduced biogas production. Be prepared to discuss your problem-solving approach in a structured manner.

Next Steps

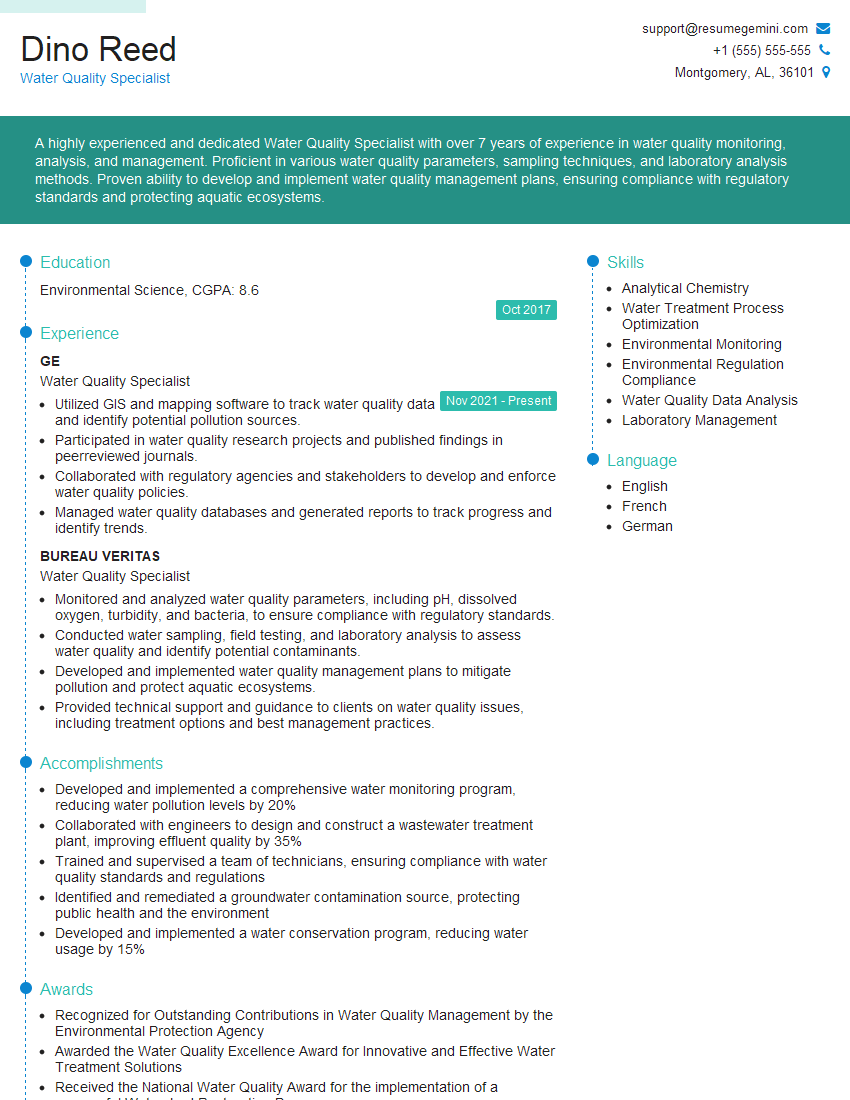

Mastering sludge digestion principles and practices is crucial for career advancement in the environmental engineering and wastewater treatment fields. A strong understanding of this area opens doors to specialized roles and leadership opportunities. To enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes tailored specifically to Sludge Digestion are available on ResumeGemini to guide your preparation. Take the next step in your career journey today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?