Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Sow Housing and Equipment Management interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Sow Housing and Equipment Management Interview

Q 1. Describe your experience with different sow housing systems (e.g., gestation stalls, group housing).

My experience encompasses a wide range of sow housing systems, from traditional individual gestation stalls to various group housing configurations. I’ve worked with both fully slatted floors and partially slatted systems with solid areas for resting. Gestation stalls, while providing individual feeding and monitoring, often limit sow movement and natural behaviors. Conversely, group housing systems, such as those utilizing pens with ample space and enrichment features, better reflect sows’ natural social and exploratory behaviors. However, careful management is crucial in group settings to minimize aggression and ensure even resource access. I’ve been involved in the transition of farms from individual stalls to group housing, which required significant planning, staff training, and close observation to address any challenges that arise during the adaptation period. This included implementing careful sow introduction protocols to minimize fighting and optimizing pen design to provide adequate space for all animals.

Q 2. What are the key considerations for designing a new sow housing facility?

Designing a new sow housing facility requires careful consideration of several key factors. First and foremost is the chosen housing system; the design will dramatically differ between individual stalls and group housing. This decision should align with animal welfare standards, farm management practices, and economic considerations. Beyond the housing system, other critical factors include:

- Space allowance: Sufficient space per sow is vital for both comfort and minimizing stress. Regulations and best practices should be followed strictly.

- Ventilation: A well-designed ventilation system is essential to maintain optimal air quality, temperature, and humidity. This helps prevent respiratory diseases.

- Manure management: An efficient manure management system minimizes environmental impact and reduces labor requirements. This often involves considerations of slurry pits, pumping systems, and environmental regulations.

- Biosecurity: The design should incorporate biosecurity measures to minimize the risk of disease transmission. This includes features like strategically placed footbaths and traffic control systems.

- Ease of cleaning and disinfection: The facility should be designed to facilitate easy and thorough cleaning and disinfection to maintain hygiene and prevent the spread of pathogens.

- Accessibility for maintenance and repairs: All equipment should be easily accessible for routine maintenance and troubleshooting.

- Work flow efficiency: The design should optimize worker movements and efficiency to minimize labor costs and improve worker safety.

Finally, building materials need to be durable, easy to clean, and withstand the harsh environment of a sow barn. The entire process requires collaboration with architects, engineers, and animal welfare experts to ensure a functional and humane environment for the sows.

Q 3. Explain the importance of biosecurity in sow housing management.

Biosecurity is paramount in sow housing management, as it’s the cornerstone of disease prevention. A breach in biosecurity can lead to devastating outbreaks of infectious diseases, resulting in significant economic losses and animal suffering. Effective biosecurity involves multiple layers of protection. This includes:

- Strict access control: Limiting access to authorized personnel only, and requiring proper hygiene protocols (e.g., changing clothing and footwear).

- Vehicle disinfection: Disinfecting all vehicles entering the farm premises.

- Rodent and pest control: Implementing strategies to prevent rodent and pest infestations which could carry diseases.

- Quarantine procedures: Quarantining newly introduced animals to monitor their health before integrating them into the main herd.

- Vaccination programs: Implementing comprehensive vaccination programs to protect sows against prevalent diseases.

- Hygiene protocols: Strict cleaning and disinfection routines for all equipment and facilities.

- All-in/all-out management: This system involves emptying and thoroughly cleaning the barn before introducing a new group of sows, effectively preventing disease build-up.

Think of it like a fortress – each layer of biosecurity is a wall protecting the herd from external threats. A single weak point can compromise the entire system.

Q 4. How do you monitor and maintain the environmental conditions (temperature, humidity, ventilation) within a sow barn?

Monitoring and maintaining environmental conditions is crucial for sow health and productivity. This typically involves using a combination of automated systems and regular manual checks. Automated systems often include:

- Temperature sensors: Placed throughout the barn to monitor temperature fluctuations.

- Humidity sensors: To monitor humidity levels, crucial for respiratory health.

- Ventilation controllers: Automated systems that adjust ventilation rates based on temperature and humidity readings.

Manual checks involve regular visual inspections and using handheld instruments to verify sensor readings. Problems such as faulty sensors or malfunctioning ventilation systems can be quickly identified. These systems should be regularly calibrated to ensure accuracy. Data logging allows us to track environmental conditions over time, helping us identify trends and potential problems. Understanding the interplay between temperature, humidity, and ventilation is key. For example, maintaining optimal ventilation is especially critical during hot weather to prevent heat stress, and conversely, during cold weather to prevent chilling.

Q 5. What are the common equipment malfunctions in sow barns, and how do you troubleshoot them?

Common equipment malfunctions in sow barns include failures in feeding systems (e.g., clogged augers, malfunctioning feeders), ventilation problems (e.g., faulty fans, broken sensors), and issues with manure management (e.g., clogged pumps, leaks in the slurry system). Troubleshooting usually starts with a visual inspection to identify the problem’s source. For example, a clogged auger in an automated feeding system might require manual clearing, while a malfunctioning sensor might need replacement or recalibration. More complex problems often require specialist knowledge and repair services. I always keep a detailed maintenance log to record problems, repairs, and preventative maintenance schedules, reducing downtime and extending the life of equipment. Preventive maintenance is a crucial strategy, involving regular inspections and lubrication of moving parts to minimize malfunctions.

Q 6. Describe your experience with automated feeding systems for sows.

My experience with automated feeding systems for sows is extensive. These systems provide accurate and efficient feed delivery, improving feed efficiency and reducing labor costs. I’ve worked with various types of systems, from those using simple auger systems to more sophisticated systems with individual sow feeding stations and electronic monitoring capabilities. These advanced systems allow for precise feed allocation based on individual sow needs and production stage. This precision feeding not only enhances sow health and productivity but also reduces feed waste. However, effective management includes regular monitoring for malfunctions like auger blockages or feeder failures. Regular calibration and preventative maintenance are essential to ensure the system’s accuracy and longevity. It’s also important to understand the nutritional needs of sows at different stages of their reproductive cycle to program the feeders appropriately.

Q 7. How do you ensure the proper functioning and maintenance of gestation crates or group housing systems?

Ensuring the proper functioning and maintenance of gestation crates or group housing systems requires a proactive approach. Regular inspections are vital to identify any potential problems early. This includes checking for structural damage, broken components, and cleanliness. For gestation crates, ensuring the latch mechanisms are functioning correctly and that the crate itself is structurally sound is key. Regular cleaning and disinfection are crucial to maintain hygiene and prevent the spread of pathogens. For group housing, ensuring adequate space, provision of sufficient feeding and resting areas, and the presence of enrichment items are essential for animal welfare. Regular monitoring of sow interactions in group housing is necessary to detect and address potential aggression issues. Preventative maintenance, including regular lubrication and repair of faulty components, plays a key role in maximizing system longevity and minimizing downtime. A documented maintenance schedule and a system for tracking repairs and maintenance actions ensures compliance and helps to anticipate potential issues.

Q 8. What are the best practices for cleaning and disinfecting sow housing facilities?

Cleaning and disinfecting sow housing is crucial for preventing disease and maintaining animal welfare. It’s a multi-step process focusing on thorough cleaning followed by effective disinfection. We begin with removing all manure and debris, ideally using high-pressure washers. This is followed by scrubbing all surfaces with a detergent solution to remove organic matter. After rinsing thoroughly, we apply an appropriate disinfectant, ensuring adequate contact time as specified on the product label. Different disinfectants are effective against various pathogens, so selection depends on the prevalent diseases in the area and the barn’s history. For example, we might use a broad-spectrum disinfectant like peracetic acid for general cleaning or a specific product targeting a particular bacterial or viral issue. Finally, the barn needs to be allowed to dry completely before repopulating.

Example: In one instance, we experienced an outbreak of *Streptococcus suis*. After thorough cleaning, we switched to a disinfectant specifically effective against this bacteria, seeing a significant reduction in cases within the next cycle.

- Step 1: Manure and debris removal

- Step 2: Detergent wash

- Step 3: Rinsing

- Step 4: Disinfectant application

- Step 5: Drying

Q 9. How do you manage manure handling and disposal in a sow barn?

Manure management is vital for environmental protection and minimizing biosecurity risks. Our system typically involves a scraped floor system that channels manure to a central collection pit. From there, we employ several disposal methods depending on local regulations and environmental considerations. Liquid manure can be stored in lagoons for later use as fertilizer, after appropriate treatment, ensuring it meets regulatory standards. Alternatively, we may utilize a manure management system that involves spreading the composted manure on fields, benefiting the soil as natural fertilizer. This method requires careful adherence to regulations to avoid environmental contamination. Solid manure is typically removed by trucks regularly, minimizing the risk of build-up and odor.

Example: In one operation, we implemented a covered lagoon system to reduce odor and prevent runoff, improving both the environment and worker well-being. This coupled with strategic field spreading minimized our disposal costs and added to soil fertility.

Q 10. What are the key performance indicators (KPIs) you use to assess the effectiveness of sow housing and equipment?

Key Performance Indicators (KPIs) are crucial for evaluating sow housing effectiveness and identifying areas for improvement. We monitor several key metrics. These include:

- Farrowing rate: The percentage of bred sows that successfully farrow (give birth).

- Pre-weaning mortality rate: The percentage of piglets that die before weaning.

- Weaning-to-estrus interval: The time it takes a sow to return to heat after weaning.

- Number of piglets weaned per sow per year: A measure of overall productivity.

- Sow health: Tracking the incidence of lameness, mastitis, and other health issues.

- Equipment downtime: The percentage of time equipment is unavailable due to malfunction.

By tracking these KPIs, we can identify bottlenecks and implement changes to enhance overall efficiency and sow welfare. Regular review of the data and comparison to benchmarks is necessary for continuous improvement.

Q 11. Explain your experience with different types of sow feeding systems.

I have experience with various sow feeding systems, including electronic sow feeders (ESFs), dry-feed systems, and wet-feed systems. ESFs offer precise control over individual sow feed intake, optimizing nutrition based on factors like pregnancy stage and body condition score. Dry-feed systems are simpler and less expensive but may be less precise in individual feed allocation. Wet-feed systems use a slurry or mash of feed, and are often less efficient than other methods, leading to higher feed costs and potential hygiene issues.

Example: In a previous operation, the transition to ESFs resulted in a significant improvement in feed efficiency and reduced feed costs because it allowed for more precise feed allocation based on the sow’s nutritional needs. We also saw a reduced incidence of aggression at the feeders since individual sow feeding reduces competition.

Q 12. How do you ensure the safety of workers and animals in the sow barn?

Ensuring safety for both workers and animals is paramount. For workers, this includes providing adequate training on safe handling procedures for sows, equipment operation, and biosecurity protocols. Personal Protective Equipment (PPE) such as sturdy boots, gloves, and eye protection are mandatory. Regular safety inspections of the barn, equipment, and electrical systems prevent accidents. The barn layout should also be designed for ease of movement and to minimize risks of slips, trips, and falls. For animals, safety is ensured through appropriate housing design to prevent injuries, regular health checks and appropriate interventions when needed, and stress reduction measures. This includes a focus on minimizing noise and providing adequate space and comfortable temperature conditions.

Example: We implemented a comprehensive safety training program including hands-on demonstrations of safe sow handling techniques, leading to a noticeable decrease in worker injuries. Similarly, modifications to the pen design reduced sow injuries from falling.

Q 13. What are your strategies for minimizing sow injuries and stress?

Minimizing sow injuries and stress involves a holistic approach. Providing sufficient space per sow to reduce competition is crucial, and proper pen design minimizing sharp edges and obstacles helps prevent injuries. Regular hoof trimming and other preventative health measures also reduce lameness, a major source of stress and injury. Implementing proper environmental enrichment, such as providing adequate bedding and opportunities for exploration, reduces stress levels. Careful handling techniques during tasks like weighing or pregnancy checking also minimize stress and the risk of injury to both the sow and the handler.

Example: We transitioned from a traditional farrowing crate to a farrowing pen with more space, resulting in a decrease in sow-related injuries and an increase in piglet survival rates. We found that the sows also exhibited less agitation and aggression.

Q 14. Describe your experience with record-keeping and data management in a sow barn.

Comprehensive record-keeping is fundamental for effective sow barn management. We utilize a combination of electronic and paper-based systems to track a wide array of data. This includes individual sow records documenting breeding information, gestation and lactation performance, health records (treatments, vaccinations), and any observed behavioral issues. Production records track farrowing rate, piglet mortality, and weaning weights. Equipment maintenance logs record servicing and repairs, enabling preventative maintenance and minimizing downtime. Data is regularly analyzed to identify trends and areas for improvement. Software helps manage the data efficiently and allows for data visualization, providing insights into the overall performance of the barn.

Example: Using our data management system, we identified a correlation between certain feed rations and an increase in pre-weaning mortality. Based on this, we adjusted the feed formulation, resulting in a noticeable improvement in piglet survival.

Q 15. How do you manage and prevent pest infestations in sow housing?

Pest control in sow housing is crucial for maintaining animal health and productivity. A multi-pronged approach is essential, focusing on prevention and proactive management. This begins with meticulous hygiene. Regular cleaning and disinfection of the barn, including manure removal and proper waste disposal, significantly reduces pest breeding grounds. We utilize a robust cleaning schedule, often incorporating high-pressure washing and the application of approved disinfectants.

Secondly, we implement preventative measures like sealing cracks and crevices in the building structure to eliminate entry points for pests. Rodent control involves strategically placed traps and bait stations, always prioritizing safe and humane methods. For insect control, we often rely on integrated pest management (IPM) strategies, employing biological controls where possible, before resorting to chemical treatments. This involves monitoring pest populations closely and only implementing chemical control when absolutely necessary, always selecting products with low toxicity and adhering to label instructions. For example, we might use pheromone traps to monitor insect populations before introducing targeted treatments.

Finally, regular inspections are vital. We conduct thorough barn inspections at least weekly, looking for signs of infestation and immediately addressing any issues detected. This proactive approach minimizes the impact of any pest problems and keeps the sows healthy and comfortable.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of ventilation systems.

My experience encompasses several ventilation systems, each with its own strengths and weaknesses. Natural ventilation, relying solely on strategically placed openings and wind pressure, is cost-effective but limited in its climate control capabilities. This is suitable for milder climates but can be challenging in extreme temperatures or humidity. I’ve also worked extensively with mechanical ventilation systems, which provide greater control. These can be further categorized into various types such as negative pressure, positive pressure, and hybrid systems. Negative pressure systems pull air out of the barn, creating a natural inflow of fresh air. Positive pressure systems force air into the barn, pushing stale air out. Hybrid systems combine elements of both.

I have hands-on experience with tunnel ventilation, commonly used in larger barns, where air is drawn in at one end and exhausted at the other, creating a consistent airflow. I’ve also worked with cross ventilation, where air is introduced from opposite sides of the barn. The choice of system depends heavily on factors such as barn size, climate, and budgetary considerations. For example, in hot, humid climates, an evaporative cooling system may be incorporated into the mechanical ventilation to mitigate heat stress on the sows. Careful monitoring of temperature, humidity, and air quality using sensors and data loggers is crucial for optimizing ventilation effectiveness regardless of the system type. Regular maintenance, including filter changes and fan inspections, is also vital to prevent system failures.

Q 17. How do you maintain and repair various types of farm equipment (e.g., feeders, waterers, manure scrapers)?

Maintaining and repairing farm equipment is a critical aspect of efficient sow production. This involves regular inspections, preventative maintenance, and timely repairs. For feeders, this includes checking for proper function, ensuring consistent feed delivery, and addressing any blockages or malfunctions. We regularly clean and lubricate moving parts and promptly replace worn components. For example, auger failures are common, so we keep spare augers on hand and have the skills to replace them quickly. For waterers, we check for leaks, ensuring sufficient water pressure and flow. Regular cleaning prevents bacterial growth and ensures hygienic drinking water for the sows. Cleaning nipple drinkers requires daily attention to prevent clogging and maintain cleanliness.

Manure scrapers, whether automated or manual, require regular lubrication and inspection of chains, sprockets, and motors. Sharp objects in the manure can cause damage, so regular checks are essential. We’re also trained to troubleshoot electrical issues and make basic repairs. More significant problems are always reported to our maintenance team immediately. Our approach always prioritizes safety – all repairs are conducted with the equipment de-energized and following appropriate safety protocols. Effective record-keeping is vital, documenting all maintenance activities and repairs, which is crucial for tracking expenses and identifying patterns that help in predictive maintenance.

Q 18. Explain your understanding of preventative maintenance schedules for sow barn equipment.

Preventative maintenance schedules are the cornerstone of minimizing equipment downtime and maximizing operational efficiency. We utilize a comprehensive schedule, tailored to the specific equipment used in the sow barn. This schedule is based on manufacturer recommendations and our own operational experience. It involves regular inspections, cleaning, lubrication, and part replacements according to predetermined intervals. For instance, we might schedule weekly checks of feeders and waterers, monthly checks of manure scrapers, and quarterly inspections of ventilation systems.

These schedules are meticulously documented, often using computerized maintenance management systems (CMMS) to track tasks and record completion dates. We’ve found that this approach is far more cost-effective than reactive repairs, saving time and money in the long run. For example, proactive lubrication of moving parts can extend the lifespan of equipment and prevent costly breakdowns. This scheduled approach also helps us anticipate potential issues, such as wear and tear on specific components, allowing for proactive replacement before catastrophic failure occurs.

Q 19. How do you address equipment breakdowns and minimize downtime?

Equipment breakdowns are inevitable, but minimizing downtime requires a well-defined process. Our first step is always to identify the nature of the problem. This often involves a visual inspection and, if necessary, testing with appropriate tools. We have a hierarchy of troubleshooting steps, starting with simple fixes (like clearing blockages or replacing fuses) before escalating to more complex issues. We maintain a readily available inventory of spare parts for commonly failing components to enable faster repairs.

For issues we can’t resolve in-house, we have established relationships with reliable maintenance contractors specializing in agricultural equipment. We maintain a log of all breakdowns, analyzing the data to identify recurring issues or weaknesses in our equipment. This helps us to adapt our preventative maintenance schedules and potentially invest in more robust equipment in the future. For example, repeated failures of a specific pump might lead us to investigate the water quality or pressure, or consider investing in a higher quality, more durable model.

Q 20. What are the common challenges associated with sow housing and how do you overcome them?

Challenges in sow housing are multifaceted. Climate control is frequently a major issue, especially in extreme temperatures. Heat stress can negatively impact sow reproduction and overall health, while cold stress can lead to decreased feed intake and increased mortality. We overcome this challenge through meticulous ventilation management and the implementation of environmental control systems, monitoring parameters like temperature and humidity and making adjustments accordingly. We’ve even incorporated climate-controlled areas within the barns for particularly vulnerable sows.

Another challenge involves maintaining optimal hygiene and biosecurity to prevent disease outbreaks. This requires rigorous cleaning and disinfection protocols, along with strict biosecurity measures to limit the introduction of pathogens. For example, we carefully manage access to the barn and implement strict cleaning protocols for anyone entering. Disease outbreaks are extremely disruptive and costly; minimizing this risk through vigilant hygiene is vital. Lastly, efficient manure management is critical. We employ systems that minimize environmental impact and ensure effective waste disposal to prevent issues like odor and pollution. This involves regular manure removal and proper storage, potentially including anaerobic digestion for biogas generation.

Q 21. What are the regulations and guidelines related to animal welfare and biosecurity that you follow?

We adhere strictly to all relevant regulations and guidelines pertaining to animal welfare and biosecurity. These are constantly evolving, and staying updated is a continuous process. We abide by national and regional legislation concerning animal housing standards, ensuring sufficient space, proper ventilation, and environmental enrichment for the sows. We provide access to information and training for staff on animal welfare best practices, and actively encourage reporting of any welfare concerns.

Biosecurity protocols are paramount, protecting our herd from disease. These protocols range from strict hygiene practices within the barn to vehicle disinfection procedures and controlled access to prevent the introduction of pathogens. We maintain detailed records of all movements of animals and personnel and implement quarantine procedures when necessary. Regular health checks of the sows, alongside collaboration with veterinary professionals, are essential in monitoring and controlling disease. We regularly review our biosecurity measures and adapt them based on current best practices and any emerging diseases to maintain a robust and protective system.

Q 22. Explain your experience with implementing new technologies in sow housing management.

Implementing new technologies in sow housing requires a careful, phased approach. It’s not just about buying the latest gadget; it’s about integrating it seamlessly into existing workflows and ensuring it improves efficiency and animal welfare. My experience involves assessing the farm’s specific needs, selecting appropriate technologies, and managing the entire implementation process, from initial planning to staff training and ongoing maintenance.

- Example: In one operation, we replaced a manual feeding system with an automated system. This required careful planning to ensure smooth transitions during the switch-over, minimizing disruption to the sows. We also provided extensive training to staff on operating and maintaining the new equipment. The result was a significant reduction in labor costs and improved feed consistency.

- Another example: We integrated data logging systems that monitor environmental conditions (temperature, humidity) and sow activity, generating real-time data for analysis. This allows for proactive problem-solving, improved environmental control, and better early detection of potential health issues.

Successful technology implementation hinges on thorough staff training, robust technical support, and a clear understanding of the technology’s capabilities and limitations.

Q 23. How do you assess and improve the overall efficiency of sow housing and equipment operations?

Assessing and improving the efficiency of sow housing and equipment operations involves a holistic approach, focusing on key performance indicators (KPIs) and continuous improvement. I utilize a structured process:

- Data Collection: Gather data on various aspects like feed conversion ratios, mortality rates, farrowing rates, labor costs, equipment downtime, and overall productivity. This involves using existing farm records and implementing additional data-logging systems where necessary.

- Benchmarking: Compare the farm’s performance to industry benchmarks and best practices to identify areas for improvement. This helps set realistic goals and measure progress.

- Process Analysis: Analyze workflows to identify bottlenecks and inefficiencies. This might involve mapping out the entire process from sow arrival to weaning and using tools like flowcharts or value stream mapping to visualize the process.

- Implementation of Improvements: Based on the analysis, implement targeted improvements. This might include equipment upgrades, changes in management practices, staff training, or adopting new technologies.

- Monitoring and Evaluation: Continuously monitor the KPIs to track the effectiveness of the implemented changes and make further adjustments as needed.

For example, identifying high equipment downtime might lead to a preventative maintenance program, while a low farrowing rate could trigger a review of breeding practices and sow health management.

Q 24. Describe your experience with budgeting and cost control in relation to sow housing and equipment.

Budgeting and cost control are crucial in sow housing management. My approach involves a combination of meticulous planning, accurate cost estimation, and ongoing monitoring. This starts with a detailed budget outlining all expected expenditures, including equipment purchases, maintenance, repairs, labor, feed, utilities, and veterinary care.

- Cost Estimation: Accurate cost estimation relies on historical data, market research, and input from vendors. Contingency funds should be included to account for unexpected expenses.

- Regular Monitoring: Costs are tracked and compared to the budget regularly, usually monthly. Any significant variances are investigated and corrective actions are implemented.

- Preventive Maintenance: Investing in preventative maintenance significantly reduces unexpected repair costs in the long run. This is a key component of cost control.

- Negotiation: Negotiating favorable contracts with suppliers for feed, equipment, and services can significantly reduce costs.

I also advocate for a cost-benefit analysis before implementing any significant capital expenditure, ensuring that the investment aligns with the farm’s overall financial goals and contributes to improved profitability.

Q 25. How do you prioritize maintenance tasks to ensure optimal barn functionality?

Prioritizing maintenance tasks is essential for ensuring optimal barn functionality and minimizing downtime. I use a combination of methods:

- Preventative Maintenance Schedules: Develop detailed preventative maintenance schedules for all equipment, based on manufacturer recommendations and historical data. This involves regular inspections, lubrication, and cleaning.

- CMMS (Computerized Maintenance Management System): Utilizing a CMMS system to track maintenance activities, schedule tasks, and manage spare parts inventory. This allows for better organization and efficiency in managing maintenance.

- Prioritization Matrix: Employ a prioritization matrix that considers the criticality of the equipment and the potential impact of a failure. This matrix assigns priorities to tasks based on factors such as safety, animal welfare, and production impact. Critical tasks are addressed immediately, while less critical ones can be scheduled for later.

- Condition-Based Maintenance: For certain equipment, condition-based maintenance is employed, using sensors and data monitoring to identify potential issues before they lead to significant breakdowns. This proactive approach reduces downtime and repair costs.

For example, cleaning of feeding systems is a high-priority task due to the impact on animal health and feed efficiency.

Q 26. How do you train and supervise staff on safe and efficient equipment operation?

Training and supervising staff on safe and efficient equipment operation is paramount for both worker safety and operational efficiency. My approach involves a multi-stage process:

- Initial Training: Provide comprehensive training on all equipment, including safety procedures, operational instructions, and troubleshooting techniques. This often involves hands-on training with experienced personnel.

- Ongoing Training: Conduct regular refresher training to reinforce safe practices and address any changes in equipment or procedures. This also includes updates on new technologies or safety regulations.

- Standard Operating Procedures (SOPs): Establish clear SOPs for each piece of equipment, detailing proper operation, maintenance, and emergency procedures. These SOPs should be readily accessible to all staff.

- Regular Supervision: Regular supervision ensures that staff are following safety procedures and operating equipment correctly. This includes observing staff during their work, providing feedback, and addressing any concerns.

- Documentation: Maintain detailed records of training and supervision activities for compliance and auditing purposes.

A good example is ensuring all staff are trained on lockout/tagout procedures before performing maintenance on electrical equipment to prevent accidents.

Q 27. How do you stay current with advancements in sow housing technology and best practices?

Staying current with advancements in sow housing technology and best practices is essential for maintaining a competitive edge. My methods include:

- Industry Publications and Journals: Regularly reading industry publications, journals, and online resources to stay informed about new technologies, research findings, and best practices.

- Conferences and Workshops: Attending industry conferences, workshops, and seminars to network with other professionals and learn about the latest developments.

- Professional Organizations: Actively participating in professional organizations related to animal agriculture and swine production to access resources and connect with peers.

- Vendor Relationships: Maintaining strong relationships with equipment suppliers to stay updated on new product releases and technological advancements.

- Online Courses and Webinars: Taking advantage of online courses and webinars to enhance my knowledge and skills in specific areas.

This continuous learning ensures that I am always equipped to make informed decisions and implement the most effective solutions for sow housing and equipment management.

Q 28. Describe a time you had to troubleshoot a complex equipment issue in a sow barn; what was your approach?

In one instance, a critical failure occurred in the automated feeding system of a large sow barn. The system suddenly stopped distributing feed, causing significant concern. My systematic approach to troubleshooting ensured a swift resolution:

- Initial Assessment: I first visually inspected the system for any obvious issues, such as power outages or physical blockages. This revealed no immediate cause.

- Data Analysis: I checked the system’s diagnostic logs and data to identify any error messages or unusual patterns. This pinpointed a potential problem with a specific sensor.

- Component Testing: I systematically tested individual components of the system, isolating the faulty sensor. This involved replacing the sensor with a known working unit to confirm the diagnosis.

- Repair or Replacement: Once the faulty sensor was identified, we replaced it with a new one. The entire process was carefully documented.

- System Verification: After the replacement, we thoroughly tested the entire feeding system to ensure it was functioning correctly.

- Root Cause Analysis: Finally, we analyzed the root cause of the sensor failure to determine whether it was due to wear and tear, environmental factors, or a manufacturing defect. This helped to prevent similar issues in the future.

The quick resolution minimized disruption to sow feeding, avoided potential animal welfare issues, and demonstrated efficient problem-solving skills.

Key Topics to Learn for Sow Housing and Equipment Management Interview

- Sow Housing Design and Welfare: Understanding different housing systems (e.g., gestation stalls, group housing), their impact on sow comfort and productivity, and relevant legislation and best practices. Consider the trade-offs between different systems and their implications for animal welfare and economic efficiency.

- Equipment Selection and Maintenance: Knowledge of various equipment used in sow farms (e.g., feeding systems, manure management systems, climate control systems). This includes understanding the principles of operation, maintenance procedures, troubleshooting common issues, and the importance of preventative maintenance for optimal performance and longevity.

- Environmental Control: Understanding the impact of temperature, humidity, ventilation, and air quality on sow health and productivity. This includes knowledge of different climate control systems and strategies for maintaining optimal environmental conditions within the barn.

- Biosecurity and Hygiene: Understanding and implementing biosecurity protocols to minimize disease transmission and maintain a healthy herd. This includes knowledge of cleaning and disinfection procedures, pest control, and waste management practices.

- Record Keeping and Data Analysis: Understanding the importance of accurate record keeping for tracking sow performance, identifying areas for improvement, and complying with regulations. This includes familiarity with different data analysis techniques to optimize farm operations.

- Financial Management and Budgeting: Understanding the cost implications associated with sow housing and equipment, including capital expenditures, operating costs, and return on investment. This includes the ability to analyze financial data and make informed decisions regarding equipment upgrades and farm improvements.

- Health and Safety: Understanding and adhering to all relevant health and safety regulations to ensure a safe working environment for all personnel. This includes knowledge of proper equipment handling procedures and hazard identification and mitigation strategies.

Next Steps

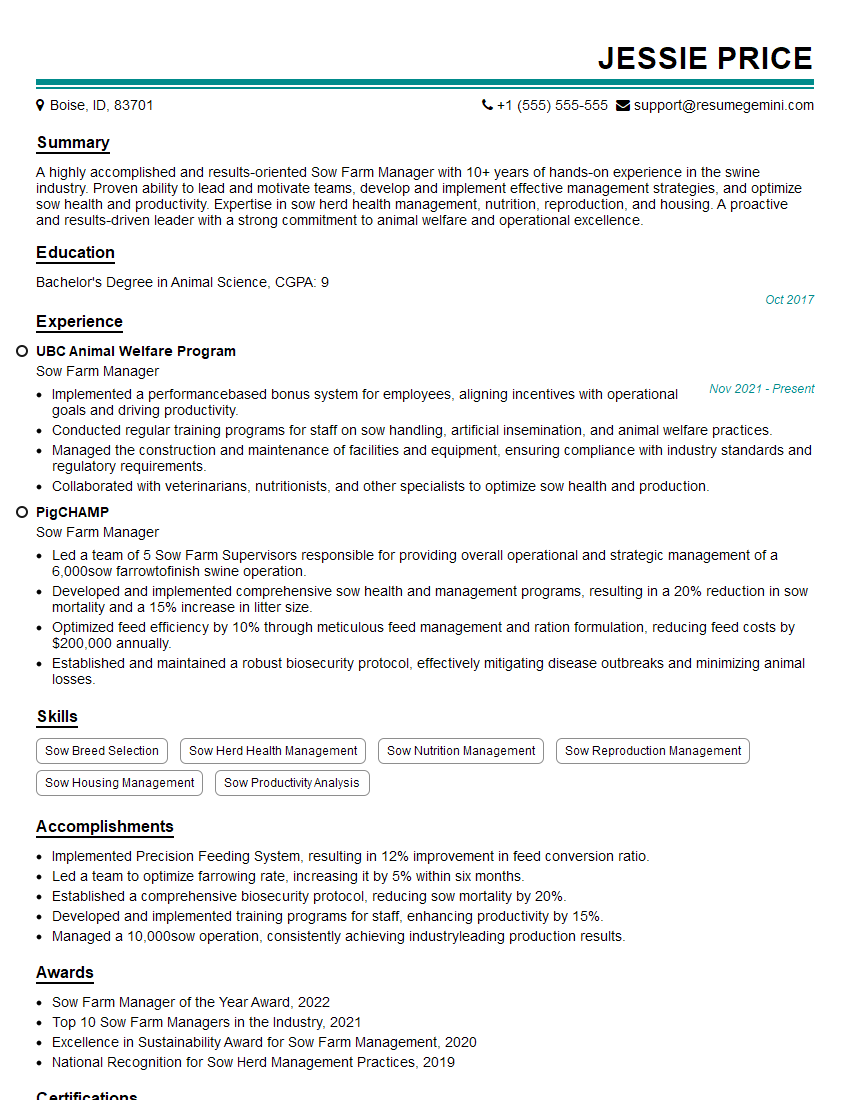

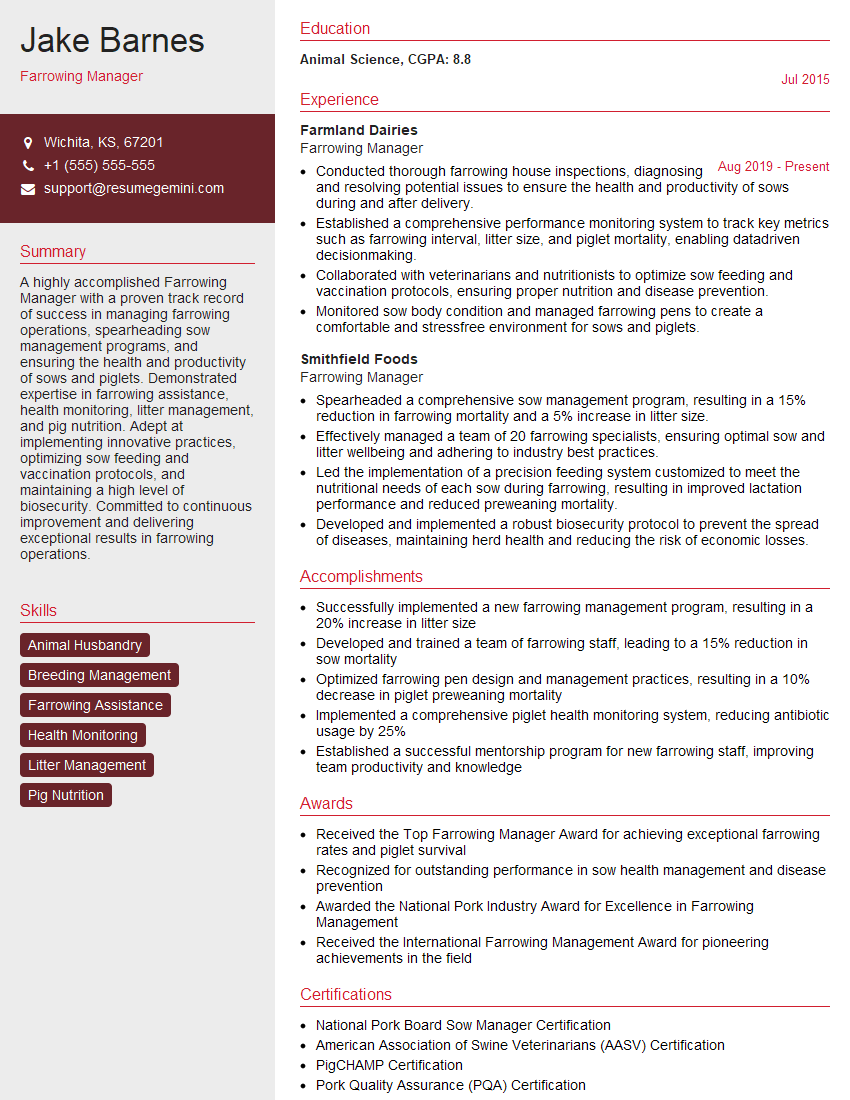

Mastering Sow Housing and Equipment Management is crucial for career advancement in the agricultural industry. A strong understanding of these principles demonstrates your commitment to efficient and ethical farming practices, increasing your value to potential employers. To significantly improve your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. We highly recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Sow Housing and Equipment Management to help you create a compelling application that stands out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?