Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Cracking a skill-specific interview, like one for Storage and Warehousing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Storage and Warehousing Interview

Q 1. Explain the FIFO and LIFO inventory methods. When would you use each?

FIFO and LIFO are two common inventory accounting methods that dictate how the cost of goods sold (COGS) and ending inventory are calculated. They impact a company’s financial statements and tax liability.

FIFO (First-In, First-Out): This method assumes that the oldest items in your inventory are sold first. Think of it like a queue at a grocery store – the first ones in line are the first ones served. This is particularly suitable for perishable goods or products with a short shelf life, such as dairy products or pharmaceuticals. Using FIFO, the cost of goods sold reflects the cost of the oldest inventory, while the ending inventory value reflects the cost of the newest inventory.

Example: Imagine a bakery that bakes 10 loaves of bread on Monday at $1 each, and 10 more on Tuesday at $1.20 each. If they sell 15 loaves, under FIFO, the COGS would be calculated as (10 loaves * $1) + (5 loaves * $1.20) = $16. The value of the remaining 5 loaves in inventory would be $6 ($1.20/loaf).

LIFO (Last-In, First-Out): This method assumes that the newest items in inventory are sold first. Imagine a stack of plates – the last plate you put on the stack is the first one you take off. LIFO is often used for non-perishable goods where the cost of goods fluctuates significantly. This method can be beneficial during periods of inflation as it results in a higher COGS, leading to lower taxable income. However, it can also lead to a lower reported net income.

Example: Using the same bakery example, under LIFO, the COGS would be (10 loaves * $1.20) + (5 loaves * $1) = $17. The value of the remaining 5 loaves in inventory would be $5 ($1/loaf).

When to use each: The choice between FIFO and LIFO depends on various factors including industry regulations, tax implications, and the nature of the inventory. FIFO is generally preferred for industries with perishable goods or where maintaining accurate inventory valuation is crucial, while LIFO might be more advantageous in industries with non-perishable goods and fluctuating prices, aiming for tax optimization. It’s important to note that LIFO is not permitted under IFRS (International Financial Reporting Standards).

Q 2. Describe your experience with Warehouse Management Systems (WMS).

I have extensive experience implementing and managing Warehouse Management Systems (WMS) across various warehouse environments. My experience spans from small-scale operations to large distribution centers with high-volume throughput. I’ve worked with both on-premise and cloud-based WMS solutions, including [mention specific WMS solutions e.g., Manhattan Associates, Blue Yonder, etc.].

My responsibilities have included:

- System selection and implementation, including requirements gathering, vendor selection, and configuration.

- Process optimization and automation using WMS functionalities such as slotting optimization, wave picking, and directed putaway.

- Integration with other enterprise systems like ERP and TMS to ensure seamless data flow.

- Training warehouse personnel on the proper use of the WMS.

- Ongoing system maintenance and troubleshooting.

- Data analysis and reporting to identify areas for improvement and cost reduction.

In one particular project, we implemented a new WMS at a distribution center which resulted in a 20% increase in order fulfillment efficiency and a 15% reduction in picking errors. This was achieved through careful planning, efficient system configuration, and targeted training for the warehouse staff.

Q 3. How do you ensure accuracy in inventory counts?

Ensuring inventory accuracy is paramount for efficient warehouse operations and financial reporting. My approach combines cycle counting, physical inventory counts, and technological solutions to maintain a high degree of accuracy.

Cycle Counting: This involves regularly counting a small subset of inventory items throughout the year. Instead of a large, disruptive annual count, we focus on high-value or frequently moved items, identifying and correcting discrepancies promptly. This allows us to continuously monitor accuracy and prevent large errors from accumulating.

Physical Inventory Counts: Periodic full or partial physical counts are necessary to verify inventory data against system records. These counts are meticulously planned and executed, following established procedures to minimize disruptions and ensure complete accuracy. We use bar code scanners and handheld devices to capture data efficiently and reduce manual data entry errors. The data is then reconciled with the WMS.

Technological Solutions: Utilizing a robust WMS with integrated barcode scanning, RFID technology (Radio-Frequency Identification), and real-time inventory tracking significantly enhances accuracy. This reduces manual data entry and provides a continuously updated view of inventory levels.

Quality Control: Rigorous training for warehouse personnel on proper inventory handling and counting procedures is critical. This includes standardized procedures, proper use of scanning devices and double-checking processes.

Q 4. What are the key performance indicators (KPIs) you track in a warehouse?

Key Performance Indicators (KPIs) are essential for monitoring and improving warehouse performance. I typically track the following:

- Order Fulfillment Rate: Percentage of orders fulfilled accurately and on time.

- Inventory Accuracy: Percentage of inventory items with accurate counts.

- Picking Accuracy: Percentage of items picked correctly.

- Storage Capacity Utilization: Percentage of available storage space being used.

- Order Cycle Time: Time taken to fulfill an order from receipt to shipment.

- Inventory Turnover Rate: Number of times inventory is sold and replaced over a period.

- Receiving Efficiency: Time taken to receive and process incoming shipments.

- Shipping Accuracy: Percentage of shipments delivered to the correct location.

- Cost per Order: Overall cost of fulfilling an order.

Regularly reviewing these KPIs allows us to identify bottlenecks, areas needing improvement, and the overall effectiveness of warehouse operations. This data-driven approach ensures that we can optimize processes and enhance productivity.

Q 5. How do you handle discrepancies between inventory records and physical counts?

Discrepancies between inventory records and physical counts require a systematic investigation to identify the root cause and implement corrective actions. My approach follows these steps:

- Investigate: Thoroughly review the discrepancy report, noting the specific items and quantities involved. Investigate potential causes such as picking errors, receiving errors, damage, theft, or system glitches.

- Reconcile: Attempt to reconcile the discrepancy by double-checking the physical count and reviewing relevant transaction data in the WMS. Look for any missing transactions or incorrect data entries.

- Identify Root Cause: Based on the investigation, pinpoint the root cause of the discrepancy. Was it a human error, a system problem, or a process flaw?

- Implement Corrective Actions: Based on the root cause, implement corrective actions to prevent similar discrepancies in the future. This might involve retraining personnel, improving processes, upgrading system software, or enhancing physical security.

- Update Records: Once the discrepancy is resolved and the root cause addressed, update the inventory records to reflect the accurate count.

- Document: Maintain comprehensive documentation of the discrepancy, the investigation, and the corrective actions taken. This helps prevent future issues and provides a record for audit purposes.

For example, a consistent discrepancy in a specific aisle might indicate a problem with the aisle’s location in the WMS, while recurrent discrepancies with a specific product could suggest a problem with its handling procedures.

Q 6. Describe your experience with different types of storage equipment (e.g., racking, shelving).

My experience with storage equipment encompasses a wide range of solutions tailored to various warehouse needs and product characteristics. I’ve worked extensively with:

- Pallet Racking: This is a common system for storing pallets efficiently. I have experience selecting the appropriate racking type (selective, drive-in, push-back, etc.) based on factors like warehouse layout, product characteristics, and throughput requirements.

- Shelving: Various shelving systems, from standard shelving units to cantilever racking for long or bulky items, are used to optimize space and accessibility. Selection considers the size and weight of the products, picking frequency, and overall warehouse design.

- Mezzanines: I’ve utilized mezzanines to create additional storage space on upper levels, maximizing vertical space utilization in high-ceiling warehouses.

- Mobile Racking: Mobile racking systems are highly space efficient; I’ve used them where maximizing space is critical. These require careful planning for accessibility and worker safety.

- AS/RS (Automated Storage and Retrieval Systems): I have experience with AS/RS systems in high-volume, automated warehouses, optimizing picking and storage through automated cranes and conveyors.

Selection of storage equipment involves careful consideration of factors such as product dimensions and weight, storage capacity requirements, picking methods, order fulfillment frequency, available space, and budget. Proper planning ensures safe, efficient, and cost-effective warehouse operations.

Q 7. Explain your process for receiving and inspecting incoming shipments.

My receiving and inspection process emphasizes accuracy, efficiency, and quality control. It involves the following steps:

- Notification and Scheduling: We receive advance shipment notifications (ASNs) from suppliers. This allows us to prepare the receiving area and assign resources accordingly.

- Receiving: Upon arrival, shipments are checked against the ASN. The quantity, condition of packaging, and overall shipment integrity are verified. This involves using barcode scanners to record each item.

- Inspection: A thorough inspection of the received goods is conducted, verifying that they meet quality standards and specifications. This might include checking for damage, defects, or discrepancies in quantity.

- Put-away: Once inspected and approved, the goods are put away in designated storage locations as guided by the WMS, optimizing space utilization and order fulfillment efficiency.

- Documentation: All receiving and inspection activities are meticulously documented. Discrepancies or damage are documented and reported to the supplier.

- Quality Control: Regular audits of the receiving process ensure that procedures are followed correctly and that any issues are addressed promptly.

This ensures that only verified and quality goods enter our warehouse, preventing potential problems down the line and safeguarding the integrity of our inventory.

Q 8. How do you manage warehouse space efficiently to optimize storage and flow?

Efficient warehouse space management is crucial for profitability. It involves strategically organizing inventory to maximize storage capacity and streamline the flow of goods. This requires a multi-pronged approach.

- Slotting Optimization: This involves assigning specific locations for inventory items based on factors like popularity, size, and weight. Fast-moving items are placed in easily accessible areas, while slower-moving items are located further back. For example, a high-demand product like a best-selling book would be in a prime location near the shipping area, while seasonal items might be stored in less accessible areas. Software solutions can assist with this process, simulating different layouts and predicting picking efficiencies.

- Inventory Management System (IMS): A robust IMS is fundamental. It provides real-time visibility into inventory levels, helping identify slow-moving or obsolete items and guiding decisions on storage allocation. For instance, an IMS might highlight an overstocked item, suggesting we consolidate its storage space or offer promotions to increase its turnover.

- Vertical Space Utilization: Maximizing vertical space is key. Using high-bay racking systems, mezzanine floors, and vertical lifts allows for a higher storage density within the same footprint. Imagine stacking pallets to the ceiling height, increasing capacity dramatically.

- Cross-Docking: For companies receiving and shipping goods quickly, cross-docking eliminates the need for long-term storage. Goods are transferred directly from inbound to outbound trucks, reducing handling and storage time. This is particularly useful in the fast-moving consumer goods industry.

- Regular Audits: Periodic audits are essential to identify areas for improvement. These may reveal inefficiencies in layout, storage methods, or processes. For example, a warehouse audit might reveal that a particular aisle is poorly organized, leading to increased picking times and potential safety hazards.

Q 9. What safety procedures do you follow in a warehouse environment?

Warehouse safety is paramount. We adhere to a rigorous safety program encompassing several key elements.

- Proper Training: All staff receive comprehensive safety training covering topics like forklift operation, hazard identification, and emergency procedures. This includes both initial training and regular refresher courses.

- Equipment Maintenance: Regular maintenance of all equipment, including forklifts, conveyors, and racking systems, ensures they are in safe working order. Regular inspections are crucial, and any defects are immediately addressed.

- Clear Signage and Markings: Well-placed signs clearly identify potential hazards, emergency exits, and designated walkways. Floor markings clearly delineate traffic patterns and storage areas.

- Personal Protective Equipment (PPE): The appropriate PPE, such as safety shoes, gloves, and high-visibility vests, is provided and mandatory in specific areas. For instance, forklift operators must always wear safety vests and helmets.

- Emergency Preparedness: Emergency drills and procedures are regularly practiced to ensure employees are prepared for various scenarios, such as fire, spills, or medical emergencies. This includes designated assembly points and clear evacuation routes.

- Housekeeping: Maintaining a clean and organized warehouse is crucial. Clear walkways, proper waste disposal, and regular cleaning significantly reduce the risk of accidents.

Q 10. How do you handle damaged or obsolete inventory?

Handling damaged or obsolete inventory requires a structured approach to minimize losses and maintain efficient operations.

- Damage Assessment: A thorough assessment determines the extent of the damage. Slightly damaged items might be salvageable and sold at a discount; significantly damaged items might need to be scrapped.

- Segregation: Damaged or obsolete items are clearly separated from usable inventory to avoid contamination and potential errors.

- Disposal Options: Depending on the nature of the goods and local regulations, disposal options include liquidation sales, donation to charities, recycling, or safe disposal at an authorized facility. We weigh the environmental and economic impact of each option.

- Inventory Management System Updates: The IMS must be updated to reflect the removal of damaged or obsolete items, ensuring accurate inventory counts and reports. Automated systems often have features specifically designed for write-offs and adjustments.

- Root Cause Analysis: Identifying the cause of damage or obsolescence helps prevent similar situations in the future. For instance, if damage is consistently occurring during shipping, we might revise packaging techniques or select more reliable carriers.

Q 11. Describe your experience with picking and packing procedures.

My experience with picking and packing procedures is extensive, encompassing various methods and technologies.

- Order Picking Strategies: I’m proficient in various order picking methods, including batch picking, zone picking, and wave picking. The choice depends on order volume, item characteristics, and warehouse layout. For example, batch picking is efficient for multiple orders with overlapping items.

- Picking Accuracy: Implementing quality control checks at each stage, such as barcode scanning or verification by a second picker, helps maintain high picking accuracy. We constantly track our accuracy rates to identify areas needing improvement.

- Packing Optimization: Efficient packing minimizes shipping costs and reduces damage during transit. This includes using appropriate packaging materials, optimizing box sizes, and implementing correct filling procedures. We always prioritize environmentally friendly packaging whenever possible.

- Packaging Supplies Management: Ensuring sufficient stock of packaging materials of various sizes is essential for smooth operations. We implement a robust inventory management system for packaging supplies, much like our product inventory management.

- Technology Integration: Experience with Warehouse Management Systems (WMS) and integration with order management systems ensures accurate picking lists, packing instructions, and shipping labels.

Q 12. How do you ensure timely order fulfillment?

Timely order fulfillment is critical for customer satisfaction and business success. Several strategies contribute to this goal.

- Accurate Forecasting: Precise demand forecasting allows us to proactively manage inventory levels, reducing the risk of stockouts and delays. We use various forecasting techniques and historical data to estimate future demand.

- Efficient Picking and Packing Processes: Streamlined picking and packing processes, utilizing appropriate technology and optimized workflows, are crucial. This includes effective training of warehouse staff and use of automation when appropriate.

- Real-time Inventory Visibility: Using a real-time inventory management system provides up-to-the-minute visibility into stock levels and order status, enabling quick responses to any potential issues.

- Transportation Management: Careful selection of carriers and effective scheduling of shipments are necessary for prompt delivery. Real-time tracking of shipments provides insights into delivery timelines.

- Communication and Collaboration: Effective communication between warehouse staff, order fulfillment teams, and transportation providers is essential for resolving any unexpected delays or problems.

Q 13. What experience do you have with barcode scanning and RFID technology?

I have significant experience with both barcode scanning and RFID technology in warehouse operations.

- Barcode Scanning: I’m proficient in using barcode scanners for tasks such as inventory tracking, order picking, and shipping label generation. This technology significantly improves accuracy and speed compared to manual processes. For example, we utilize barcode scanners during the receiving process to verify the quantity and condition of incoming goods against purchase orders.

- RFID Technology: I understand and have utilized RFID technology for real-time inventory tracking and management. RFID tags provide greater accuracy and allow for tracking of items without line-of-sight, offering advantages over barcode scanning for high-volume environments or items stored in pallets or containers. For example, we can track entire pallet movements and inventory levels without manually scanning each item, leading to more efficient inventory counts.

- Integration with WMS: Both barcode scanning and RFID data seamlessly integrate with our WMS, providing comprehensive data analysis and reporting capabilities. This data helps in optimizing inventory management, improving picking accuracy, and identifying potential bottlenecks.

Q 14. Describe your experience with managing warehouse staff.

Managing warehouse staff effectively requires a blend of leadership, communication, and operational expertise.

- Team Building and Motivation: Creating a positive and collaborative work environment is crucial. This includes regular communication, recognizing achievements, and providing opportunities for professional development. We often hold team meetings to address concerns and celebrate successes.

- Performance Management: Establishing clear performance expectations and providing regular feedback helps maintain high standards. We use Key Performance Indicators (KPIs) to track individual and team performance, identifying areas for improvement.

- Training and Development: Providing ongoing training ensures staff are equipped with the necessary skills and knowledge to perform their jobs effectively and safely. This includes safety training, operational procedures, and technology training.

- Delegation and Empowerment: Delegating tasks and empowering staff to take ownership of their responsibilities fosters a sense of responsibility and improves efficiency. We encourage suggestions and ideas from the team to continuously improve processes.

- Conflict Resolution: Addressing conflicts promptly and fairly is vital for maintaining a harmonious work environment. We encourage open communication and strive to resolve disputes effectively and fairly.

Q 15. How do you handle peak seasons or increased order volume?

Handling peak seasons requires a proactive, multi-faceted approach. It’s not just about throwing more bodies at the problem; it’s about strategic planning and resource allocation. We begin by forecasting demand well in advance, analyzing historical data to predict potential surges. This allows us to implement strategies like:

- Temporary Staffing: Hiring temporary workers to supplement the existing team, ensuring sufficient manpower for increased order volume. We prioritize thorough training to maintain quality and efficiency.

- Overtime Allocation: Offering overtime to existing employees, incentivizing them to handle the increased workload. This leverages existing expertise and familiarity with processes.

- Process Optimization: Reviewing and streamlining existing processes to identify bottlenecks and inefficiencies. This might involve implementing lean methodologies or automating tasks to improve throughput.

- Inventory Management: Ensuring sufficient stock levels are maintained to meet peak demand. We use sophisticated inventory management systems to track stock levels in real-time and proactively order additional inventory as needed. This prevents stockouts which are costly during peak season.

- External Partnerships: Collaborating with third-party logistics providers (3PLs) to handle overflow, supplementing our own warehouse capacity. This scalability is crucial during unexpected surges.

For example, during the holiday season, we might increase our staffing levels by 50%, implement overtime pay, and utilize a 3PL to handle a significant portion of the overflow. Post-peak season, we thoroughly analyze the data to refine our forecasting and processes for future years.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the security of goods within the warehouse?

Warehouse security is paramount. We employ a multi-layered approach combining physical security measures with technological safeguards. This involves:

- Physical Security: This includes robust perimeter fencing, secured entry points with access control systems (like keypads, card readers, or biometric scanners), and well-lit areas to deter unauthorized access. Regular patrols by security personnel further enhance protection.

- Surveillance Systems: Closed-circuit television (CCTV) cameras strategically placed throughout the warehouse provide real-time monitoring and recording capabilities. This acts as a deterrent and enables quick response to any suspicious activity.

- Access Control: Strict access control protocols limit access to specific areas based on employee roles and responsibilities. This minimizes the risk of unauthorized handling or theft of goods.

- Inventory Management Systems: Sophisticated warehouse management systems (WMS) track inventory movements, providing real-time visibility and facilitating the detection of discrepancies. Any inconsistencies trigger immediate investigation.

- Employee Training: Regular security awareness training for employees is critical. They’re educated on best practices, recognizing and reporting security breaches, and handling sensitive information.

Imagine a situation where a pallet goes missing. Our CCTV footage will help pinpoint when and where the discrepancy occurred. Our WMS will show us the last known location, allowing us to swiftly investigate and take corrective action.

Q 17. What is your experience with cross-docking operations?

Cross-docking is a highly efficient warehouse operation where goods are unloaded from an incoming shipment and immediately loaded onto an outgoing shipment, minimizing storage time. My experience with cross-docking encompasses all aspects – from planning and execution to performance analysis.

- Strategic Planning: Effective cross-docking requires careful coordination between suppliers and distributors. Detailed scheduling and precise communication are key to a smooth operation. We use advanced planning tools to optimize workflow and minimize delays.

- Efficient Receiving and Loading: A well-designed warehouse layout with optimized dock configurations is crucial for efficient cross-docking. We use barcode scanners and RFID tags to ensure accurate tracking of goods.

- Real-Time Tracking and Monitoring: Real-time tracking of inbound and outbound shipments is essential to identify bottlenecks and ensure the timely movement of goods. Data analysis helps us identify improvements in speed and efficiency.

- Quality Control: While goods aren’t stored, quality checks are still crucial during the transfer process to ensure goods are undamaged and meet quality standards.

For instance, in a retail operation, we might receive a shipment of products directly from a manufacturer and immediately transfer them to trucks bound for various retail stores, eliminating the need for intermediate storage. This significantly reduces handling time and storage costs.

Q 18. How familiar are you with different types of warehouse layouts?

I’m familiar with various warehouse layouts, each designed to optimize specific operational needs. These include:

- U-shaped Layout: Efficient for smaller warehouses with a single loading dock. It minimizes material handling distances.

- I-shaped Layout: Simple layout ideal for low-volume operations, often found in smaller facilities with limited space.

- L-shaped Layout: A compromise between U-shaped and I-shaped layouts offering flexibility and scalability.

- Aisle Layout: Characterized by a grid of aisles that intersect perpendicularly. It accommodates high volumes of inventory and allows for easy access to individual storage units.

- Block Stacking Layout: Simple method where inventory is stacked in blocks, suitable for large, homogenous items.

The choice of layout depends heavily on factors like the type of goods stored, order fulfillment methods, and the available space. For example, a distribution center dealing with fast-moving consumer goods would likely benefit from an aisle layout for high throughput, while a warehouse storing bulky furniture might opt for a block stacking layout.

Q 19. Explain your understanding of warehouse layout optimization.

Warehouse layout optimization is a crucial aspect of efficient warehouse operations. It involves strategically designing the layout to minimize travel time, maximize storage capacity, and enhance overall efficiency. This is achieved through:

- Space Utilization Analysis: A thorough analysis of the available space to identify optimal storage locations based on product turnover rate, size, and weight. Fast-moving items are placed closer to shipping docks, while less frequently accessed items are positioned further back.

- Workflow Optimization: Designing the layout to ensure a smooth flow of goods from receiving to shipping. This minimizes material handling, reducing labor costs and increasing throughput.

- Technology Integration: Utilizing warehouse management systems (WMS) and other technologies to track inventory movements, automate tasks, and optimize space utilization. Automated guided vehicles (AGVs) can further streamline the workflow.

- Ergonomics and Safety: Designing the layout with employee safety and ergonomics in mind. This includes providing adequate aisle widths, safe walkways, and ergonomic workstations to reduce the risk of accidents and improve worker productivity.

- Simulation and Modeling: Using simulation software to model different layout options and assess their impact on efficiency before implementation. This allows for informed decision-making and minimizes disruptions.

For instance, by optimizing the location of fast-moving items and implementing a WMS, we can reduce picking time by 20% and increase overall order fulfillment rate.

Q 20. How do you prioritize tasks in a high-pressure environment?

Prioritizing tasks in a high-pressure environment requires a structured approach. My method relies on a combination of factors:

- Urgency and Importance: Using a prioritization matrix (like the Eisenhower Matrix) to categorize tasks based on their urgency and importance. Urgent and important tasks take precedence, while less critical tasks are scheduled accordingly.

- Order Fulfillment Deadlines: Orders with tight deadlines are given priority to ensure timely delivery and customer satisfaction. We track order progress closely to avoid delays.

- Inventory Management: Prioritizing tasks that ensure the timely replenishment of stock levels and prevent stockouts. This avoids production disruptions and keeps operations running smoothly.

- Communication and Collaboration: Maintaining open communication with the team to ensure everyone is aware of priorities and potential bottlenecks. Collaboration is key to effective task management during peak times.

- Delegation: Effectively delegating tasks to team members based on their skills and expertise, optimizing workload distribution and efficiency.

For example, if we have an urgent order with a tight deadline, that takes priority over less urgent tasks, even if those other tasks are considered important from a long-term perspective.

Q 21. Describe your experience with using warehouse reporting tools.

My experience with warehouse reporting tools is extensive. I’ve used a variety of systems to track key performance indicators (KPIs) and generate insightful reports. This helps in identifying areas for improvement and optimizing warehouse operations. I’m proficient with tools that provide data on:

- Inventory Levels: Tracking stock levels, identifying slow-moving and obsolete items, and predicting future demand.

- Order Fulfillment Rates: Monitoring the efficiency of order picking, packing, and shipping processes.

- Labor Productivity: Analyzing labor costs, identifying areas for improvement, and optimizing workforce allocation.

- Storage Capacity Utilization: Tracking the utilization of warehouse space, identifying areas for improvement in storage efficiency.

- Shipping and Receiving Metrics: Tracking the timeliness and accuracy of receiving and shipping operations.

For instance, by analyzing data on order fulfillment rates, we identified a bottleneck in the picking process. This led us to implement a new picking strategy, resulting in a 15% improvement in efficiency. The reporting tools provided the concrete data that drove this improvement.

Q 22. What methods do you use to improve warehouse efficiency?

Improving warehouse efficiency is a multifaceted process focusing on optimizing workflows, space utilization, and technology integration. I employ several key methods, including:

- Lean methodologies: Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) to eliminate waste and improve workflow. For example, in a previous role, we significantly reduced picking times by optimizing the layout of our picking zones based on product frequency.

- Warehouse Management Systems (WMS): Utilizing WMS software to automate tasks like inventory tracking, order fulfillment, and labor management. A successful implementation I oversaw involved a 20% reduction in order processing time and a 15% decrease in picking errors.

- Cross-docking: Minimizing storage time by directly transferring goods from inbound to outbound shipments, particularly effective for high-volume, fast-moving products. This reduced storage space needs and expedited delivery times.

- Automation: Integrating automated guided vehicles (AGVs), conveyor systems, and robotic picking solutions to streamline material handling and reduce reliance on manual labor. I have experience specifying and implementing AGV systems, leading to a 30% increase in throughput.

- Data analysis: Regularly analyzing warehouse data (e.g., order volume, picking times, storage utilization) to identify bottlenecks and areas for improvement. This data-driven approach allowed us to make targeted improvements, leading to a 10% overall efficiency increase.

Q 23. How do you maintain a safe and organized warehouse environment?

Maintaining a safe and organized warehouse environment is paramount for productivity and employee well-being. My approach involves:

- 5S implementation: As mentioned earlier, 5S creates a clean, organized, and safe workspace. Regular audits ensure adherence to 5S standards.

- Proper safety training: All staff receive comprehensive training on safe operating procedures, including forklift operation, material handling, and hazard identification. This includes regular refresher courses and emergency response drills.

- Clear signage and labeling: Using clear, visible signage to identify hazardous areas, emergency exits, and storage locations. Proper labeling of materials ensures accurate identification and prevents mishaps.

- Regular inspections: Conducting routine inspections of equipment, facilities, and safety measures to identify and address potential hazards proactively. This includes checking for fire hazards, damaged equipment, and obstructed walkways.

- Emergency preparedness: Establishing and regularly testing emergency procedures, including evacuation plans, fire drills, and spill response protocols. This ensures everyone knows what to do in case of an emergency.

- Ergonomic design: Optimizing workspace design to minimize physical strain on employees, such as adjusting workstation heights and providing proper lifting equipment. This reduces the risk of workplace injuries.

Q 24. Explain your experience with inventory forecasting and planning.

Inventory forecasting and planning are critical for effective warehouse management. My experience involves using various forecasting methods, including:

- Time series analysis: Analyzing historical sales data to identify trends and seasonality patterns to predict future demand. I have successfully used this method to accurately predict seasonal peaks and troughs, enabling proactive inventory adjustments.

- Statistical modeling: Employing statistical models (e.g., ARIMA, exponential smoothing) to forecast demand with greater accuracy, considering factors like promotions, economic conditions, and competitor actions. This allowed for optimized stock levels and minimized stockouts.

- Demand planning software: Utilizing specialized software to integrate various data sources and create more sophisticated forecasts. This includes collaborating with sales and marketing teams to incorporate promotional plans and market insights into forecasting models.

- Safety stock calculations: Determining appropriate safety stock levels to mitigate against unexpected demand fluctuations or supply chain disruptions. This balances the cost of holding excess inventory with the risk of stockouts.

- Collaborative forecasting: Working with internal and external stakeholders (suppliers, retailers) to share information and improve the accuracy of demand forecasts. This collaborative approach has consistently led to more robust and reliable predictions.

Q 25. What is your experience with different types of inventory control systems?

I have experience with several inventory control systems, each with its strengths and weaknesses:

- First-In, First-Out (FIFO): This method ensures that older inventory is used before newer inventory, minimizing spoilage and obsolescence. It’s particularly useful for perishable goods.

- Last-In, First-Out (LIFO): This method prioritizes the use of newer inventory. It can be advantageous in situations with fluctuating prices, but it can also lead to higher spoilage for perishable items.

- Just-In-Time (JIT): This system minimizes inventory holding costs by receiving goods only when needed. It requires close coordination with suppliers and precise demand forecasting.

- ABC analysis: This method categorizes inventory based on its value and consumption rate (A: high value, high consumption; B: medium value, medium consumption; C: low value, low consumption). It allows for focused attention on high-value items, optimizing inventory control efforts.

- WMS integration: Utilizing WMS systems to track inventory levels, monitor stock movements, and automate inventory control processes. This offers real-time visibility and improved accuracy.

Q 26. How do you track and manage warehouse costs?

Tracking and managing warehouse costs requires a systematic approach. I employ the following methods:

- Cost categorization: Categorizing costs into different areas, such as labor, storage, equipment maintenance, utilities, and transportation. This allows for targeted cost reduction efforts.

- Cost allocation: Accurately allocating costs to different products or services based on their consumption. This provides a clearer understanding of the profitability of individual items.

- Benchmarking: Comparing our warehouse costs to industry benchmarks to identify areas for improvement. This provides a valuable external perspective on cost efficiency.

- Performance metrics: Tracking key performance indicators (KPIs) such as order fulfillment costs, storage costs per square foot, and labor costs per unit. This allows for monitoring and controlling costs over time.

- Budgeting and forecasting: Developing detailed budgets and forecasts to anticipate and manage expenses effectively. This enables proactive adjustments to spending plans.

- Technology utilization: Employing technology to optimize resource utilization and reduce costs. Examples include automated systems for inventory management, energy-efficient lighting, and optimized route planning for delivery.

Q 27. How do you resolve conflicts or issues among warehouse staff?

Resolving conflicts among warehouse staff requires a fair, consistent, and empathetic approach. My strategy involves:

- Open communication: Creating an environment where employees feel comfortable voicing concerns and opinions without fear of retribution. Regular team meetings and one-on-one conversations help foster open communication.

- Active listening: Carefully listening to all sides of the conflict to understand the root causes and perspectives involved. This demonstrates respect and builds trust.

- Mediation and facilitation: Facilitating discussions to help conflicting parties find common ground and reach a mutually agreeable solution. I often use collaborative problem-solving techniques.

- Clear expectations and policies: Establishing clear guidelines on workplace conduct, performance expectations, and conflict resolution procedures. This reduces ambiguity and promotes fairness.

- Fair and consistent discipline: Applying disciplinary actions fairly and consistently when necessary. This reinforces expectations and ensures a respectful work environment. This often involves documentation of the issue and steps taken to resolve it.

- Performance improvement plans: Developing performance improvement plans for employees who consistently contribute to conflict or fail to meet expectations. This is a proactive approach to addressing recurring problems.

Q 28. Describe your experience with implementing new warehouse processes or technologies.

I have extensive experience in implementing new warehouse processes and technologies. For example, in a previous role, I led the implementation of a new WMS system. This involved:

- Needs assessment: Conducting a thorough assessment of our existing systems and identifying areas for improvement. This included interviews with staff, analysis of current processes, and benchmarking against industry best practices.

- Vendor selection: Evaluating different WMS vendors based on their functionality, scalability, and cost-effectiveness. This included detailed demonstrations and reference checks.

- System configuration: Customizing the WMS to meet our specific business requirements, including defining workflows, integrating with existing systems, and configuring reporting dashboards.

- Training and rollout: Developing and delivering comprehensive training programs for warehouse staff to ensure effective adoption of the new system. This involved phased rollout to minimize disruption.

- Post-implementation support: Providing ongoing support and maintenance to address any issues that arise after the system goes live. This includes regular system monitoring and ongoing user training.

- Process optimization: The implementation of the WMS also led to significant process optimization. We refined our picking and packing procedures, leading to a 25% reduction in order fulfillment times and a 10% decrease in errors.

In another project, I successfully implemented a new automated sorting system, which increased our throughput by 40% and reduced labor costs by 15%.

Key Topics to Learn for Storage and Warehousing Interview

- Inventory Management: Understanding inventory control systems (FIFO, LIFO, etc.), cycle counting, and stock replenishment strategies. Practical application: Explain how you would optimize inventory levels to minimize waste and maximize efficiency in a fast-paced warehouse environment.

- Warehouse Layout and Design: Knowledge of different warehouse layouts (e.g., U-shaped, I-shaped), their advantages and disadvantages, and the impact on workflow efficiency. Practical application: Describe how you would design a warehouse layout to improve order fulfillment speed and reduce travel time for warehouse equipment.

- Warehouse Safety and Compliance: Familiarity with OSHA regulations, safety procedures, and hazard identification. Practical application: Explain your approach to maintaining a safe and compliant warehouse environment, including risk assessment and preventative measures.

- Warehouse Management Systems (WMS): Understanding the functionality of WMS software, including order processing, inventory tracking, and reporting. Practical application: Describe your experience using a WMS and how you would troubleshoot common issues.

- Material Handling Equipment: Knowledge of various material handling equipment (forklifts, conveyor belts, etc.) and their safe operation. Practical application: Explain how you would select the appropriate equipment for a specific task, considering factors like load capacity and space constraints.

- Supply Chain Logistics: Understanding the broader context of warehousing within the supply chain, including inbound and outbound logistics. Practical application: Explain how effective warehousing contributes to the overall efficiency and cost-effectiveness of the supply chain.

- Problem-Solving and Decision-Making: Ability to identify and resolve operational challenges, optimize processes, and make data-driven decisions. Practical application: Describe a situation where you had to solve a complex warehouse problem and the steps you took to find a solution.

Next Steps

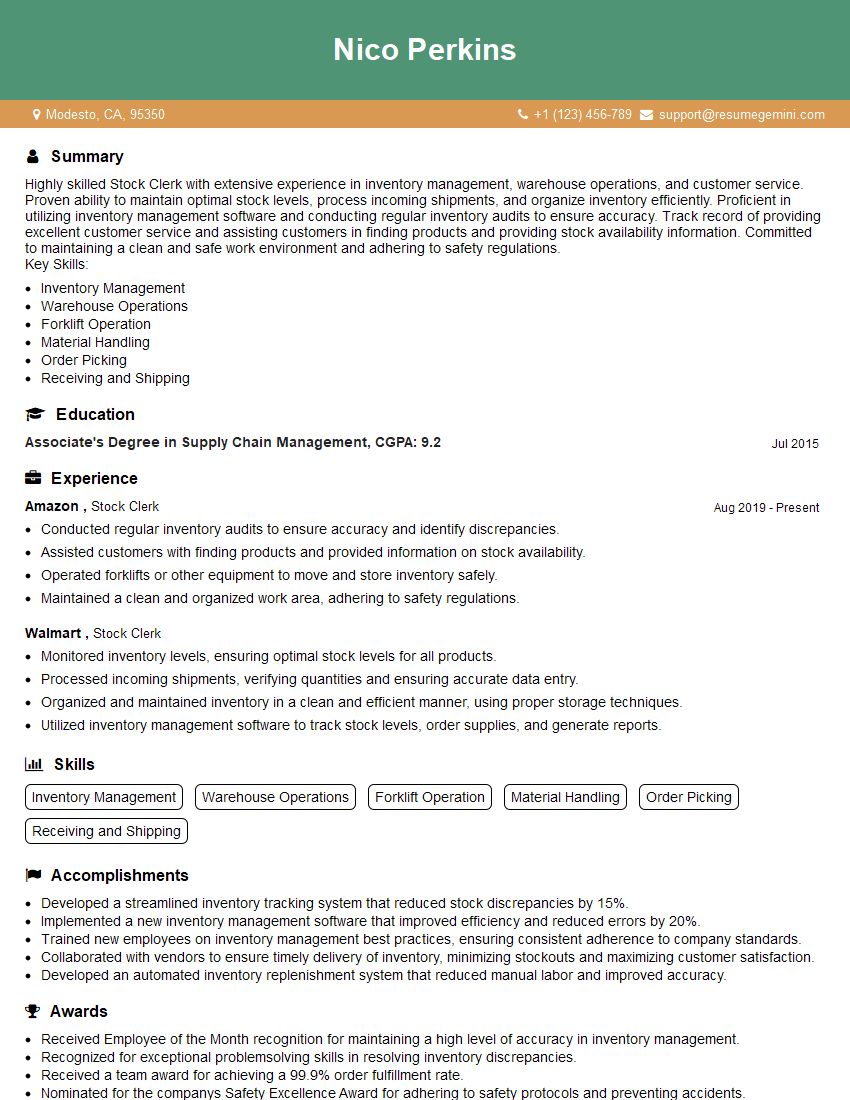

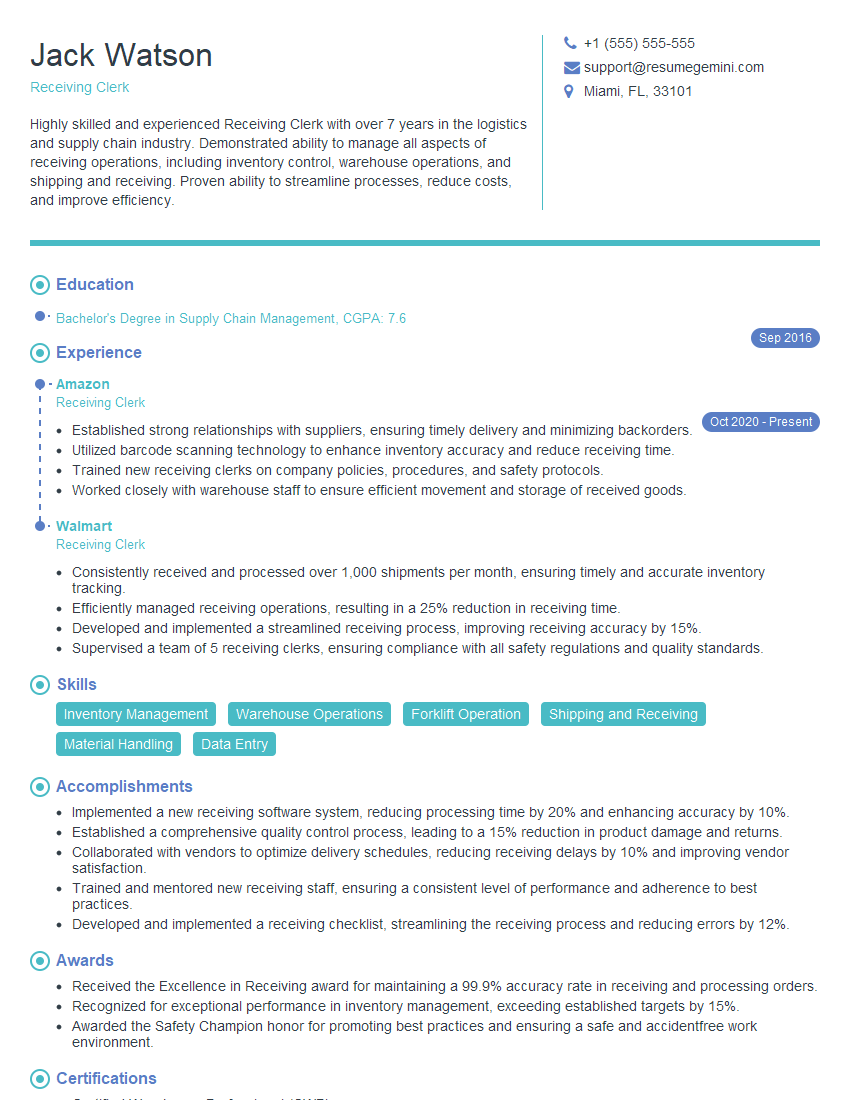

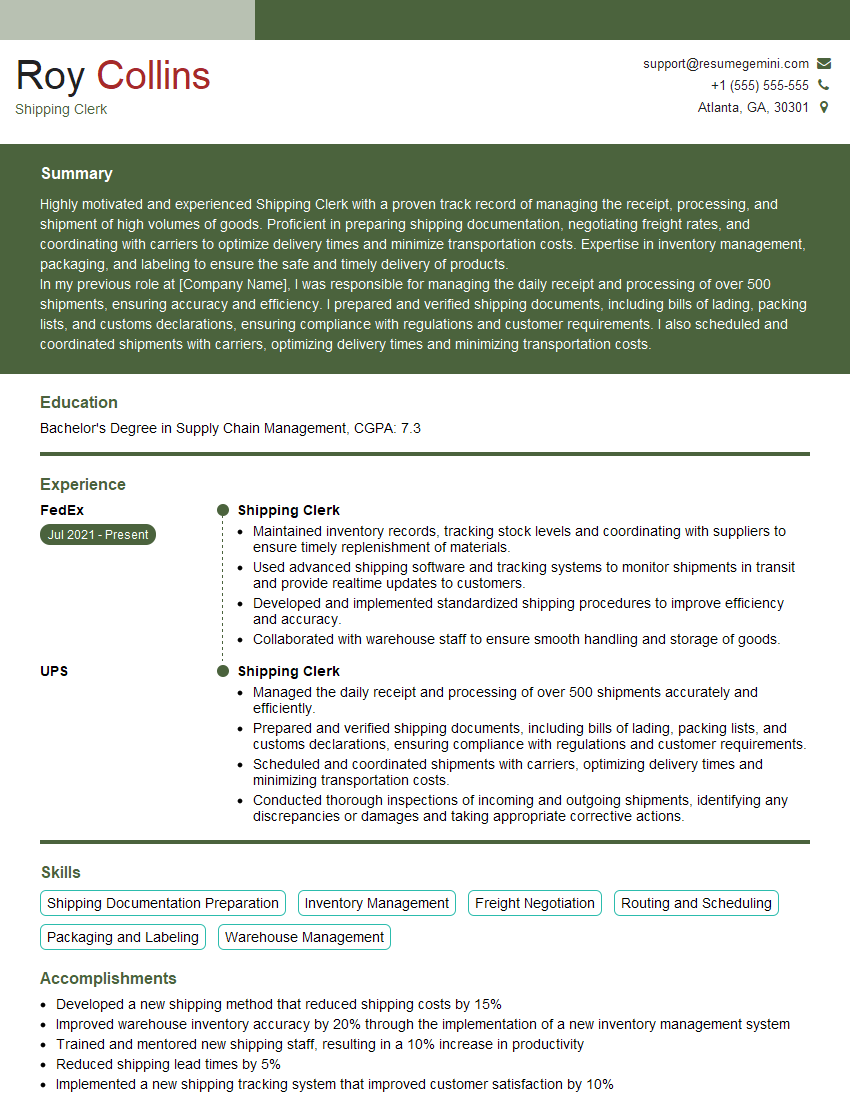

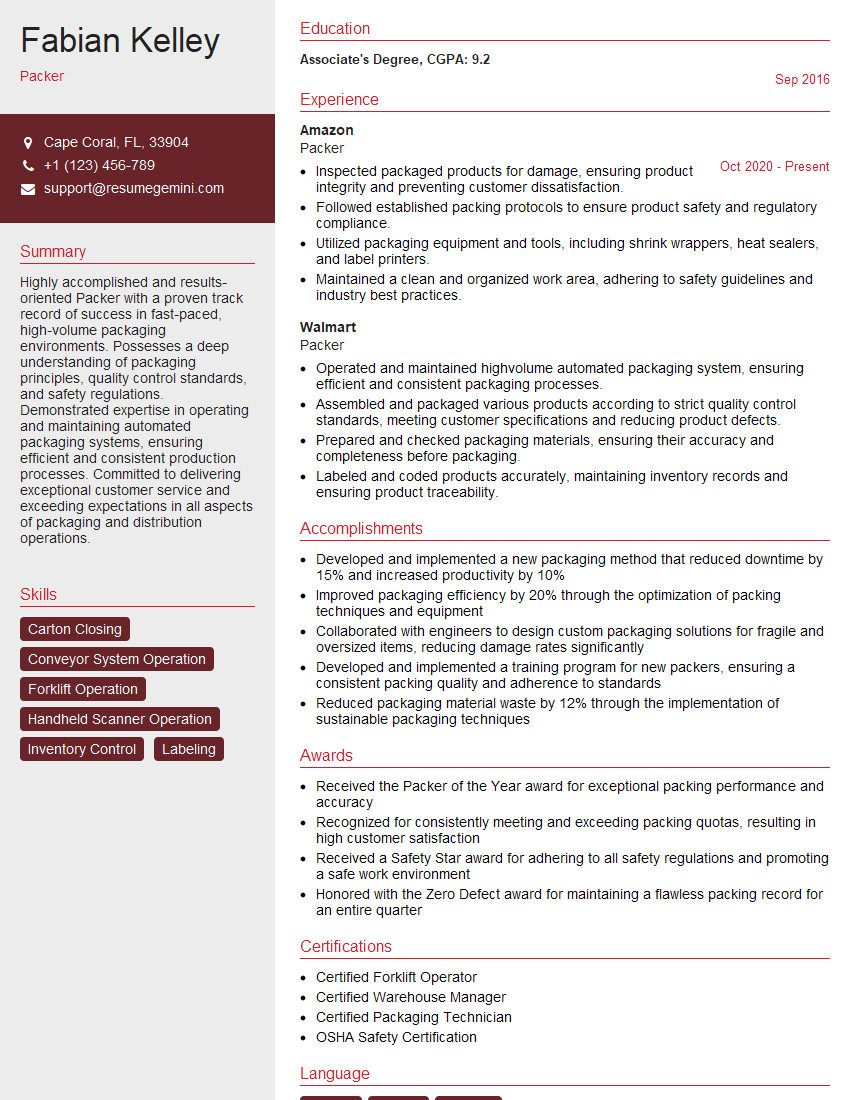

Mastering Storage and Warehousing principles opens doors to exciting career opportunities with significant growth potential. A strong resume is crucial for showcasing your skills and experience to potential employers. Building an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that highlights your accomplishments and qualifications. Examples of resumes tailored to Storage and Warehousing positions are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?