The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Supplier Management and Quality Control interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Supplier Management and Quality Control Interview

Q 1. Describe your experience with supplier selection and evaluation processes.

Supplier selection and evaluation is a critical process for ensuring a reliable and high-quality supply chain. It’s not just about finding the cheapest option; it’s about finding the best fit for your organization’s needs. My process typically involves several key stages:

- Identifying Potential Suppliers: This involves market research, leveraging industry databases, and networking to uncover suitable candidates. I often use online tools and industry publications to research potential suppliers.

- Pre-qualification Screening: I evaluate potential suppliers based on initial criteria such as financial stability, capacity, certifications (e.g., ISO 9001), and general reputation. This often involves reviewing financial statements and conducting initial reference checks.

- Detailed Evaluation: This stage involves a more in-depth assessment. I use a weighted scoring system to evaluate suppliers based on factors such as quality management systems, delivery performance, pricing, technological capabilities, and sustainability initiatives. For example, a scorecard might weigh quality at 40%, cost at 30%, and delivery at 20%.

- On-site Visits (optional): For critical suppliers, I conduct on-site visits to assess their facilities, processes, and overall capabilities firsthand. This provides a crucial opportunity to observe their work environment and culture.

- Supplier Selection: Based on the evaluation results, the top-performing suppliers are selected. The choice often involves a trade-off between various factors, not just the lowest price.

For example, in a previous role, we were selecting a supplier for a specialized component. While one supplier offered the lowest price, their quality control processes were questionable. Another supplier, while slightly more expensive, had a robust quality system and a proven track record. We chose the second supplier, prioritizing long-term reliability and quality over short-term cost savings. This decision proved to be crucial in avoiding costly product recalls later on.

Q 2. How do you manage supplier performance and address underperformance?

Managing supplier performance requires a proactive and data-driven approach. Regular monitoring and performance reviews are key. I usually employ a system incorporating:

- Key Performance Indicators (KPIs): We define clear KPIs, such as on-time delivery, defect rate, and lead time, to track supplier performance. These KPIs are tailored to the specific needs of each supplier and contract.

- Regular Reporting and Communication: Suppliers submit regular performance reports, allowing us to monitor their progress. Open communication is critical – we hold regular meetings to discuss performance, identify issues, and collaborate on solutions.

- Performance Reviews: Formal performance reviews are conducted at regular intervals (e.g., quarterly or annually). These reviews assess the supplier’s performance against the agreed-upon KPIs and identify areas for improvement.

- Corrective Actions: When underperformance occurs, we work collaboratively with the supplier to identify the root causes and implement corrective actions. This often involves root cause analysis techniques such as the 5 Whys.

- Performance Improvement Plans (PIPs): In cases of significant underperformance, we develop PIPs with specific targets and timelines for improvement. If the supplier fails to meet these targets, it may result in contract termination.

For instance, if a supplier consistently misses delivery deadlines, we would work with them to understand the underlying reasons, such as capacity constraints or inefficient processes. We might collaborate to implement solutions such as lean manufacturing techniques or improved forecasting methods to address the problem.

Q 3. Explain your approach to conducting supplier audits.

My approach to supplier audits is systematic and thorough, ensuring objectivity and consistency. I generally follow these steps:

- Planning and Scoping: Before the audit, we define the scope, objectives, and criteria based on the supplier’s criticality and the relevant standards (e.g., ISO 9001, industry-specific regulations). This ensures a focused and effective audit.

- Audit Execution: The audit itself involves reviewing documentation, observing processes, and interviewing personnel. We use checklists and standardized procedures to ensure consistency and completeness. This might involve checking for compliance with quality management system documentation, reviewing production records, and observing worker safety practices.

- Data Collection and Analysis: We meticulously document findings, including both positive aspects and areas for improvement. Data analysis helps identify trends and systemic issues.

- Reporting and Follow-up: A formal audit report is issued, summarizing the findings and recommendations. A follow-up meeting is held with the supplier to discuss the report and agree on corrective actions.

- Corrective Action Verification: We follow up to verify that the supplier has implemented the necessary corrective actions and that improvements have been made. This is often followed by a subsequent audit to validate the efficacy of the corrective actions.

For example, in auditing a supplier of electronic components, we’d examine their process controls to ensure adherence to standards preventing counterfeit parts. We might review their traceability documentation and their procedures for handling and storing components.

Q 4. What quality control methodologies are you familiar with (e.g., Six Sigma, ISO 9001)?

My experience encompasses various quality control methodologies, including:

- Six Sigma: This data-driven approach focuses on minimizing defects and variability in processes. I’ve used DMAIC (Define, Measure, Analyze, Improve, Control) to systematically improve supplier processes and reduce defects.

- ISO 9001: I’m well-versed in ISO 9001 quality management system standards and have conducted internal audits and assisted suppliers in achieving certification. Understanding this standard is crucial for evaluating and managing suppliers effectively.

- Statistical Process Control (SPC): SPC charts and techniques help monitor processes and identify potential issues before they lead to defects. I have used control charts to track defect rates and ensure timely intervention when needed.

- Total Quality Management (TQM): TQM principles guide my approach, emphasizing continuous improvement, customer focus, and employee involvement in quality improvement efforts. It’s not just about meeting standards, but surpassing expectations consistently.

I regularly integrate these methodologies into supplier evaluations and performance management to ensure continuous improvement and maintain the highest quality standards throughout the supply chain.

Q 5. How do you mitigate supply chain risks?

Mitigating supply chain risks is crucial for business continuity. My approach focuses on identifying potential risks and implementing strategies to reduce their impact:

- Risk Assessment: We regularly conduct risk assessments to identify potential disruptions, such as geopolitical instability, natural disasters, supplier financial distress, and pandemics. This often involves brainstorming sessions with key stakeholders.

- Diversification: We diversify our supplier base to reduce dependence on any single supplier. This spreads the risk and provides greater resilience in the face of disruptions.

- Redundancy Planning: We establish backup suppliers or alternative sourcing strategies to ensure continuity of supply in case of unexpected events. This includes having contingency plans in place for critical components.

- Inventory Management: We employ strategic inventory management techniques, such as safety stock, to mitigate the risk of stockouts due to supply disruptions. The optimal inventory levels are determined by balancing holding costs and the risk of shortages.

- Supplier Relationship Management (SRM): Strong supplier relationships are essential for mitigating risks. Open communication and collaboration help us anticipate and address potential issues early on.

- Contractual Safeguards: Our contracts include clauses that address potential risks, such as force majeure and penalties for non-performance. These provisions protect our interests in the event of unexpected disruptions.

For example, during the recent global chip shortage, our diversification strategy proved invaluable. While some suppliers faced significant delays, we were able to source components from other suppliers, minimizing the impact on our production schedule.

Q 6. Describe your experience with negotiating contracts with suppliers.

Negotiating contracts with suppliers is a critical skill requiring a balance of collaboration and assertiveness. My approach is based on:

- Preparation: Thorough preparation is key. This involves understanding market pricing, analyzing the supplier’s capabilities, and defining clear requirements and expectations.

- Clear Communication: Open and transparent communication throughout the negotiation process is essential. We clarify terms and conditions, addressing potential ambiguities early on.

- Value-Based Negotiation: We focus on creating value for both parties. We strive for win-win outcomes, balancing cost optimization with ensuring supplier profitability and sustainability. This creates long-term, mutually beneficial relationships.

- Risk Management: Contracts must address potential risks and liabilities. We include clauses addressing quality, delivery, payment terms, and intellectual property.

- Documentation: All agreements are meticulously documented to avoid misunderstandings and disputes. Contracts are reviewed by legal counsel to ensure compliance with applicable laws and regulations.

In one instance, I successfully negotiated a long-term contract with a key supplier, securing favorable pricing and improved delivery terms by demonstrating the long-term value of the partnership. This included investing in their capacity building, which resulted in benefits for both parties.

Q 7. How do you ensure compliance with regulatory requirements in your supplier management processes?

Ensuring compliance with regulatory requirements is paramount in supplier management. My approach involves:

- Identifying Applicable Regulations: We identify all relevant regulations, including those related to environmental protection, labor standards, health and safety, and data privacy. This might involve reviewing legislation specific to the industry, country of origin, and the products being sourced.

- Supplier Due Diligence: We conduct due diligence on suppliers to assess their compliance with these regulations. This includes reviewing their certifications, policies, and procedures.

- Contractual Compliance Clauses: We include explicit clauses in our contracts requiring suppliers to comply with all applicable regulations and standards. This holds them accountable for meeting legal obligations.

- Regular Monitoring and Audits: We regularly monitor supplier compliance through performance reviews, audits, and third-party assessments. This ensures continued adherence to regulations.

- Training and Awareness: We provide training to our teams on relevant regulations and compliance requirements. This fosters a culture of compliance within the organization and promotes effective communication with our suppliers.

- Reporting and Remediation: We have robust reporting mechanisms in place to track compliance performance and address any non-compliance issues promptly and effectively. This includes implementing corrective actions and escalating serious violations as needed.

For example, when sourcing materials from overseas, we ensure our suppliers comply with relevant export control regulations and labor laws in their respective countries. We might utilize third-party verification services to confirm compliance.

Q 8. Explain your understanding of Total Quality Management (TQM).

Total Quality Management (TQM) is a holistic management approach dedicated to achieving long-term success through customer satisfaction. It’s not just about quality control at the end of the production line; it’s woven into every aspect of an organization and its supply chain. Think of it as a continuous improvement cycle, where every department and supplier works collaboratively to identify and eliminate defects, improve processes, and meet or exceed customer expectations.

Key elements of TQM include:

- Customer Focus: Understanding and meeting customer needs is paramount.

- Continuous Improvement (Kaizen): Constantly striving for better efficiency and quality through incremental changes.

- Employee Empowerment: Giving employees the authority and resources to identify and solve problems.

- Process Improvement: Streamlining processes to eliminate waste and improve efficiency (Lean principles often play a significant role here).

- Supplier Partnerships: Developing strong relationships with suppliers to ensure consistent high-quality inputs.

- Data-Driven Decision Making: Using metrics and data analysis to track progress and make informed choices.

For example, in a manufacturing setting, TQM might involve implementing statistical process control (SPC) to monitor production processes, regularly soliciting customer feedback, and actively engaging suppliers in collaborative problem-solving to address material defects.

Q 9. How do you manage relationships with key suppliers?

Managing key supplier relationships requires a strategic approach focused on building trust, open communication, and mutual benefit. It’s about moving beyond a purely transactional relationship to a collaborative partnership.

- Regular Communication: Establishing consistent communication channels, such as regular meetings and performance reviews, is crucial. This could include video conferences, site visits, and shared online platforms.

- Performance Evaluation and Feedback: Regularly evaluating supplier performance based on pre-agreed metrics (discussed further in question 4) and providing constructive feedback. This ensures transparency and allows for continuous improvement.

- Collaboration and Problem Solving: Working proactively with suppliers to address challenges and identify solutions collaboratively. This fosters a sense of partnership and joint responsibility for success.

- Shared Goals and Objectives: Aligning supplier goals with those of the organization, fostering a shared vision and ensuring mutual success. This might involve joint process improvement initiatives or investments in supplier capability.

- Relationship Management Tools: Using tools like supplier relationship management (SRM) software to streamline communication, track performance, and manage documentation.

For instance, I once worked with a key supplier struggling with on-time delivery. Through open communication and collaborative problem-solving, we identified bottlenecks in their production process and implemented a just-in-time inventory system, improving their delivery performance significantly. This improved their efficiency and strengthened our working relationship.

Q 10. How do you handle supplier disputes or disagreements?

Handling supplier disputes requires a structured and professional approach, prioritizing open communication and a collaborative problem-solving strategy.

- Identify the Root Cause: Begin by clearly identifying the source of the disagreement. This might involve a thorough investigation, including reviewing contracts, communication records, and performance data.

- Facilitate Open Communication: Establish a formal channel for communication between both parties. A neutral mediator might be beneficial for complex disagreements.

- Collaborative Problem Solving: Work together to find a mutually acceptable solution. This may involve negotiation, compromise, and possibly arbitration if necessary.

- Document Everything: Keep detailed records of all communication, agreements, and actions taken. This creates a clear history and avoids future misunderstandings.

- Escalation Procedure: Establish a clear process for escalating the issue to higher management if a resolution can’t be reached at the initial level.

For instance, a disagreement over payment terms might be resolved by negotiating a revised payment schedule. A more serious quality issue might require a thorough root cause analysis, collaborative corrective actions, and potentially financial compensation for impacted goods.

Q 11. What metrics do you use to track supplier performance?

Tracking supplier performance requires a robust system of key performance indicators (KPIs). The specific metrics will vary depending on the industry, product, and individual supplier relationship, but common examples include:

- On-Time Delivery (OTD): The percentage of orders delivered on or before the agreed-upon date.

- Quality Rate: The percentage of delivered goods or services that meet quality specifications. This often includes defect rates, return rates, and customer complaints.

- Lead Time: The time it takes from order placement to delivery.

- Cost: The price paid for goods or services, often considering cost per unit and total cost of ownership.

- Compliance: Adherence to regulatory requirements, ethical standards, and company policies.

- Responsiveness: How quickly suppliers respond to inquiries and address issues.

- Innovation: The supplier’s ability to innovate and improve their products or services.

These metrics are typically tracked using a supplier scorecard or performance dashboard, allowing for regular monitoring and identification of trends. A regularly updated scorecard allows for proactive issue management and continuous improvement in supplier relationships.

Q 12. Describe your experience with supplier development initiatives.

Supplier development initiatives focus on improving the capabilities of suppliers, leading to better quality, cost, and delivery performance. It’s an investment in the long-term health of the supply chain.

My experience includes:

- Capability Assessments: Conducting thorough assessments to identify areas for improvement within supplier operations. This might involve evaluating processes, technology, quality systems, and employee skills.

- Training and Development Programs: Providing training and mentorship to suppliers to improve their knowledge and skills in areas like quality control, lean manufacturing, or supply chain management.

- Technology Upgrades: Supporting suppliers in upgrading their technology and equipment to improve efficiency and quality. This could include investments in new machinery or software solutions.

- Process Improvement Projects: Collaborating with suppliers on process improvement projects using methodologies like Six Sigma or Lean.

- Financial Support: Providing financial incentives or grants to assist suppliers with improvements.

For example, I worked with a supplier who lacked efficient quality control procedures. Through a tailored training program, we implemented Statistical Process Control (SPC) methodologies. This resulted in a significant reduction in defects and improved overall product quality. This demonstrated the value of investing in supplier capability.

Q 13. How do you ensure the timely delivery of goods and services from suppliers?

Ensuring timely delivery involves proactive management and collaboration throughout the supply chain.

- Clear Contracts and SLAs: Establishing clear contracts with well-defined delivery schedules and service level agreements (SLAs). These should include penalties for late delivery.

- Supply Chain Visibility: Maintaining visibility into the entire supply chain through real-time tracking and communication. This might involve using supply chain management software.

- Demand Forecasting: Accurate demand forecasting enables suppliers to plan their production and logistics effectively. Collaboration on forecasting improves accuracy.

- Inventory Management: Effective inventory management helps avoid stockouts and ensures sufficient materials are available for timely production. Just-in-time (JIT) inventory systems can be very effective but require strong supplier relationships.

- Risk Management: Identifying and mitigating potential risks to timely delivery, such as supplier disruptions or logistical challenges.

- Regular Monitoring and Communication: Continuously monitoring supplier performance and maintaining open communication channels to address potential delays proactively.

For instance, working with a supplier, we implemented a vendor-managed inventory (VMI) system, giving them responsibility for managing inventory levels at our facility. This improved on-time delivery while reducing our inventory holding costs.

Q 14. What is your experience with root cause analysis in relation to supplier quality issues?

Root cause analysis (RCA) is crucial for effectively addressing supplier quality issues. It’s not enough to treat the symptoms; we must identify the underlying causes to prevent recurrence.

My experience with RCA in relation to supplier quality issues includes using several methodologies such as:

- 5 Whys: A simple yet effective method that involves repeatedly asking “why” to uncover the root cause of a problem. This is an iterative process.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps identify potential causes of a problem by categorizing them into categories such as materials, methods, manpower, machinery, measurement, and environment.

- Pareto Analysis: Identifying the vital few causes responsible for the majority of quality problems (the 80/20 rule often applies).

The process typically involves:

- Define the Problem: Clearly state the quality issue.

- Gather Data: Collect relevant data on the problem.

- Identify Potential Causes: Use the chosen RCA methodology to identify possible root causes.

- Verify the Root Cause: Analyze the data and confirm the identified root cause.

- Develop Corrective Actions: Create and implement solutions to address the root cause.

- Monitor Effectiveness: Track the effectiveness of the corrective actions to ensure the problem is resolved and doesn’t reoccur.

For example, if a supplier is consistently delivering defective parts, RCA might reveal a lack of proper training for their operators, leading to incorrect machine calibration. Corrective action would involve implementing a training program and improving calibration processes.

Q 15. How do you implement and monitor corrective and preventive actions (CAPA) with suppliers?

Implementing and monitoring Corrective and Preventive Actions (CAPA) with suppliers is crucial for maintaining product quality and preventing future issues. It’s a cyclical process that starts with identifying a problem, determining its root cause, implementing corrective actions to fix the immediate problem, and then preventive actions to stop it from happening again.

My approach involves a structured process:

- Problem Identification and Reporting: Suppliers are required to report any non-conformances immediately through a defined system (e.g., a dedicated online portal). This includes detailed descriptions, affected quantities, and any immediate containment actions taken.

- Root Cause Analysis (RCA): We use various RCA tools like 5 Whys, Fishbone diagrams, or Fault Tree Analysis to collaboratively determine the underlying cause of the problem. This often involves on-site visits or virtual meetings with the supplier’s quality team.

- Corrective Action Plan: Once the root cause is identified, a corrective action plan is developed and agreed upon, outlining specific steps the supplier will take to rectify the immediate problem. This includes timelines and measurable targets.

- Preventive Action Plan: To prevent recurrence, a preventive action plan is created to address the systemic issues identified during the RCA. This might involve process improvements, training, updated equipment, or changes to materials.

- Verification and Validation: We rigorously verify that the corrective and preventive actions have been implemented effectively. This might involve audits, inspections, and reviewing supplier-provided data. We often utilize statistical process control (SPC) charts to track key metrics and ensure sustained improvements.

- Continuous Monitoring and Review: The effectiveness of the CAPA is continuously monitored through regular performance reviews and data analysis. We might use key performance indicators (KPIs) such as defect rates, on-time delivery, and customer complaint rates to track progress.

For example, if a supplier consistently delivers parts with dimensional inaccuracies, our CAPA process would involve investigating their manufacturing process, identifying issues with their calibration equipment, implementing corrective actions such as recalibration and operator retraining, and preventive actions like implementing a more robust preventative maintenance schedule for the equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common challenges in supplier management, and how have you addressed them?

Common challenges in supplier management include inconsistent quality, unreliable delivery, communication breakdowns, and managing diverse supplier capabilities.

I’ve addressed these challenges through:

- Proactive Supplier Selection and Development: Rigorous supplier selection processes including pre-qualification audits, reference checks, and capability assessments help ensure we choose reliable partners. Ongoing supplier development programs, including training and technical assistance, help improve their capabilities and performance.

- Strong Communication and Collaboration: Open and transparent communication channels are essential. This includes regular meetings, shared dashboards, and prompt feedback on performance. We use collaborative platforms to facilitate information sharing.

- Performance Monitoring and Measurement: Supplier scorecards and performance dashboards allow for continuous monitoring of key performance indicators (KPIs), providing early warning signs of potential problems. This data-driven approach enables proactive intervention rather than reactive firefighting.

- Risk Management: Identifying and mitigating potential risks is vital. This includes supply chain diversification, developing contingency plans for critical suppliers, and incorporating risk assessments into our supplier selection and management process.

- Building Strong Relationships: Developing strong, collaborative relationships with key suppliers fosters trust and mutual understanding, improving communication and problem-solving. This includes regular visits to supplier facilities and joint problem-solving sessions.

For instance, to address unreliable delivery from a key supplier, we implemented a Vendor Managed Inventory (VMI) system. This gave the supplier greater visibility into our inventory needs, allowing them to better manage their production and delivery schedules, ultimately improving on-time delivery rates significantly.

Q 17. Describe your experience with different supplier types (e.g., domestic vs. international).

My experience encompasses working with both domestic and international suppliers, each presenting unique challenges and opportunities.

Domestic Suppliers: Working with domestic suppliers generally involves easier communication, shorter lead times, and less complex logistical issues. However, challenges can include higher labor costs and limited access to specialized technologies or materials.

International Suppliers: International suppliers often offer cost advantages and access to specialized skills and resources unavailable domestically. However, this comes with increased complexity in communication, logistics, cultural differences, and potential regulatory hurdles. Language barriers, time zone differences, and navigating international trade regulations can add significant complexities.

To manage these differences, I adapt my approach. For international suppliers, I rely heavily on clear contracts, robust communication systems (including video conferencing and instant messaging), and thorough due diligence to ensure compliance with relevant regulations and ethical standards. I also leverage third-party logistics providers for international shipments to manage the complexities of global supply chains. For domestic suppliers, I focus on building strong personal relationships and fostering open communication to address issues swiftly.

Q 18. How do you utilize technology to enhance supplier management processes?

Technology plays a crucial role in enhancing supplier management processes. We leverage several technologies:

- Supplier Relationship Management (SRM) Software: This software streamlines communication, manages supplier performance data, facilitates collaboration, and automates tasks such as contract management and performance reviews.

- Enterprise Resource Planning (ERP) Systems: Integration with ERP systems enables seamless data flow between our internal systems and supplier systems, improving visibility into inventory levels, orders, and payments.

- Data Analytics and Business Intelligence Tools: These tools analyze supplier performance data to identify trends, predict potential issues, and drive continuous improvement. This allows for proactive risk management and improved decision-making.

- Collaboration Platforms: Tools such as Microsoft Teams or Slack facilitate communication and information sharing with suppliers, enabling faster resolution of issues and improved collaboration.

- Blockchain Technology: For enhanced traceability and transparency, especially in complex supply chains, blockchain technology can be used to track materials and products throughout their journey from origin to final delivery. This improves supply chain visibility and accountability.

For example, our SRM software automates the process of sending out supplier performance questionnaires, collecting the data, and generating performance reports. This saves significant time and resources compared to manual processes.

Q 19. What is your experience with supplier scorecards and performance dashboards?

Supplier scorecards and performance dashboards are critical components of our supplier management system. Scorecards provide a summarized view of supplier performance across various key performance indicators (KPIs), while dashboards provide a dynamic, visual representation of this data over time.

My experience involves designing and implementing scorecards that track KPIs such as:

- Quality: Defect rate, on-time delivery, adherence to specifications.

- Delivery: On-time delivery performance, lead time.

- Cost: Price competitiveness, cost reduction initiatives.

- Innovation: New product development collaboration, process improvements.

- Sustainability: Environmental impact, ethical sourcing practices.

These KPIs are weighted based on their importance to our business, and the scorecards provide a clear picture of each supplier’s overall performance. Dashboards provide a visual representation of this data, allowing for easy identification of trends and potential problems. This enables proactive intervention and continuous improvement. Regular reviews of these scorecards and dashboards form a crucial part of our supplier performance management meetings.

For instance, if a supplier’s on-time delivery consistently falls below our target, the scorecard will clearly reflect this, triggering a review of the situation and prompting discussions with the supplier to identify and address the root cause.

Q 20. Explain your experience with implementing and managing supplier contracts.

Implementing and managing supplier contracts is a critical aspect of supplier management. It involves defining the terms and conditions of the relationship, protecting both parties’ interests, and ensuring compliance. My approach involves:

- Clear and Comprehensive Contracts: Contracts should clearly define the scope of work, payment terms, quality requirements, delivery schedules, intellectual property rights, and dispute resolution mechanisms. They must be legally sound and unambiguous.

- Negotiation and Collaboration: Developing mutually beneficial contracts requires effective negotiation and collaboration with suppliers. The goal is to build a strong, long-term relationship based on trust and mutual understanding.

- Risk Management: Contracts should incorporate clauses addressing potential risks, such as force majeure events, intellectual property infringement, and liability limitations.

- Performance Monitoring and Evaluation: Contracts should include mechanisms for monitoring supplier performance and addressing any non-conformances. Regular performance reviews are critical to ensure contract compliance.

- Contract Management System: A centralized system for managing contracts, including their creation, approval, execution, and renewal, improves efficiency and reduces the risk of errors.

I’ve successfully negotiated contracts with a variety of suppliers, from small, local businesses to large multinational corporations. For example, when negotiating a contract for a critical component, I ensured the contract included clear quality specifications, strict inspection procedures, and penalties for non-compliance, protecting our interests while fostering a collaborative relationship with the supplier.

Q 21. How do you ensure ethical and sustainable sourcing practices?

Ethical and sustainable sourcing practices are paramount. We ensure this through:

- Supplier Code of Conduct: We require all suppliers to adhere to a strict code of conduct that addresses issues such as labor practices, environmental protection, and ethical sourcing of materials. This code is regularly reviewed and updated to align with evolving standards.

- Supplier Audits and Assessments: Regular audits and assessments verify supplier compliance with our code of conduct and relevant regulations. This may involve on-site visits, document reviews, and interviews with supplier personnel.

- Traceability and Transparency: We strive for maximum transparency and traceability in our supply chains, understanding the origin of materials and the conditions under which they are produced. This enables us to identify and address any potential ethical or environmental concerns.

- Collaboration with Ethical Sourcing Organizations: We work with industry organizations and NGOs to stay informed about best practices and evolving standards in ethical and sustainable sourcing.

- Continuous Improvement: We continuously monitor and improve our sourcing practices, striving to reduce our environmental footprint and ensure fair and ethical treatment throughout our supply chain.

For example, we actively source materials from suppliers certified under relevant environmental and social standards, such as Fairtrade or B Corp certifications. This ensures that our sourcing practices align with our commitment to sustainability and ethical conduct.

Q 22. Describe your experience with supplier relationship management (SRM) software.

My experience with Supplier Relationship Management (SRM) software spans several years and various platforms. I’ve worked extensively with systems ranging from basic ERP modules with integrated supplier portals to sophisticated, cloud-based SRM solutions. These systems have enabled me to streamline various aspects of supplier management, from onboarding and performance monitoring to contract management and communication. For instance, I used a system that automated purchase order generation, reducing manual errors and processing times significantly. Another system I worked with featured a robust reporting dashboard that provided real-time visibility into supplier performance, allowing proactive identification of potential risks and bottlenecks. In essence, successful SRM software adoption requires not just technical proficiency, but also a well-defined process for data entry, system maintenance, and user training. The ultimate goal is to leverage the technology to improve communication, enhance collaboration, and build stronger, more efficient relationships with suppliers.

Q 23. How do you leverage data analytics to improve supplier performance?

Data analytics is crucial for improving supplier performance. We leverage data in several ways. First, we use key performance indicators (KPIs) such as on-time delivery, defect rates, and lead times. Tracking these KPIs over time reveals trends and areas for improvement. For example, if we see a consistent rise in late deliveries from a specific supplier, we can investigate the root cause – perhaps it’s a capacity issue or a problem with their internal processes. Secondly, we utilize predictive analytics to forecast potential disruptions. By analyzing historical data, we can identify patterns and predict potential risks, allowing for proactive mitigation strategies. Imagine a supplier whose performance consistently dips during peak seasons; this predictive insight allows us to collaborate on mitigation strategies and prevent supply chain disruptions. Finally, we conduct root cause analysis using data to pinpoint the underlying causes of quality issues or delivery delays. This involves techniques such as Pareto charts (identifying the vital few issues) and fishbone diagrams (exploring contributing factors). This data-driven approach makes supplier management less reactive and more proactive.

Q 24. How do you manage supplier capacity and ensure sufficient supply?

Managing supplier capacity and ensuring sufficient supply is a multi-faceted process. It starts with accurate demand forecasting – we must accurately anticipate future needs. This forecast informs our capacity planning, which involves assessing the capabilities of our existing suppliers to meet those demands. We use a combination of techniques including regular communication with suppliers about their production capacity, reviewing their production schedules, and using capacity modeling software. If existing capacity is insufficient, we might explore several options: negotiating increased capacity with current suppliers, onboarding new suppliers, or diversifying our sourcing strategy across multiple suppliers to mitigate risk. We also maintain safety stock levels to buffer against unforeseen disruptions. Furthermore, we regularly monitor supplier performance, looking for signs of capacity constraints, like increasing lead times or rising costs. By proactively managing capacity and constantly monitoring our supply chain, we can minimize the risk of shortages and delays.

Q 25. What is your experience with supplier onboarding processes?

Supplier onboarding is a critical process that sets the stage for a successful long-term relationship. Our process is structured and thorough, and includes several key steps. It begins with a detailed pre-qualification assessment, where we evaluate potential suppliers based on their financial stability, quality management systems, and environmental compliance. Once a supplier is selected, we provide them with a comprehensive onboarding package, including our expectations for quality, delivery, and communication. This is followed by an on-site audit or virtual assessment to verify their capabilities and compliance. Throughout the process, we maintain clear and consistent communication, ensuring that the supplier understands our requirements and procedures. We use a checklist to track progress and ensure all necessary documentation is complete and reviewed. This methodical approach minimizes the risk of misunderstandings and ensures a smooth transition into our supply chain.

Q 26. Describe your approach to continuous improvement in supplier management.

Continuous improvement in supplier management is an ongoing commitment. We employ a structured approach using the Plan-Do-Check-Act (PDCA) cycle. We plan improvements by identifying areas for optimization based on data analysis and supplier feedback. We then implement those changes (Do), monitor their effectiveness (Check), and adjust our strategies based on the results (Act). For example, if we identify a supplier with high defect rates, we might implement a collaborative improvement plan. This might involve providing training, sharing best practices, or jointly developing a corrective action plan. Regular supplier performance reviews, coupled with feedback mechanisms, provide invaluable insights for ongoing improvement. We also embrace innovative technologies and methodologies like AI-powered analytics to further enhance efficiency and effectiveness. This iterative approach ensures that our supplier management practices remain dynamic and responsive to evolving business needs.

Q 27. How do you handle situations where supplier quality doesn’t meet expectations?

When supplier quality doesn’t meet expectations, we follow a structured approach emphasizing collaboration and corrective action. First, we promptly communicate the issue to the supplier, providing detailed documentation and evidence of non-conformances. This is crucial for transparency and ensuring they fully understand the severity of the problem. We then work collaboratively to identify the root cause of the issue, using tools like root cause analysis. This may involve joint on-site inspections or detailed data analysis. Once the root cause is identified, we co-develop a corrective action plan (CAPA) with the supplier, outlining specific actions to prevent recurrence. This plan includes timelines and clear responsibilities. We then monitor the supplier’s implementation of the CAPA and verify its effectiveness. In severe cases, we may need to implement containment measures (such as rejecting non-conforming materials) and potentially consider alternative suppliers if the issue isn’t resolved effectively.

Q 28. What is your experience with different quality control tools (e.g., control charts, Pareto charts)?

I have extensive experience with various quality control tools. Control charts are vital for monitoring process stability and detecting variations. For example, using a control chart to track the defect rate from a supplier allows us to identify trends and react promptly to potential process shifts. Pareto charts are invaluable in prioritizing improvement efforts. By visualizing the frequency of different defects, we can focus our attention on the few critical issues that account for the majority of problems. Other tools I utilize include flowcharts to map out processes and identify bottlenecks, fishbone diagrams (Ishikawa diagrams) for conducting root cause analysis, and scatter diagrams to explore potential correlations between variables. Mastering these tools isn’t just about understanding their mechanics; it’s about interpreting the data they provide to make informed decisions and drive meaningful improvements in our suppliers’ quality management systems.

Key Topics to Learn for Supplier Management and Quality Control Interview

- Supplier Selection and Evaluation: Understanding criteria for selecting suppliers (e.g., cost, quality, reliability, capacity), developing robust evaluation methods (e.g., audits, performance metrics), and implementing risk mitigation strategies.

- Supplier Relationship Management (SRM): Building and maintaining strong relationships with key suppliers, fostering collaboration, negotiating contracts, and managing performance expectations effectively. Practical application includes negotiating favorable terms and resolving disputes.

- Quality Control Systems and Standards: Familiarity with ISO 9001, Six Sigma, or other relevant quality management systems. Understanding quality control methodologies, including statistical process control (SPC) and root cause analysis (RCA).

- Supply Chain Risk Management: Identifying and mitigating potential risks throughout the supply chain, including geopolitical factors, natural disasters, and supplier disruptions. Practical application involves developing contingency plans and diversification strategies.

- Continuous Improvement Initiatives: Understanding and applying lean manufacturing principles, implementing Kaizen events, and driving ongoing improvements in supplier performance and quality.

- Quality Assurance and Auditing: Conducting internal and external audits to ensure compliance with quality standards and regulations. Understanding different audit methodologies and reporting techniques.

- Data Analysis and Reporting: Utilizing data to track key performance indicators (KPIs), identify trends, and make informed decisions regarding supplier performance and quality control processes. This includes interpreting charts and graphs to identify improvement opportunities.

- Regulatory Compliance: Understanding relevant industry regulations and ensuring supplier compliance with those regulations. This may include safety standards, environmental regulations, and ethical sourcing practices.

Next Steps

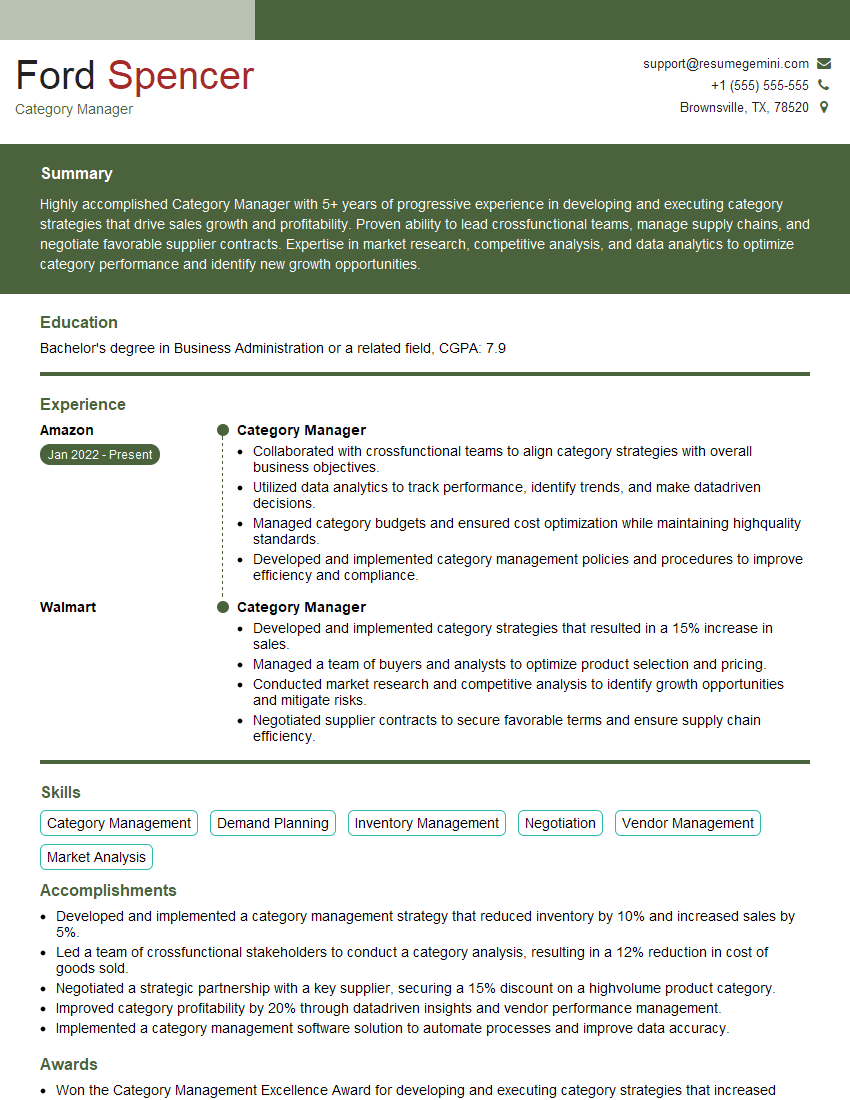

Mastering Supplier Management and Quality Control is crucial for a successful and rewarding career in procurement, operations, or quality assurance. These skills are highly sought after and open doors to diverse and challenging roles within many industries. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific skills and experience. Examples of resumes tailored to Supplier Management and Quality Control are available to help you craft your best application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?