Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Sustainability in Supply Chain Management interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Sustainability in Supply Chain Management Interview

Q 1. Explain the concept of a circular economy and how it applies to supply chain management.

The circular economy is a model of production and consumption that involves keeping resources in use for as long as possible, extracting maximum value from them while in use, then recovering and regenerating products and materials at the end of each service life. Instead of a linear ‘take-make-dispose’ model, it embraces a cyclical approach focusing on reducing waste and pollution. In supply chain management, this means redesigning processes to minimize waste generation at every stage, from sourcing raw materials to product disposal. This could involve designing products for disassembly, reusing components, recycling materials, and recovering energy.

For example, consider a clothing company. A circular economy approach would involve using sustainable materials, designing clothes for durability and easy repair, implementing take-back programs for end-of-life garments, and recycling or upcycling materials into new products. This contrasts with the traditional model where clothes are produced, consumed, and often end up in landfills.

Applying the circular economy in supply chains requires collaboration across the entire value chain – from suppliers to manufacturers, retailers, and consumers. It demands a shift in mindset, embracing innovation and developing new business models that prioritize resource efficiency and waste reduction.

Q 2. Describe different lifecycle assessment (LCA) methodologies used in supply chain sustainability.

Lifecycle Assessment (LCA) methodologies provide a comprehensive environmental evaluation of a product or process across its entire life cycle. Several methodologies exist, but they generally share common phases:

- Goal and Scope Definition: Defining the purpose of the LCA and specifying the product system boundaries, functional unit (e.g., per ton of product), and assessment criteria.

- Inventory Analysis: Quantifying all inputs and outputs associated with the product system, including material and energy flows, emissions, and waste generation. This often involves using databases like ecoinvent.

- Impact Assessment: Evaluating the environmental impacts of the identified inputs and outputs using various impact categories (e.g., climate change, ozone depletion, acidification). Different methods are used here, such as midpoint and endpoint approaches (e.g., ReCiPe, IMPACT).

- Interpretation: Analyzing the results to identify significant environmental impacts and suggest improvement strategies.

Popular LCA software packages assist with the data collection and analysis, like SimaPro and GaBi. Different methodologies vary in their level of detail and the specific impact categories considered. Choosing the appropriate methodology depends on the specific application and desired level of accuracy.

Q 3. How would you measure and report on a company’s carbon footprint within its supply chain?

Measuring and reporting a company’s carbon footprint within its supply chain requires a multi-stage approach:

- Scope Definition: Define the boundaries of your assessment. This includes defining which suppliers and activities are included (Scopes 1, 2, and 3 emissions). Scope 1 covers direct emissions (e.g., from company-owned vehicles), Scope 2 covers indirect emissions from purchased energy, and Scope 3 encompasses all other indirect emissions across the value chain (e.g., from transportation, waste disposal, and purchased goods and services).

- Data Collection: Gather data on emissions from all relevant sources. This may involve working with suppliers to collect data on their emissions or using industry average data if specific data isn’t available. Data points to collect include energy consumption, transportation distances and modes, waste generated, and materials used. Tools like carbon accounting software can help manage data.

- Emissions Calculation: Calculate the total carbon footprint using appropriate emission factors. Emission factors convert the collected data into CO2 equivalents (CO2e).

- Reporting: Report the findings transparently, adhering to established standards such as the Greenhouse Gas Protocol. This usually involves presenting Scope 1, 2, and 3 emissions separately and providing a clear breakdown of the sources.

- Verification: Consider third-party verification to ensure the accuracy and credibility of the reported footprint.

Example: A clothing company could collect data on emissions from cotton farming (Scope 3), manufacturing (Scope 1 and 2), transportation (Scope 3), and end-of-life disposal (Scope 3) to calculate its full supply chain carbon footprint.

Q 4. What are the key environmental regulations impacting global supply chains?

Numerous environmental regulations significantly impact global supply chains. Key examples include:

- EU Emissions Trading System (ETS): A cap-and-trade system regulating greenhouse gas emissions from large industrial installations.

- California Air Resources Board (CARB) regulations: Strict regulations on vehicle emissions and greenhouse gas reduction targets.

- Waste Electrical and Electronic Equipment (WEEE) Directive: Requires the collection and recycling of electronic waste.

- Restriction of Hazardous Substances (RoHS) Directive: Restricts the use of certain hazardous substances in electrical and electronic equipment.

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) Regulation: Requires registration of chemicals and restricts or authorizes the use of certain substances.

- National and regional regulations on deforestation and illegal logging: Increasingly strict regulations targeting the supply of unsustainable timber and agricultural products.

These regulations vary by region and sector, requiring businesses to maintain compliance across their global operations. Failure to comply can lead to hefty fines and reputational damage.

Q 5. How can blockchain technology improve sustainability efforts in the supply chain?

Blockchain technology, with its decentralized and immutable ledger, can enhance supply chain sustainability by improving traceability and transparency. This allows for better tracking of materials and products throughout the supply chain, from origin to consumer.

- Improved Traceability: Tracking the journey of materials and products, verifying their origin and ensuring compliance with sustainability standards (e.g., confirming that timber comes from sustainably managed forests).

- Reduced Counterfeiting: Ensuring the authenticity of sustainable certifications and preventing the entry of counterfeit products into the supply chain.

- Enhanced Transparency: Providing stakeholders with greater visibility into the environmental and social impacts of the supply chain, fostering accountability and promoting responsible sourcing.

- Improved Efficiency: Streamlining processes and reducing administrative overhead associated with tracking and verifying sustainability credentials.

For instance, a coffee company could use blockchain to trace the origin of its beans, ensuring that they are ethically sourced and grown sustainably. This provides transparency to consumers and enhances brand reputation while promoting sustainable farming practices.

Q 6. Discuss the role of sustainable procurement in minimizing environmental impacts.

Sustainable procurement involves selecting goods and services that minimize environmental and social impacts while considering economic factors. It plays a crucial role in reducing the environmental footprint of a supply chain.

- Sourcing Sustainable Materials: Prioritizing suppliers who use recycled materials, renewable resources, and environmentally friendly production processes.

- Reducing Waste: Optimizing packaging, minimizing material usage, and promoting reusable or recyclable materials.

- Improving Energy Efficiency: Selecting products and services with lower energy consumption throughout their lifecycle.

- Promoting Fair Labor Practices: Ensuring that suppliers adhere to ethical labor standards and avoid exploitative practices.

- Lifecycle Cost Analysis: Considering the total environmental and economic costs associated with purchasing and using a product or service over its entire life cycle, not just the initial cost.

For example, a company could choose to purchase office furniture made from recycled materials or select a supplier committed to renewable energy. These choices contribute to a smaller carbon footprint and promote environmentally and socially responsible business practices.

Q 7. What are some common barriers to implementing sustainable practices in a supply chain, and how can they be overcome?

Implementing sustainable practices in supply chains often faces various barriers:

- Cost: Investing in sustainable technologies and practices can be expensive in the short term.

- Lack of Awareness and Commitment: A lack of understanding or commitment from stakeholders (suppliers, managers, employees) to sustainable practices can hinder implementation.

- Lack of Data and Transparency: Difficulty in collecting accurate data on environmental and social impacts across the entire supply chain.

- Complexity of Supply Chains: Managing sustainability across complex, global supply chains with numerous stakeholders is challenging.

- Lack of Standardization: The absence of standardized metrics and reporting frameworks makes it difficult to compare the sustainability performance of different suppliers and products.

Overcoming these barriers requires a multifaceted approach:

- Investing in technology and training: Improve data collection and analysis, supporting sustainable practices with technology.

- Collaboration and communication: Building partnerships with suppliers and engaging employees in sustainability initiatives.

- Setting clear targets and incentives: Providing incentives for suppliers to adopt sustainable practices and rewarding internal teams for their efforts.

- Utilizing standardized frameworks and metrics: Facilitating the comparison of sustainability performance and promoting transparency.

- Long-term perspective: Understanding that sustainable practices often generate long-term cost savings and improve competitiveness.

Q 8. Explain how you would develop a supplier sustainability program.

Developing a robust supplier sustainability program requires a phased approach, focusing on collaboration, transparency, and continuous improvement. It’s not a one-time project, but an ongoing journey.

- Phase 1: Assessment and Goal Setting: Begin by conducting a thorough materiality assessment to identify the most significant environmental and social risks within your supply chain. This involves analyzing your product’s lifecycle, from raw material sourcing to end-of-life management. Then, set specific, measurable, achievable, relevant, and time-bound (SMART) sustainability goals aligned with your overall business strategy and industry best practices. For example, you might aim to reduce carbon emissions by 20% across your supply chain within five years.

- Phase 2: Supplier Engagement and Education: Engage your suppliers in the process. This could involve workshops, training sessions, and the provision of resources to help them understand your sustainability expectations. Clear communication is crucial. Share your sustainability policy, standards, and performance expectations. Collaborate with them to set achievable sustainability targets, tailored to their individual capabilities and circumstances. Consider offering incentives or support for improvements.

- Phase 3: Monitoring and Performance Measurement: Implement a system to track supplier sustainability performance. This might involve using a combination of self-assessments, third-party audits, and data analytics. Regularly collect data on key performance indicators (KPIs) such as energy consumption, waste generation, and greenhouse gas emissions. Use this data to identify areas for improvement and provide constructive feedback to your suppliers.

- Phase 4: Continuous Improvement: Sustainability is an ongoing journey. Regularly review and update your supplier sustainability program. This may involve adjusting your goals, refining your monitoring processes, or implementing new technologies to enhance sustainability performance. Share best practices among your suppliers to foster a culture of continuous improvement.

For example, a clothing company might prioritize sustainable cotton sourcing, reducing water consumption at manufacturing facilities, and implementing ethical labor practices throughout their supply chain.

Q 9. How do you identify and assess supply chain sustainability risks?

Identifying and assessing supply chain sustainability risks involves a multi-faceted approach encompassing both qualitative and quantitative methods.

- Qualitative Risk Assessment: This involves using expert judgment, stakeholder consultations, and scenario planning to identify potential risks related to environmental (e.g., deforestation, water scarcity, pollution), social (e.g., human rights violations, child labor, unfair labor practices), and governance (e.g., corruption, lack of transparency) issues. We might use tools like SWOT analysis or risk matrices to categorize and prioritize these risks.

- Quantitative Risk Assessment: This involves using data analytics to quantify the potential impact of identified risks. For instance, you could assess the carbon footprint of your supply chain, analyze the likelihood of disruptions due to climate change events, or model the financial implications of supply chain disruptions. This involves collecting data from various sources, including supplier questionnaires, sustainability reports, and industry databases.

- Materiality Assessment: A key step is understanding which risks are most significant to your business and stakeholders. A materiality assessment allows you to prioritize the most impactful issues and focus your resources where they are needed most. This process involves engaging with various stakeholders, including customers, investors, and employees to understand their concerns and expectations.

For instance, a technology company sourcing rare earth minerals might assess the risk of human rights violations in mining operations or the environmental impact of mineral extraction. A food company might assess the risks associated with water scarcity in agricultural production or the potential for food safety issues.

Q 10. Describe your experience with different sustainability certifications (e.g., B Corp, Fairtrade).

I have extensive experience working with various sustainability certifications, including B Corp, Fairtrade, and others such as Global Reporting Initiative (GRI), ISO 14001, and the Sustainable Apparel Coalition’s Higg Index. Each certification offers a unique framework for assessing and validating a company’s sustainability performance.

- B Corp Certification: This certification assesses a company’s overall social and environmental performance, covering aspects like governance, workers, community, environment, and customers. It requires a rigorous assessment process and a commitment to meeting high standards of transparency and accountability. I’ve worked with companies seeking B Corp certification, helping them identify areas for improvement and navigate the certification process.

- Fairtrade Certification: This certification focuses on ensuring fair prices and working conditions for farmers and producers in developing countries. I’ve collaborated with companies integrating Fairtrade products into their supply chains, helping to manage and trace the origin of materials and to ensure compliance with Fairtrade standards. This requires a deep understanding of the supply chains of agricultural products.

- Other Certifications: My experience also includes working with companies implementing ISO 14001 (environmental management systems), GRI standards (sustainability reporting), and the Higg Index (measuring the environmental and social performance of apparel and footwear products). These certifications provide a framework for measuring and improving specific aspects of sustainability, requiring close collaboration with suppliers to collect data and implement improvements.

Understanding the nuances of each certification allows me to develop tailored strategies to meet the specific requirements of each program and maximize the positive impact on the supply chain.

Q 11. How can you use data analytics to track and improve supply chain sustainability performance?

Data analytics plays a crucial role in tracking and improving supply chain sustainability performance. It allows us to move beyond anecdotal evidence and develop data-driven strategies for improvement.

- Data Collection: First, establish a robust data collection system, integrating data from various sources, such as supplier questionnaires, ERP systems, environmental monitoring devices, and third-party databases. This might involve developing customized dashboards or using specialized supply chain management software.

- Data Analysis and Visualization: Utilize various analytical techniques to identify trends, patterns, and anomalies in sustainability data. This could involve using descriptive statistics to understand key performance indicators (KPIs), predictive modeling to forecast future impacts, or machine learning to optimize resource allocation. Data visualization tools are essential for communicating insights effectively.

- Performance Monitoring and Reporting: Use data analytics to track progress towards sustainability goals, identify areas for improvement, and measure the effectiveness of interventions. Generate regular reports that highlight key performance indicators and provide insights into areas needing attention.

- Predictive Analytics and Risk Management: Employ predictive modeling to forecast potential risks, such as supply chain disruptions due to climate change or resource scarcity. This enables proactive risk management and mitigation strategies.

For example, a manufacturing company might use data analytics to track energy consumption at its factories, identify inefficient processes, and implement energy-saving measures. Or a retailer could use data to track the carbon footprint of its product shipments and optimize its logistics network to minimize emissions.

Q 12. What are some key performance indicators (KPIs) for measuring sustainability in a supply chain?

Key performance indicators (KPIs) for measuring supply chain sustainability vary depending on the specific industry and company goals, but some commonly used metrics include:

- Environmental KPIs:

- Greenhouse gas (GHG) emissions (Scope 1, 2, and 3): Measures the total emissions across the supply chain.

- Energy consumption: Tracks energy usage in manufacturing, transportation, and other processes.

- Water consumption: Monitors water usage across the supply chain.

- Waste generation: Measures the amount of waste generated during production and disposal.

- Renewable energy usage: Tracks the percentage of renewable energy used.

- Social KPIs:

- Human rights compliance: Measures adherence to labor standards and human rights regulations.

- Employee safety: Tracks workplace accidents and injuries.

- Supplier diversity: Measures the proportion of diverse suppliers in the supply chain.

- Fair wages and working conditions: Assesses compensation, working hours, and overall treatment of workers.

- Economic KPIs:

- Supply chain resilience: Measures the ability of the supply chain to withstand disruptions.

- Cost savings from sustainability initiatives: Tracks cost reductions associated with sustainability improvements.

- Return on investment (ROI) for sustainability projects: Measures the financial return on investments in sustainability.

Choosing the right KPIs requires careful consideration of your company’s specific sustainability priorities and the availability of data. It is important to establish baselines and track progress over time to demonstrate improvements.

Q 13. How would you incorporate sustainability considerations into supplier selection criteria?

Incorporating sustainability considerations into supplier selection criteria is crucial for building a responsible and resilient supply chain. It’s not just about the lowest price but about long-term value and ethical sourcing.

- Develop a Sustainability Scorecard: Create a weighted scorecard that assigns points to suppliers based on their performance across various sustainability criteria. This could include factors like environmental certifications (e.g., ISO 14001), social responsibility initiatives (e.g., Fairtrade), and commitment to transparency and traceability.

- Pre-qualification Questionnaire: Use a detailed questionnaire to assess potential suppliers’ sustainability practices. This could cover topics such as waste management, energy efficiency, water usage, ethical labor practices, and supply chain traceability.

- Supplier Audits: Conduct regular audits of your suppliers to verify their compliance with your sustainability standards. This could involve on-site inspections and document reviews.

- Transparency and Traceability: Prioritize suppliers who are committed to transparency and traceability in their supply chains. This allows you to better understand the origins of materials and identify potential risks.

- Incentivize Sustainable Practices: Offer incentives or rewards to suppliers who demonstrate exemplary sustainability performance. This could encourage continuous improvement and foster a culture of sustainability.

For example, a furniture company might prioritize suppliers who use sustainably sourced wood, have robust waste management systems, and adhere to ethical labor practices. A tech company might focus on suppliers who are committed to reducing e-waste and using recycled materials.

Q 14. Explain the difference between Scope 1, Scope 2, and Scope 3 emissions in a supply chain.

Scope 1, 2, and 3 emissions represent different levels of responsibility for greenhouse gas emissions within a supply chain. Understanding these scopes is critical for developing effective emissions reduction strategies.

- Scope 1 Emissions: These are direct emissions from sources owned or controlled by an organization. This includes emissions from company-owned vehicles, on-site energy generation, and fugitive emissions from equipment. Think of it as emissions that happen directly on your property or from assets you directly control.

- Scope 2 Emissions: These are indirect emissions associated with the purchase of electricity, heat, or steam generated at a location other than the organization’s facilities. This is essentially the emissions associated with the energy you consume.

- Scope 3 Emissions: These are all indirect emissions that occur in the value chain outside of the organization’s direct control. This is the largest and most challenging category to manage. Examples include emissions from purchased goods and services, transportation and distribution, waste generated by the organization, and the use of sold products. These emissions often come from your suppliers, your customers’ use of your product, and transportation of your goods.

For example, a clothing company’s Scope 1 emissions might come from its factory’s boilers, Scope 2 emissions from the electricity used in the factory, and Scope 3 emissions from the manufacturing of fabrics by its suppliers, transportation of garments, and the eventual disposal of the clothes by consumers.

Q 15. How can technology (e.g., AI, IoT) enhance sustainable supply chain practices?

Technology plays a crucial role in enhancing sustainable supply chain practices. Think of it as giving your supply chain a superpower – the ability to see, understand, and optimize itself in real-time for minimal environmental impact. Artificial intelligence (AI) and the Internet of Things (IoT) are key players here.

AI for Optimization: AI can analyze massive datasets from across the supply chain – from raw material sourcing to final product delivery – to identify inefficiencies and areas for improvement. For instance, AI can predict demand more accurately, reducing waste from overproduction. It can also optimize transportation routes, minimizing fuel consumption and emissions. Imagine an AI system that automatically adjusts delivery schedules based on real-time traffic conditions and fuel prices, resulting in significant savings and reduced carbon footprint.

IoT for Visibility and Traceability: IoT sensors embedded in products and throughout the supply chain provide real-time data on location, temperature, humidity, and other crucial factors. This enhanced visibility allows for proactive management of risks, such as spoilage or damage, reducing waste and improving efficiency. For example, sensors on refrigerated trucks ensure that perishable goods maintain optimal temperature throughout the transportation process. This reduces spoilage and minimizes waste, while also improving food safety.

Combined Power: When combined, AI and IoT create a powerful tool for sustainable supply chain management. AI can analyze the data collected by IoT sensors to identify patterns and make informed decisions. This allows businesses to not only monitor but also predict and prevent environmental issues. For example, the AI could identify a specific supplier consistently producing high carbon emissions and suggest alternative, more sustainable options.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Discuss your experience with life cycle costing and its application to sustainable supply chains.

Life Cycle Costing (LCC) is a crucial methodology for evaluating the total cost of a product or service throughout its entire lifespan, from cradle to grave. This includes design, manufacturing, transportation, use, and disposal. In sustainable supply chains, LCC helps businesses make informed decisions that balance economic viability with environmental and social considerations.

In my previous role at GreenTech Solutions, we implemented LCC analysis for a client manufacturing solar panels. We considered factors like raw material extraction, energy consumption during manufacturing, transportation emissions, panel lifespan, and end-of-life recycling or disposal costs. By quantifying these costs, we identified areas where design changes could significantly reduce the overall environmental impact while maintaining cost competitiveness. For example, we found that using recycled materials in panel construction, although initially more expensive, resulted in lower overall LCC due to reduced material extraction costs and lower disposal fees.

LCC isn’t just about numbers; it’s about holistic thinking. It allows us to make strategic decisions that minimize environmental burden and maximizes long-term value, not just immediate profits.

Q 17. How would you prioritize sustainability initiatives within a limited budget?

Prioritizing sustainability initiatives with a limited budget requires a strategic approach. It’s like investing your money wisely – you want the biggest return for your investment. I would utilize a framework that prioritizes high-impact, low-cost actions first, then gradually move towards more complex initiatives.

Quick Wins: Identify low-hanging fruit – easily implemented changes with significant impact. Examples include reducing energy consumption through improved lighting or switching to energy-efficient equipment, implementing a robust recycling program, and optimizing transportation routes to reduce fuel usage.

Materiality Assessment: Conduct a thorough materiality assessment to identify the environmental and social issues most relevant to your business and stakeholders. This helps focus resources on areas with the most significant impact.

Collaborate and Innovate: Explore partnerships with suppliers and other stakeholders to share best practices and reduce costs collaboratively. This might include jointly investing in new technologies or implementing a shared logistics system.

Measure and Report: Track your progress and report your achievements transparently to stakeholders. This helps justify further investments and demonstrate the value of your sustainability initiatives. Quantifiable results make it easier to secure additional funding.

Q 18. Describe a time you had to resolve a conflict between cost optimization and sustainability goals.

In a previous project with a clothing manufacturer, we faced a conflict between cost optimization and sustainability goals. The company wanted to switch to a cheaper, but less sustainable, fabric source. This would cut costs significantly in the short term, but negatively impact their environmental footprint and potentially their brand image.

To resolve this, we presented a comprehensive cost-benefit analysis, comparing the short-term savings with the long-term consequences of using the less sustainable fabric. This included potential fines for non-compliance with environmental regulations, reputational damage, and the costs of implementing future remediation efforts. We also explored alternative options – negotiating better prices with more sustainable suppliers or exploring innovative, cost-effective sustainable fabric options. Ultimately, we convinced the company to adopt a phased approach, gradually transitioning to the more sustainable fabric while minimizing immediate cost increases through a combination of negotiation and process optimization.

The key was open communication, data-driven decision-making, and a focus on the long-term value of sustainability.

Q 19. How do you ensure ethical sourcing within the supply chain?

Ensuring ethical sourcing is paramount in a sustainable supply chain. It’s not just about minimizing environmental impact; it’s about ensuring fair labor practices and responsible resource management across the entire supply chain. It requires a multi-pronged approach.

Supplier Audits and Due Diligence: Regular audits and thorough due diligence of suppliers are essential to verify ethical sourcing. This includes verifying compliance with labor laws, environmental regulations, and ethical codes of conduct.

Traceability and Transparency: Implementing traceability systems allows us to track materials and products through the entire supply chain, ensuring transparency and accountability. Blockchain technology is emerging as a powerful tool for enhancing traceability.

Collaboration and Partnerships: Working with reputable organizations and industry initiatives dedicated to ethical sourcing is crucial. This provides access to best practices, tools, and resources.

Worker Empowerment and Fair Wages: Supporting fair wages and safe working conditions for workers is a cornerstone of ethical sourcing. This includes fostering communication and collaboration with suppliers to address any labor-related concerns.

Continuous Improvement: Ethical sourcing is an ongoing process. Regularly reviewing and updating policies and practices is essential to ensure continuous improvement and adaptation to evolving best practices.

Q 20. What is your experience with designing and implementing a sustainability strategy?

Designing and implementing a sustainability strategy involves a systematic process. At EcoSupplyChain Solutions, I led the development of a comprehensive sustainability strategy for a large retailer. Our approach involved these key steps:

Materiality Assessment: Identifying the environmental and social issues that are most relevant to the business and its stakeholders.

Setting Ambitious Targets: Defining measurable, achievable, relevant, and time-bound (SMART) sustainability goals aligned with global sustainability initiatives like the SDGs.

Developing Action Plans: Creating detailed plans to achieve the targets, identifying responsibilities, and establishing timelines.

Stakeholder Engagement: Engaging with various stakeholders – including suppliers, employees, customers, and investors – to ensure buy-in and collaboration.

Implementation and Monitoring: Implementing the action plans, regularly monitoring progress, and making adjustments as needed.

Reporting and Communication: Regularly communicating sustainability performance to stakeholders through comprehensive reports and other communication channels.

The key to a successful strategy is clear communication, a robust monitoring system, and a commitment to continuous improvement. It’s an ongoing journey, not a destination.

Q 21. Explain how you would communicate sustainability performance to stakeholders.

Communicating sustainability performance to stakeholders requires a multifaceted approach. It’s about transparency, credibility, and demonstrating the value of your sustainability efforts.

Sustainability Reports: Creating comprehensive, standardized reports that use clear, concise language and relevant metrics. Frameworks like the Global Reporting Initiative (GRI) can provide guidance.

Data Visualization: Employing graphs, charts, and infographics to make complex data easily understandable for a broader audience. This enhances engagement and understanding.

Storytelling: Using compelling narratives to illustrate the impact of your sustainability initiatives. This helps connect with stakeholders on an emotional level and makes the data more relatable.

Third-Party Verification: Seeking independent verification of your sustainability performance to enhance credibility and build trust with stakeholders.

Interactive Platforms: Using websites, online dashboards, or interactive tools to provide stakeholders with transparent and readily accessible information.

Stakeholder Engagement: Actively engaging with stakeholders through forums, workshops, and feedback mechanisms to ensure two-way communication and build trust.

The choice of communication method should align with your target audience. For example, investors may appreciate detailed financial data, while customers may be more interested in the social and environmental impacts of your products.

Q 22. How can you promote a culture of sustainability within a supply chain organization?

Promoting a culture of sustainability within a supply chain requires a multi-pronged approach that goes beyond simply implementing policies. It’s about fostering a genuine commitment to environmental and social responsibility at all levels of the organization. Think of it like building a house – you need a strong foundation, sturdy walls, and a beautiful roof.

Strong Leadership Commitment: The foundation starts with top-level buy-in. Leaders must visibly champion sustainability initiatives, integrating them into strategic goals and performance metrics. This sends a powerful message throughout the organization.

Education and Training: The walls are built through comprehensive training programs. Employees at all levels need to understand the organization’s sustainability goals, their roles in achieving them, and the business benefits of sustainable practices. Interactive workshops, online modules, and case studies can be very effective.

Incentivization and Recognition: A roof, or the final flourish, is created by acknowledging and rewarding employees for their contributions to sustainability efforts. This could involve bonuses, public recognition, or opportunities for professional development in this area.

Collaboration and Communication: Open communication is key. Regular updates on progress, challenges, and successes should be shared across teams and departments. Internal communication platforms and town hall meetings can create transparency and foster a sense of collective responsibility.

Supplier Engagement: Sustainability doesn’t stop at your organization’s doors. Engaging suppliers in your sustainability journey is crucial. This could involve collaborative projects, shared best practices, and setting shared sustainability targets.

For example, in a previous role, we implemented a sustainability reward program where teams that exceeded their waste reduction targets received additional resources for further improvements. This created a healthy competition and significantly boosted our overall performance.

Q 23. What are some emerging trends in sustainable supply chain management?

The field of sustainable supply chain management is constantly evolving. Some of the most prominent emerging trends include:

Increased focus on Scope 3 emissions: Companies are increasingly acknowledging their responsibility for emissions throughout their entire value chain, not just within their direct operations (Scope 1 and 2). This necessitates greater collaboration with suppliers and a deeper understanding of their environmental footprints.

Circular economy principles: A shift away from the linear “take-make-dispose” model towards closed-loop systems that prioritize reuse, repair, and recycling of materials is gaining momentum. This involves designing products for durability, recyclability, and re-manufacturing.

Blockchain technology: Blockchain offers enhanced traceability and transparency in supply chains, allowing for better tracking of materials, ensuring ethical sourcing, and reducing counterfeiting. This builds trust and accountability.

Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are being leveraged to optimize logistics, reduce waste, predict disruptions, and improve resource efficiency. This can lead to significant cost savings and environmental benefits.

Sustainable packaging solutions: There’s a growing emphasis on reducing plastic waste and transitioning towards biodegradable, compostable, or reusable packaging materials. This aligns with consumer demand for environmentally friendly products.

For instance, many companies are now using AI-powered route optimization software to minimize fuel consumption and carbon emissions during transportation.

Q 24. What is your understanding of the concept of ‘greenwashing’ and how can it be avoided?

Greenwashing is the practice of making misleading or unsubstantiated claims about the environmental benefits of a product, service, or company. It’s essentially a form of marketing deception where companies exaggerate their sustainability efforts to appeal to environmentally conscious consumers without actually implementing meaningful changes.

To avoid greenwashing, companies should:

Focus on verifiable metrics: Instead of making vague claims like “eco-friendly,” provide concrete data on environmental performance, such as reduced carbon emissions or water usage. This allows for third-party verification.

Use credible certifications: Seek independent certifications from reputable organizations to validate sustainability claims. Certifications like B Corp, Fairtrade, or LEED provide credibility.

Transparency and disclosure: Be open about both your successes and challenges in your sustainability journey. Transparency builds trust with consumers and stakeholders.

Life cycle assessment (LCA): Conduct a thorough LCA to understand the environmental impact of your products across their entire life cycle, from raw material extraction to disposal. This helps identify areas for improvement.

Engage with stakeholders: Solicit feedback from consumers, NGOs, and other stakeholders to ensure your sustainability initiatives are truly meaningful and impactful. This helps identify blind spots.

An example of greenwashing would be a company claiming their product is “sustainable” because it’s packaged in recycled cardboard, while neglecting the fact that its production process uses significant amounts of energy and generates substantial waste.

Q 25. Describe your experience with developing and implementing sustainability policies.

In my previous role at a large manufacturing company, I led the development and implementation of a comprehensive sustainability policy framework. This involved several key steps:

Materiality Assessment: We first conducted a materiality assessment to identify the environmental and social issues most relevant to our business and stakeholders. This involved analyzing our supply chain, identifying key risks and opportunities, and prioritizing actions.

Policy Development: Based on the materiality assessment, we drafted a comprehensive sustainability policy that outlined our commitment to environmental stewardship, social responsibility, and ethical sourcing. The policy included specific targets and timelines for key performance indicators (KPIs).

Stakeholder Engagement: We engaged with various stakeholders – employees, suppliers, customers, and NGOs – to solicit feedback and ensure the policy was relevant, achievable, and aligned with their expectations.

Implementation and Monitoring: We developed a detailed implementation plan, including resource allocation, training programs, and monitoring mechanisms. We tracked progress against our KPIs regularly and made adjustments as needed.

Reporting and Communication: We published annual sustainability reports that documented our progress, challenges, and future plans. This provided transparency and accountability to our stakeholders.

This framework resulted in significant reductions in energy consumption, waste generation, and greenhouse gas emissions. The successful implementation demonstrates the effectiveness of a well-structured, participatory approach to sustainability policy development.

Q 26. How do you ensure compliance with environmental regulations throughout the supply chain?

Ensuring compliance with environmental regulations throughout the supply chain requires a proactive and multi-faceted approach. It’s not just about meeting minimum standards; it’s about exceeding them and fostering a culture of compliance.

Regulatory Mapping: The first step is to thoroughly map all relevant environmental regulations in each region where your supply chain operates. This includes laws related to waste management, emissions, water usage, and hazardous materials handling. This can be complex, as regulations vary significantly across jurisdictions.

Supplier Audits: Regular audits of suppliers are crucial to assess their compliance with environmental regulations and your company’s sustainability standards. These audits can involve on-site inspections, document reviews, and interviews with supplier personnel.

Training and Education: Training programs for both internal staff and suppliers are essential to ensure everyone understands and complies with the relevant regulations. This should include awareness of potential risks and consequences of non-compliance.

Technology and Tracking: Leveraging technology such as supply chain management software can assist in tracking materials, monitoring environmental performance, and identifying potential compliance issues early on.

Continuous Improvement: Compliance is not a one-time event; it’s an ongoing process. Regular monitoring, reporting, and continuous improvement efforts are necessary to stay ahead of changing regulations and emerging best practices.

For example, we used a third-party auditing firm to conduct regular assessments of our suppliers’ compliance with environmental standards, ensuring that all our partners operate within legal and ethical boundaries.

Q 27. What is your approach to managing and mitigating the environmental and social risks associated with global supply chains?

Managing and mitigating environmental and social risks in global supply chains requires a comprehensive risk management framework. This includes:

Risk Identification and Assessment: A thorough assessment of potential environmental and social risks throughout the supply chain is the first step. This involves identifying areas of vulnerability, such as deforestation, human rights violations, or pollution. Tools like risk matrices can be beneficial.

Due Diligence and Supplier Selection: Selecting suppliers based on their environmental and social performance is critical. This includes conducting due diligence, evaluating their sustainability practices, and requiring them to meet your company’s standards. This might entail pre-qualification questionnaires or site visits.

Monitoring and Reporting: Continuous monitoring of supplier performance is essential to track progress and identify emerging risks. This requires implementing key performance indicators (KPIs) and regular reporting mechanisms.

Mitigation Strategies: Developing and implementing effective mitigation strategies is critical to addressing identified risks. This may involve working with suppliers to improve their practices, providing technical assistance, or even terminating relationships with non-compliant partners.

Transparency and Accountability: Transparency and accountability are key. Publicly reporting on sustainability performance builds trust and fosters a culture of responsibility throughout the supply chain.

In a previous project, we used a third-party platform to assess and manage the social and environmental risks associated with our global supply chain. This provided real-time visibility into potential issues and enabled us to take proactive steps to mitigate them. For example, we worked with a supplier to improve their worker safety practices after identifying some deficiencies during a risk assessment.

Key Topics to Learn for Sustainability in Supply Chain Management Interview

- Sustainable Sourcing: Understanding ethical sourcing practices, fair trade principles, and the impact of material selection on environmental and social responsibility. Consider exploring certifications like Fairtrade, Rainforest Alliance, and B Corp.

- Supply Chain Transparency & Traceability: Implementing systems to track materials and products throughout the supply chain, identifying and mitigating risks related to environmental impact and social injustices. Discuss blockchain technology and its applications.

- Carbon Footprint Reduction: Analyzing and minimizing the environmental impact of transportation, warehousing, and manufacturing processes. Explore strategies like carbon offsetting, renewable energy integration, and efficient logistics.

- Waste Management & Circular Economy: Designing products and processes for recyclability, reducing waste generation, and promoting reuse and repurposing of materials. Discuss the principles of the circular economy and its role in sustainable supply chains.

- Sustainable Packaging: Evaluating packaging materials for their environmental impact, exploring biodegradable and compostable alternatives, and reducing overall packaging waste. Consider lifecycle assessment methodologies.

- Stakeholder Engagement & Communication: Building strong relationships with suppliers, customers, and other stakeholders to promote sustainable practices throughout the supply chain. Discuss effective communication strategies and reporting frameworks (e.g., GRI).

- Metrics & Reporting: Understanding key performance indicators (KPIs) for measuring sustainability performance, such as carbon emissions, water usage, and waste generation. Explore relevant sustainability reporting standards and frameworks.

- Risk Management & Compliance: Identifying and mitigating sustainability-related risks throughout the supply chain, complying with relevant regulations and standards. Discuss due diligence processes and potential legal liabilities.

- Innovation & Technology: Exploring the role of emerging technologies, such as AI and IoT, in improving supply chain sustainability. Discuss examples of innovative solutions addressing sustainability challenges.

Next Steps

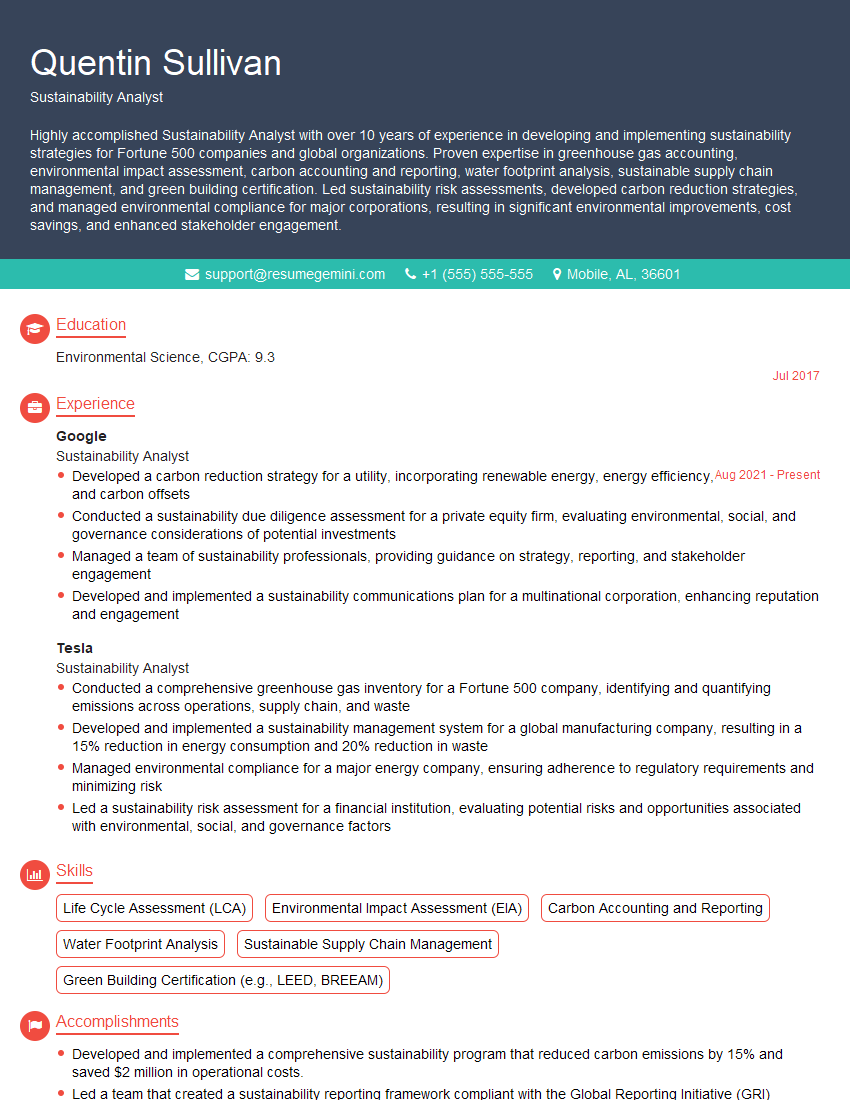

Mastering Sustainability in Supply Chain Management is crucial for career advancement in a rapidly evolving landscape. Demonstrating expertise in these areas will significantly enhance your job prospects. Creating an ATS-friendly resume is paramount to ensuring your application gets noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Take advantage of their tools and resources, including examples of resumes tailored to Sustainability in Supply Chain Management, to present yourself effectively and land your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?