Unlock your full potential by mastering the most common Synthetic Fiber Production interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Synthetic Fiber Production Interview

Q 1. Explain the different types of synthetic fibers and their properties.

Synthetic fibers are manufactured from polymers, offering a wide array of properties tailored to diverse applications. Key types include:

- Polyester: Known for its strength, wrinkle resistance, and elasticity. Think of your favorite performance sportswear or durable upholstery fabrics. It’s often used in blends for its versatility.

- Nylon: Highly resilient and abrasion-resistant, making it ideal for carpets, hosiery, and outdoor gear. Its strength-to-weight ratio is exceptional.

- Acrylic: A cost-effective alternative to wool, mimicking its softness and warmth. It’s frequently used in blankets, sweaters, and synthetic furs. Its ability to take dyes brilliantly is a key advantage.

- Polypropylene: Lightweight, water-resistant, and relatively inexpensive. Commonly found in carpets, ropes, and non-woven fabrics. Its resistance to chemical degradation makes it suitable for many applications.

- Rayon: A semi-synthetic fiber made from cellulose, it offers a silky drape and excellent absorbency. It is often used in clothing and home textiles. It combines the benefits of natural and synthetic fibers.

Each fiber’s properties are influenced by its chemical composition, molecular weight, and processing conditions, allowing manufacturers to fine-tune them for specific end-uses.

Q 2. Describe the process of polymerization in synthetic fiber production.

Polymerization is the fundamental process in synthetic fiber production, where smaller molecules (monomers) are linked together to form long chains (polymers). Think of it like building a chain out of individual links. This process usually involves a chemical reaction often catalyzed to increase the speed and yield of the process.

For example, in the production of polyethylene terephthalate (PET), used in polyester fibers, the monomers ethylene glycol and terephthalic acid react under heat and pressure to create long PET chains. The reaction can be broadly described as a condensation polymerization. The chain length (degree of polymerization) dictates many of the final fiber’s properties. A higher degree of polymerization generally means stronger and more durable fibers.

The polymerization reaction is carefully controlled to achieve the desired molecular weight and distribution. Factors such as temperature, pressure, catalysts, and reaction time are meticulously monitored to ensure a consistent and high-quality polymer.

Q 3. What are the key quality control parameters in synthetic fiber manufacturing?

Quality control in synthetic fiber manufacturing is paramount. Key parameters include:

- Fiber Diameter and Uniformity: Consistent diameter is crucial for even yarn and fabric structures, affecting the final product’s appearance and performance. This is typically measured using optical or laser techniques.

- Fiber Length: Affects the strength and spinnability of the fiber. Shorter fibers can lead to weaker yarns.

- Polymer Molecular Weight: Determines the fiber’s strength, elasticity, and other properties. It is often measured using gel permeation chromatography (GPC).

- Crimp and Curl: These characteristics add bulk and softness to the fiber and are assessed visually and by measurement of the crimp frequency and amplitude.

- Tensile Strength and Elongation: Measures the fiber’s resistance to breaking and stretching.

- Dye Uptake: How well the fiber accepts dyes, impacting the final product’s color fastness and intensity.

Regular quality checks at various stages of production, from polymerization to final product, are essential to maintain consistent standards.

Q 4. How do you ensure the consistency of fiber diameter and length?

Ensuring consistency in fiber diameter and length requires precise control throughout the manufacturing process. Key methods include:

- Careful control of the polymerization process: The molecular weight distribution of the polymer directly impacts fiber properties.

- Precise spinneret design and operation: Spinnerets are the devices that extrude the molten polymer, and their design and operation are optimized to create fibers with consistent diameters.

- Precise control of extrusion parameters: This includes temperature, pressure, and flow rate.

- Online monitoring and control systems: These systems provide real-time feedback and adjustments to maintain consistent fiber characteristics.

- Careful selection and control of spinning parameters: Factors such as draw ratio, take-up speed, and the level of stretching significantly influence fiber length and diameter.

Regular calibration of equipment and thorough training of personnel contribute to a consistent final product.

Q 5. Explain the role of extrusion in synthetic fiber production.

Extrusion is a critical step in synthetic fiber production. It’s the process where the molten polymer is forced through a spinneret, a device with tiny holes that shape the polymer into continuous filaments. Think of it as squeezing toothpaste from a tube. However, the spinneret has carefully designed holes to control the shape and size of the fibers formed from the liquid polymer.

The spinneret’s design is paramount. The size and shape of the holes determine the fiber diameter. The extrusion process must be carefully controlled to maintain a consistent flow rate and pressure to ensure uniform fiber formation. Factors such as temperature and the polymer’s viscosity (thickness) directly influence the extrusion process.

Q 6. Describe different spinning methods used in synthetic fiber manufacturing.

Several spinning methods are used in synthetic fiber manufacturing, each with its advantages and disadvantages:

- Melt Spinning: Used for thermoplastic polymers like polyester and nylon. The polymer is melted and then extruded through the spinneret. This is a very common and efficient method.

- Dry Spinning: Used for polymers that are not easily melted. The polymer is dissolved in a solvent, extruded, and then the solvent is evaporated. This method is suitable for polymers that degrade at high temperatures.

- Wet Spinning: Similar to dry spinning, the polymer solution is extruded into a coagulation bath, which causes the polymer to solidify into fibers. This is often used for rayon and some specialty fibers.

The choice of spinning method depends on the polymer type, desired fiber properties, and cost considerations.

Q 7. What are the common defects found in synthetic fibers, and how are they addressed?

Common defects in synthetic fibers include:

- Fiber breakage: Caused by weak points in the fiber structure, often due to inconsistencies in the polymerization or spinning process.

- Non-uniform diameter: Leads to uneven yarn and fabric textures. This is frequently due to inconsistent extrusion or spinning parameters.

- Neps: Small entangled fiber clusters that affect the appearance of the fabric.

- Slubs: Thick areas in the fiber, indicative of variations in polymer flow during extrusion.

- Pilling: The formation of small balls of fiber on the fabric surface, caused by fiber abrasion.

Addressing these defects requires careful monitoring of the manufacturing process, identifying the root cause, and making adjustments to equipment or process parameters. For example, improving spinneret design can help reduce non-uniform diameter, while adjustments to the spinning parameters can alleviate slubs. Regular quality checks and continuous improvement efforts are essential to minimize these defects.

Q 8. Explain the importance of fiber orientation in the final product properties.

Fiber orientation, or the alignment of polymer chains within a fiber, significantly impacts the final product’s properties. Think of it like laying bricks – if you lay them haphazardly, the wall will be weak and uneven. But if you carefully align them, the wall becomes much stronger and more resistant to stress. Similarly, aligned fibers lead to higher tensile strength, improved abrasion resistance, and better dimensional stability.

For example, in a highly oriented yarn, the polymer chains are predominantly aligned along the fiber axis. This results in a strong, stiff fiber ideal for applications like tire cord or high-strength fabrics. Conversely, a less oriented yarn will be softer, more flexible, and potentially more absorbent, making it suitable for clothing or upholstery.

Controlling fiber orientation is achieved through various spinning techniques and post-spinning processes such as drawing and heat setting. The degree of orientation can be precisely controlled to tailor the fiber properties to meet specific end-use requirements.

Q 9. How do you handle waste management in synthetic fiber production?

Waste management is crucial in synthetic fiber production, both for environmental reasons and economic efficiency. We employ a multi-pronged approach. Firstly, we strive for process optimization to minimize waste generation. This involves precise control of raw material feed rates, efficient process parameters, and regular equipment maintenance.

Secondly, we implement closed-loop systems where feasible, recycling process water and recovering valuable by-products. For instance, some spinning solutions can be partially recovered and reused after purification.

Thirdly, we prioritize waste segregation and proper disposal. Non-recyclable waste is handled in accordance with environmental regulations, often through specialized waste management companies. We’re also actively exploring innovative technologies like chemical recycling to convert plastic waste back into usable polymers, reducing our reliance on virgin materials.

Q 10. Describe the process of fiber finishing and treatment.

Fiber finishing and treatment involves a series of processes applied to the spun fibers to enhance their aesthetic and performance properties. It’s like giving the fiber a makeover to make it fit for its intended purpose. These processes can include:

- Sizing: Applying a protective coating to enhance the fiber’s strength and reduce friction during weaving or knitting.

- Dyeing: Imparting color using various dyeing techniques, such as solution dyeing, dope dyeing, or fiber dyeing.

- Heat setting: Applying heat to stabilize the fiber’s structure and improve its dimensional stability and crease resistance.

- Softening: Treating fibers to enhance their softness and handle, often through the use of chemical softeners.

- Anti-static treatment: Reducing the fiber’s tendency to attract static electricity.

- Water repellent treatment: Making the fabric resistant to water absorption.

The specific treatments chosen depend on the fiber type, the end-use application, and the desired final properties.

Q 11. What are the environmental considerations in synthetic fiber production?

Environmental considerations are paramount in synthetic fiber production. The major concerns revolve around:

- Greenhouse gas emissions: The production of synthetic polymers often relies on fossil fuels, contributing to greenhouse gas emissions. We mitigate this through energy efficiency improvements, the use of renewable energy sources, and carbon capture technologies.

- Water consumption: Many synthetic fiber processes require significant amounts of water. Water recycling and efficient water management practices are crucial to minimize our environmental footprint.

- Waste generation: As mentioned earlier, minimizing waste generation and implementing effective waste management strategies are key to reducing environmental impact.

- Microplastic pollution: The shedding of microplastics during washing and use of synthetic fabrics is a growing concern. We support research and development of solutions that address this, like the development of biodegradable or compostable fibers.

Sustainable practices are not just an ethical imperative but also increasingly important for our business sustainability. Consumers are becoming more aware of the environmental implications of their purchases, demanding environmentally friendly products.

Q 12. How do you troubleshoot common problems in the spinning process?

Troubleshooting in the spinning process involves a systematic approach. It starts with careful observation of the problem: Is the yarn breaking frequently? Is the yarn uneven? Is the output rate too low?

Once the problem is identified, we investigate potential causes. For example, frequent yarn breakage might indicate problems with fiber quality, insufficient lubrication, or improper spinning parameters. Uneven yarn could point to inconsistencies in the polymer melt or spinning solution, or issues with the spinneret. Low output might be due to equipment malfunction or process inefficiencies.

Troubleshooting typically involves adjusting process parameters (temperature, speed, pressure), inspecting and maintaining equipment, and analyzing the quality of raw materials. Data analysis, using process control systems and quality control testing, provides valuable insights. A well-trained team and proactive maintenance are essential to preventing and resolving problems quickly and efficiently.

Q 13. Explain the difference between melt spinning and solution spinning.

Melt spinning and solution spinning are two primary methods of producing synthetic fibers. They differ fundamentally in how the polymer is processed:

- Melt spinning: Involves melting the polymer and then extruding it through spinnerets (small holes) to form fibers. This method is suitable for polymers that can be melted without degradation, like polyethylene terephthalate (PET) used in polyester fibers.

- Solution spinning: Involves dissolving the polymer in a suitable solvent, then extruding the solution through spinnerets. After extrusion, the solvent is evaporated, leaving behind the solid polymer fiber. This method is used for polymers that degrade upon melting, such as those used to make acrylic or rayon fibers.

The choice of method depends on the specific polymer’s properties and the desired fiber characteristics. Melt spinning is generally simpler and less expensive, while solution spinning offers more versatility for certain polymers and fiber types.

Q 14. What are the different types of synthetic fiber polymers used?

A wide range of synthetic fiber polymers is used, each offering unique properties. Some common examples include:

- Polyester (PET): A strong, versatile polymer used in clothing, packaging, and industrial applications. It’s known for its wrinkle resistance, durability, and low cost.

- Nylon (polyamide): Another strong, resilient fiber often used in clothing, carpets, and industrial applications. Nylon is known for its elasticity and abrasion resistance.

- Acrylic: A fiber that mimics the properties of wool, often used in warm clothing. It’s soft, comfortable, and relatively inexpensive.

- Polypropylene: A lightweight, water-resistant fiber used in outdoor clothing, carpets, and automotive applications.

- Polyethylene: Used in specialty fibers for applications requiring high strength or chemical resistance.

The choice of polymer depends on the intended application and desired properties of the final fiber. Research and development constantly introduces new polymers with improved properties and enhanced sustainability features.

Q 15. Discuss the impact of temperature and pressure on fiber properties.

Temperature and pressure play crucial roles in determining the final properties of synthetic fibers. Think of it like baking a cake – the oven temperature and pressure (though less significant in baking) directly impact the texture and structure of the final product. In fiber production, these parameters influence the polymerization process, the spinning process, and the final fiber morphology.

Polymerization: Higher temperatures generally accelerate the polymerization reaction, leading to faster production but potentially affecting the molecular weight distribution and hence the fiber’s strength and flexibility. Pressure can also influence the reaction rate and the degree of polymerization.

Spinning: During melt spinning, the temperature of the melt affects its viscosity, which in turn dictates the fiber diameter and its uniformity. Pressure is critical in extruding the molten polymer through the spinneret, influencing the fiber’s final shape and smoothness. In solution spinning, temperature and pressure control the solvent evaporation rate, affecting fiber structure and properties.

Fiber Morphology: Temperature influences the rate of crystallization in the fiber, impacting its crystallinity and hence its tensile strength, elasticity, and moisture absorption. Pressure during the drawing process (stretching the fiber) affects the orientation of polymer chains, impacting its tenacity (strength).

For example, a higher temperature during melt spinning of polyethylene terephthalate (PET) might lead to thinner fibers with lower tenacity, while lower temperatures might result in thicker, more brittle fibers. Precise control over temperature and pressure throughout the process is therefore paramount in achieving the desired fiber properties.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the safety of workers in a synthetic fiber plant?

Worker safety in a synthetic fiber plant is paramount and achieved through a multi-layered approach involving engineering controls, administrative controls, and personal protective equipment (PPE).

Engineering Controls: These are built-in safety features that minimize hazards at their source. This includes enclosed machinery with interlocks to prevent accidental access, automated systems to reduce manual handling, and well-ventilated areas to mitigate exposure to fumes and dust.

Administrative Controls: These involve procedures and training designed to reduce risks. Regular safety audits, comprehensive training programs on machine operation and hazard awareness, and clear safety protocols are essential. Establishing clear emergency procedures and regular drills are crucial for effective response in case of an incident.

Personal Protective Equipment (PPE): Workers must always wear appropriate PPE, such as safety glasses, gloves, respirators (depending on the specific hazards), and hearing protection, depending on their specific job tasks. Regular inspections and maintenance of PPE are essential.

For instance, workers handling chemicals might require specialized respirators and protective clothing, while those operating machinery need hearing protection and safety glasses. A robust safety culture, fostered through regular communication, employee involvement in safety initiatives, and immediate reporting of incidents, is fundamental to a safe working environment.

Q 17. What are the different types of testing performed on synthetic fibers?

Synthetic fibers undergo rigorous testing to ensure they meet quality standards and intended applications. Testing methods are highly specific to the fiber type and its end-use.

Tensile Strength: Measures the fiber’s resistance to breaking under tension, indicating its strength and durability.

Elongation: Measures the fiber’s ability to stretch before breaking, indicating its elasticity and flexibility.

Moisture Regain: Measures the fiber’s ability to absorb moisture from the air, impacting its comfort and performance in certain applications.

Shrinkage: Measures the fiber’s tendency to shorten when exposed to heat or moisture, important for dimensional stability.

Microscopic Examination: Examines the fiber’s cross-section and surface morphology to identify defects and assess uniformity.

Colorfastness: Assesses the fiber’s resistance to fading when exposed to light or washing.

Chemical Resistance: Tests the fiber’s resistance to various chemicals, crucial for industrial applications.

The specific tests performed will vary depending on the intended use. For example, fibers for clothing will undergo extensive colorfastness and abrasion resistance testing, while fibers for industrial applications will focus on chemical resistance and tensile strength.

Q 18. How do you interpret the results of fiber testing?

Interpreting fiber testing results requires a thorough understanding of the test methods and the relationship between test results and fiber performance. Results are compared against pre-defined specifications or standards.

Comparing to Standards: Results are compared against industry standards (e.g., ASTM standards) or internal company specifications to ensure the fiber meets the required quality criteria. Any deviation from the standards needs investigation.

Identifying Trends: Analyzing trends in test results across batches of production helps identify potential problems in the manufacturing process. Consistent deviations might indicate a need to adjust processing parameters.

Correlation with Performance: Understanding the correlation between test results and the fiber’s end-use performance is crucial. For example, high tensile strength might correlate with durability, while high elongation might correlate with comfort and elasticity.

Troubleshooting: Deviations from expected results can indicate problems in the manufacturing process, such as inconsistencies in raw materials, processing parameters, or equipment malfunctions. A systematic investigation is essential to identify and rectify the root cause.

For instance, if tensile strength is consistently lower than expected, it might indicate a problem with the polymerization process or the drawing process, prompting a review of temperature and pressure settings or the quality of raw materials.

Q 19. Describe the role of additives in synthetic fiber production.

Additives play a critical role in modifying the properties of synthetic fibers, enhancing their performance, and improving the manufacturing process. They are incorporated into the polymer melt or solution before spinning.

Lubricants: Reduce friction during spinning, leading to smoother fibers and less breakage.

Antioxidants: Protect the polymer from degradation during processing and use, extending its lifespan.

UV Stabilizers: Protect the fiber from degradation caused by ultraviolet (UV) radiation, preventing discoloration and weakening.

Flame Retardants: Enhance the fiber’s resistance to burning, improving fire safety.

Dyes and Pigments: Provide color to the fibers.

Antistatic Agents: Reduce the build-up of static electricity, improving handling and reducing potential hazards.

For example, adding a lubricant can significantly reduce fiber breakage during spinning, improving production efficiency and reducing waste. The choice of additives depends heavily on the intended end-use of the fiber.

Q 20. Explain the concept of crimping in synthetic fibers.

Crimping in synthetic fibers refers to the introduction of waves or curls into the fiber, altering its physical structure and properties. It’s like giving the fiber a permanent wave! This is often done to improve the fiber’s bulk, hand (feel), and other performance characteristics.

Methods of Crimping: Crimping can be introduced during the spinning process itself (e.g., using a special spinneret design) or as a post-spinning process (e.g., mechanical crimping).

Effects of Crimping: Crimped fibers have a higher bulk, which means more volume for the same weight, leading to softer and more comfortable fabrics. Crimping also increases the fiber’s ability to trap air, enhancing its insulation properties.

For example, crimped polyester fibers are commonly used in fleece fabrics because the crimping enhances the softness and warmth of the garment. The level of crimp is precisely controlled to achieve the desired properties for a specific application.

Q 21. What are the key performance indicators (KPIs) for a synthetic fiber plant?

Key Performance Indicators (KPIs) for a synthetic fiber plant are carefully chosen metrics that provide insights into the plant’s overall efficiency, profitability, and operational health. These KPIs need to align with the plant’s strategic goals and are regularly monitored and analyzed.

Production Output: Measured in tons or kilograms of fiber produced per unit time (e.g., tons per day).

Production Efficiency: Measured as a percentage of the planned production capacity that is actually achieved.

Quality Rate: Percentage of produced fibers that meet quality specifications.

Waste Rate: Percentage of raw materials or finished products lost due to defects or other issues.

Energy Consumption: Amount of energy used per unit of fiber produced, often expressed in kilowatt-hours per kilogram.

Downtime: Total time the plant is not in operation due to maintenance, repairs, or other unplanned stoppages.

Safety Incidents: Number of safety incidents per unit of production or per worker-hour.

Profitability: Calculated using standard accounting measures (e.g., net profit margin).

Regular monitoring and analysis of these KPIs help identify areas for improvement, optimize the production process, and enhance the overall performance and profitability of the synthetic fiber plant.

Q 22. How do you optimize production efficiency in a synthetic fiber plant?

Optimizing production efficiency in a synthetic fiber plant involves a multifaceted approach focusing on maximizing output while minimizing waste and downtime. It’s like conducting an orchestra – each section (process) needs to be in perfect harmony.

Process Optimization: Analyzing each stage of production – polymerization, spinning, drawing, texturing – to identify bottlenecks. This might involve streamlining workflows, upgrading outdated equipment, or implementing lean manufacturing principles to eliminate unnecessary steps. For example, adjusting the extrusion parameters to improve fiber uniformity can significantly reduce waste.

Preventive Maintenance: Regular scheduled maintenance prevents unexpected equipment failures. Think of it as regularly servicing your car to prevent major breakdowns. A proactive maintenance program includes regular inspections, lubrication, and component replacements, minimizing costly downtime.

Inventory Management: Efficient inventory control ensures a smooth flow of raw materials and finished goods. Just-in-time inventory systems prevent storage costs and minimize waste from spoilage or obsolescence. This requires robust forecasting and accurate demand planning.

Energy Efficiency: Synthetic fiber production is energy-intensive. Implementing energy-saving technologies, such as heat recovery systems and optimized process parameters, can significantly reduce operational costs and environmental impact. Investing in energy-efficient motors and lighting can also make a substantial difference.

Automation and Robotics: Automating repetitive tasks reduces human error and improves consistency. Robotics can handle hazardous or physically demanding jobs, increasing worker safety and productivity. For instance, automated winding machines can significantly increase output and reduce material waste.

Q 23. Explain the principles of process control in synthetic fiber manufacturing.

Process control in synthetic fiber manufacturing is crucial for maintaining consistent product quality and efficiency. It’s about using technology and strategies to keep the process running smoothly and predictably, much like a thermostat maintains a consistent temperature in your home.

Feedback Control Loops: These systems continuously monitor key process variables (e.g., temperature, pressure, flow rate) and make adjustments to maintain them within a specified range. For instance, a feedback loop might adjust the spinneret temperature to maintain consistent fiber diameter.

Supervisory Control and Data Acquisition (SCADA) Systems: SCADA systems integrate data from various sensors and control devices, providing a centralized view of the entire process. This allows operators to identify and address deviations from the setpoints in real-time, preventing major problems. Think of it as a central dashboard showing the status of all aspects of the production line.

Quality Control (QC) Measures: Regular testing of raw materials and finished products ensures adherence to quality standards. This might involve testing fiber strength, elongation, and other properties to ensure compliance with customer specifications.

Statistical Process Control (SPC): SPC uses statistical methods to monitor and control process variation, helping to identify potential problems before they escalate. Control charts help visualize process stability and identify outliers that may indicate a need for adjustments.

Q 24. Describe your experience with different types of synthetic fiber machinery.

My experience encompasses a wide range of synthetic fiber machinery, from traditional melt spinning lines to advanced air-jet texturing machines. I’ve worked with:

Melt Spinning Lines: These are used for producing continuous filament yarns from molten polymers. I’ve overseen the operation and maintenance of various melt spinning lines, including those producing polyester, nylon, and polypropylene fibers. This includes troubleshooting issues with spinnerets, pumps, and other critical components.

Solution Spinning Lines: Used for producing fibers from polymer solutions, often used for specialized fibers like acrylic or rayon. I have familiarity with the challenges unique to these lines, such as solvent recovery and coagulation bath control.

Draw-Twisting Machines: These machines enhance the properties of fibers, such as strength and elasticity. I’ve worked with various draw-twisting machines, adjusting parameters to achieve desired fiber characteristics.

Air-Jet Texturing Machines: Used to produce textured yarns with improved bulk and softness. I’ve troubleshooted issues related to air pressure, yarn tension, and false twisting.

Fiber Cutting and Winding Machines: Essential for converting continuous filaments into staple fibers or packages of yarn. I’ve worked with several types of these machines, ensuring consistent quality and efficient operation.

Q 25. How do you manage inventory in a synthetic fiber production facility?

Managing inventory in a synthetic fiber production facility is crucial for maintaining production flow and minimizing costs. It requires a delicate balance between having enough materials on hand to meet production demands without tying up excessive capital in storage.

Demand Forecasting: Accurate forecasting is the cornerstone of effective inventory management. This involves analyzing historical sales data, market trends, and customer orders to predict future demand.

Just-in-Time (JIT) Inventory: JIT aims to minimize inventory levels by receiving materials only when needed. This reduces storage costs and the risk of obsolescence, but requires precise coordination with suppliers.

Material Requirements Planning (MRP): MRP systems use production schedules and inventory levels to calculate the required quantities of raw materials and components. This helps optimize procurement and prevents shortages.

Inventory Tracking System: A robust system for tracking materials from receipt to finished goods is essential. This could involve using barcode scanners, RFID tags, or a sophisticated ERP system to maintain accurate inventory records.

Regular inventory audits are vital to ensure the accuracy of inventory records and identify any discrepancies.

Q 26. What are the challenges in scaling up synthetic fiber production?

Scaling up synthetic fiber production presents numerous challenges, ranging from technical hurdles to logistical complexities. It’s like expanding a small bakery into a large-scale production facility – you need to ensure all aspects of the operation can handle the increased volume.

Maintaining Quality Consistency: Scaling up requires ensuring that the quality of the product remains consistent at higher production volumes. This necessitates meticulous process control and rigorous quality assurance.

Capacity Constraints: Existing equipment may not be able to handle the increased output, necessitating investment in new machinery or upgrades. Ensuring sufficient infrastructure, like power and water supply, is also critical.

Supply Chain Management: Securing a reliable supply of raw materials in sufficient quantities is crucial. This may involve negotiating with multiple suppliers or establishing long-term contracts.

Waste Management: Increased production also leads to increased waste. Effective waste management strategies are essential to minimize environmental impact and comply with regulations.

Process Optimization: Scaling up often necessitates revisiting and optimizing the production process. What works efficiently on a small scale may not be optimal for a larger operation.

Q 27. How do you ensure compliance with industry regulations in synthetic fiber production?

Ensuring compliance with industry regulations in synthetic fiber production is paramount. This involves adhering to environmental, safety, and quality standards set by national and international bodies. It’s about maintaining a responsible and ethical operation – showing that you care about people and the planet.

Environmental Regulations: These relate to emissions, wastewater discharge, and waste disposal. Strict adherence is crucial and often involves implementing and maintaining pollution control systems and obtaining necessary permits.

Safety Regulations: Maintaining a safe working environment for employees is vital. This necessitates adherence to occupational safety and health standards, including providing personal protective equipment and conducting regular safety training.

Quality Standards: Meeting the required quality standards for the produced fibers is paramount, often involving certifications and adherence to international standards like ISO 9001.

Waste Management Regulations: Proper handling and disposal of waste materials are crucial for environmental protection. This includes recycling, reuse, and safe disposal of hazardous materials according to regulations.

Record Keeping: Maintaining comprehensive records of all aspects of the production process is essential for demonstrating compliance and facilitating audits.

Q 28. Describe your experience with troubleshooting equipment malfunctions in a synthetic fiber plant.

Troubleshooting equipment malfunctions is a routine part of working in a synthetic fiber plant. It requires a systematic approach, much like a detective solving a case, identifying clues and building toward the solution.

Identifying the Problem: The first step is to accurately diagnose the malfunction. This involves observing the symptoms, checking sensor readings, and analyzing error logs.

Systematic Troubleshooting: Employ a methodical approach, checking components and systems one by one. For example, if a melt spinning line is producing faulty fibers, check the spinneret, the polymer melt temperature, the drawing process, and the winding mechanism to isolate the source of the problem.

Using Diagnostics Tools: Modern machinery often incorporates diagnostic tools that can help identify and pinpoint problems. These tools can provide valuable information about the cause and nature of the malfunction.

Consult Technical Manuals and Experts: Technical manuals provide detailed information about the equipment, its components, and troubleshooting procedures. If the problem is complex, it may be necessary to consult with experienced technicians or engineers.

Preventive Measures: After resolving the problem, analyze the root cause to prevent future occurrences. This might involve making adjustments to operating parameters, implementing preventive maintenance procedures, or upgrading components.

Key Topics to Learn for Your Synthetic Fiber Production Interview

Ace your interview by mastering these key areas of synthetic fiber production. We’ve broken down the essential concepts to help you confidently showcase your expertise.

- Polymer Chemistry: Understand the fundamental chemical processes involved in polymer synthesis, including polymerization types (addition, condensation), and the properties of different polymers used in fiber production (e.g., polyester, nylon, acrylic).

- Spinning Processes: Gain a thorough understanding of various spinning techniques (melt spinning, solution spinning, dry spinning) and their impact on fiber properties like strength, tenacity, and elasticity. Be prepared to discuss the advantages and disadvantages of each method.

- Fiber Modification & Finishing: Explore techniques used to modify fiber properties post-spinning, such as drawing, heat setting, texturing, and dyeing. This includes understanding the impact of these processes on the final product’s performance and aesthetics.

- Quality Control & Testing: Familiarize yourself with standard quality control procedures and testing methods used to ensure the consistent quality and performance of synthetic fibers. Consider examples of common tests and their significance.

- Equipment & Machinery: Develop a working knowledge of the key machinery and equipment involved in the synthetic fiber production process. Be prepared to discuss their operation, maintenance, and troubleshooting.

- Process Optimization & Troubleshooting: Practice identifying potential bottlenecks and problems within the production process and propose solutions based on your understanding of the underlying principles. Think about scenarios requiring process adjustments.

- Sustainability & Environmental Impact: Demonstrate awareness of the environmental considerations in synthetic fiber production, including waste management, energy efficiency, and the use of sustainable materials.

Next Steps: Set Yourself Up for Success

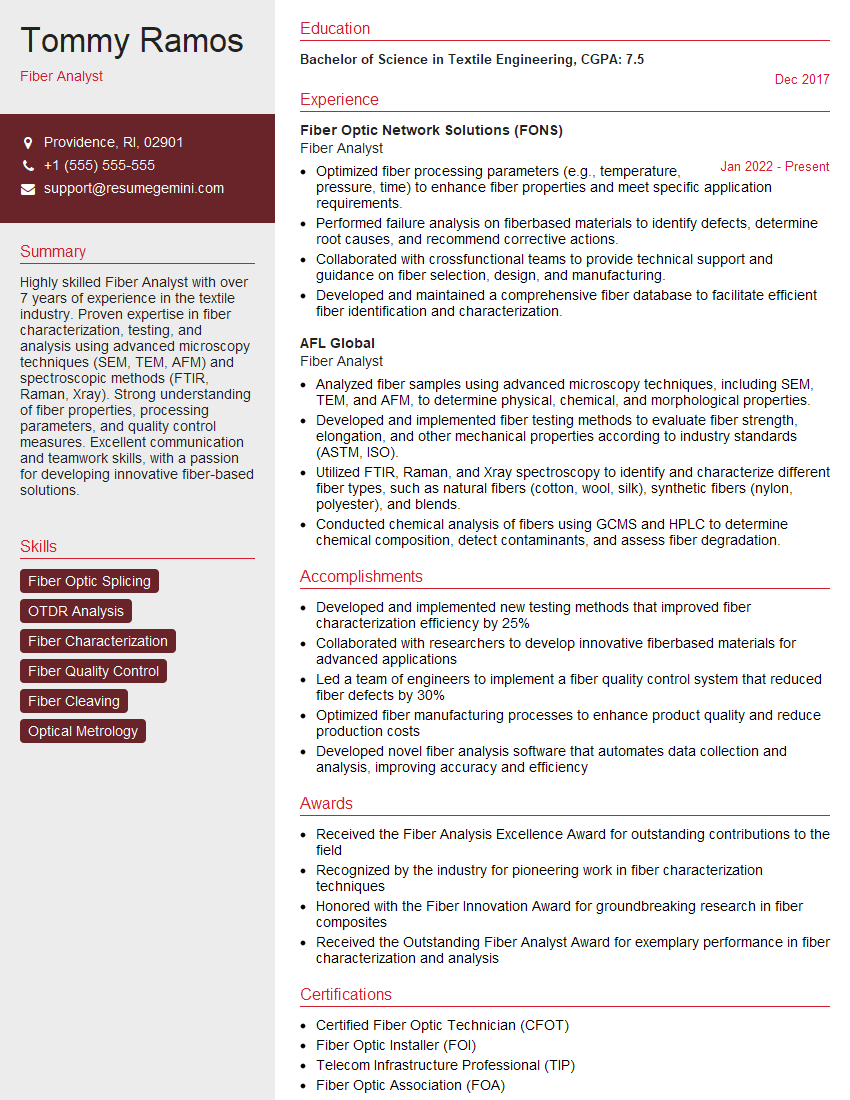

Mastering synthetic fiber production opens doors to exciting career opportunities in a dynamic industry. To maximize your chances of landing your dream job, invest time in creating a compelling, ATS-friendly resume that showcases your skills and experience effectively.

ResumeGemini can help you build a professional resume that stands out from the competition. Their user-friendly platform empowers you to create a document that highlights your qualifications in a way that Applicant Tracking Systems (ATS) can easily read and understand. They even provide examples of resumes tailored to the Synthetic Fiber Production industry to guide you.

Take the next step towards your ideal career. Craft a strong resume, and let your expertise in synthetic fiber production shine!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?