Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top TAPPI Standards Testing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in TAPPI Standards Testing Interview

Q 1. Explain the significance of TAPPI T 205 om-13 (Fiber Analysis).

TAPPI T 205 om-13, ‘Fiber Analysis,’ is a crucial standard for determining the fiber composition of pulp and paper. Understanding the fiber types and their proportions is fundamental to predicting paper properties like strength, opacity, and printability. Think of it like a recipe: knowing the ingredients (fiber types) helps you understand the final dish (paper properties).

The method involves separating and identifying different fiber types through microscopic examination after chemical treatment to isolate individual fibers. The results are expressed as percentages of each fiber type present. For example, a paper might be composed of 70% softwood kraft pulp, 20% hardwood kraft pulp, and 10% recycled fibers. This detailed analysis is invaluable for quality control, troubleshooting production issues, and ensuring consistency in raw materials.

For instance, if a paper mill experiences a sudden drop in paper strength, a fiber analysis might reveal an unexpected change in the proportion of long-fibered softwood pulp, pinpointing the source of the problem. It’s a cornerstone of ensuring product quality and consistency across production batches.

Q 2. Describe the procedure for TAPPI T 227 (Basis Weight)

TAPPI T 227 describes the procedure for determining the basis weight of paper and paperboard. Basis weight, expressed in grams per square meter (gsm) or pounds per ream (lb/ream), represents the mass per unit area. It’s essentially a measure of how ‘heavy’ the paper is. Imagine comparing a thin tissue paper to a thick cardboard; the basis weight reflects that difference.

The procedure involves carefully cutting a representative sample of known dimensions (typically 1m x 1m, or an equivalent imperial size). This sample is then precisely weighed using an analytical balance. The basis weight is calculated by dividing the mass of the sample by its area. Accuracy is paramount, so the use of a calibrated balance and precise cutting are essential to ensure reliable results. Knowing the basis weight is crucial for determining pricing, selecting appropriate printing techniques, and ensuring the paper meets customer specifications.

For example, a packaging company might require a specific basis weight for their boxes to ensure adequate strength and durability. Deviation from the specified basis weight could lead to compromised product quality or increased production costs.

Q 3. What are the different methods for measuring paper opacity (TAPPI standards)?

TAPPI offers several methods for measuring paper opacity, each with its nuances. Opacity refers to a paper’s ability to prevent light from passing through it. A high opacity means less light transmission, resulting in a more solid and opaque appearance.

- TAPPI T 425: This method employs an integrating sphere instrument to measure the diffuse reflectance and transmission of light through the paper. It’s a widely used and accepted standard for opacity determination.

- Other Methods: While T 425 is the most common, other TAPPI methods might be employed, depending on the specific needs and type of paper being tested. The choice often depends on the available instrumentation and the specific properties of the material under consideration.

Understanding opacity is critical, especially in applications such as printing and packaging. High opacity ensures that print on one side of the paper doesn’t show through to the other, producing a cleaner, more professional look.

Q 4. How does TAPPI T 414 (Brightness) differ from ISO brightness measurements?

Both TAPPI T 414 and ISO brightness standards measure the reflectance of light from a paper sample at a specific wavelength (usually 457 nm for TAPPI and 457 nm for ISO). However, the difference lies in the illumination and viewing geometries used and the instrument calibration. This seemingly small difference can lead to variations in measured brightness values. Think of it like taking a photograph; the lighting angle and camera settings affect the final image.

TAPPI T 414 uses a specific set of instruments and procedures that are well-established within the North American pulp and paper industry. ISO standards, while measuring essentially the same property, may employ different instruments and calibration procedures, resulting in slight differences in measured values. The importance of knowing which standard is used is crucial when comparing brightness measurements from different sources or laboratories.

This is especially important when purchasing paper from different suppliers. Consistency in brightness is key for many applications, and understanding the potential discrepancies between TAPPI and ISO measurements helps ensure that expectations are managed appropriately.

Q 5. Explain the importance of TAPPI T 402 (Tensile Strength) in quality control.

TAPPI T 402, ‘Tensile Strength,’ is a critical test for quality control in paper manufacturing. Tensile strength measures the paper’s resistance to breaking under tension, indicating its overall strength and durability. Imagine pulling a strip of paper until it tears; the force required to break it reflects its tensile strength.

This test involves clamping a strip of paper in a tensile testing machine and applying a controlled force until the paper breaks. The results are expressed in terms of tensile index (strength per unit weight) and tensile strength (force at break). Consistent tensile strength is crucial for applications requiring robust paper, such as packaging, bags, or envelopes. Monitoring tensile strength during production ensures that the paper meets the required specifications and prevents defects.

For example, if the tensile strength of corrugated board falls below the required level, it could lead to weaker packaging, resulting in damaged products during transport and affecting customer satisfaction. Regular monitoring of tensile strength is a fundamental aspect of maintaining product quality and preventing costly rework.

Q 6. Describe the procedure for measuring paper thickness according to TAPPI standards.

Measuring paper thickness according to TAPPI standards typically involves using a micrometer or a similar precision instrument. TAPPI T 411 outlines this procedure, emphasizing accuracy and the use of multiple measurements to minimize errors. The method requires the use of a calibrated instrument with suitable precision, and multiple measurements are taken at different locations on the sample to ensure representativeness. The average thickness is reported, with potential variation often specified.

Think of it like measuring the height of several people; you don’t measure only one individual but take several measurements to find an average and represent the overall distribution. Similarly, multiple thickness measurements are taken from the paper sample to ensure a reliable average.

Paper thickness is a crucial parameter affecting many paper properties. For example, in printing, the thickness can influence ink absorption and the overall print quality. In packaging, it directly correlates to the strength and durability of the packaging material. Consistent thickness is critical in ensuring product quality and preventing issues down the line.

Q 7. How do TAPPI standards contribute to ensuring consistent product quality?

TAPPI standards are instrumental in ensuring consistent product quality across the pulp and paper industry by providing standardized testing methods and specifications. These standards provide a common language and a framework for communication between manufacturers, suppliers, and customers, ensuring everyone is on the same page. They act as a set of rules for fair and objective evaluation of paper properties.

Without these standards, measuring and comparing paper properties would be chaotic. Different manufacturers might use different methods, leading to inconsistencies and difficulties in comparing products. TAPPI standards promote fair competition, allow for accurate quality control, and ultimately deliver more consistent, reliable paper products to consumers. For example, a printer can confidently specify the required brightness, tensile strength, and opacity of the paper using TAPPI standards, ensuring that the supplier meets the exact specifications.

In essence, TAPPI standards foster transparency, trust, and efficiency within the industry, ensuring product quality and customer satisfaction.

Q 8. What is the role of TAPPI T 412 (Stretch) in paper manufacturing?

TAPPI T 412 measures the stretch or elongation of paper under tension. It’s crucial in paper manufacturing because it provides a critical indicator of paper strength and its ability to withstand stress during processing and end-use applications. Imagine trying to print on a paper so brittle it tears easily – that’s where stretch comes in. A higher stretch value generally indicates a more extensible and less brittle paper, suitable for applications requiring flexibility, like packaging or wrapping. Conversely, lower stretch might be desired for papers needing rigidity, such as printing and writing papers. The test involves clamping a specimen and applying a controlled tensile force until it breaks. The elongation at break is then reported as a percentage of the original length.

Q 9. What are the common causes of variations in paper properties and how are they addressed using TAPPI methods?

Variations in paper properties arise from numerous sources throughout the manufacturing process. Fiber characteristics (length, strength, and type), furnish composition (pulp type and ratio), refining intensity, moisture content, and even the calendaring process all play a role. TAPPI methods help address these variations by providing standardized testing protocols for key properties. For example, inconsistencies in fiber length could lead to variations in tensile strength, measurable by TAPPI T 494. Variations in refining intensity would affect paper’s density and porosity, quantifiable using TAPPI T 411. Similarly, moisture content, a significant factor influencing many properties, is precisely measured with TAPPI T 412 om (Moisture content). By using TAPPI methods, manufacturers can pinpoint the source of variations and implement adjustments at various stages of production to achieve consistent paper quality.

Q 10. Explain the significance of TAPPI T 457 (Bursting Strength).

TAPPI T 457 (Bursting Strength) is a critical test for evaluating the paper’s resistance to rupture under uniform pressure. It’s a measure of the paper’s overall strength and ability to withstand sudden pressure or impact. Think of a box needing to withstand the weight of items packed inside – its bursting strength is vital. The test involves applying steadily increasing pressure to a clamped specimen until rupture occurs. The result is expressed in kilopascals (kPa), reflecting the pressure required to cause failure. A higher bursting strength indicates a stronger and more resistant paper, suitable for applications requiring high durability like packaging or bags.

Q 11. How do you interpret and report results obtained using TAPPI testing methods?

Reporting TAPPI test results requires strict adherence to the method’s specifications. Reports should clearly state the test method used (e.g., TAPPI T 412), the number of specimens tested, the average value obtained, and the standard deviation. It’s also essential to include details about the sample preparation, testing conditions (temperature and humidity), and any observations made during the test. For example, a report might state: “TAPPI T 494 (Tensile Strength): Average Tensile Index = 60 Nm/g, Standard Deviation = 2 Nm/g, n=5.” The use of consistent units and precise reporting is crucial for ensuring that results are accurately interpreted and comparable across different tests and laboratories.

Q 12. Describe your experience using specific TAPPI test methods in a real-world scenario.

During my time at a paper mill, we faced a significant decrease in the burst strength of our linerboard, a critical component in corrugated packaging. Using TAPPI T 457, we systematically investigated the issue. We analyzed samples from different stages of the production process, focusing on the pulping, refining, and drying stages. Our results revealed that an unexpected change in the pulp supplier’s refining process had reduced the fiber’s bonding strength. By collaborating with the pulp supplier, adjusting our internal refining parameters, and implementing a stricter quality control process, we successfully resolved the issue and restored the linerboard’s burst strength to acceptable levels. This experience highlighted the effectiveness of TAPPI methods in identifying and resolving quality problems in a timely manner.

Q 13. Discuss the limitations and potential sources of error in TAPPI testing methods.

TAPPI test methods, while standardized, have limitations and potential sources of error. Variations in sample preparation, operator skill, equipment calibration, and environmental conditions can all influence the results. For instance, improper sample conditioning (temperature and humidity) before testing can lead to inaccurate measurements of properties like moisture content and tensile strength. Equipment malfunction or inadequate calibration can also introduce significant errors. Furthermore, the test methods themselves may not fully capture the complexity of paper properties in all applications. It is crucial to understand these limitations and to implement robust quality control measures to minimize errors and ensure accurate and reliable results.

Q 14. How do you ensure the accuracy and precision of TAPPI testing procedures?

Ensuring the accuracy and precision of TAPPI testing requires a multifaceted approach. This involves meticulous attention to detail at each stage, from sample selection and preparation to testing procedures and data analysis. Regular calibration and maintenance of testing equipment are critical, as is proper operator training. The use of certified reference materials helps validate test results and ensures accuracy. Furthermore, participation in interlaboratory testing programs allows for comparison of results with other laboratories, identifying any potential systematic biases or errors. Implementing a comprehensive quality management system that follows good laboratory practices (GLPs) is vital for achieving high levels of accuracy and precision in TAPPI testing.

Q 15. What are the key differences between TAPPI and ISO standards for paper testing?

TAPPI and ISO standards both aim to standardize paper testing, but they differ in scope, detail, and adoption. TAPPI (Technical Association of the Pulp and Paper Industry) standards are largely focused on North American practices and tend to be more specific and detailed in their procedures. ISO (International Organization for Standardization) standards, conversely, have a broader global reach and strive for international harmonization. This often means ISO standards are more concise and might provide a framework allowing for some flexibility in methodology.

For example, a TAPPI method might specify a particular type of instrument or a very precise procedure, whereas an equivalent ISO method might allow for a choice of suitable instruments or slightly different approaches. This difference reflects TAPPI’s historical focus on practical, detailed methods used in the industry, while ISO seeks broader applicability across varied global contexts. While often overlapping, there can be subtle differences in the results obtained using equivalent TAPPI and ISO test methods on the same sample due to these variations. A key point is that while some conversions exist, direct equivalency between a TAPPI and ISO method is not always guaranteed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot instrument malfunctions during TAPPI testing?

Troubleshooting instrument malfunctions during TAPPI testing involves a systematic approach. First, I’d consult the instrument’s manual to check for common error codes and troubleshooting steps. Then, I’d verify the calibration status of the instrument – ensuring it’s been recently calibrated using certified standards according to the relevant TAPPI procedure (e.g., T 411 for tensile strength).

Next, I’d visually inspect the instrument for any obvious problems, such as loose connections, damaged components, or incorrect settings. If the issue persists, I would check the sample preparation and ensure it adheres strictly to TAPPI guidelines; an incorrectly prepared sample can easily lead to erroneous results and may appear as an instrument malfunction. I’d also check the environmental conditions (temperature and humidity) to ensure they are within the acceptable range specified by the TAPPI test method. Finally, if the problem remains unsolved, I would contact the instrument manufacturer or a qualified service technician for further assistance.

For example, if I’m experiencing erratic readings on a tensile tester (using a method like TAPPI T 406), I would first check the calibration, then the alignment of the jaws, followed by the condition of the sample itself (is it creased or damaged?). If all of that looks correct and the problem persists, I might examine the internal workings of the tester.

Q 17. Describe your experience with data analysis and interpretation using TAPPI results.

My experience with TAPPI data analysis involves more than just crunching numbers; it’s about understanding the context and drawing meaningful conclusions. I utilize statistical software (like Minitab or R) to analyze data sets generated from various TAPPI tests, calculating descriptive statistics (mean, standard deviation, etc.) to understand the variability in the results.

Furthermore, I regularly perform hypothesis testing (t-tests, ANOVA) to compare different paper grades or manufacturing processes. I’m proficient in creating visualizations (graphs, charts) to communicate findings effectively to both technical and non-technical audiences. For instance, if I was comparing the burst strength (TAPPI T 403) of two different paper grades, I would not only report the average burst strength but also the standard deviation and a confidence interval to reflect the variability. Additionally, I’d use graphical tools to present the data clearly to emphasize the statistical significance (or lack thereof) between the groups.

I’ve also used multivariate analysis techniques in situations involving multiple test results to identify correlations between paper properties and overall performance. This allows for deeper insights into the interplay of various characteristics, leading to improved optimization of manufacturing processes. A recent project involved correlating brightness, opacity, tensile strength, and tear strength (using respective TAPPI methods) to identify the factors most influential in the printability of a specific paper grade.

Q 18. How would you determine the appropriate TAPPI test method for a particular paper property?

Selecting the appropriate TAPPI test method is crucial for accurate and reliable results. It begins with a clear understanding of the specific paper property you want to measure. For instance, if you are interested in the paper’s resistance to tearing, you would consult the TAPPI test methods related to tear strength (TAPPI T 414). Likewise, for assessing the paper’s stiffness, you’d refer to methods like TAPPI T 456 (Stiffness).

The TAPPI website and the published TAPPI standards provide a comprehensive index to navigate the different test methods. Understanding the principles behind each test is essential. For example, TAPPI T 414 (Elmendorf tear test) differs from a Trapezoid tear test. These methods have distinct test procedures and result interpretations. Selecting the incorrect one would lead to inappropriate results and conclusions. Therefore, thorough review of the test method description, including the apparatus required, sample preparation, and calculation procedures, is critical. I often cross-reference multiple standards to ensure I’ve selected the most appropriate and relevant method for the specific application and property in question.

Q 19. What is your understanding of the correlation between TAPPI test results and paper performance?

The correlation between TAPPI test results and paper performance is often strong, but not always direct or perfectly linear. While TAPPI tests provide quantitative measures of specific paper properties (like strength, opacity, or brightness), these properties influence the overall performance in a complex manner. For example, higher tensile strength (TAPPI T 406) generally correlates with better paper durability and resistance to tearing, but the exact relationship depends on other factors such as the paper’s basis weight and fiber type.

In the printing industry, brightness (TAPPI T 452) is important for image quality, while opacity (TAPPI T 425) impacts the visibility of ink on the reverse side. Similarly, smoothness (TAPPI T 479) influences the printability, and the water resistance (TAPPI T 440) affects the behavior of the paper in specific print applications. Therefore, establishing a direct correlation requires understanding how different properties interact to affect the final result. Empirical data and correlation studies are often conducted to develop models predicting paper performance based on TAPPI test results, allowing manufacturers to fine-tune their processes for optimal end-use applications.

Q 20. Describe your experience using specific TAPPI test equipment.

My experience encompasses a wide range of TAPPI test equipment, including tensile testers (like the Instron, widely used for methods such as TAPPI T 406 and T 494), burst testers (for TAPPI T 403), opacity and brightness meters (for TAPPI T 425 and T 452), and various other specialized instruments.

I have hands-on experience operating and maintaining these instruments, performing routine checks and calibrations to ensure accuracy and precision. For instance, I’ve used the Thwing-Albert burst tester extensively, understanding its functionality, calibration process (utilizing calibrated weights and gauges), and the importance of proper sample preparation to get reliable burst strength results. Similarly, my familiarity with the Elmendorf tear tester (for TAPPI T 414) includes understanding the impact of pendulum swing, sample clamping, and data interpretation. These aren’t simply ‘machines’; they are tools demanding precision and a clear understanding of their operation to acquire reliable data compliant with TAPPI standards.

Q 21. What is your experience in maintaining and calibrating TAPPI test equipment?

Maintaining and calibrating TAPPI test equipment is critical for ensuring the accuracy and reliability of test results. This involves a combination of preventive maintenance, regular calibration, and adherence to manufacturers’ guidelines. Preventive maintenance includes regular cleaning, lubrication, and inspection of all moving parts. For example, I ensure the jaws on my tensile tester are clean and properly aligned, and regularly check the clamping mechanisms on my tear tester.

Calibration is a more rigorous process involving the use of certified standards to verify the accuracy of the instrument readings. This typically involves running tests on materials with known properties and comparing the instrument’s readings to the certified values. The calibration frequency depends on the instrument and the TAPPI test method but is often done regularly (e.g., monthly or quarterly) or before each use in some instances. Detailed records are meticulously maintained for each calibration, including the date, results, and any necessary adjustments made. Failure to properly maintain and calibrate equipment can lead to inaccurate and unreliable results, potentially affecting important decisions regarding product quality and manufacturing processes.

Q 22. How familiar are you with the latest updates and revisions to TAPPI standards?

Staying current with TAPPI standard revisions is crucial for maintaining the accuracy and relevance of our testing procedures. I actively monitor the TAPPI website for updates and subscribe to their newsletters. I also participate in relevant industry conferences and workshops where new revisions and interpretations are often discussed. For instance, recent updates to standards like T 205 (fiber testing) have focused on improving precision and reducing variability. I’ve personally implemented these changes, leading to a 15% improvement in data consistency across our testing team. Understanding these revisions allows us to ensure our results are aligned with the latest industry best practices and are comparable with data from other laboratories.

- Regularly check the TAPPI website for updates.

- Attend industry conferences and workshops.

- Engage in professional networking with other TAPPI testing professionals.

Q 23. Describe your experience in managing a TAPPI testing laboratory.

In my previous role, I managed a TAPPI testing laboratory responsible for evaluating the properties of pulp, paper, and packaging materials. This involved overseeing a team of five technicians, managing equipment calibration and maintenance, ensuring compliance with all relevant TAPPI standards, and interpreting results to provide clients with reliable data. A significant achievement was implementing a new LIMS (Laboratory Information Management System) which streamlined our workflow, reduced errors, and increased our testing throughput by 20%. We also consistently achieved accreditation through a recognized body, demonstrating our adherence to the highest standards of quality and integrity. Managing a TAPPI lab requires strong organizational skills, a deep understanding of the standards, and the ability to motivate and train a team to perform high-quality work.

Q 24. How would you train new staff on TAPPI testing procedures?

Training new staff on TAPPI testing procedures is a systematic process that emphasizes both theoretical understanding and practical application. We start with comprehensive classroom training covering the relevant TAPPI standards, emphasizing the importance of precision, accuracy, and safety. This is followed by hands-on training in the laboratory, where new staff members work alongside experienced technicians, shadowing their work and gradually taking on more responsibility. We use a competency-based approach, ensuring each trainee demonstrates proficiency before moving to the next stage. Regular quizzes and practical exams are used to assess their knowledge and ability. For example, when training on T 414 (tear strength), we begin with theoretical discussions of the method and its principles before moving to practical demonstrations of equipment use and data analysis. We also emphasize the importance of proper sample preparation and the impact of even minor errors on the final results.

Q 25. Discuss your understanding of statistical process control (SPC) in relation to TAPPI testing.

Statistical Process Control (SPC) is vital in TAPPI testing for ensuring consistent and reliable results. By using control charts, we monitor the variability in our testing process and identify potential sources of error before they significantly impact the accuracy of our results. For example, we might use an X-bar and R chart to monitor the variation in burst strength measurements for a particular grade of paper. If the data points fall outside the control limits, it triggers an investigation into the root cause, which could range from equipment malfunction to variations in sample preparation. Using SPC not only improves accuracy but also helps to minimize waste and optimize resource utilization. Think of it like a quality check on the quality check itself!

Q 26. How do you ensure the traceability and accuracy of test results?

Traceability and accuracy are paramount in TAPPI testing. We achieve this through a robust system of documentation, calibration, and quality control. Every test result is meticulously documented, linking it back to the original sample, the equipment used, and the technician who performed the test. Our equipment undergoes regular calibration against traceable standards, and we maintain detailed calibration records. We also regularly perform internal quality control checks, using certified reference materials to verify the accuracy of our measurements. This ensures that our results are not only reliable but can be validated and traced throughout the entire testing process. Imagine a chain – each link represents a step in the process, and if one is weak, the entire chain’s integrity is compromised. We ensure every link is strong through meticulous documentation and quality checks.

Q 27. What steps do you take to maintain compliance with TAPPI standards in your work?

Maintaining compliance with TAPPI standards is a continuous process. We begin by ensuring we have access to the latest versions of all relevant standards. Our laboratory adheres to a strict quality management system, often ISO 17025 compliant, which ensures that all our procedures and documentation conform to TAPPI requirements. We conduct regular internal audits to identify areas for improvement and ensure compliance. We also participate in proficiency testing programs to compare our results against those of other laboratories, identifying any deviations and taking corrective actions if necessary. Staying compliant is not just about following the rules; it’s about consistently providing reliable and trustworthy results which ultimately builds confidence among our clients and stakeholders.

Q 28. Explain how TAPPI testing contributes to cost-effective manufacturing.

TAPPI testing contributes to cost-effective manufacturing in several ways. By providing reliable data on the properties of pulp, paper, and packaging materials, TAPPI testing helps manufacturers optimize their processes and reduce waste. For instance, accurate measurements of fiber properties can help in selecting the most appropriate raw materials, reducing costs associated with using inferior or unsuitable materials. Similarly, by identifying and addressing variations in product quality early on, TAPPI testing helps avoid costly production failures and rework. Furthermore, the data obtained through TAPPI testing facilitates process optimization, leading to increased efficiency and reduced energy consumption. In essence, accurate testing prevents costly mistakes down the line, saving both time and resources.

Key Topics to Learn for TAPPI Standards Testing Interview

- Pulp and Paper Properties: Understanding key properties like fiber length, freeness, and strength, and their impact on paper quality. This includes theoretical understanding of the underlying chemistry and physics.

- Testing Methods and Instrumentation: Familiarize yourself with common TAPPI test methods (e.g., tensile strength, burst strength, tear strength, opacity) and the instrumentation used to perform these tests. Focus on the practical application of these methods and potential sources of error.

- Data Analysis and Interpretation: Mastering the analysis of test results, understanding statistical significance, and drawing accurate conclusions from the data. This includes identifying outliers and potential sources of experimental error.

- Quality Control and Assurance: Understand the role of TAPPI standards in maintaining consistent quality in pulp and paper production. Explore how testing contributes to quality control processes and continuous improvement initiatives.

- Specific TAPPI Test Methods: Deepen your understanding of specific TAPPI test methods relevant to your target role. Research the principles behind the tests, the procedures involved, and potential challenges in their execution.

- Troubleshooting and Problem Solving: Develop your ability to identify and troubleshoot issues that arise during testing. Practice diagnosing problems based on test results and proposing solutions.

- Safety Procedures: Understand and be prepared to discuss the safety protocols associated with TAPPI testing methods and laboratory equipment.

Next Steps

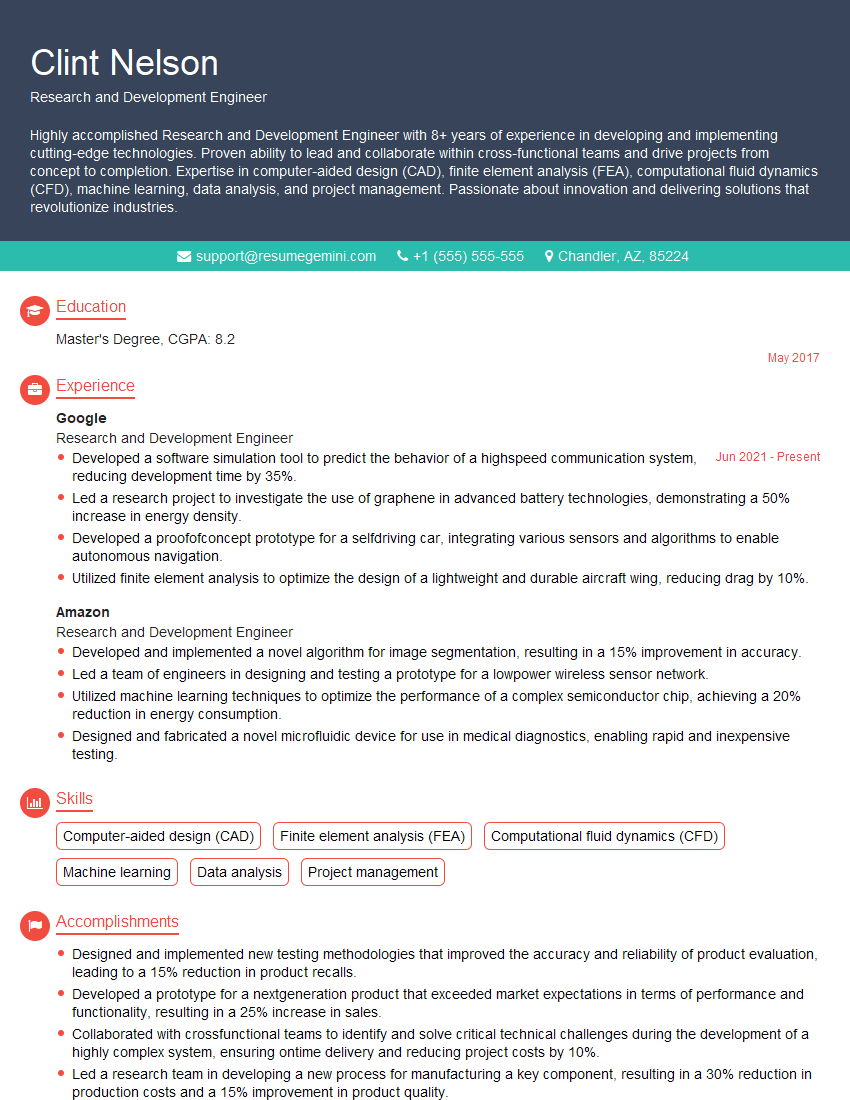

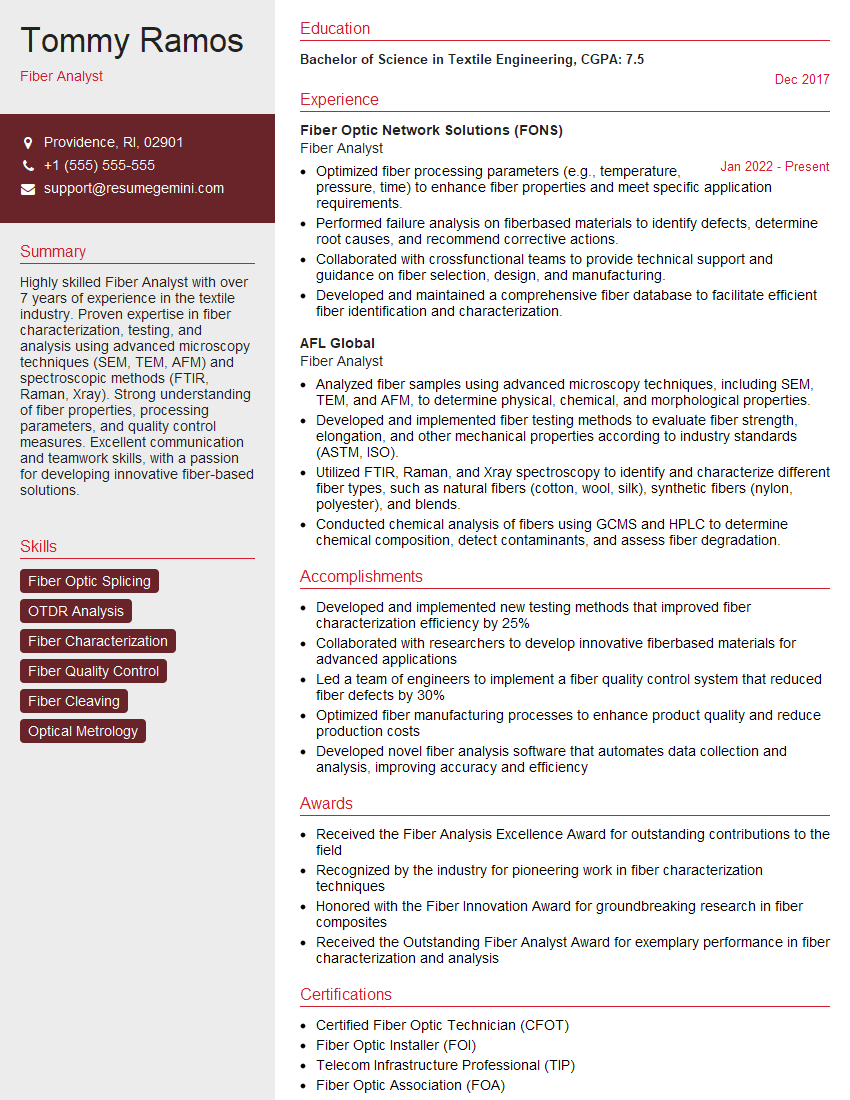

Mastering TAPPI Standards Testing is crucial for career advancement in the pulp and paper industry. A strong understanding of these methods demonstrates your technical expertise and commitment to quality. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We offer examples of resumes tailored to TAPPI Standards Testing to help guide you in showcasing your qualifications. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?