Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Terrazzo Casting interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Terrazzo Casting Interview

Q 1. Describe the process of mixing Terrazzo aggregate and binder.

Mixing terrazzo aggregate and binder is a crucial step, demanding precision and attention to detail. Think of it like baking a cake – the right proportions are vital for the final product’s quality. The process typically involves dry-mixing the aggregate (marble chips, quartz, glass, etc.) to ensure even distribution of materials. Then, the binder (typically cement, but also sometimes resin) is gradually added while mixing continuously. This prevents clumping and ensures a homogenous mixture with the desired consistency. The water content is carefully controlled because too much will weaken the terrazzo, while too little will make it difficult to work with. The ideal mix will be workable, yet not so wet that it segregates (the aggregate separates from the binder). Imagine trying to build a sandcastle with too much or too little water – the result isn’t ideal! Experienced terrazzo installers often judge the consistency by feel and appearance.

Q 2. Explain different types of Terrazzo aggregates and their properties.

Terrazzo aggregates are the heart and soul of the material, dictating its aesthetic appeal and some of its performance characteristics. Common types include:

- Marble: Offers a classic look with a wide range of colors and veining. It’s relatively durable and polishes well.

- Quartz: Highly durable and resistant to staining and wear, providing a longer-lasting finish. It often comes in lighter colors.

- Granite: Adds strength and visual interest with its distinct patterns and textures, but it’s also one of the more expensive options.

- Glass: Introduces sparkle and modern flair. Recycled glass offers sustainability advantages.

- Mother of Pearl: Provides an iridescent, luxurious look. This is typically used sparingly.

The choice of aggregate depends on the project’s aesthetic goals, budget, and desired performance characteristics. For instance, a high-traffic commercial space might benefit from the durability of quartz, while a residential project might prioritize the elegant appearance of marble.

Q 3. What are the common methods for casting Terrazzo?

Terrazzo casting methods broadly fall into two categories: in-situ and precast. In-situ casting, also known as wet casting, is done directly on-site. The mix is poured into the prepared area, consolidated, and finished in place. Precast terrazzo, on the other hand, involves casting the terrazzo in prefabricated molds (typically steel or fiberglass) off-site. Once cured and finished, these precast elements are installed on-site. This method allows for greater control over the quality and consistency of the final product, as well as the ability to create complex shapes and designs that might be more difficult to achieve with in-situ casting.

Q 4. How do you ensure proper consolidation of the Terrazzo mix?

Proper consolidation is essential for achieving a dense, durable terrazzo surface, free from voids and inconsistencies. This is typically accomplished through vibration. Using a vibrating screed or hand-held vibrator, the air bubbles are removed, allowing the aggregate to settle evenly within the binder. Think of it like gently compacting soil for a foundation – eliminating air pockets ensures a stable and solid base. Insufficient consolidation can lead to a weak surface, prone to cracking and chipping. The vibration should be applied in controlled bursts to prevent segregation of the materials. The process requires experience to achieve the optimal density without damaging the mix’s integrity. Visual inspection after vibration helps identify any areas needing additional consolidation.

Q 5. Describe the process of curing Terrazzo.

Curing is a critical step that allows the terrazzo to gain strength and durability. It involves maintaining the appropriate temperature and humidity to allow the binder to properly hydrate and harden. For cement-based terrazzo, this typically involves keeping the surface moist for a specific period (usually several days) to prevent premature drying and cracking. This can be achieved through covering the surface with damp burlap, spraying it with water regularly, or using curing compounds. The curing time and method depends on the type of binder, the ambient temperature and humidity, and the thickness of the terrazzo. Insufficient curing results in a weaker, more brittle surface, making it susceptible to damage.

Q 6. What are the different methods for grinding and polishing Terrazzo?

Grinding and polishing are multi-stage processes that transform the rough terrazzo surface into a smooth, glossy finish. It starts with coarse diamond abrasives to level the surface and remove any imperfections. Gradually finer and finer abrasives are used to achieve progressively smoother finishes, culminating in high-gloss polishing. This process typically involves specialized grinding machines with diamond tooling attached. The skill lies in maintaining a consistent level and avoiding uneven grinding, which could result in unsightly defects. Regular inspection of the surface ensures the desired level of smoothness and shine is achieved. Water is often used to keep the surface cool and remove debris during the grinding and polishing stages. This prevents premature wearing of tooling and provides a clearer surface for evaluation.

Q 7. Explain the importance of proper surface preparation before Terrazzo installation.

Proper surface preparation is paramount for successful terrazzo installation. A poorly prepared substrate can lead to issues like delamination (separation of the terrazzo from the base), cracking, and uneven settling. This typically involves thoroughly cleaning the surface to remove any dust, debris, oil, or loose material. Any cracks or imperfections in the substrate should be repaired and filled using a suitable material. The substrate also needs to be sound, level, and stable to provide a secure base for the terrazzo. Priming the surface may also be necessary to enhance bonding and prevent moisture from wicking up from below. Imagine attempting to lay tiles on a wall that hasn’t been cleaned or properly prepped – the results would be disastrous! Prioritizing surface preparation prevents future issues and ensures a long-lasting, high-quality installation.

Q 8. What are the common problems encountered during Terrazzo casting, and how do you address them?

Common problems in Terrazzo casting often stem from material inconsistencies, improper mixing, and inadequate curing. For example, uneven aggregate distribution can lead to a weak or aesthetically unpleasing surface. Poorly mixed cement can result in cracking or discoloration. Insufficient curing allows for moisture loss, weakening the bond and leading to shrinkage cracks.

- Addressing Material Issues: We rigorously source high-quality aggregates, ensuring consistent size, shape, and color. Careful batching and weighing of materials are crucial. We utilize controlled environments to ensure consistent aggregate grading.

- Improving Mixing Techniques: We use mechanical mixers to achieve thorough and consistent blending of the cement, aggregates, and pigments. Careful monitoring of mixing times is essential to prevent segregation. We regularly calibrate our mixing equipment to maintain consistent performance.

- Optimizing Curing Procedures: We employ controlled curing regimes, including moisture retention techniques (e.g., covering the cast surface with damp burlap) and maintaining stable temperatures. This prevents rapid moisture loss and minimizes shrinkage stress, therefore reducing cracking.

- Addressing Air Entrainment: Excessive air entrapment can weaken the terrazzo, therefore we use appropriate admixtures to manage air content and improve workability.

Imagine building a house – you wouldn’t use mismatched bricks, would you? Similarly, consistent materials are paramount for a strong, beautiful Terrazzo floor.

Q 9. How do you ensure the color consistency in a large Terrazzo project?

Maintaining color consistency across a large Terrazzo project requires meticulous planning and execution. The key is to minimize variation in the constituent materials and the mixing process.

- Pigment Pre-mixing: We pre-mix large batches of pigment with the binder (cement and other additives) to ensure uniform color distribution. This technique helps to create a more homogeneous mix than simply adding pigment to the dry mix.

- Color Calibration: We use a spectrophotometer to measure and maintain consistent color throughout the project. This device precisely measures color values, allowing for adjustments during production to maintain consistency. We create color control samples at the beginning of each batch to constantly ensure the color remains true.

- Batching and Mixing Control: As previously stated, strict control over batching and mixing is crucial. We use precise weighing systems and automated mixing to ensure consistency across multiple batches. Any variations are immediately corrected.

- Aggregate Sourcing: Selecting aggregates from a single source and batch ensures consistency in size, texture, and color. Careful examination of the aggregates for color variations is crucial before the mixing process.

Think of it like painting a mural – you wouldn’t change paint colors mid-way. The same principle applies to Terrazzo: careful color management is essential for a visually appealing and consistent final product.

Q 10. Describe the different types of Terrazzo finishes.

Terrazzo finishes vary widely, influencing the final look and feel. The choice of finish depends on the intended use and aesthetic preferences.

- Honed Finish: A smooth, matte finish achieved through mechanical grinding and polishing. It’s a popular choice for its understated elegance and relative ease of maintenance.

- Polished Finish: A high-gloss, reflective finish achieved through multiple stages of grinding and polishing with progressively finer abrasives. This finish enhances the beauty of the aggregates and adds a touch of luxury.

- Satin Finish: A semi-gloss finish that falls between honed and polished, offering a balance of luster and practicality.

- Exposed Aggregate Finish: A rugged, textured finish where the aggregates are left partially exposed, creating a unique, visually appealing surface.

Imagine the difference between a smooth, polished countertop and a rough-textured stone wall – each finish serves a different purpose and aesthetic.

Q 11. How do you determine the appropriate thickness of a Terrazzo slab?

Determining the appropriate thickness of a Terrazzo slab depends on several factors, primarily the intended use and structural requirements. Thicker slabs are generally stronger and better suited for high-traffic areas, while thinner slabs might be suitable for lighter applications.

- Intended Use: High-traffic areas like commercial entrances or public walkways require thicker slabs (typically 1 ½” to 2”). Residential applications may allow for thinner slabs (1” to 1 ½”).

- Span and Support: The distance between supports affects the required slab thickness. Larger spans require thicker slabs to prevent deflection.

- Substrate Conditions: The existing substrate (e.g., concrete) needs to be strong enough to support the Terrazzo. If there is any concern about the substrate we may need to compensate with a thicker Terrazzo to provide enough strength and durability.

- Design Considerations: The design itself might also influence thickness. Complex designs with intricate patterns or large aggregate pieces might necessitate a thicker slab for support.

It’s like choosing the right beam for a bridge – the load it has to support determines its required size. Similarly, the intended use and conditions dictate the thickness of a Terrazzo slab.

Q 12. What are the safety precautions for working with Terrazzo materials and tools?

Safety is paramount when working with Terrazzo. The materials and tools involved present several potential hazards.

- Respiratory Protection: Dust generated during grinding and polishing can be harmful. Workers should always wear appropriate respirators.

- Eye Protection: Flying debris and dust particles can cause eye injuries. Safety glasses are mandatory.

- Hearing Protection: The noise generated from power tools can cause hearing damage. Ear protection is essential.

- Hand Protection: Gloves should be worn to protect hands from cuts and abrasions from sharp aggregates or tools.

- Foot Protection: Steel-toed boots should be used to protect feet from dropped objects and heavy equipment.

- Proper Tool Use: All power tools should be used according to manufacturer’s instructions. Regular maintenance of tools is important for safe operation.

Safety is not just a precaution; it is a commitment. By implementing the above, we create a safe working environment and ensure the wellbeing of our team.

Q 13. How do you repair cracks or chips in existing Terrazzo surfaces?

Repairing cracks or chips in existing Terrazzo surfaces requires precision and attention to detail. The goal is to match the existing material and create an invisible repair.

- Crack Repair: Small cracks can be filled with epoxy resin that matches the Terrazzo’s color. The resin is injected into the crack using a syringe and allowed to cure. After curing, the excess resin is ground and polished smooth to blend seamlessly.

- Chip Repair: Larger chips require more extensive repair. We may need to remove the damaged section, carefully match the aggregate and color, fill the area with a new Terrazzo mixture, and then grind and polish to match the existing surface.

- Color Matching: Achieving a perfect color match is critical for a successful repair. We often need to create custom color mixtures from multiple pigments to achieve the desired effect.

Imagine patching a hole in a wall – you wouldn’t want the repair to stand out. Similarly, precise color matching and careful blending are crucial for invisible Terrazzo repairs.

Q 14. Explain the difference between precast and in-situ Terrazzo.

Precast and in-situ Terrazzo differ primarily in their manufacturing process.

- Precast Terrazzo: This involves casting the Terrazzo in a controlled factory environment. The slabs are then transported to the installation site and set in place. This method allows for better quality control and faster installation, but it might limit design flexibility and increase transportation costs.

- In-situ Terrazzo: This method involves casting the Terrazzo directly on-site. This offers greater design freedom and potentially lower transportation costs, but requires more on-site work and can be more susceptible to environmental influences that affect quality and curing.

Think of it like building a house: precast is like using prefabricated panels, efficient and controlled, while in-situ is like building it brick by brick, more flexible but time-consuming.

Q 15. What are the maintenance requirements for Terrazzo flooring?

Terrazzo flooring, while incredibly durable, requires regular maintenance to preserve its beauty and longevity. Think of it like caring for a classic car – a little attention goes a long way.

Regular sweeping and mopping: This removes loose dirt and debris, preventing scratches and dulling. Use a pH-neutral cleaner to avoid damaging the resin binder. Avoid abrasive cleaners.

Periodic sealing: Sealing protects the Terrazzo from staining and makes cleaning easier. The frequency depends on the traffic and type of sealant used, but generally every 1-3 years is recommended. Professional sealing is best for consistent results.

Repairing chips and cracks: Promptly address any damage to prevent further deterioration. Small chips can often be repaired with epoxy matching the Terrazzo’s color. Larger cracks may require professional intervention.

Professional cleaning: Consider periodic deep cleaning by professionals, especially in high-traffic areas. This removes ingrained dirt and grime that regular cleaning may miss.

For example, in a busy commercial building, you’d likely need to sweep and mop daily, seal annually, and schedule professional cleaning every few years. In a residential setting, the frequency would be lower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle edge details and transitions in Terrazzo installations?

Handling edge details and transitions in Terrazzo installations requires careful planning and execution. Think of it as framing a beautiful picture – the edges must complement the overall masterpiece.

Metal edging: Metal strips, often brass or stainless steel, provide a clean, finished edge and protect the Terrazzo from chipping. This is common around stairs and other transitions.

Bullnosed edges: A rounded edge, achieved by carefully shaping the Terrazzo during installation, creates a smooth, aesthetically pleasing finish, especially effective on steps.

Coved edges: A curved edge, ideal for transitioning between flooring and walls, eliminates sharp corners and improves hygiene.

Matching adjacent materials: Transitions to other flooring materials require careful selection and installation to ensure a seamless look. This might involve using matching grout or creating a subtle level change.

For instance, in a bathroom, a coved edge at the wall junction prevents water buildup and creates a visually appealing transition. In a hallway, metal edging on stairs enhances safety and durability.

Q 17. Describe the process of installing Terrazzo around intricate shapes.

Installing Terrazzo around intricate shapes requires meticulous planning and craftsmanship. Imagine sculpting with concrete – precision is key.

The process typically involves creating a custom formwork precisely matching the shape. This formwork is carefully constructed using materials like plywood or metal, ensuring its stability and accurate representation of the desired contours. The Terrazzo mix is then poured and vibrated into the form, carefully ensuring complete filling and avoiding air pockets. After the initial setting, the formwork is carefully removed, and any excess material is trimmed and finished. Finally, the surface is ground and polished to achieve a smooth, even finish that matches the surrounding Terrazzo.

For example, installing Terrazzo around a column requires creating a cylindrical formwork that perfectly fits the column’s diameter. The formwork must be strong enough to withstand the weight of the wet Terrazzo and must be precisely positioned to ensure a clean fit.

Q 18. How do you calculate the amount of materials needed for a Terrazzo project?

Calculating materials for a Terrazzo project requires accurate measurements and careful consideration of material properties. It’s similar to baking a cake – you need the right amount of each ingredient.

The process involves:

Precise measurements: Accurately measure the area to be covered, accounting for all shapes and transitions.

Material density: Determine the density of the chosen aggregate and binder. This information is crucial for calculating the volume of the mix needed.

Waste factor: Include a waste factor (typically 5-10%) to account for material loss during mixing, installation, and cutting.

Calculations: Multiply the area by the thickness of the Terrazzo and the density to determine the total volume of the mix required. Adjust the calculation based on the waste factor.

For instance, a 100 sq ft area with a 1-inch thick Terrazzo, using a mix with a density of 150 lbs/cubic ft, would require approximately 1250 lbs of material (accounting for a 10% waste factor). Remember, this is an estimate; consulting with a Terrazzo specialist is advisable for complex projects.

Q 19. What are the advantages and disadvantages of using Terrazzo?

Terrazzo offers a unique blend of advantages and disadvantages. It’s like choosing between two beautiful homes – each with its own set of features.

Advantages:

- Durability and longevity

- Customization options – a wide variety of colors and aggregates

- Easy maintenance (with proper sealing)

- High resistance to wear and tear

- Aesthetically pleasing and visually unique

Disadvantages:

- Higher initial cost compared to other flooring options

- Installation is more complex and time-consuming

- Susceptible to staining if not properly sealed

- Can be cold underfoot

- Repairing larger damages can be expensive

For example, a hospital might choose Terrazzo for its durability and ease of cleaning, while a homeowner might opt for a different material due to the higher initial investment.

Q 20. What are the common types of resins used in Terrazzo casting?

The choice of resin in Terrazzo casting significantly impacts the final product’s properties. It’s like choosing the right glue for a delicate project – the wrong choice can ruin everything.

Common types include:

Epoxy resins: Offer excellent strength, durability, and chemical resistance. They are commonly used in high-traffic areas and where chemical resistance is crucial. They usually cure quickly and are highly resistant to cracking.

Polyester resins: Provide good strength and are generally less expensive than epoxy resins. However, they are less chemically resistant and may be more susceptible to UV degradation.

Methyl methacrylate (MMA) resins: These offer extremely fast curing times, allowing for quicker installation. However, they are generally more expensive and may have limitations in terms of aggregate compatibility.

The selection depends on the project’s requirements – high-traffic commercial spaces might favor epoxy resins, while a less demanding residential project could use polyester.

Q 21. Explain the importance of using proper safety equipment during Terrazzo work.

Safety is paramount during Terrazzo work. It’s like working with any other construction material – neglecting safety can lead to serious injuries.

Essential safety equipment includes:

Respiratory protection: Dust masks or respirators are crucial to protect against inhaling silica dust, generated during grinding and polishing.

Eye protection: Safety glasses or goggles are essential to prevent eye injuries from flying debris.

Hearing protection: Earplugs or earmuffs are necessary to protect against the loud noise generated by grinding and polishing equipment.

Hand protection: Gloves protect hands from cuts, abrasions, and chemical exposure.

Foot protection: Steel-toe safety boots protect feet from heavy objects and potential drops.

Proper ventilation: Adequate ventilation is necessary to remove dust and fumes generated during mixing and installation.

Ignoring these precautions can result in serious health issues like silicosis (lung disease) or hearing loss, and injuries such as eye damage or cuts. Proper safety measures are a must.

Q 22. How do you prevent staining and discoloration in Terrazzo?

Preventing staining and discoloration in terrazzo is crucial for its long-term beauty and durability. It involves a multi-pronged approach starting from material selection to proper maintenance.

Careful Material Selection: Using high-quality, colorfast aggregates and cement is paramount. Avoid aggregates known to easily stain, like some porous stones. The type of resin used in the mix also influences stain resistance. Epoxy resins, for instance, generally offer superior stain resistance compared to cementitious binders.

Proper Sealer Application: A high-quality penetrating sealer is vital. This forms a barrier against liquids and prevents them from penetrating the surface and staining the underlying aggregates and binder. Multiple coats are usually necessary, following the manufacturer’s instructions precisely. The sealer should be appropriate for the type of terrazzo (e.g., epoxy, cementitious).

Prompt Stain Removal: Speed is key. The faster a spill is cleaned, the less likely it is to stain. Using a neutral pH cleaner and avoiding abrasive cleaning methods is essential. For stubborn stains, professional cleaning may be necessary. Testing any cleaning solution on an inconspicuous area first is always a wise precaution.

Regular Maintenance: Regular sweeping and damp mopping help prevent dirt and grime buildup, reducing the potential for staining. Avoid harsh chemicals and abrasive cleaners. Periodic re-sealing helps maintain the protective barrier.

For example, I once worked on a project where the client insisted on using a particular type of marble aggregate known for its susceptibility to staining. We mitigated the risk by specifying a high-performance epoxy resin and applying three coats of a specialized stain-resistant sealer. This proactive approach ensured the finished terrazzo remained pristine.

Q 23. What is your experience with different types of Terrazzo tooling?

My experience encompasses a wide range of terrazzo tooling, from traditional hand tools to modern, high-tech equipment. The choice of tooling depends heavily on the project scope, design complexity, and desired finish.

Hand Tools: These include trowels (various sizes and shapes), wood floats, steel brushes, and grinding stones for achieving specific textures and smoothing the surface. These are essential for intricate designs and smaller jobs.

Power Tools: Grinding and polishing machines are crucial for achieving a smooth, polished finish. This includes various diamond abrasives for different stages of the grinding and polishing process. Larger projects often involve specialized equipment like ride-on grinders and scarifiers for large surface area preparation.

Specialized Tools: For specific tasks like creating intricate patterns or embedded designs, specialized tools like routers, jigs, and templates are necessary. I’ve used laser cutting for custom stencils in recent projects, achieving precision and efficiency.

For example, on a recent large-scale project involving a complex geometric pattern, we utilized a CNC-controlled grinder to ensure the precision and consistency required for the design. The automated process significantly improved efficiency and quality compared to solely relying on hand tools.

Q 24. Describe your experience with quality control measures in Terrazzo casting.

Quality control in terrazzo casting is an ongoing process, starting from material selection and extending to final inspection. Several key measures are implemented to ensure the highest standards.

Material Inspection: Rigorous testing of aggregates and binders is essential to ensure they meet the required specifications for color, strength, and durability. This often involves checking for consistency in size, shape and color of the aggregates.

Mix Design Control: Precise measurement and mixing of materials are crucial to ensure uniformity and prevent inconsistencies in the finished product. We use calibrated equipment and adhere to strict mixing procedures.

In-Process Monitoring: Regular inspections during the casting and finishing stages are critical. This includes checking for proper compaction, surface levelness, and the absence of defects like air pockets or voids.

Testing and Inspection: We perform various tests, including compressive strength and abrasion resistance tests, to verify that the finished terrazzo meets project specifications and industry standards.

Documentation: Meticulous record-keeping is crucial. We maintain detailed logs of all materials used, mixing ratios, and testing results. This ensures traceability and assists in troubleshooting if issues arise.

For instance, on a recent project, we discovered slight variations in the color of an aggregate batch during the initial inspection. By addressing this early, we prevented a costly and time-consuming rework later in the process.

Q 25. How do you handle project delays or unexpected issues during a Terrazzo installation?

Project delays and unexpected issues are inevitable in construction. Proactive planning and effective communication are key to mitigation.

Proactive Planning: Detailed scheduling, considering potential risks and contingencies, is essential. This includes buffer time for unforeseen circumstances.

Effective Communication: Open communication with the client, subcontractors, and the project team is paramount. Keeping everyone informed about potential delays and their impact is critical.

Problem Solving: A systematic approach to problem-solving is vital. This involves identifying the root cause of the delay, assessing its impact, and developing a viable solution. Sometimes, this may involve adjusting the schedule, exploring alternative materials or methods, or requesting extensions.

Contingency Planning: Having backup plans for critical elements helps minimize the impact of unforeseen issues. For instance, having alternative sources for materials or skilled labor can significantly reduce delays.

For example, I once encountered a delay due to a supplier’s failure to deliver aggregates on time. We immediately explored alternative sources, communicated the delay to the client, and adjusted the project schedule to minimize disruption. Transparent communication prevented misunderstandings and preserved a positive client relationship.

Q 26. Explain your experience working with different types of substrates for Terrazzo.

The choice of substrate for terrazzo is crucial for its performance and longevity. The substrate must provide sufficient strength and stability to support the weight of the terrazzo and resist cracking or movement.

Concrete: The most common substrate is concrete, which should be properly cured and leveled before terrazzo installation. The strength of the concrete should be suitable for the expected loads and the thickness of the terrazzo.

Metal Decks: For applications on metal decks, a suitable underlayment is required to provide a stable and level surface. This typically involves the use of a cementitious overlay.

Existing Terrazzo: In renovation projects, installing terrazzo over existing terrazzo requires careful assessment of the existing surface’s condition. Repairing cracks and ensuring a sound bond are essential.

Wood: While less common, wood substrates require specialized treatment and underlayments to ensure dimensional stability and prevent moisture transfer.

I’ve worked with all these substrates and the key is careful preparation. Proper surface preparation and the selection of suitable bonding agents are crucial for ensuring a strong and durable bond between the terrazzo and the substrate, preventing delamination and ensuring long-term performance.

Q 27. What is your experience with different types of Terrazzo designs and patterns?

Terrazzo designs and patterns are virtually limitless, offering incredible flexibility for architects and designers.

Simple Patterns: These involve using a consistent mix of aggregates with minimal variation in color and size. They create a uniform, classic look.

Geometric Patterns: These incorporate geometric shapes, lines, and borders, achieved by carefully placing different aggregates or using colored pigments to create visual interest.

Custom Designs: More intricate and complex designs are often created with custom aggregate mixes, colored resins, and inlaid materials. Logos, emblems, and detailed artwork can be incorporated into the terrazzo surface.

Venetian Terrazzo: This style features larger, more prominent pieces of aggregate, often marble, creating a bold and luxurious aesthetic.

I’ve worked on numerous projects involving a wide variety of patterns and designs. For example, I recently completed a project incorporating a custom-designed mosaic in a terrazzo floor for a prestigious hotel lobby. This involved collaborating closely with the designers to translate their vision into reality. The intricate detail required meticulous planning and skilled craftsmanship.

Q 28. Describe your experience with working as part of a team on a large-scale Terrazzo project.

Collaboration is paramount in large-scale terrazzo projects. Success relies on effective teamwork and communication between the design team, subcontractors, and the installation crew.

Clear Communication: Regular meetings and detailed communication protocols ensure that everyone is on the same page regarding design specifications, timelines, and quality control measures.

Coordination: Effective coordination of different trades is crucial to avoid delays and conflicts. This requires careful scheduling and a clear understanding of each team’s responsibilities.

Problem Solving: Large projects inevitably encounter challenges. A collaborative approach to problem-solving, where all stakeholders contribute their expertise, is vital for overcoming obstacles efficiently.

Shared Goals: A shared understanding of the project’s objectives and commitment to quality ensures a successful outcome.

On a recent museum renovation, we worked as a large, multi-disciplinary team. Through daily meetings, clear communication channels, and a collaborative approach to problem-solving, we successfully completed the complex terrazzo flooring installation on time and within budget. The success of this project highlights the power of effective teamwork in managing large-scale projects.

Key Topics to Learn for Terrazzo Casting Interview

- Material Properties: Understanding the composition and properties of terrazzo, including its aggregates, binders, and pigments. Consider the impact of different materials on the final product’s durability and aesthetic qualities.

- Casting Techniques: Familiarize yourself with various terrazzo casting methods, their applications, and the advantages and disadvantages of each. Explore topics like mold preparation, pouring techniques, and curing processes.

- Design and Aesthetics: Explore the creative aspects of terrazzo design, including color palettes, pattern creation, and the integration of terrazzo into different architectural styles. Consider how design choices affect the final product’s visual appeal.

- Quality Control and Troubleshooting: Learn about common issues encountered during the terrazzo casting process, such as air bubbles, cracking, and color inconsistencies. Understand quality control measures and troubleshooting techniques to ensure a high-quality final product.

- Safety Regulations and Practices: Become familiar with relevant safety regulations and best practices associated with handling materials and operating equipment during the terrazzo casting process. This demonstrates a commitment to workplace safety.

- Project Management and Cost Estimation: Explore the project management aspects of terrazzo casting, including scheduling, budgeting, and resource allocation. Understanding cost estimation techniques will showcase your practical skills.

Next Steps

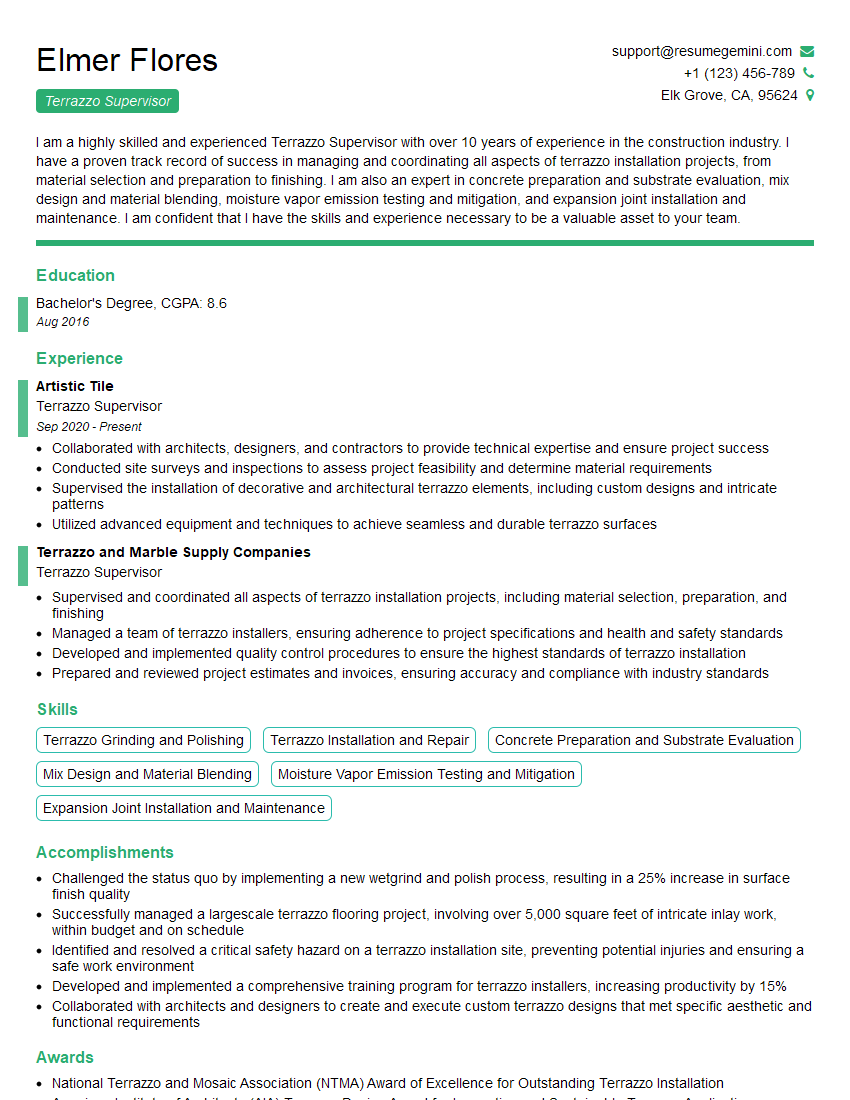

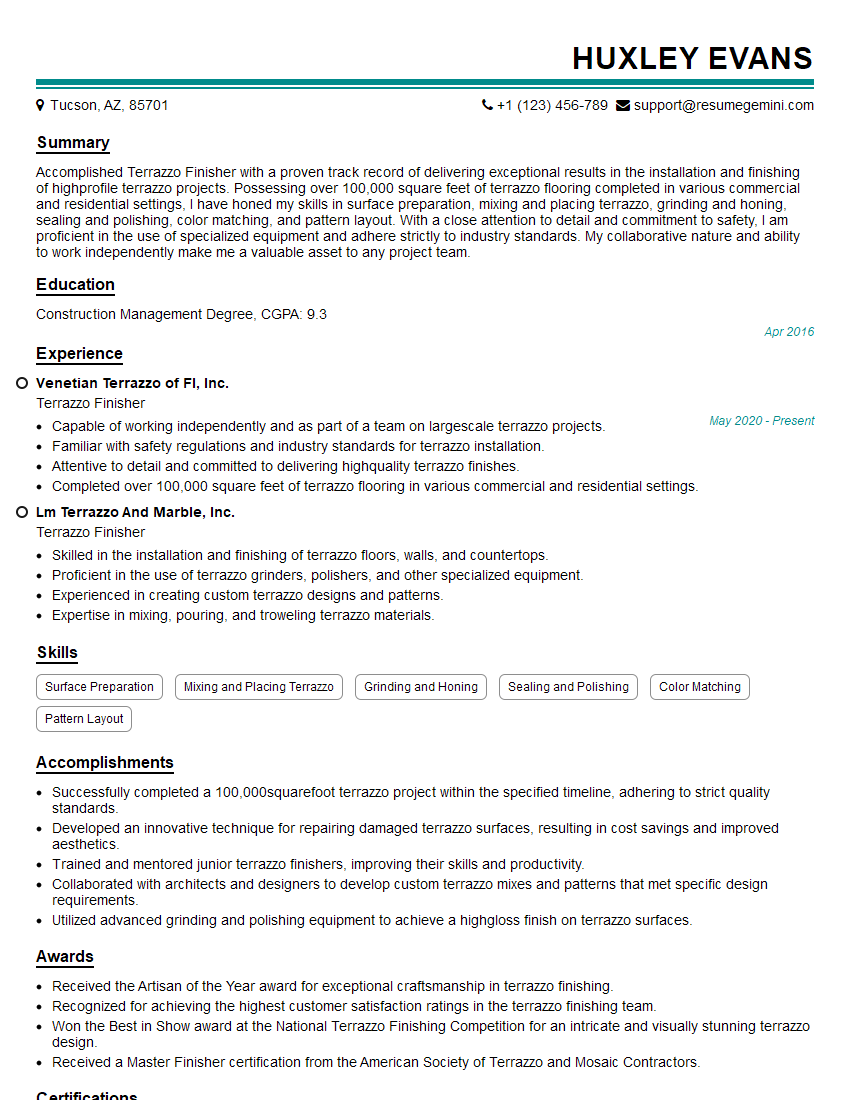

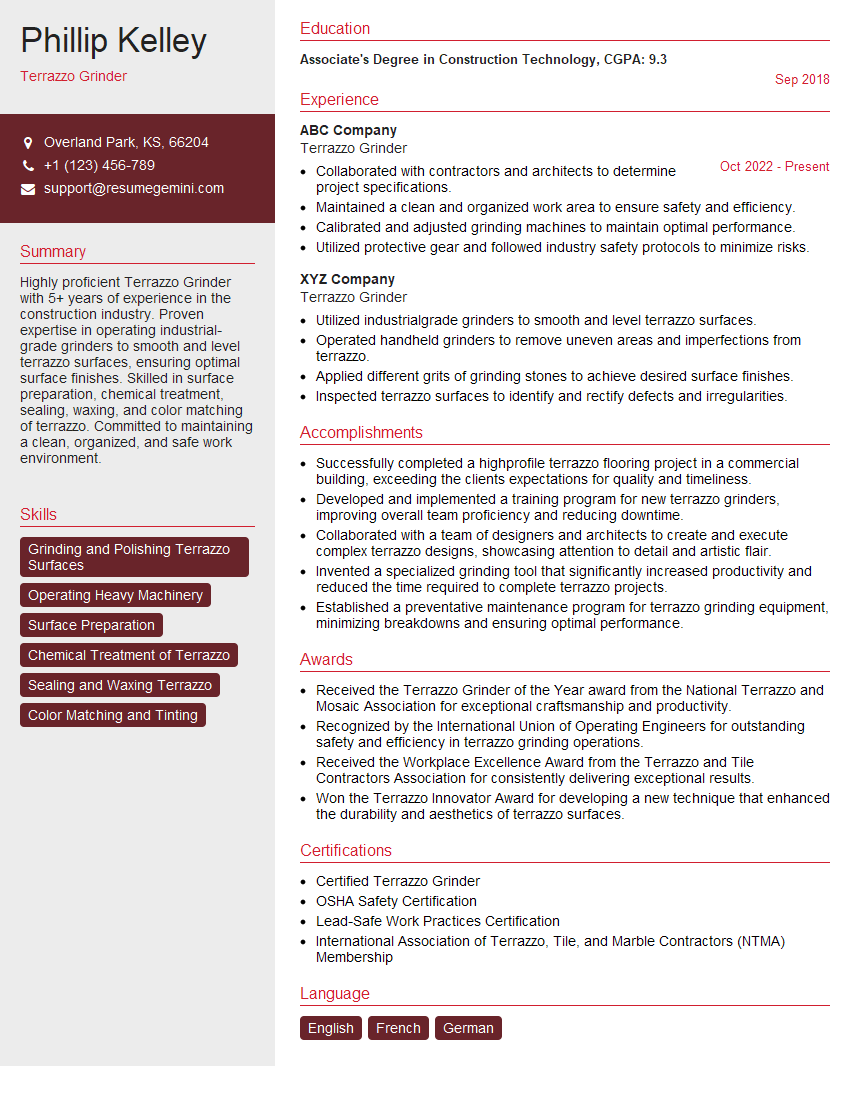

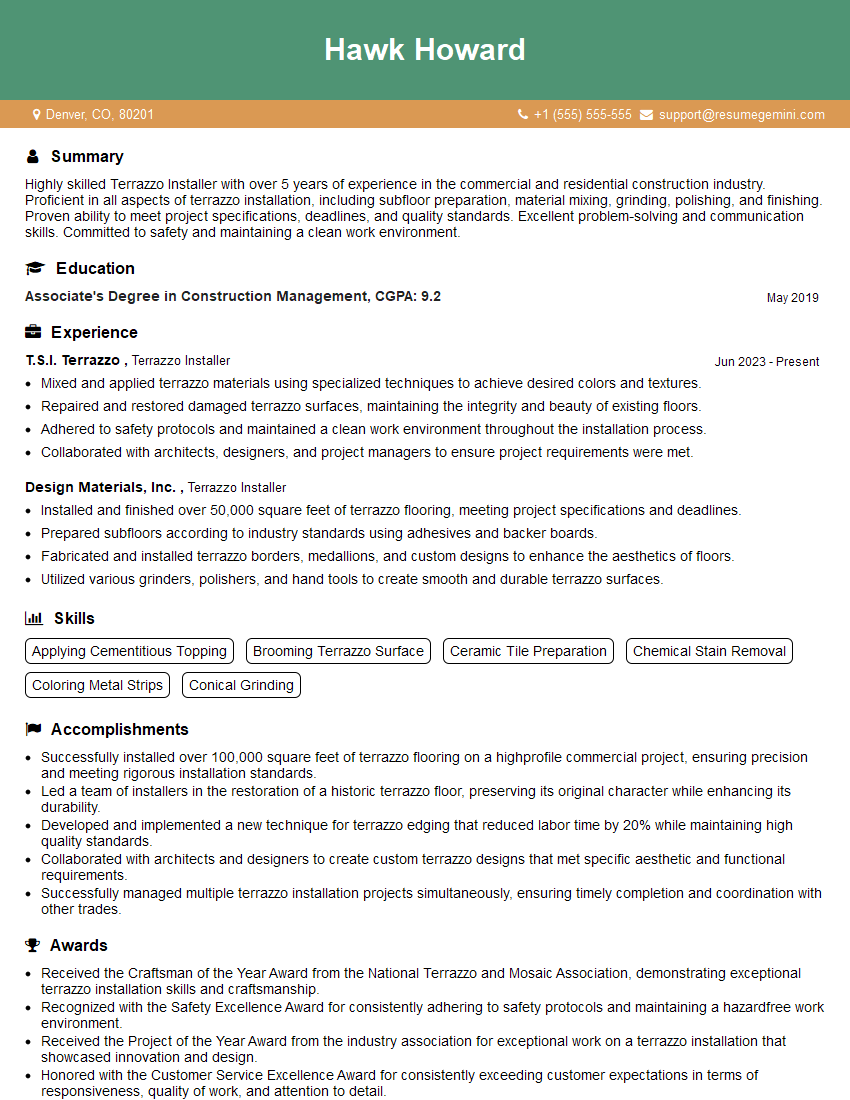

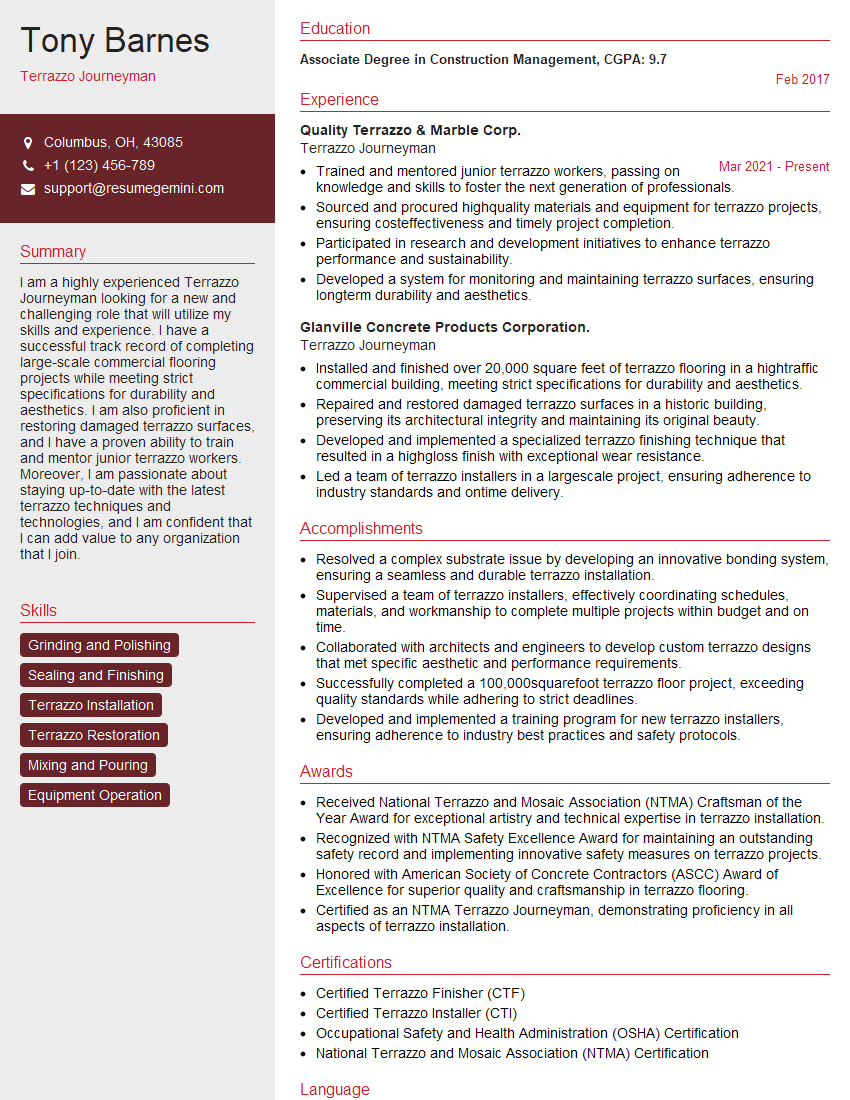

Mastering Terrazzo Casting opens doors to exciting career opportunities in a growing field, offering diverse roles and potential for advancement. To significantly improve your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. We highly recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini can help you craft a document that effectively showcases your qualifications. Examples of resumes tailored to the Terrazzo Casting industry are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?