Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Terrazzo Countertops interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Terrazzo Countertops Interview

Q 1. Describe the different types of terrazzo mixes and their applications.

Terrazzo mixes are broadly categorized by the aggregate material used. The aggregate, usually marble, granite, quartz, or glass, determines the final look and durability. The binder, typically cement or resin, holds the aggregate together.

- Cement-based terrazzo: This traditional type uses Portland cement as the binder. It’s durable and cost-effective, suitable for high-traffic areas like commercial buildings and public spaces. Think of the classic speckled terrazzo floors you might see in older schools or hospitals. The color palette is often limited by the cement, but variations are possible using different aggregates and dyes.

- Resin-based terrazzo: Using epoxy or polyester resins as binders provides superior strength, stain resistance, and a wider range of colors and finishes. This makes it ideal for luxurious countertops, where aesthetics and maintenance are key. Imagine a sleek, black terrazzo countertop with shimmering quartz aggregates in a modern kitchen.

- Metallic terrazzo: This option incorporates metal pieces into the mix, adding a unique industrial or contemporary flair. It’s often seen in high-end design projects and can be stunning as a statement piece, say, a bar top in a sophisticated lounge.

The choice of mix depends on the project’s budget, aesthetic goals, and the anticipated level of wear and tear.

Q 2. Explain the process of terrazzo grinding and polishing.

Grinding and polishing are crucial for achieving the smooth, lustrous finish characteristic of terrazzo. It’s a multi-stage process involving progressively finer diamond abrasives.

- Rough Grinding: This initial step removes excess material and levels the surface using coarse diamond tooling. Imagine smoothing out the bumps on a freshly poured cake.

- Fine Grinding: Finer diamond grits progressively refine the surface, removing scratches from the previous stage and achieving a smooth, even plane. This is like sanding the cake to a perfectly level surface.

- Polishing: This final stage uses polishing compounds to achieve a high gloss finish. Think of polishing the cake to a brilliant sheen. Different polishing compounds can yield various finishes, from a satin sheen to a mirror-like gloss.

Each stage requires careful control of the machine and the abrasive to avoid unevenness or damage. Experienced technicians use specialized machines with varying speeds and water cooling systems for optimum results.

Q 3. What are the common problems encountered during terrazzo installation, and how are they addressed?

Common problems during terrazzo installation include:

- Uneven surfaces: This can result from inadequate preparation of the substrate. Solution: Ensure the base is perfectly level and properly prepared using a self-leveling compound if necessary.

- Cracking: Caused by poor mix proportions, insufficient curing, or movement in the substrate. Solution: Use proper mix ratios, allow sufficient curing time, and employ expansion joints where needed.

- Pitting and voids: These imperfections may arise from improper mixing or consolidation of the terrazzo. Solution: Careful mixing and proper consolidation techniques are crucial. Vibration during the pouring process helps eliminate air pockets.

- Discoloration: This can be caused by inconsistent mixing or improper sealing. Solution: Consistent mixing and proper sealing are essential to protect the terrazzo and maintain its color integrity.

Preventing these issues through careful planning, proper material selection, and skilled installation is far more efficient than remediation.

Q 4. How do you ensure the proper curing of terrazzo?

Proper curing is vital for the strength and durability of terrazzo. It involves maintaining appropriate temperature and humidity conditions to allow the binder to fully harden.

For cement-based terrazzo, this typically involves keeping the surface moist for several days, often using wet burlap covers. This prevents premature drying and cracking. For resin-based terrazzo, the curing time is typically shorter, but the manufacturer’s instructions should always be followed carefully. This may involve maintaining a specific temperature and humidity during a certain period after the resin has set.

Incorrect curing can lead to weakness and increased susceptibility to cracking and staining, so it’s crucial to follow best practices to ensure a long-lasting countertop.

Q 5. What safety precautions are necessary when working with terrazzo materials and tools?

Working with terrazzo involves potential hazards, so safety precautions are paramount:

- Respiratory protection: Dust generated during grinding and polishing can be harmful. Use respirators rated for dust particles.

- Eye protection: Always wear safety glasses or goggles to protect against flying debris.

- Hearing protection: Grinding and polishing equipment is noisy; use earplugs or earmuffs.

- Hand protection: Wear gloves to protect hands from abrasives and chemicals.

- Foot protection: Sturdy safety shoes are needed to prevent foot injuries from dropped objects.

- Proper ventilation: Ensure adequate ventilation to remove dust and fumes, especially when working with resins.

Following these safety measures is not just a matter of compliance; it’s essential for the health and well-being of the workers.

Q 6. Describe the process of repairing chipped or damaged terrazzo surfaces.

Repairing chipped or damaged terrazzo involves matching the existing material as closely as possible. The process is intricate and usually requires the expertise of a terrazzo professional.

- Preparation: Clean the damaged area thoroughly and remove any loose material.

- Matching: Select a matching aggregate and binder. For small chips, color matching epoxy resin can be used.

- Application: Carefully fill the damaged area with the chosen material. For larger repairs, the section might need to be completely replaced.

- Grinding and Polishing: After the repair material has cured, carefully grind and polish the surface to blend seamlessly with the surrounding terrazzo. This process will require specialized equipment and skill to ensure the repaired area is invisible.

While minor repairs might be attempted by a homeowner, larger or complex repairs should always be entrusted to experienced terrazzo professionals.

Q 7. How do you calculate the amount of terrazzo mix needed for a given project?

Calculating the amount of terrazzo mix required involves several steps:

- Determine the area: Measure the length and width of the countertop or floor area in square feet or square meters.

- Determine the thickness: The desired thickness of the terrazzo will affect the volume needed.

- Calculate the volume: Multiply the area by the thickness to get the volume in cubic feet or cubic meters.

- Factor in waste: Add an additional 10-15% to account for waste and spillage during mixing and installation.

- Convert to weight: The mix is usually sold by weight (e.g., per cubic yard). Use the density of the specific terrazzo mix to convert the volume to weight.

For instance, if you need 10 sq ft of terrazzo with 1.5 inches thickness, the volume is approximately 1.25 cubic feet. Considering 15% wastage, you would need approximately 1.44 cubic feet of mix. Consult the supplier for the precise conversion to weight and specific mix ratios.

Q 8. What are the different types of terrazzo sealers and their applications?

Terrazzo sealers are crucial for protecting your investment and maintaining the beauty of your terrazzo countertops. They prevent staining, protect against moisture damage, and enhance the overall luster. There are several types, each with its own strengths:

- Epoxy Sealers: These are incredibly durable and offer superior protection against stains and chemicals. They’re ideal for high-traffic areas and kitchens, providing a long-lasting, protective barrier. Think of them as the ‘bodyguard’ sealers for your terrazzo. However, they can be more difficult to apply and require professional installation in most cases.

- Acrylic Sealers: These are easier to apply than epoxy sealers and offer good protection against staining and moisture. They’re a good option for areas with moderate traffic, like bathrooms or less-used countertops. They’re more like the ‘reliable friend’ – offering good protection, but not as robust as epoxy.

- Penetrating Sealers: Unlike epoxy and acrylic sealers which sit on the surface, penetrating sealers soak into the terrazzo, hardening the surface from within. This provides excellent protection against staining and weathering but may not provide the same level of gloss or sheen as other sealers. This is the ‘gentle protector’ offering subtle but effective long-term care.

The choice of sealer depends heavily on the application and the desired level of protection. For instance, I’d always recommend an epoxy sealer for a busy commercial kitchen, while an acrylic sealer might suffice for a less frequently used powder room.

Q 9. Explain the importance of proper edge finishing in terrazzo countertops.

Proper edge finishing is absolutely paramount for the longevity and aesthetic appeal of terrazzo countertops. A poorly finished edge is not only unsightly but can also be prone to chipping, cracking, and staining. Imagine a beautiful painting with a ragged, unfinished edge – it detracts from the overall masterpiece.

There are several techniques for achieving a perfect edge:

- Bullnose: Creates a rounded edge, providing a smooth, comfortable profile and a classic look. This is especially preferred in areas where people might bump into edges.

- Ogee: Features a more complex, curved profile with a slight upward curve. This offers a sophisticated and elegant touch.

- Eased Edge: Simply a slightly rounded edge, offering a subtle refinement without being overly dramatic. It’s ideal for contemporary designs.

- Square Edge: Offers a clean, minimalist look, but requires precise cutting and handling to avoid chipping.

The choice of edge profile should complement the overall design and functionality of the space. We always discuss this carefully with the client to ensure they select an edge profile that matches both their aesthetics and the practical considerations.

Q 10. How do you handle color variations in terrazzo?

Color variations are inherent to the beauty and unique character of terrazzo. It’s part of what makes it so desirable! Instead of trying to eliminate variations, we embrace and manage them. The key is to ensure the variations are consistent and aesthetically pleasing throughout the piece.

Here’s how we achieve that:

- Careful Material Selection: We source aggregates and binders carefully, paying close attention to color consistency within each batch and across different batches used in a single project. Imagine creating a mosaic – the colors have to work together harmoniously.

- Thorough Mixing: The mixing process is critical. We use specialized equipment and techniques to ensure that the aggregates are evenly distributed throughout the binder. Consistent and thorough mixing is akin to having a well-trained pastry chef meticulously folding ingredients into a cake batter.

- Strategic Placement: In some cases, we might strategically place aggregates to balance or complement color variations across a larger countertop. It’s like a painter working on a canvas, thoughtfully placing colors to create a balanced, visually appealing composition.

- Client Consultation: Transparency with the client is key. We always show them samples and explain how natural variations will add to the unique character of their countertops.

Q 11. What are the advantages and disadvantages of terrazzo compared to other countertop materials?

Terrazzo offers a compelling blend of advantages and disadvantages compared to other countertop materials:

Advantages:

- Durability: Terrazzo is incredibly tough and resistant to scratches, stains, and heat, making it a highly durable choice. Think of it as a sturdy, long-lasting investment.

- Customization: The virtually limitless color and aggregate options allow for incredible customization, offering unparalleled design flexibility.

- Sustainability: Often made with recycled materials, terrazzo offers a more eco-friendly alternative to some other countertop materials.

- Low Maintenance: With proper sealing, terrazzo requires minimal maintenance and is easy to clean.

Disadvantages:

- Cost: Terrazzo can be more expensive than some other countertop materials, depending on the complexity of the design and material choices.

- Porosity: While sealers mitigate this, terrazzo is naturally porous, requiring proper sealing to prevent staining.

- Installation Time: The installation process can be time-consuming, particularly for complex designs and large countertops.

The decision to use terrazzo ultimately depends on balancing these factors against the client’s needs, budget, and design preferences. We always provide a comprehensive discussion of the pros and cons before proceeding.

Q 12. Describe your experience with different terrazzo tooling and equipment.

My experience encompasses a wide range of terrazzo tooling and equipment, from traditional methods to advanced technologies. I’m proficient in using:

- Grinding machines: These are essential for achieving a smooth, polished finish, with different grits for different stages of the process. I’ve worked with both handheld grinders and larger, automated systems.

- Honing and polishing machines: These take the grinding process further to achieve a high-gloss or satin finish. The selection of diamond pads and the polishing compound are key to a successful outcome.

- Cutting tools: Precision cutting is critical, especially for creating intricate designs or working with curved surfaces. I have considerable experience with diamond blades, and water-cooled saws.

- Mixing equipment: Proper mixing is vital for ensuring a consistent color and texture throughout the countertop. I have utilized both manual and automated mixing systems.

I’m also familiar with various types of resins, pigments, and aggregates and understand how each impacts the final product. Proficiency in this diverse range of tools and equipment enables us to handle any project with precision and efficiency.

Q 13. How do you maintain the quality and consistency of terrazzo throughout a project?

Maintaining quality and consistency across a terrazzo project requires meticulous attention to detail throughout the entire process. It’s like conducting an orchestra – every section needs to be in harmony to create a beautiful symphony.

Here’s how we ensure quality and consistency:

- Batch Control: We meticulously track and document every batch of material, ensuring consistency in color, aggregate size, and resin composition throughout the project.

- Quality Control Checks: At every stage of the process, from mixing to grinding, rigorous quality checks are implemented to detect and correct any deviations from specifications.

- Experienced Craftsmanship: Our team comprises highly skilled and experienced artisans who are trained in the proper techniques and adhere to strict quality standards.

- Consistent Work Environment: We maintain consistent environmental conditions during the mixing and pouring processes to avoid any unwanted variations caused by temperature or humidity.

- Proper Curing: Proper curing allows the terrazzo to fully harden, ensuring durability and longevity. This phase needs careful control of temperature and humidity.

By implementing these measures, we ensure the final product meets the highest standards of quality, consistency, and aesthetic appeal.

Q 14. Explain the process of installing terrazzo countertops on a curved surface.

Installing terrazzo on a curved surface requires specialized techniques and expertise. It’s a significantly more challenging undertaking than installing it on a flat surface, comparable to sculpting rather than painting.

The process generally involves:

- Creating a Form: A strong, stable form is crucial. This form needs to accurately reflect the desired curvature and provide the necessary support for the wet terrazzo mixture.

- Pre-shaped Aggregates: In some cases, pre-shaped aggregates may be employed to aid in conforming to the curve.

- Multiple Layers: Often, multiple thin layers of terrazzo are applied, allowing each layer to partially cure before applying the next. This ensures better adherence to the curved form.

- Careful Troweling and Finishing: The troweling and finishing processes must be exceptionally precise to ensure a uniform thickness and surface throughout the curve.

- Specialized Grinding and Polishing: Grinding and polishing a curved surface requires specialized tools and techniques to avoid uneven surfaces or damage to the edges.

Installing terrazzo on curves requires significant expertise in both material handling and shaping techniques. It’s a demanding process that requires a deep understanding of the material properties and the ability to adapt standard techniques to meet the unique requirements of curved applications.

Q 15. How do you measure and cut terrazzo accurately?

Accurately measuring and cutting terrazzo requires precision and the right tools. First, we carefully measure the countertop area using a steel tape measure, ensuring accuracy to the nearest 1/16th of an inch. Detailed drawings are crucial. Then, we transfer these measurements to the terrazzo slab using a marking pencil or chalk. For cutting, we utilize specialized diamond-blade saws, either wet or dry, depending on the thickness and type of terrazzo. Wet saws are preferred for cleaner cuts and dust reduction. The cutting process itself needs to be slow and steady to avoid chipping or cracking the material. Think of it like cutting a very delicate cake – slow, deliberate movements are key. After cutting, the edges are usually ground and polished to achieve a smooth, finished look. For intricate shapes, we often use CNC (Computer Numerical Control) machines for programmable precision. This technology allows for complex designs and flawless execution, especially for custom projects.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different methods for polishing terrazzo?

Polishing terrazzo is a multi-step process designed to enhance its shine and durability. There are several methods, each employing different levels of abrasiveness:

- Grinding: This initial step uses progressively finer diamond grinding pads to level the surface and remove any imperfections. It’s like sanding wood, going from coarse to fine grit to achieve smoothness.

- Honing: After grinding, honing further refines the surface using increasingly finer abrasive stones or pads. This process removes any remaining scratches and creates a smooth, matte finish.

- Polishing: The final stage involves using polishing compounds and specialized polishing pads to achieve the desired level of gloss. We usually start with a coarser compound and gradually move to a finer one for a brilliant, mirror-like finish. This is where the real shine comes in.

Q 17. How do you ensure the proper alignment and leveling of terrazzo countertops?

Ensuring proper alignment and leveling is critical for a professional-looking and functional terrazzo countertop. We begin by establishing a perfectly level base using a laser level and shims. The terrazzo slabs are then carefully placed and adjusted to ensure they are aligned perfectly with the surrounding cabinetry and other surfaces. We use precise measurements and leveling tools throughout this process. Any gaps are filled with appropriate epoxy resin that matches the terrazzo color for seamless integration. Think of building a brick wall – each brick (terrazzo slab) needs to be perfectly aligned and level to create a structurally sound and aesthetically pleasing result. Finally, once the resin has cured, the entire countertop is carefully ground and polished to ensure a smooth, even surface. This meticulous approach eliminates any visible seams or imperfections.

Q 18. What are the common causes of cracking or staining in terrazzo?

Cracking and staining in terrazzo are usually caused by several factors:

- Improper Installation: Insufficient support or uneven subflooring can lead to stress on the terrazzo, causing cracks. Think of a foundation for a house – if it’s weak, the entire structure suffers.

- Moisture Damage: Water penetration, especially from spills or leaks, can damage the binder and aggregate, leading to staining and potential cracking. This can happen if proper sealing wasn’t done during installation.

- Aggressive Cleaning Agents: Using harsh chemicals or abrasive cleaners can etch or dull the surface, increasing the susceptibility to staining. Gentle cleaning methods are best.

- Thermal Shock: Sudden temperature changes can cause thermal stress, leading to cracking, especially if the terrazzo wasn’t properly cured. This is less common in well-installed and cured terrazzo.

Q 19. Describe your experience with different types of terrazzo resins.

My experience encompasses various terrazzo resins, each with its own properties:

- Epoxy Resins: These are the most common, offering excellent strength, durability, and chemical resistance. They’re suitable for high-traffic areas and demanding environments. Different epoxy formulations exist, offering various levels of color stability and UV resistance.

- Polyester Resins: While less common now, polyester resins are less expensive but offer lower strength and chemical resistance. They may also yellow over time with UV exposure.

- Cement-based Resins: This type of resin offers the ability to create more traditional looking terrazzo, particularly useful when matching historic terrazzo.

Q 20. How do you clean and maintain terrazzo countertops?

Cleaning and maintaining terrazzo countertops is straightforward but requires the right approach:

- Regular Cleaning: Daily cleaning with a damp mop or cloth and a mild, pH-neutral cleaner is sufficient. Avoid abrasive cleaners and scouring pads.

- Stain Removal: For stubborn stains, use a specialized terrazzo cleaner or a mixture of baking soda and water. Gentle scrubbing can remove many common stains.

- Sealing: Periodic sealing helps protect the terrazzo from stains and water damage. The frequency of sealing depends on the type of resin and the level of traffic. I usually recommend resealing every few years to maintain its beauty and longevity.

Q 21. What are the different types of aggregates used in terrazzo?

The aggregates used in terrazzo are incredibly diverse, contributing to its unique aesthetic appeal and performance. Common types include:

- Marble Chips: These offer a classic look and excellent durability. The color and size variation can be extensive.

- Granite Chips: Granites provide strength and a variety of colors, often used for more contemporary designs.

- Quartz Chips: These offer excellent durability and resistance to scratching. They are a modern choice.

- Glass Chips: Adds sparkle and shine, giving the terrazzo a modern twist. The size and color can dramatically alter the overall look.

- Recycled Materials: Increasingly popular, recycled glass, porcelain, and other materials offer sustainability and unique visual effects.

Q 22. Explain your experience with different types of terrazzo edge profiles.

Terrazzo edge profiles are crucial for the overall aesthetic and functionality of a countertop. They define the finished look of the edge and can significantly impact durability. My experience encompasses a wide range, from classic profiles to more contemporary designs.

- Bullnose: A rounded edge, offering a soft, smooth finish, ideal for kitchens where safety and a less severe look are priorities. I’ve used this extensively in family homes.

- Ogee: An elegant, S-shaped profile, adding a touch of sophistication. It’s a popular choice for bathrooms and high-end kitchen projects where a more decorative edge is desired. I recently completed a project with an ogee edge that perfectly complemented the client’s Art Deco style.

- Square/Straight: A simple, clean-cut edge, offering a modern and minimalist look. It’s incredibly durable and easy to maintain, perfect for commercial kitchens where hygiene is paramount. This is frequently used in my commercial projects.

- Bevel: A slanted edge, offering a subtle visual interest. I’ve incorporated bevels to add a sleek touch to contemporary designs, often combining it with other profiles for a layered look.

- Dupont: A more complex profile, featuring a combination of bevels and curves. This adds a significant element of luxury and is often used in high-end residential settings.

The choice of edge profile often depends on the overall design, the intended use of the countertop, and the client’s preferences. I always discuss the options thoroughly with clients, providing samples and visual aids to help them make an informed decision.

Q 23. How do you deal with uneven sub-surfaces before installing terrazzo?

Uneven sub-surfaces are a common challenge in terrazzo installation. Ignoring this can lead to cracking, instability, and an overall poor finish. My approach involves a meticulous leveling process before any terrazzo is laid.

- Assessment: I begin by carefully assessing the sub-surface using a level and straight edge. This identifies high and low points needing attention.

- Preparation: Depending on the severity of the unevenness, I might use various methods including self-leveling compounds, cement backer board, or a combination of both. The goal is to create a completely flat and stable base.

- Verification: Once the leveling compound is dry, I re-check the surface for any imperfections. This ensures a smooth, even foundation for the terrazzo.

- Priming: Finally, I apply a primer to enhance adhesion between the sub-surface and the terrazzo mix. This helps prevent future problems.

This thorough preparation ensures the longevity and structural integrity of the terrazzo installation. I’ve found that taking this extra time significantly reduces the likelihood of future problems and ensures client satisfaction.

Q 24. What are the environmental considerations when working with terrazzo?

Environmental considerations are increasingly important in construction, and terrazzo is no exception. My approach incorporates sustainable practices throughout the project lifecycle.

- Material Sourcing: I prioritize using recycled aggregates and responsibly sourced cement whenever possible, minimizing the environmental impact of material extraction.

- Waste Reduction: Careful planning and precise cutting techniques minimize material waste. Leftover materials are often repurposed or recycled.

- Low-VOC Products: I use low-VOC (Volatile Organic Compound) resins and sealants to reduce harmful emissions during and after installation.

- Water Conservation: I employ water-saving techniques during the installation process, such as using dustless grinding methods.

These measures not only reduce the environmental footprint but also contribute to a healthier working environment for my team and the clients. I believe that sustainable practices are essential for the future of the construction industry.

Q 25. Describe your experience with installing terrazzo in high-traffic areas.

Installing terrazzo in high-traffic areas requires extra attention to durability and longevity. I’ve successfully completed numerous projects in such environments, focusing on the following:

- High-Density Mix: I use a higher-density terrazzo mix, incorporating stronger binding agents and durable aggregates. This ensures the surface can withstand significant wear and tear.

- Proper Sealing: Multiple coats of high-quality sealant are applied to protect the terrazzo from staining, scratches, and moisture damage. This is crucial in high-traffic settings.

- Joint Design: Strategic placement of control joints is essential to manage stress and prevent cracking due to foot traffic or heavy equipment. The joint design needs to be aesthetically pleasing as well as functional.

- Maintenance Plan: I always provide clients with a detailed maintenance plan to prolong the life of the terrazzo, which includes regular cleaning and sealing recommendations.

For example, in a recent project for a busy airport terminal, we used a particularly dense, highly polished terrazzo with strategically placed control joints. The result was a beautiful and exceptionally durable floor that still looks great years later.

Q 26. How do you manage project timelines and deadlines for terrazzo installations?

Managing project timelines effectively is crucial for successful terrazzo installations. My approach involves a detailed and collaborative process.

- Thorough Planning: This includes a comprehensive site survey, material ordering, and a detailed installation schedule.

- Realistic Scheduling: I avoid over-committing and build in buffer time for unforeseen delays. This prevents rushing the process which can compromise quality.

- Regular Communication: I maintain open and consistent communication with clients, keeping them informed of progress and addressing any potential issues promptly. This fosters transparency and trust.

- Experienced Team: I work with a skilled and reliable team, ensuring efficient execution of each phase of the project.

Using project management software, I track progress meticulously and make adjustments as needed, ensuring timely project completion without compromising quality.

Q 27. Explain your experience with different types of terrazzo backsplashes.

Terrazzo backsplashes offer a unique and durable alternative to traditional materials. My experience includes a variety of styles and applications.

- Matching Countertops: A seamless continuation of the countertop material, creating a unified and elegant look. This is very popular for creating a cohesive kitchen design.

- Accent Colors: Using contrasting colors or aggregates to create a striking visual focal point. This is perfect for adding a pop of personality to a space.

- Custom Designs: Incorporating intricate patterns or logos, providing a bespoke and personalized touch. I’ve created stunning custom backsplashes with client-provided images or themes.

- Thickness Variations: Using different thicknesses of terrazzo to create interesting textures and visual depth. I often integrate these with the countertop thickness for a consistent look.

The choice of backsplash depends heavily on the overall design aesthetic and the client’s preferences. I always work collaboratively with clients to ensure the backsplash complements the space and reflects their personal style.

Q 28. What are the latest trends and innovations in the terrazzo industry?

The terrazzo industry is experiencing a resurgence in popularity, driven by renewed interest in sustainable materials and unique design options. Here are some key trends:

- Recycled Aggregates: A significant shift towards using recycled glass, porcelain, and other materials in the mix, promoting sustainability and reducing environmental impact. This is rapidly becoming an industry standard.

- Larger Aggregates: Designs featuring larger, more prominent aggregates are gaining traction, adding a bold and textural element. This creates visually captivating surfaces.

- Metallic Accents: Incorporating metallic chips or powders adds a touch of glamour and modernity. It’s proving to be very popular in contemporary home designs.

- Custom Color Blends: The ability to create bespoke color blends allows for infinite design possibilities, creating truly unique and personalized installations.

- Digital Design and Fabrication: Technological advancements are enabling more precise control over the creation and installation of terrazzo, offering enhanced quality and efficiency.

These innovations are transforming terrazzo from a traditional material into a versatile and highly sought-after option for contemporary design projects.

Key Topics to Learn for Terrazzo Countertops Interview

- Material Composition and Properties: Understanding the mix of aggregates (marble, granite, quartz, glass), cement binder, and pigments used in terrazzo. Knowing the resulting properties like durability, stain resistance, and maintenance requirements.

- Manufacturing Processes: Familiarize yourself with different terrazzo production methods, including precast and cast-in-place techniques. Understand the stages involved, from mixing to polishing and finishing.

- Installation and Finishing Techniques: Learn about proper substrate preparation, adhesive selection, and installation methods for terrazzo countertops. Understand different polishing techniques and their impact on the final finish.

- Design and Aesthetics: Explore the various design options available with terrazzo, including color palettes, aggregate sizes, and patterns. Understand how to incorporate terrazzo into different design styles.

- Maintenance and Repair: Learn about routine cleaning, stain removal, and repair techniques for terrazzo countertops. Understanding common problems and their solutions is crucial.

- Cost Estimation and Budgeting: Develop an understanding of the factors influencing the cost of terrazzo countertops, including material selection, labor, and installation. Learn how to create accurate cost estimates.

- Sustainability and Environmental Impact: Research the environmental impact of terrazzo production and disposal. Familiarize yourself with sustainable practices in the terrazzo industry.

- Troubleshooting and Problem Solving: Be prepared to discuss common issues encountered during installation or maintenance and how to effectively resolve them.

Next Steps

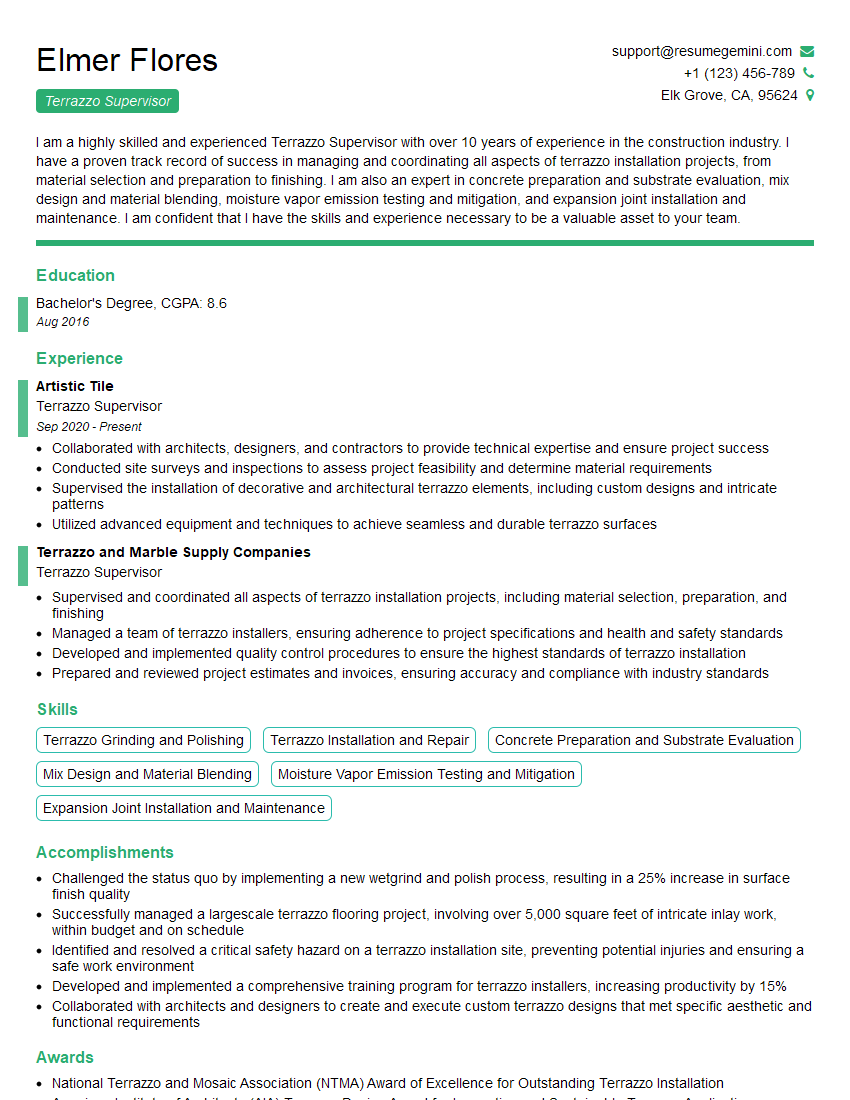

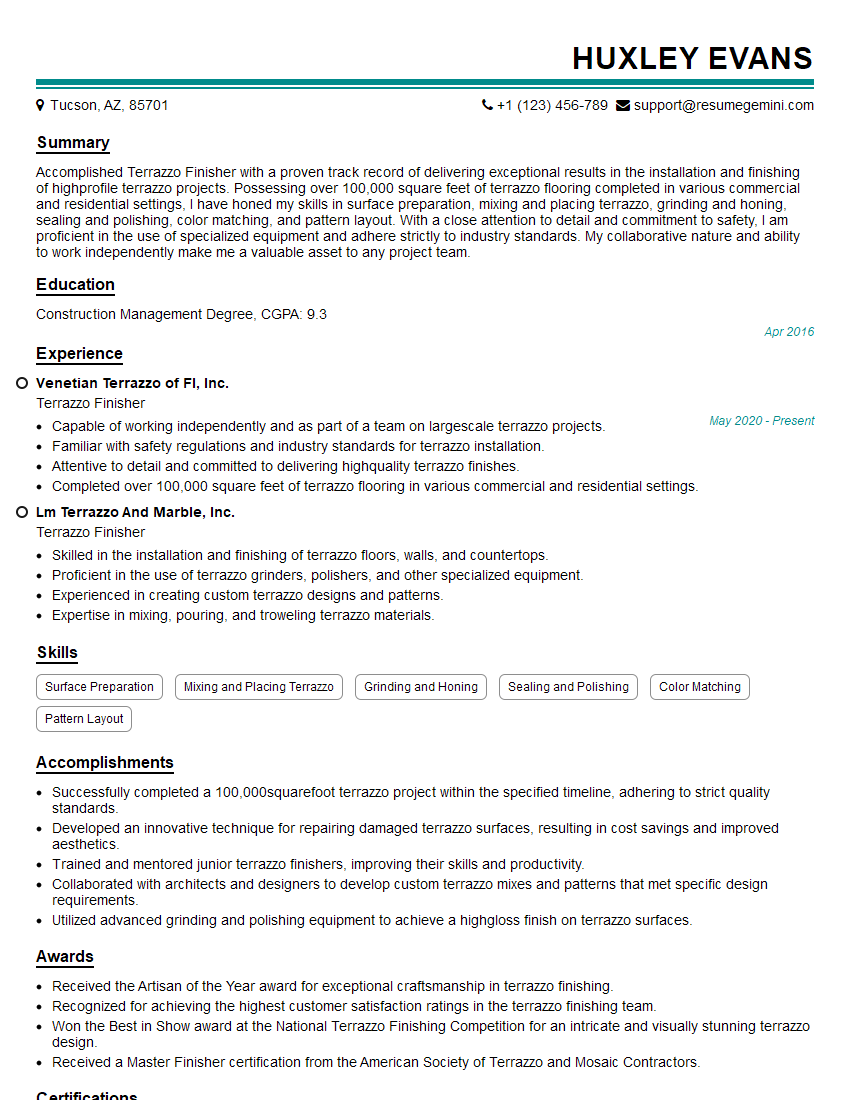

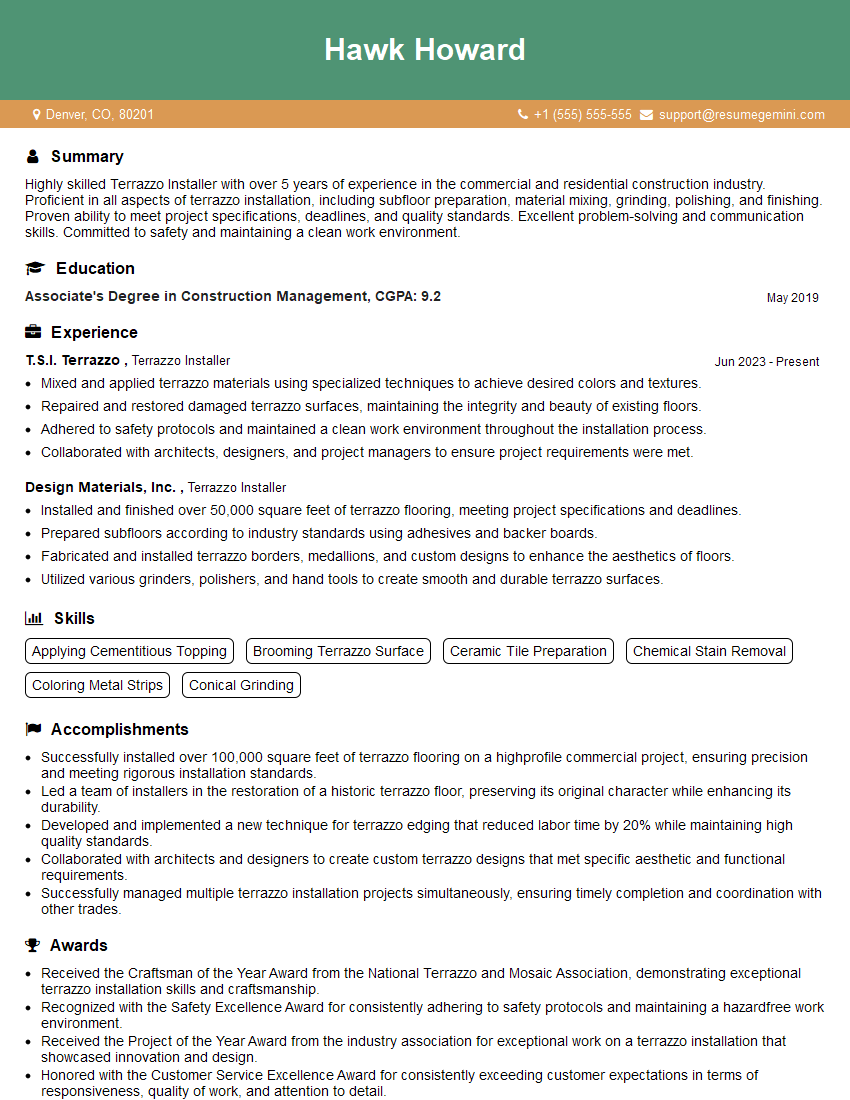

Mastering the intricacies of terrazzo countertops significantly enhances your career prospects within the construction, design, and renovation sectors. A strong understanding of these materials positions you as a valuable asset to any team. To maximize your job search success, focus on creating an ATS-friendly resume that highlights your relevant skills and experience. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a streamlined process and provides examples of resumes tailored to the Terrazzo Countertops industry, helping you present your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?