Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Terrazzo Mural interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Terrazzo Mural Interview

Q 1. Describe your experience with various terrazzo aggregate types and their applications in murals.

My experience with terrazzo aggregates is extensive, encompassing a wide range of materials and their unique properties. The choice of aggregate significantly impacts the final aesthetic and durability of the mural. For example, marble chips offer a classic, elegant look with a varied color palette, perfect for more traditional settings. Glass aggregates, on the other hand, add sparkle and vibrancy, creating a contemporary feel, especially suited to modern or playful designs. Quartz aggregates provide exceptional durability and a consistent, smooth finish, ideal for high-traffic areas. I’ve also worked with recycled materials, such as granite and porcelain, to create sustainable and unique murals. The application depends largely on the desired effect and the overall design concept. A mural incorporating multiple aggregate types, sizes, and colors can achieve a richly textured and visually compelling result. For instance, I once used a combination of white marble, blue glass, and black granite to create a wave-like pattern representing the ocean for a coastal hotel.

Q 2. Explain the process of creating a terrazzo mural design from concept to completion.

Creating a terrazzo mural is a meticulous process that involves several key stages. It begins with the conceptualization and design phase, where the client’s vision and the physical space are carefully considered. We develop detailed drawings and color palettes, often using digital design software to refine the aesthetic. Next, we prepare the substrate, ensuring it’s level, clean, and primed for optimal adhesion. Then comes the layout and installation of the chosen aggregates. This requires precision and artistry to maintain the design’s integrity. We carefully embed the aggregates into the cement binder, ensuring proper spacing and avoiding air pockets. Finally, the surface undergoes grinding, polishing, and sealing to achieve the desired finish. This multi-step process ensures the longevity and beauty of the mural, resulting in a piece that’s not only visually stunning but also durable enough to last for generations.

Q 3. What are the different methods for preparing a substrate for a terrazzo mural?

Substrate preparation is crucial for the longevity and adhesion of a terrazzo mural. The surface must be completely clean, structurally sound, and level. Different methods are used depending on the existing substrate. For concrete, we may need to grind down the surface to achieve a smooth, even base, repairing any cracks or imperfections with appropriate filler. For existing tile or other surfaces, we ensure there’s proper adhesion using a bonding agent. Proper moisture control is essential to prevent problems such as cracking or delamination down the line. In some cases, we use a waterproofing membrane before applying the terrazzo mixture. A properly prepared substrate is the foundation for a successful terrazzo mural; ignoring this step can lead to significant issues later on.

Q 4. How do you ensure proper color blending and consistency in a large-scale terrazzo mural?

Achieving consistent color blending in large-scale murals is a challenge that demands careful planning and execution. We begin by meticulously mixing the cement binder and aggregates in batches, ensuring uniformity in color and texture. Color samples are created beforehand and approved by the client. We also employ a systematic approach to installation, working in sections and carefully matching the colors and aggregates from one section to the next. Regular color checks throughout the process help catch any inconsistencies. In very large murals, we may even create numbered and labelled batches to keep track of the aggregate mixtures for seamless transitions between sections. Think of it like painting a mural – careful preparation and methodical execution are crucial for a smooth and aesthetically pleasing outcome.

Q 5. What safety precautions are essential during terrazzo mural installation and finishing?

Safety is paramount in terrazzo work. Grinding and polishing generate significant dust, which requires respiratory protection, such as respirators with appropriate filters. Eye protection is also crucial to prevent injuries from flying debris. We always wear appropriate safety footwear and gloves to protect against chemical exposure from the cement and sealants. The work area should be well-ventilated to minimize dust accumulation, and proper disposal of waste materials is critical. Regular safety briefings and the use of proper personal protective equipment (PPE) are essential to ensure the well-being of the entire team throughout the project.

Q 6. Explain your experience with different terrazzo finishing techniques (polishing, grinding, sealing).

My experience with terrazzo finishing techniques covers the entire spectrum. Grinding uses progressively finer diamond abrasives to achieve a smooth, level surface. This process removes any imperfections and prepares the surface for polishing. Polishing, done with polishing compounds and specialized equipment, enhances the shine and brings out the luster of the aggregates. Finally, sealing is critical to protect the terrazzo from stains and wear. We use high-quality sealants that enhance the durability and longevity of the mural. The choice of sealant is dependent on the specific aggregate type and intended use of the mural. Different techniques are employed to achieve a variety of finishes, from a high-gloss to a more matte or honed look. Careful execution of these steps is crucial for achieving the desired aesthetic and ensuring the long-term durability of the terrazzo mural.

Q 7. How do you handle complex designs and intricate details in a terrazzo mural?

Handling intricate designs in terrazzo requires a high level of skill and precision. We utilize detailed design templates and carefully select the appropriate aggregate sizes and colors to accurately represent fine details. Often, smaller aggregates are used for intricate areas. For extremely complex designs, we may utilize stencils or other specialized techniques to guide the placement of the aggregates, ensuring the design’s integrity. Experienced artisans are essential in meticulously placing each piece of aggregate to achieve the desired result. We may also pre-assemble small sections of complex designs outside the mural area to ensure accuracy before placement, similar to working with a mosaic. This approach makes the process manageable, reducing the chance of errors and ensuring the final outcome faithfully represents the design.

Q 8. Describe your experience with troubleshooting common issues during terrazzo mural installation.

Troubleshooting terrazzo mural installations often involves addressing issues related to the substrate, the mix design, and the finishing process. For instance, uneven substrate surfaces can lead to an uneven finished product. I address this by ensuring a properly leveled and prepared base before installation, sometimes employing leveling compounds. Another common problem is improper mixing of the terrazzo mix, leading to inconsistencies in color and texture. To avoid this, I meticulously follow the manufacturer’s instructions for resin ratios and aggregate blending, using calibrated equipment for precise measurements. Finally, issues with polishing and sealing can result in a dull or uneven finish. This is solved by using appropriate polishing techniques and high-quality sealants, paying close attention to the application process to ensure an even distribution. I regularly monitor each stage, addressing problems proactively to avoid costly rework.

For example, on a recent project, we encountered an issue with the resin curing unevenly due to fluctuating ambient temperature. I rectified this by implementing temperature control measures in the work area and adjusting the resin selection to one better suited to the environmental conditions. The result was a perfectly even, high-quality mural.

Q 9. What software or tools do you use for designing and planning terrazzo murals?

Designing and planning terrazzo murals involves a combination of artistic vision and technical precision. I utilize various software tools to achieve this. For initial design concepts and client presentations, I use Adobe Photoshop and Illustrator to create detailed visuals of the mural, showcasing color palettes, aggregate patterns, and overall aesthetics. Once the design is finalized, I utilize AutoCAD or SketchUp for precise dimensioning, detailing the layout, and generating cut lists for the aggregates. This ensures a seamless transition from the digital design to the physical execution. Furthermore, I employ specialized software for terrazzo mix design calculation, ensuring the proper ratios of aggregates, resin, and pigments are maintained for consistent quality.

Q 10. How do you manage project timelines and budgets for terrazzo mural projects?

Managing project timelines and budgets for terrazzo murals requires a meticulous approach. I begin by creating a detailed project schedule that outlines all phases, from initial design consultation to final installation and sealing. This schedule includes buffer time to account for unexpected delays. I also develop a comprehensive budget that outlines all material costs (aggregates, resins, pigments, etc.), labor costs, equipment rentals, and any potential contingencies. This is achieved by obtaining quotes from multiple vendors and carefully estimating labor hours based on the project’s complexity. Regular progress meetings with clients are crucial to ensure transparency and to proactively address any potential challenges that may impact the timeline or budget. For example, on a large-scale project, we discovered unforeseen delays in aggregate delivery. I immediately communicated with the client, explored alternative sourcing options, and adjusted the schedule accordingly, ensuring minimal disruption to the overall project timeline.

Q 11. Explain your understanding of different types of resins and their suitability for terrazzo murals.

Resins are crucial to the longevity and aesthetic quality of terrazzo murals. Epoxy resins are popular due to their excellent strength, durability, and chemical resistance. They offer a high-gloss finish and excellent color retention. However, epoxy resins can be more expensive and require specific working conditions (temperature and humidity) for proper curing. Polyester resins are a more economical alternative, but they offer slightly lower strength and durability compared to epoxy resins and are less resistant to chemicals. Selecting the right resin depends on factors such as budget, the desired finish, the expected level of wear and tear, and the environmental conditions the mural will be exposed to. For high-traffic areas, I would opt for epoxy resins, while for less demanding environments, polyester resins could be a suitable choice. In my experience, understanding the resin’s properties is crucial for achieving a high-quality and long-lasting mural.

Q 12. Describe your experience working with various clients and meeting their specific requirements.

Working with diverse clients requires adaptability and excellent communication skills. I always begin each project with a thorough consultation to understand the client’s vision, preferences, and budget constraints. I actively listen to their needs and offer creative solutions within those limitations. For example, one client wanted a mural that reflected their company’s brand identity. We collaborated closely to develop a design incorporating their logo elements and brand colors, resulting in a stunning mural that successfully integrated art and branding. Another client had a limited budget. I helped them find cost-effective alternatives, using readily available aggregates and optimizing the design to minimize material usage without compromising the aesthetic appeal. Successfully managing client expectations and delivering on the project goals is critical to building strong relationships and receiving positive reviews.

Q 13. How do you ensure the durability and longevity of a terrazzo mural?

Ensuring the durability and longevity of a terrazzo mural involves careful attention to detail at every stage of the process. This starts with selecting high-quality materials – durable aggregates, and appropriate resins. Proper substrate preparation is critical to prevent cracking or delamination. The precision of the installation process, including the proper mixing and placement of the terrazzo mix, also contributes significantly. Finally, a high-quality sealant protects the mural from moisture damage, staining, and wear. The type of sealant chosen will depend on the specific environment and the anticipated level of traffic. Proper maintenance also plays a crucial role in extending the lifespan of the mural. I always educate my clients on the best practices for cleaning and maintaining their terrazzo murals.

Q 14. What are your preferred methods for maintaining and repairing terrazzo murals?

Maintaining and repairing terrazzo murals is typically straightforward. Regular cleaning with a pH-neutral cleaner and water is essential. Avoid using harsh chemicals or abrasive cleaners. For minor chips or scratches, epoxy resin fillers can be used for repair. Larger areas of damage may require more extensive repairs, possibly involving the replacement of sections of the mural. For significant damage or structural issues, a professional assessment is required. It’s important to remember that preventative maintenance is key, ensuring regular cleaning and prompt attention to any small issues prevents the escalation into costly major repairs. This approach ensures the mural remains aesthetically pleasing and structurally sound for many years.

Q 15. How do you handle unexpected challenges or changes during a terrazzo mural project?

Unexpected challenges are par for the course in any artistic endeavor, especially one as intricate as a terrazzo mural. My approach centers around proactive planning and a flexible mindset. For example, if a supplier delivers the wrong aggregate, I wouldn’t panic. Instead, I’d immediately assess the impact on the design, explore substitute materials with similar properties, and communicate the change transparently with the client. If a structural issue arises during installation (say, an uneven substrate), I have a protocol for addressing it—ranging from localized substrate repair to adjusting the design itself to accommodate the unforeseen problem. Documentation is key; meticulous record-keeping helps me track changes, justify decisions, and ensure everyone remains informed. Ultimately, successfully navigating challenges boils down to problem-solving skills, effective communication, and a commitment to finding creative solutions.

For instance, on a recent project, a sudden rainstorm threatened to damage the freshly laid terrazzo. My team quickly erected a temporary shelter, and the project was completed without incident due to our preparedness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your knowledge of relevant building codes and regulations for terrazzo installations.

Understanding building codes is crucial for successful terrazzo installations. My knowledge spans several key areas: ADA compliance (ensuring accessibility), fire safety regulations (especially concerning materials and adhesives), structural requirements (ensuring proper support for the weight of the mural), and environmental regulations (related to waste disposal and material sourcing). I thoroughly research the specific codes applicable to each project’s location, and I collaborate closely with architects and engineers to ensure compliance. This often involves submitting design plans for review and obtaining necessary permits before commencing work. Ignoring these regulations could lead to costly delays, legal issues, or even project failure.

For example, I recently had to adjust a design to meet specific ADA requirements concerning slope and surface texture. This involved modifying the design to ensure proper accessibility without compromising the overall aesthetic appeal.

Q 17. What is your experience with different types of terrazzo tooling and equipment?

My experience encompasses a wide range of terrazzo tooling and equipment, from traditional hand tools to advanced machinery. I’m proficient with grinders (both angle grinders and specialized terrazzo grinders), polishing machines, diamond blades for cutting, and various mixing tools for preparing the terrazzo mix. I’m also familiar with laser-guided cutting systems for achieving precise cuts in complex designs. Safety is paramount, so I’m thoroughly trained in the safe operation and maintenance of all equipment. Furthermore, I understand the importance of selecting the right tools for each stage of the process, from initial roughing to final polishing, ensuring optimal efficiency and a high-quality finish.

For instance, the use of a laser-guided cutting system offers significant accuracy advantages over manual cutting, particularly for intricate designs that require precise geometric patterns.

Q 18. How do you measure and cut terrazzo pieces to precise dimensions for a mural?

Precision is paramount when cutting terrazzo for a mural. I use a combination of techniques. For simple cuts, I’d typically use a diamond blade wet saw, ensuring the blade is appropriately sized and sharp for clean, accurate cuts. For complex shapes, I’d utilize either a CNC router or a water jet cutter, depending on the project’s complexity and the material’s properties. Prior to cutting, I meticulously measure and mark the terrazzo pieces using accurate measuring tools and templates, often created digitally and transferred to the material using projection technology. I always double-check measurements to avoid costly errors. Precise cutting ensures the final mural fits perfectly, maintaining the artist’s vision and the integrity of the design.

Think of it like assembling a jigsaw puzzle—each piece needs to be precisely cut to fit flawlessly into its intended place.

Q 19. Explain your understanding of the properties of different aggregate materials.

Different aggregate materials significantly impact the final appearance and durability of a terrazzo mural. I understand the properties of various aggregates, including marble chips, granite, quartz, glass, and recycled materials. Marble chips offer elegance and a classic look, while granite provides exceptional durability. Quartz offers a harder, more resilient surface, ideal for high-traffic areas. Glass adds sparkle and reflectivity. The choice of aggregate depends on factors like aesthetic preferences, desired durability, and budget constraints. For example, using glass aggregates increases the cost but adds a unique visual element. Understanding the characteristics—like hardness, color consistency, and potential staining—is key to making informed material selections that align with the project’s requirements.

The selection of aggregates is a critical design choice impacting both the aesthetics and the long-term performance of the mural.

Q 20. How do you account for expansion and contraction in terrazzo mural design and installation?

Expansion and contraction due to temperature fluctuations is a critical consideration in terrazzo mural design and installation. I account for this by incorporating control joints into the design. These are strategically placed gaps that allow the terrazzo to expand and contract without cracking or warping. The size and placement of these joints are carefully calculated based on the expected temperature variations and the size of the mural. The joints are then filled with a flexible sealant, which maintains the structural integrity while allowing for movement. Furthermore, I select materials and adhesives that are known for their thermal stability and flexibility, minimizing stress on the finished product. Neglecting these precautions can lead to cracking and unsightly damage to the mural over time.

Think of it as designing seams in clothing to accommodate movement; the control joints do the same for the terrazzo.

Q 21. How do you create a realistic cost estimate for a terrazzo mural project?

Creating a realistic cost estimate for a terrazzo mural project involves a detailed breakdown of several factors. This includes the cost of materials (aggregates, binder, pigments, sealants), labor (including design, fabrication, installation, and finishing), equipment rental or purchase, and any necessary permits or inspections. I consider the complexity of the design, the size of the mural, and the required level of finishing. Contingency costs are factored in to account for unforeseen challenges or material price fluctuations. I typically provide clients with a detailed breakdown, explaining each cost component transparently, which fosters trust and avoids unexpected expenses. Accurate cost estimation is essential for successful project management and client satisfaction.

A thorough, itemized estimate ensures transparency and prevents unexpected cost overruns for both the client and contractor.

Q 22. Describe your experience with working on high-profile or large-scale terrazzo mural projects.

My experience encompasses a wide range of large-scale terrazzo mural projects. For example, I was the lead artisan on a 2000 sq ft mural for a major university, incorporating intricate geometric patterns and a vibrant color scheme. This project required meticulous planning, precise execution, and close collaboration with architects and engineers to ensure structural integrity and aesthetic appeal. Another significant project involved creating a series of smaller, interconnected murals for a luxury hotel lobby, each depicting a different scene from local folklore. This demanded creative flexibility and a deep understanding of how to unify diverse artistic elements into a cohesive whole. These projects highlighted not only my technical skill in terrazzo installation but also my ability to manage complex logistics, deadlines, and large teams.

Q 23. What are your preferred methods for cleaning and maintaining the tools and equipment used in terrazzo work?

Maintaining tools and equipment is crucial for longevity and consistent quality. My preferred method involves a three-step process: immediate cleaning, preventative maintenance, and periodic deep cleaning. Immediately after use, I thoroughly clean all tools with water and a suitable degreaser, paying special attention to removing any hardened cement or aggregate. Preventative maintenance includes regularly lubricating moving parts and inspecting for damage. This minimizes wear and tear, extending the life of the tools. Finally, a periodic deep cleaning, perhaps once a month or after a large project, ensures all components are thoroughly cleaned and inspected for any potential issues.

For example, diamond blades require careful cleaning to prevent clogging and ensure optimal cutting performance. Similarly, grout floats and trowels need regular cleaning to maintain their smooth surfaces and prevent the build-up of material that can compromise the quality of the finished work.

Q 24. How do you ensure the structural integrity of a terrazzo mural?

Ensuring structural integrity is paramount. This begins with the substrate preparation. The base must be completely level, sound, and free of any defects. Cracks or weaknesses in the substrate can compromise the mural’s stability over time. We use a high-strength bonding agent to create a robust connection between the terrazzo and the substrate. Then, the terrazzo mix itself must be carefully proportioned, ensuring the correct aggregate-to-binder ratio for optimal strength and durability. The thickness of the terrazzo layer also plays a crucial role, and it needs to be determined based on the size and design complexity of the mural. Finally, proper curing is essential to allow the terrazzo to achieve maximum strength before any finishing or sealing is applied.

Imagine building a house: a weak foundation will eventually cause problems. Similarly, a poorly prepared substrate for a terrazzo mural could result in cracking, chipping, or even detachment of sections of the artwork over time.

Q 25. How familiar are you with sustainable and eco-friendly practices in terrazzo installation?

Sustainability is a growing concern in construction, and the terrazzo industry is adapting. I’m well-versed in using recycled aggregates, such as crushed glass or porcelain, reducing the environmental impact of the materials. We also focus on low-VOC (volatile organic compound) resins and sealants, minimizing harmful emissions during installation and reducing long-term off-gassing. Furthermore, proper waste management practices are crucial; separating and recycling materials such as metal and plastic reduces landfill waste. This commitment to sustainability aligns with my professional values and ensures that my work minimizes its impact on the environment.

Q 26. Describe your experience with different color palettes and design styles for terrazzo murals.

My experience with color palettes and design styles is extensive. I’ve worked with everything from minimalist monochromatic schemes to bold, vibrant, multi-hued designs. I’m adept at translating client visions into reality, whether that involves creating custom blends of colors or sourcing specific aggregates to match a particular aesthetic. For instance, I worked on a project that called for a muted, earthy palette, achieved by using recycled aggregates in tones of beige, brown, and gray. In contrast, another project required a bright and energetic feel; we used recycled glass in various shades of blue, green, and yellow, creating a visually stunning effect. The design style can vary, including geometric patterns, abstract forms, or representational imagery. I thrive on the challenge of translating diverse design concepts into durable and visually engaging terrazzo murals.

Q 27. How do you coordinate with other tradespeople involved in a construction project involving a terrazzo mural?

Coordination with other trades is vital. I typically begin by reviewing the project’s blueprints and schedule with the general contractor and other relevant trades, such as electricians and plumbers, to identify potential conflicts or coordination needs. This includes establishing clear timelines for access to the work area and ensuring that all necessary utilities and infrastructure are in place before my team begins the terrazzo installation. We establish clear communication protocols, and I regularly communicate with the project manager to keep everyone updated on our progress and address any unforeseen challenges. Open communication and proactive planning are crucial for ensuring a smooth and efficient process.

Q 28. Describe a time you had to adapt your approach to a challenging terrazzo mural project.

One particularly challenging project involved creating a large-scale mural with intricate, three-dimensional relief work. The design required extremely precise aggregate placement and a highly skilled approach to creating the desired depth and texture. Our initial approach proved too time-consuming, and we were behind schedule. To overcome this, I assembled my team, and we developed a new system for pre-assembling sections of the mural in a modular fashion. This allowed for parallel work, significantly speeding up the process and ensuring we met the project deadline without compromising on the quality. This experience taught me the importance of flexibility and adaptability in responding to unforeseen obstacles.

Key Topics to Learn for Terrazzo Mural Interview

- Design Principles: Understanding the aesthetic principles behind successful terrazzo mural design, including color theory, composition, and pattern creation.

- Material Selection & Properties: Knowledge of various aggregates, binders, and pigments used in terrazzo, and their impact on the final product’s durability and appearance. Understanding limitations and potential challenges.

- Fabrication Techniques: Familiarity with different methods of terrazzo production, including in-situ pouring, pre-cast panels, and the use of specialized tooling.

- Scale and Dimensioning: Experience in planning and executing large-scale terrazzo murals, considering factors like substrate preparation, structural support, and grout selection.

- Maintenance and Restoration: Understanding the long-term care of terrazzo murals, including cleaning, repair, and preservation techniques.

- Project Management: Experience in budgeting, scheduling, and coordinating with contractors and stakeholders throughout the project lifecycle.

- Safety Procedures: Thorough knowledge of relevant safety regulations and best practices for working with terrazzo materials and tools.

- Client Communication: Ability to effectively communicate design concepts, project timelines, and potential challenges to clients.

- Troubleshooting & Problem Solving: Ability to identify and resolve issues related to material defects, color inconsistencies, or other challenges during the fabrication or installation process.

Next Steps

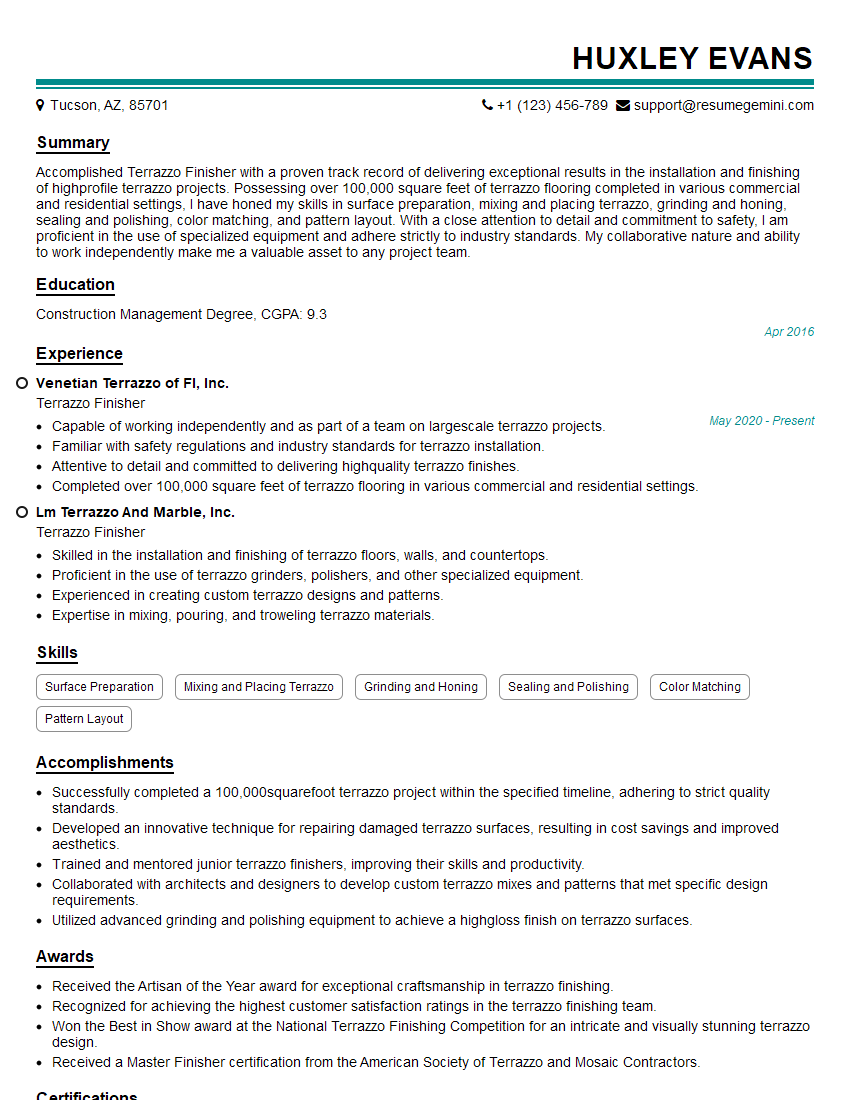

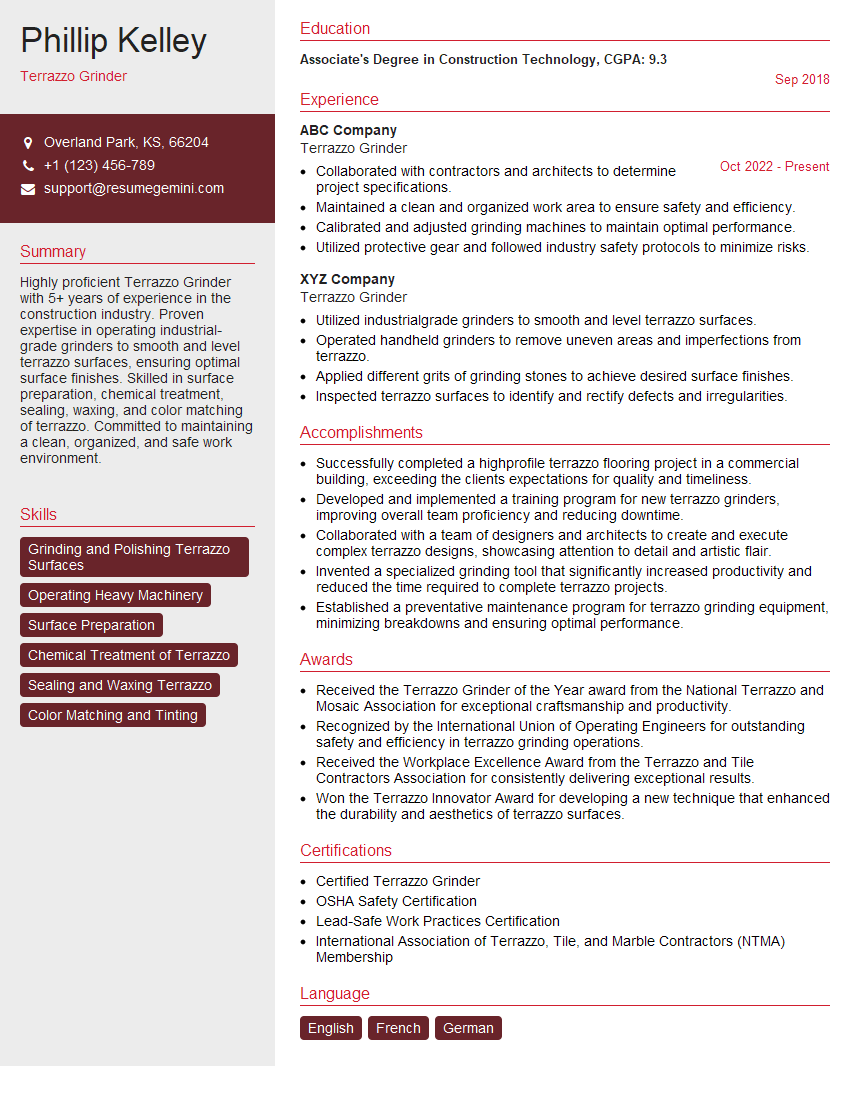

Mastering Terrazzo Mural techniques and knowledge opens doors to exciting career opportunities in artistic design, construction, and project management. A strong understanding of this specialized field significantly enhances your marketability and allows you to pursue rewarding roles within the industry. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your Terrazzo Mural expertise. Examples of resumes tailored to this field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?