The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Tile Layout interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Tile Layout Interview

Q 1. Explain the process of calculating tile quantities for a given area, accounting for waste.

Calculating tile quantity requires more than just dividing the area by the tile’s size. You must account for waste, which can be substantial depending on the complexity of the layout and the tile’s shape. Think of it like baking a cake – you always need extra ingredients to account for spills and imperfections.

Here’s a step-by-step process:

- Measure the area: Accurately measure the length and width of the area to be tiled. For irregular shapes, break them down into smaller, easily measurable sections.

- Calculate the total area: Multiply the length and width to get the total square footage (or square meters).

- Determine tile area: Calculate the area of a single tile. For square tiles, it’s simply side x side. For rectangular tiles, it’s length x width.

- Estimate the number of tiles needed: Divide the total area by the area of a single tile. This gives you a base number.

- Add waste: This is crucial! Waste percentage varies. For simple layouts with rectangular tiles, 5-10% might suffice. Complex layouts (herringbone, diagonal), intricate cuts, or large amounts of waste from irregularly shaped areas might require 15-20% or even more. Experienced tilers often refine this estimate based on years of experience with specific tile sizes and patterns.

- Round up: Always round the final number up to the nearest whole tile. You can’t buy fractions of tiles!

Example: Let’s say you have a 10ft x 12ft room and are using 1ft x 1ft tiles. The total area is 120 sq ft. With a 10% waste factor, you’d need 120 + (120 * 0.10) = 132 tiles.

Q 2. Describe different tile layout patterns (e.g., running bond, herringbone, diagonal).

Tile layout patterns significantly impact the final look and feel of a tiled area. The choice often depends on the room’s style, the tile’s shape and size, and personal preference.

- Running Bond: This is the simplest and most common pattern. Tiles are laid in parallel rows with offsetting joints, much like bricks. It’s easy to install and minimizes waste.

- Herringbone: Tiles are arranged in a V-shape, creating a classic and elegant pattern. This requires more cutting and planning but offers a distinct visual appeal. Requires rectangular or elongated tiles.

- Diagonal: Tiles are laid at a 45-degree angle to the walls. It’s visually striking, but it requires more precise cuts and calculations and often leads to more waste.

- Basketweave: Uses rectangular tiles arranged in a woven pattern, resembling a basket. This design is versatile and suitable for both floors and walls.

- Stack Bond: The simplest pattern where tiles are arranged in straight lines with no offsetting. Ideal for large format tiles.

Choosing the right pattern is a balance between aesthetics and practicality. A herringbone pattern might look fantastic but demands more skill and will increase labor costs.

Q 3. How do you ensure proper spacing and alignment during tile installation?

Maintaining proper spacing and alignment is critical for a professional-looking tile installation. Inconsistent spacing creates an amateurish finish. Think of it like building a brick wall – each brick needs to be perfectly positioned for structural integrity and visual appeal.

Here’s how to achieve it:

- Use spacers: Plastic or tile spacers are essential. These maintain uniform grout lines between tiles. The size of the spacer dictates the grout line width.

- Snap lines: Use chalk lines or laser levels to create straight lines for accurate tile placement, especially important for larger areas or intricate patterns. It helps ensure straight rows and columns.

- Check alignment frequently: Regularly check the alignment of tiles using a level and square to prevent cumulative errors. A slight misalignment early on can amplify across the whole tiled area.

- Work in sections: Installing tiles in smaller sections, then carefully checking the alignment before moving on prevents large-scale errors.

For complex patterns, meticulous planning and marking are vital. Using templates or pre-layout mockups can be extremely helpful for visualization and to reduce errors.

Q 4. What are the common methods for cutting tiles to fit specific areas?

Cutting tiles is a necessary part of most tile installations, especially when dealing with edges, corners, or obstacles like pipes and doorways.

- Wet saw: The most common method. A wet saw uses a diamond blade to cut tiles cleanly and precisely. The water keeps the blade cool and prevents dust.

- Nippers: Used for smaller cuts and scoring tiles for snapping. They’re handy for small adjustments or breaking off small pieces, but they are not suitable for large cuts.

- Angle grinder with diamond blade: Offers more versatility for awkward cuts, but it produces more dust and requires additional safety precautions.

- Manual tile cutter: A more basic tool best for straight cuts, but it might not be suitable for all tile materials or complex shapes.

The choice of cutting method depends on the tile material, the type of cut needed, and the installer’s experience. A wet saw is generally preferred for its precision and ease of use, especially with ceramic or porcelain tiles.

Q 5. Explain the importance of proper substrate preparation before tile installation.

Substrate preparation is the foundation of any successful tile installation. A poorly prepared substrate will lead to tile failure, cracking, or uneven surfaces – essentially, all your hard work will be wasted. It’s like building a house on unstable ground; the house will eventually collapse.

Proper preparation involves:

- Cleaning: The surface must be clean, free of dust, debris, grease, and any loose material. This ensures proper adhesion of the mortar.

- Leveling: The substrate should be level and even. Any significant unevenness needs to be addressed using self-leveling compounds or other leveling techniques. Uneven surfaces will lead to inconsistent grout lines and possibly cracked tiles.

- Priming: In some cases, a primer might be needed to enhance adhesion between the substrate and the mortar, especially on porous surfaces.

- Moisture control: Check the moisture content of the substrate, especially for concrete. Excessive moisture can cause the tiles to loosen and grout to fail.

Skipping any of these steps can result in a disastrous outcome. Taking the time for careful substrate preparation is an investment in the longevity and beauty of the finished tile installation.

Q 6. Describe different types of tile setting mortars and their applications.

Tile setting mortars are the glue that holds the tiles to the substrate. Different mortars are suited for different applications and tile types.

- Portland cement-based mortars: These are the most common type, offering good strength and durability. Suitable for most interior and exterior applications. They are available in various mixes offering different properties like rapid setting, improved workability or enhanced bond strength.

- Modified mortars: These contain polymers or other additives that enhance their flexibility, workability, and bond strength. They are excellent for use on less-than-perfect substrates or for larger format tiles.

- Thin-set mortars: Used for smaller-format tiles and have a thinner consistency allowing for precise tile placement. Requires a level substrate.

- Thick-set mortars: Used for larger-format tiles or to level uneven substrates. It can provide more support for large tiles.

The choice of mortar depends on several factors including the tile type, substrate material, environmental conditions, and the tile size. Selecting the correct mortar ensures the tiles adhere securely and the installation lasts.

Q 7. How do you handle uneven surfaces before tiling?

Uneven surfaces are a common problem that needs to be addressed before tile installation. Tiling over uneven surfaces will result in cracked tiles and a poor finished look. Think of it like trying to paint a picture on a wobbly canvas—it’s impossible to create a clean and even finish.

Methods for handling uneven surfaces include:

- Self-leveling compounds: These are poured onto the substrate to create a perfectly level surface. They are easy to use and provide a smooth, even base for tile installation. The drying time varies based on the product used.

- Backer board: Cement board or other backer boards can be used to create a level surface over uneven substrates. These are installed over the substrate and then the tiles are applied over the backer board. This adds additional support and creates a level base. Requires proper fastening to the substrate.

- Thin-set mortar in thick layers: For minor imperfections, a thick layer of thin-set mortar can be used to level the surface, but this can be less consistent than self-leveling compounds or backer board. It is not suitable for large variations in height.

The best method depends on the severity of the unevenness and the type of substrate. For significant irregularities, self-leveling compound or backer board are preferred, offering a stronger and more stable base for the tile.

Q 8. What are the safety precautions you take during tile installation?

Safety is paramount in tile installation. It’s not just about protecting the finished product, but also preventing injuries. My safety protocols begin with proper personal protective equipment (PPE), including safety glasses to protect my eyes from flying debris, a dust mask to prevent inhaling silica dust (especially when working with natural stone), and sturdy work gloves to safeguard my hands. I always ensure the work area is clean and free of obstructions to prevent tripping hazards. Before starting any cutting, I secure the tile firmly to prevent it from shifting unexpectedly. For larger projects, I establish a clear pathway for safe movement and maintain good lighting to enhance visibility. Finally, I meticulously follow all manufacturer’s instructions for handling adhesives, grouts, and sealants, paying close attention to safety warnings and ventilation requirements.

For example, when using a wet saw, I always wear safety glasses and ensure the blade guard is in place. I also make sure to use a water-fed saw to minimize dust generation.

Q 9. How do you determine the best grout color and type for a specific tile installation?

Choosing the right grout color and type is crucial for the overall aesthetic appeal and longevity of the tile installation. The grout color should complement the tile color, enhancing the design. A contrasting grout color can make the tiles stand out, while a similar-colored grout creates a more seamless look. For instance, light-colored grout with dark tiles creates a defined and modern look, whereas a light grout with light tiles offers a minimalist appeal. The grout type is equally important; it should match the tile material and environment. For instance, epoxy grout is ideal for wet areas such as showers and pools due to its water-resistance properties; it’s also great for high-traffic areas as it’s exceptionally durable. Cement-based grout is a more common and budget-friendly option, perfectly suitable for less demanding areas. Always consider the porosity of the tile when selecting grout; a highly porous tile requires a grout that doesn’t stain easily.

For example, in a bathroom with dark grey porcelain tiles, a light grey grout would provide a nice contrast without being jarring, while in a kitchen with off-white ceramic tiles, a similar off-white grout might create a cleaner, unified look.

Q 10. Explain the process of grouting and cleaning excess grout.

Grouting is the process of filling the gaps between tiles with grout, providing structural support and preventing water penetration. I begin by preparing the grout according to the manufacturer’s instructions, ensuring the consistency is workable—neither too thick nor too thin. Using a rubber grout float held at a 45-degree angle, I apply the grout by pressing it firmly into the joints, working in small sections. I then use the float’s flat side to remove excess grout, ensuring the joints are filled evenly and the tile surfaces are clean. Once the grout has partially set (usually 20-30 minutes depending on the grout and weather), I use a damp sponge to remove any remaining residue, rinsing the sponge frequently to prevent grout from accumulating on the tile surface. It’s crucial to be gentle to avoid scratching the tiles. Finally, after the grout has fully cured (typically 24-72 hours), I apply a grout sealant to protect the grout against staining and water damage.

Cleaning excess grout efficiently is key to a professional finish. A systematic approach, working in small sections and regularly cleaning the sponge, minimizes the time spent on this essential process and ensures a pristine result.

Q 11. What are the common problems encountered during tile installation, and how do you resolve them?

Common tile installation problems include uneven surfaces, cracked tiles, lippage (uneven tile heights), and grout haze. Uneven surfaces can be addressed by using a self-leveling compound before tile installation. Cracked tiles usually result from improper handling or poor-quality tiles and require replacement. Lippage, where one tile edge sits higher than an adjacent one, indicates incorrect tile placement or inconsistent adhesive application; careful attention to spacing and adhesive application can prevent this. Grout haze, a whitish film on the tile surface, is caused by excess grout residue and can be effectively removed using a grout haze remover. If the problem persists, I would consult with the tile manufacturer for specific cleaning recommendations. Throughout the installation, careful planning and precision are crucial to minimize these issues. For example, regularly checking the tile level with a level tool prevents significant lippage issues from arising.

Problem-solving in tile installation requires a combination of experience, attention to detail, and the right tools. Addressing problems promptly often prevents more extensive repairs down the line.

Q 12. How do you handle challenging cuts, such as curved or angled cuts?

Handling challenging cuts, like curves or angles, requires specialized tools and techniques. For curved cuts, I use a wet saw with a flexible blade or a tile nibbler for smaller, intricate curves. For angled cuts, a wet saw with an adjustable miter gauge is essential. Accuracy is key here; careful measuring and precise cutting are crucial to ensure a seamless fit. I always make test cuts on scrap tiles before cutting the actual tiles to ensure the angle and cut are accurate. Templates can be incredibly helpful, especially with complex shapes, allowing me to trace the pattern onto the tile for accurate cutting. For very intricate shapes, a tile-cutting router is often the best option.

For example, when installing tiles around a curved window, I would first create a template from cardboard to accurately trace the curve onto the tile before cutting.

Q 13. Describe your experience with different types of tile (ceramic, porcelain, natural stone).

My experience encompasses various tile types, each with unique characteristics. Ceramic tiles are versatile, affordable, and easy to maintain, suitable for various applications. Porcelain tiles, known for their durability and water resistance, are excellent choices for high-traffic areas and bathrooms. Natural stone tiles, like marble, granite, or slate, offer luxurious aesthetics but require more meticulous handling and sealing to prevent staining and damage. Each type needs a specific approach; for example, porcelain tiles require a more precise cut due to their hardness compared to ceramic tiles, and natural stone often necessitates more thorough sealing. The preparation of the substrate, the adhesive used, and the tools employed all vary depending on the specific tile material. Understanding these differences allows me to optimize the installation process for each project, ensuring both the longevity and beauty of the finished work.

For example, I’ve worked on projects ranging from a simple ceramic tile backsplash to an intricate natural stone flooring installation, tailoring my approach to each tile type’s specific needs and characteristics.

Q 14. How do you manage a tile installation project timeline and budget?

Managing a tile installation project’s timeline and budget effectively requires meticulous planning from the outset. This starts with a detailed assessment of the project scope, including area calculations, material estimations, and labor requirements. Creating a realistic schedule involves breaking down the project into smaller, manageable tasks with assigned timelines. I factor in potential delays, such as material sourcing and unforeseen issues. Budget management necessitates obtaining multiple quotes for materials, comparing different suppliers and negotiating prices. Labor costs are also thoroughly accounted for, including factoring in overtime and any potential contingency funds for unexpected events. Regular progress checks against the schedule and budget ensure timely completion and cost control. Open communication with the client keeps them informed throughout the process. A detailed breakdown of costs and payment schedules ensures transparency.

For example, a project timeline might include detailed tasks like substrate preparation (2 days), tile layout and cutting (3 days), adhesive application and tile setting (4 days), grouting (1 day), and final cleaning (1 day). A budget would include individual line items for tile, adhesive, grout, sealant, tools, labor, and a contingency for unexpected issues.

Q 15. Explain the importance of using proper tools and equipment for tile installation.

Using the right tools and equipment for tile installation isn’t just about getting the job done; it’s about ensuring a high-quality, long-lasting result and, importantly, your safety. Improper tools can lead to uneven cuts, cracked tiles, and even injuries.

- Notched Trowels: These aren’t just flat spatulas; the notches dictate the amount of thin-set mortar applied, crucial for proper adhesion. Using the wrong size notch can lead to insufficient or excessive mortar, causing issues with the tile bond. For example, a large-format tile will need a larger notched trowel than a small mosaic tile.

- Tile Cutters: Wet saws provide precise cuts for large tiles, preventing chipping. Manual cutters are suitable for smaller projects, but require skill and practice to avoid breakage. The wrong cutter can mean damaged tiles and costly replacements.

- Leveling Systems: These systems ensure flat surfaces, especially critical with large format tiles. They minimize lippage (uneven tile heights) which improves aesthetics and prevents cracking.

- Safety Gear: Safety glasses, gloves, and dust masks are essential to protect you from flying debris, chemical irritants, and silica dust from cutting tiles. This is non-negotiable for both professional and DIY projects.

In my experience, investing in quality tools is an investment in the longevity and quality of my work. A professional appearance speaks volumes about my attention to detail and commitment to quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper curing time for mortar and grout?

Proper curing time for mortar and grout is paramount to the strength and durability of a tile installation. It allows the materials to fully hydrate and reach their maximum bond strength.

- Mortar: The manufacturer’s instructions are crucial. Typically, this involves keeping the newly installed tiles moist for 24-72 hours to prevent premature drying and cracking. This can involve covering the tiles with plastic sheeting or using a curing compound.

- Grout: Grout also needs time to cure properly. Allowing it to dry fully before heavy use is vital. Avoid excessive water during cleaning, as this can weaken the grout. The manufacturer will indicate the curing time, but generally, it takes a few days to fully cure. You need to let it dry naturally – forcing the process can damage it.

I’ve learned the hard way that rushing this process leads to problems down the line. One memorable incident involved a job where the client insisted on using the shower too soon; the grout wasn’t fully cured, and small cracks started to appear. Proper curing avoids costly repairs and ensures customer satisfaction.

Q 17. What are the different methods for waterproofing a tile installation?

Waterproofing is essential, particularly in wet areas like showers and bathrooms. Neglecting this can lead to water damage, mold growth, and structural problems.

- Membrane Systems: These are applied to the substrate before tiling. They act as a barrier, preventing water from penetrating the wall or floor. There are several types including peel-and-stick and liquid-applied membranes.

- Water-Resistant Mortar and Grout: Choosing the correct products from the start is crucial. Look for products specifically designed for wet areas. They are designed to be more water-resistant than standard options.

- Proper Installation Techniques: Ensuring tiles are properly sealed is critical. Using caulk around edges to seal gaps is essential to prevent water from seeping behind the tiles. This will create a waterproof seal for greater durability.

I always recommend a multi-layered approach, combining a waterproof membrane with water-resistant mortar and grout, and meticulous attention to sealing. This approach minimizes the risk of water damage and ensures the longevity of the installation.

Q 18. Explain your experience with various tile installation methods (thin-set, thick-set).

Thin-set and thick-set methods are both common in tile installation, each suited to different applications.

- Thin-set: This method uses a thin layer of mortar (typically 1/8 inch to 3/8 inch) and is ideal for most interior tile installations. It’s faster, uses less mortar, and is suitable for most ceramic and porcelain tiles. This is my go-to method for most projects.

- Thick-set: This uses a thicker layer of mortar, and is necessary for larger tiles, uneven substrates or when extra adhesion is required. It also requires more skill and precision to ensure the tile is evenly set.

I have extensive experience with both methods. I’ve successfully used thin-set for countless kitchen backsplashes and bathroom floor installations. However, I’ve also relied on thick-set for large format porcelain tiles in living areas to ensure an incredibly stable and secure installation, even with slight variations in the substrate.

Q 19. How do you handle customer requests or changes during a project?

Handling customer requests and changes during a project is a vital aspect of project management. It requires professionalism, clear communication, and a willingness to adapt.

- Open Communication: I maintain constant communication with the client, clearly explaining the implications of any changes. This can include discussing potential impacts on timeline, budget, and the overall aesthetic outcome.

- Detailed Documentation: Any changes are documented in writing, ensuring everyone is on the same page. This includes revised specifications, budget adjustments, and revised timelines.

- Realistic Expectations: I manage expectations by setting realistic timelines and clearly explaining the complexities of making changes mid-project. I often break down complex changes to smaller, more manageable tasks, making the process smoother for all parties involved.

One project involved a last-minute tile selection change. While initially a challenge, the thorough documentation and open communication minimized any disruptions, ensuring a satisfactory outcome that met the client’s vision.

Q 20. Describe your experience with installing large-format tiles.

Installing large-format tiles presents unique challenges, demanding precision and expertise. The weight and size necessitate careful planning and execution.

- Substrate Preparation: The substrate needs to be perfectly flat and strong enough to support the weight. Any imperfections will be magnified with large tiles.

- Mortar Selection: A high-performance mortar is necessary for secure adhesion. I typically use modified thin-set or thick-set depending on the substrate and tile material.

- Installation Technique: Special care is required to avoid lippage (uneven tile heights). I commonly use leveling systems to guarantee a perfectly flat surface.

- Cutting and Handling: Large tiles require specialized cutting tools, like wet saws, and careful handling to avoid breakage during transport and installation. It also requires more physical effort.

I’ve successfully installed large-format porcelain tiles in numerous projects, consistently delivering high-quality results. My experience includes handling the challenges of uneven substrates and meticulous attention to detail.

Q 21. How do you calculate the cost of a tile installation project?

Calculating the cost of a tile installation project requires a detailed breakdown of various factors.

- Material Costs: This includes the cost of tiles, mortar, grout, sealant, and any other necessary materials. This is calculated based on square footage and the type of material.

- Labor Costs: This is determined by the hourly rate, and the estimated time required for demolition, preparation, installation, and cleanup. This is based on my expertise and experience.

- Overhead Costs: These include transportation costs, permits (if required), equipment rental, and waste disposal. This is included in the overall quote.

- Contingency: A percentage is added to cover unforeseen expenses or delays. This helps to mitigate any unexpected challenges that might occur during a project.

I create a detailed estimate, itemizing each cost component for transparency and client understanding. My goal is to provide upfront pricing, avoiding unexpected costs during the project.

Q 22. Explain your experience with different types of tile trim and edging.

Tile trim and edging are crucial for achieving a professional finish and protecting the tile edges. My experience encompasses a wide variety of materials and styles, each with its own advantages and disadvantages.

- Metal trims: These, including aluminum, brass, and stainless steel, offer durability and a sleek, modern look. I’ve used them extensively in high-traffic areas and wet environments like showers, where their resistance to moisture and wear is essential. For instance, I recently used brushed nickel trim to accentuate the subway tile in a contemporary bathroom remodel.

- Plastic trims: These are cost-effective and come in a range of colors and profiles, offering flexibility in design. However, they are generally less durable than metal and may not be suitable for high-impact zones. I often utilize these for less demanding areas or where budget is a significant concern.

- Ceramic and porcelain trims: These offer a seamless transition between different tile types or from tile to other materials like drywall. Matching the trim to the main tile creates a unified and elegant aesthetic. I’ve used this extensively when transitioning from wall tiles to a shower niche.

- Bullnose tiles: These tiles have a rounded edge, eliminating the need for separate trim. They’re a classic and simple solution, often preferred for a more traditional look. I find them ideal for countertops or stair treads.

Selecting the appropriate trim depends on the project’s specific requirements – the tile type, the location, the desired aesthetic, and the budget. My experience allows me to advise clients on the best option for their needs, ensuring a long-lasting and beautiful result.

Q 23. How do you deal with expansion joints and movement in a tile installation?

Expansion joints are critical for preventing cracking and damage to tile installations due to movement from temperature fluctuations, building settling, or substrate expansion. My approach involves careful planning and execution.

- Planning: Before installation, I assess the area for potential movement and plan the location of expansion joints accordingly. These joints should be placed at intervals based on the tile type and substrate, following manufacturer guidelines and industry best practices. For example, in large floor areas, I’ll incorporate control joints at intervals of about 10-12 feet, depending on the substrate and tile size.

- Materials: I use appropriate joint fillers, such as flexible sealants or expansion joint membranes, ensuring compatibility with both the tile and the substrate. These materials allow for controlled movement without compromising the structural integrity of the tile installation. Choosing the right sealant is crucial; I always select one rated for the specific environment (e.g., waterproof for showers).

- Installation: I meticulously install the expansion joints using the correct tools and techniques, ensuring a clean and professional finish. The joint needs to be wide enough to accommodate movement, usually 1/4 inch or more, and the sealant needs to be properly tooled and cleaned to prevent unsightly residue.

Ignoring expansion joints leads to costly repairs down the line. My meticulous attention to this detail is a crucial element of ensuring the longevity and aesthetic appeal of my tile installations.

Q 24. What is your experience with installing tiles on different surfaces (e.g., walls, floors, showers)?

My experience with tile installation encompasses various surfaces, each demanding a unique approach.

- Floors: Floor tile installation requires a level, solid substrate. This often involves preparing the subfloor, ensuring it’s free from cracks and imperfections, and using the appropriate underlayment. I have experience working with various floor substrates, including concrete, plywood, and existing tile, selecting the right type of mortar and method for each.

- Walls: Wall tile installation requires appropriate backer board or cement board to provide a stable and water-resistant surface. I pay close attention to the wall’s plumbness and levelness to ensure a straight and even tile layout. I also understand the importance of using proper thin-set mortar and ensuring good coverage to prevent tile from falling off.

- Showers: Shower tile installations demand exceptional waterproofing. This requires creating a waterproof membrane using specialized materials and techniques to prevent water damage. I’m proficient in installing shower pans, waterproofing the walls, and ensuring proper slope for drainage. My attention to detail in these areas prevents costly water damage repairs.

Each surface requires a specific skill set and understanding of the materials and techniques. My experience enables me to adapt my approach based on the surface and the project’s specifications.

Q 25. Describe your experience with troubleshooting common tile installation issues.

Troubleshooting is a vital part of tile installation. My experience has equipped me to handle a variety of issues effectively.

- Uneven grout lines: This is often caused by improper spacing or inconsistent pressure during tile setting. The solution involves using spacers consistently and applying even pressure when setting the tiles.

- Cracked tiles: Cracks can result from improper substrate preparation, insufficient support, or using the wrong type of mortar. Identifying the root cause is crucial, which might necessitate removing and replacing the affected tiles.

- Lippage: Uneven tile heights cause unsightly lippage. This usually stems from inadequate mortar coverage or inconsistent tile setting. Addressing this might require using a leveling system or carefully adjusting individual tiles.

- Efflorescence: This whitish powdery deposit appears on the tile surface due to moisture issues. Addressing this involves determining the source of moisture and allowing the affected area to dry completely before cleaning.

My approach is systematic – first, identify the root cause, then select the appropriate solution. I always prioritize preventative measures to minimize the occurrence of such problems.

Q 26. What software or tools do you use to create tile layouts or estimates?

While I don’t rely solely on software, it plays a supportive role in my workflow.

- SketchUp: I use SketchUp for creating 3D models of complex tile layouts, especially for intricate designs or when working with clients who want a visual representation of the finished product. This allows for precise material calculations and helps avoid potential layout issues.

- Spreadsheets: I utilize spreadsheets for estimating material quantities and calculating project costs. This involves considering the tile size, layout, waste factor, and other relevant variables. Accurate calculations ensure that I have enough material on hand and prevent unnecessary expenses.

- Measuring tools: Precise measurements are paramount, so I rely heavily on laser measuring tools, tape measures, and levels for accurate planning and execution. A well-measured space is the foundation of a successful tile installation.

The combination of software and traditional measuring tools ensures accuracy and efficiency in my project planning and execution.

Q 27. How do you maintain a clean and organized worksite during tile installation?

Maintaining a clean and organized worksite is essential for safety, efficiency, and the quality of the finished product. My approach involves meticulous planning and execution.

- Staging Area: I designate a specific area to store materials and tools, keeping them organized and easily accessible. This prevents clutter and ensures a safe working environment.

- Waste Management: I use separate containers for different types of waste (e.g., cardboard, plastic, tile scraps) and dispose of them properly to maintain a clean workspace and respect environmental considerations.

- Regular Cleaning: I clean up debris regularly throughout the day, preventing accumulation and making the space safer and easier to work in. This also makes it easier to spot potential issues earlier.

- Protective Measures: I use drop cloths and masking tape to protect surfaces not being tiled, minimizing damage and simplifying post-installation cleanup.

A clean and organized workspace is not just about aesthetics; it significantly impacts efficiency, reduces accidents, and improves the overall quality of the tile installation. This is a key aspect of my professional approach.

Key Topics to Learn for Tile Layout Interview

- Fundamentals of Tile Layout Algorithms: Understand different approaches to arranging tiles (e.g., grid-based, flexible, responsive layouts), their strengths, and weaknesses.

- Responsive Design Principles: Learn how to create tile layouts that adapt seamlessly across various screen sizes and devices (desktops, tablets, mobiles).

- Performance Optimization: Explore techniques to ensure efficient rendering and minimize loading times for tile-based interfaces, considering factors like image optimization and lazy loading.

- Accessibility Considerations: Understand how to design accessible tile layouts that cater to users with disabilities, following WCAG guidelines.

- Practical Application: Case Studies: Analyze real-world examples of effective tile layouts in different applications (e.g., dashboards, image galleries, e-commerce product displays) to understand design choices and implementation strategies.

- Data Handling & Integration: Explore methods for dynamically populating tile layouts with data from various sources (e.g., APIs, databases).

- Common Frameworks and Libraries: Familiarize yourself with popular frameworks and libraries used for implementing tile layouts (mentioning specific technologies is outside the scope, allowing candidates to research independently).

- Debugging and Troubleshooting: Develop your ability to identify and resolve common issues related to tile layout rendering, responsiveness, and data handling.

Next Steps

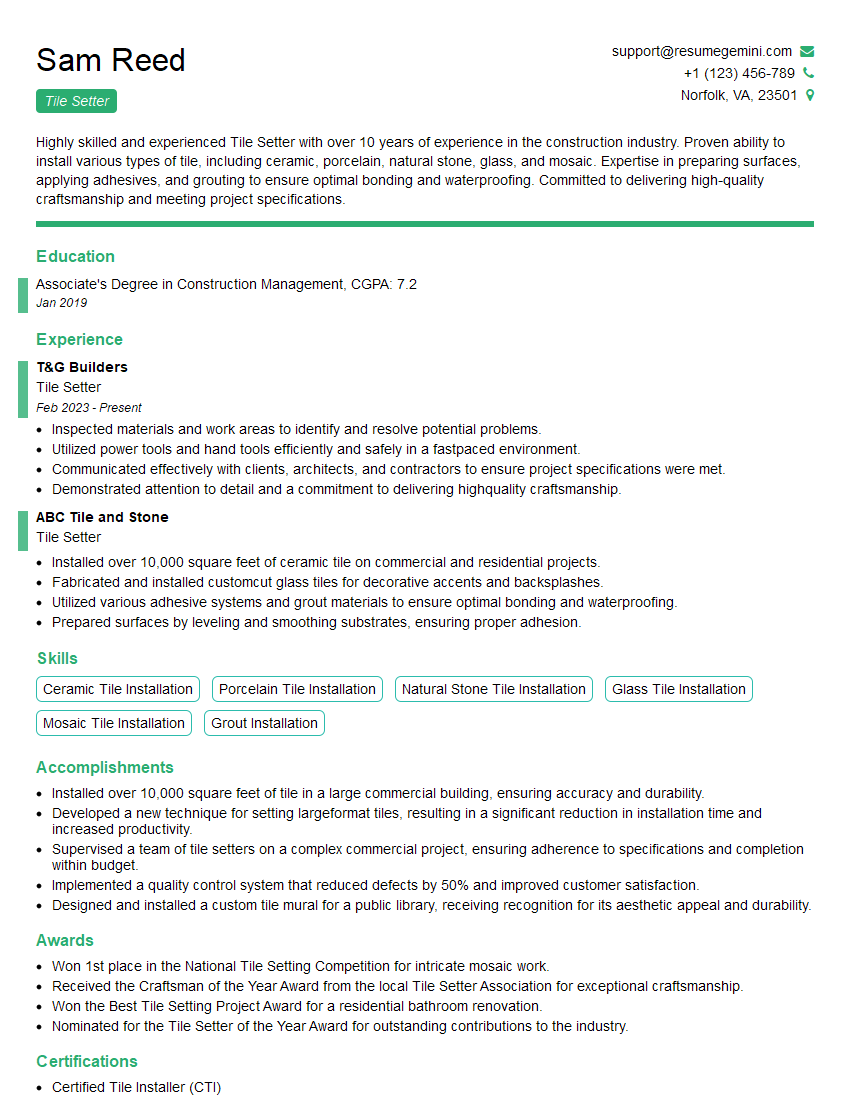

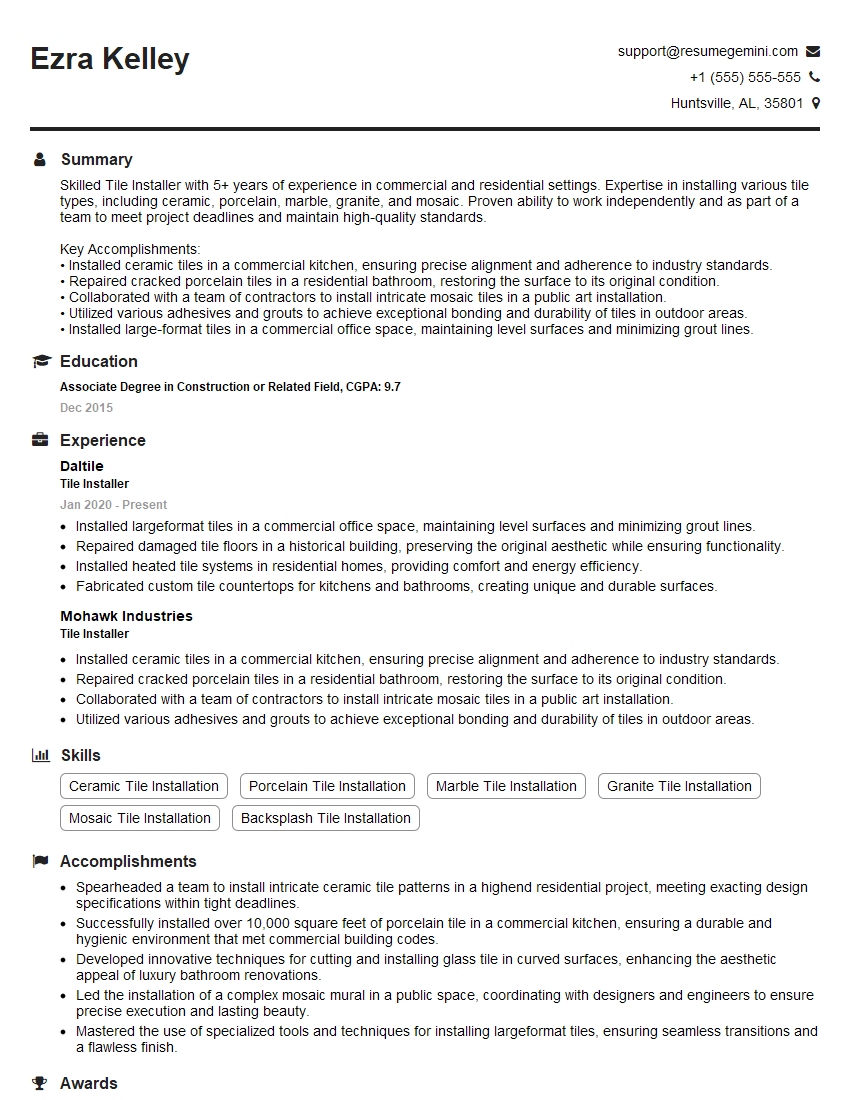

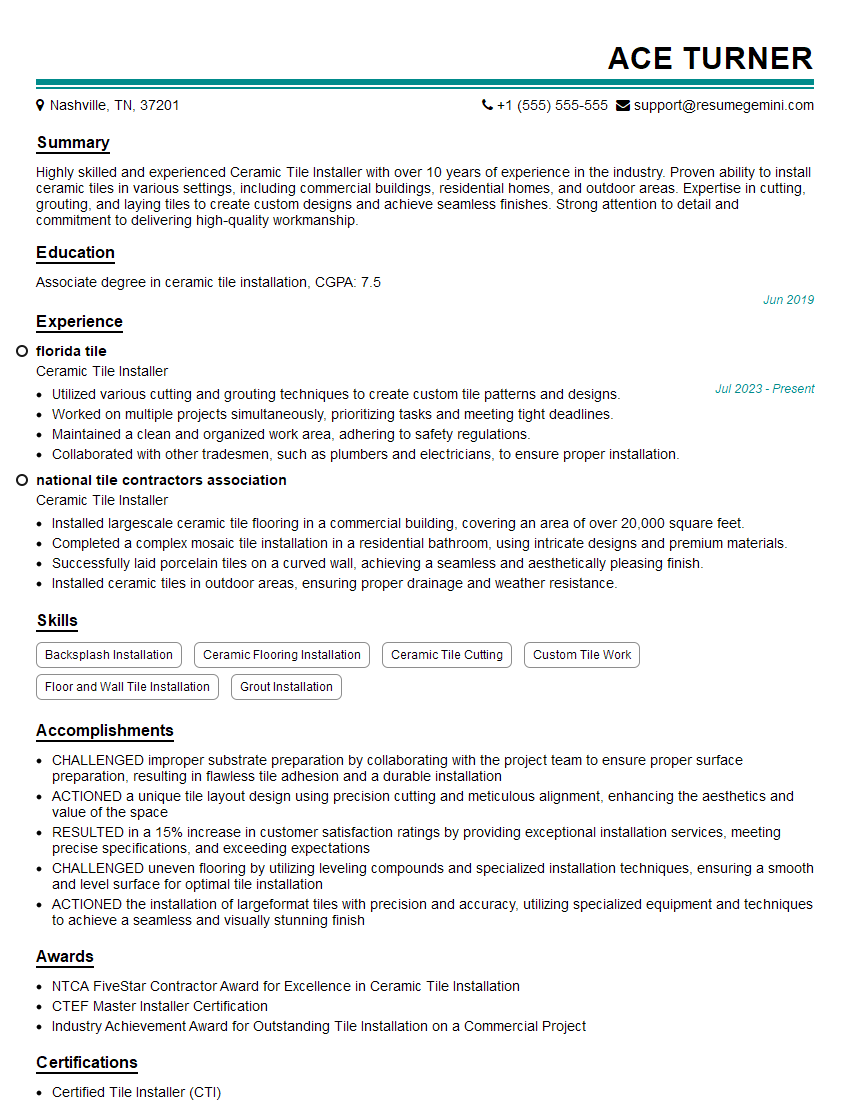

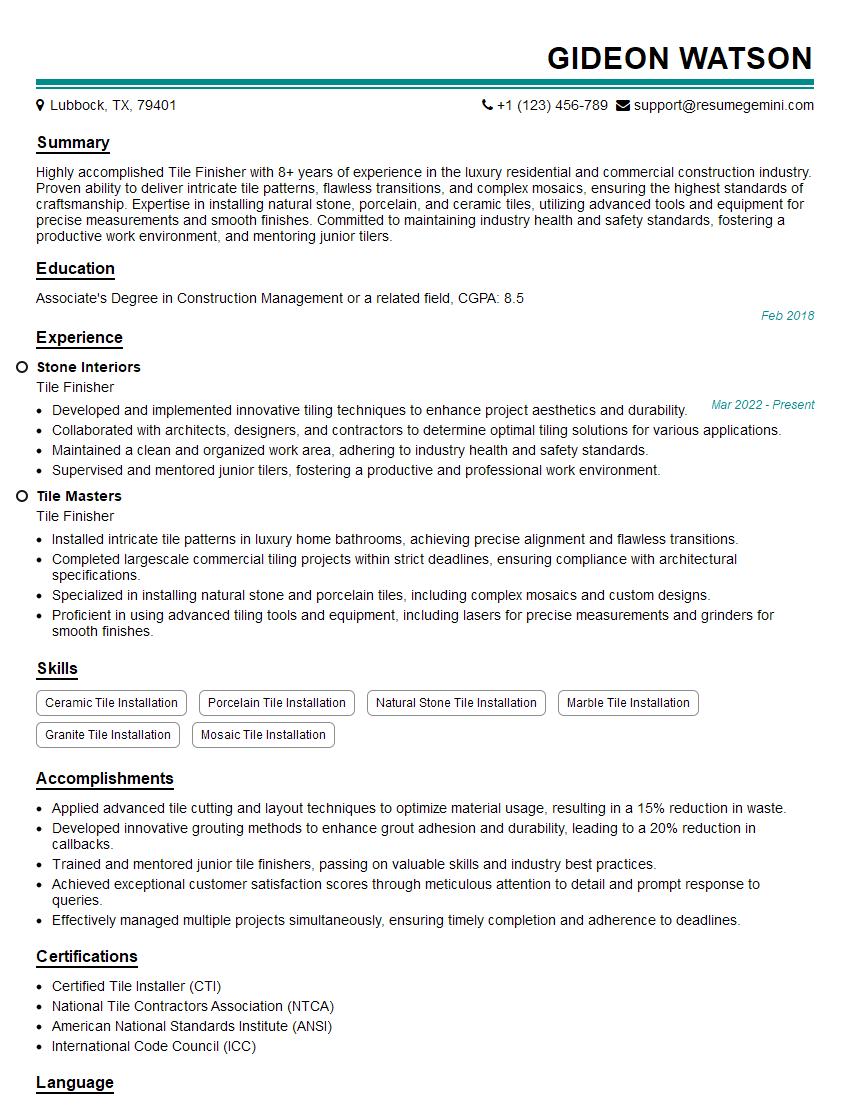

Mastering tile layout techniques significantly enhances your value as a front-end developer or UI/UX designer, opening doors to exciting opportunities in diverse industries. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience in tile layout. Examples of resumes specifically tailored to Tile Layout are available for your review, helping you present your qualifications effectively to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456