The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Tiling and Flooring interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Tiling and Flooring Interview

Q 1. What types of tile are you experienced with installing?

My experience encompasses a wide range of tile types, including ceramic, porcelain, natural stone (marble, granite, travertine), glass, and even some specialty tiles like metal or large-format porcelain slabs. I’m comfortable working with different tile sizes, thicknesses, and finishes, understanding that each material requires a slightly different approach to installation. For instance, porcelain tiles, known for their durability, often necessitate a more precise cutting technique compared to ceramic tiles. Natural stone, on the other hand, requires extra care to avoid cracking or chipping during handling and installation.

- Ceramic Tile: A common and versatile option, available in numerous colors, sizes, and finishes.

- Porcelain Tile: Highly durable and water-resistant, ideal for high-traffic areas and wet environments.

- Natural Stone Tile: Offers a luxurious look and feel but requires more careful handling and sealing.

- Glass Tile: Adds a touch of elegance but needs precise installation to prevent breakage.

Q 2. Describe your experience with different tile laying patterns (e.g., running bond, herringbone).

I’m proficient in various tile laying patterns, each contributing a unique aesthetic to a space. The choice of pattern often depends on the room’s size, shape, and the client’s design preferences.

- Running Bond: The simplest and most common pattern, where tiles are laid in parallel rows with a staggered offset. Think of brickwork – it’s the same principle.

- Herringbone: A classic and visually appealing pattern formed by laying tiles in a V-shape, creating a zig-zag effect. This pattern requires more precise cutting and planning.

- Basketweave: This pattern uses rectangular tiles arranged in a woven pattern, reminiscent of a basket. It requires careful layout and cutting.

- Diagonal: Tiles are laid at a 45-degree angle, adding a dynamic feel to the space. This pattern demands accurate measurements and cutting to ensure straight lines.

For example, a herringbone pattern in a small bathroom might require more cuts and careful planning to minimize waste and maximize the visual impact, while a running bond pattern would be more suitable for a larger area and easier to install. I always discuss the pros and cons of different patterns with my clients to ensure the best fit for their project.

Q 3. Explain the process of preparing a subfloor for tile installation.

Subfloor preparation is crucial for a successful tile installation. A poorly prepared subfloor can lead to cracked tiles, uneven surfaces, and ultimately, project failure. The process typically involves these steps:

- Cleaning: Thoroughly remove any debris, dust, loose particles, or old adhesive from the subfloor.

- Assessing Flatness: Check the subfloor’s levelness using a long straight edge and a level. Any significant dips or high spots need to be addressed.

- Leveling: For minor imperfections, self-leveling compound can be used to create a smooth, even surface. Significant unevenness might require more extensive work like replacing damaged sections of the subfloor.

- Moisture Mitigation: Moisture is the enemy of tile. Testing for moisture content is essential, especially in basements or areas prone to dampness. A moisture barrier may be necessary to prevent moisture damage.

- Priming: Applying a primer helps to improve the bond between the subfloor and the thin-set mortar, ensuring better adhesion.

Imagine baking a cake – you wouldn’t use a cracked, uneven pan, would you? Similarly, a well-prepared subfloor is the foundation for a beautiful and long-lasting tile installation.

Q 4. What are the different methods for setting tile (thin-set, mastic)?

Tile setting methods depend on several factors, including the tile type and the subfloor condition. The two most common methods are thin-set mortar and mastic.

- Thin-set Mortar: A cement-based adhesive that provides excellent bonding strength and is suitable for most tile types. It’s ideal for larger tiles, areas with potential movement, or when a longer-lasting installation is required. Application involves spreading a thin layer of mortar onto the subfloor, then embedding the tiles firmly.

- Mastic: A more flexible, organic adhesive, often used for smaller tiles and less demanding applications. Mastic is easier to clean up, but is less durable and less suitable for large-format tiles or wet areas.

Choosing the right method is crucial. For instance, I’d never use mastic for large porcelain tiles in a shower; thin-set mortar is the only appropriate option for such applications, providing the necessary strength and moisture resistance.

Q 5. How do you ensure proper grout spacing and application?

Consistent grout spacing and proper application are essential for a professional-looking and functional tile installation. Several techniques ensure this:

- Spacers: Plastic or other spacers are used to maintain uniform grout lines between tiles. These are crucial for consistent spacing and a clean aesthetic.

- Grout Application: Grout is applied by pressing it firmly into the joints between tiles, then removing excess grout with a damp sponge. I use a specialized grout float to ensure even filling.

- Grout Cleaning: Cleaning is vital for a high-quality finish. This requires removing excess grout immediately to avoid staining or discoloration.

Think of it like frosting a cake – you wouldn’t just slap it on. Careful application and cleanup are needed to create a clean and even finish. I often demonstrate to clients how to properly clean grout, so they understand how to maintain their new tile installation.

Q 6. How do you handle uneven subfloors?

Uneven subfloors present a challenge but are manageable with the right approach. The solution depends on the severity of the unevenness.

- Self-Leveling Compound: For minor imperfections, a self-leveling compound is an effective solution. This compound is poured onto the subfloor and self-levels to create a smooth surface.

- Backer Board: In cases of more significant unevenness, using a cement backer board can help to level the surface and create a solid base for tile installation.

- Subfloor Replacement: In extreme cases of damage or unevenness, subfloor replacement may be necessary before tiling can begin.

Addressing uneven subfloors is essential for preventing cracked tiles and ensuring a level installation. Failing to address this will result in a frustrating and ultimately costly mistake.

Q 7. What safety precautions do you take during tile installation?

Safety is paramount during tile installation. My safety procedures include:

- Personal Protective Equipment (PPE): This includes safety glasses, gloves, dust masks, and hearing protection. This safeguards against dust, debris, and potential eye injuries.

- Proper Tool Usage: I always ensure that all tools are in good working order and used correctly, following the manufacturer’s instructions. This minimizes risk of injury or accidents.

- Wet Area Safety: When working in wet areas, appropriate precautions must be taken to avoid slips, falls, and electric shock. This includes ensuring proper grounding of tools and using non-slip mats.

- Lifting Techniques: Tile is heavy! Using proper lifting techniques prevents back injuries and strain. I ensure proper handling of all materials.

Safety isn’t just about following rules, it’s about creating a proactive work environment that prioritizes the well-being of both myself and anyone else on site. It’s an essential part of a successful project.

Q 8. What tools and equipment are essential for tiling?

Having the right tools is paramount for efficient and high-quality tile installation. It’s not just about speed; the right tools ensure accuracy and prevent damage. My essential toolkit includes:

- Measuring Tools: Tape measure (accurate to 1/16th of an inch), a square (to ensure right angles), and a level (to check for even surfaces).

- Cutting Tools: A wet saw (for precise cuts, especially with ceramic and porcelain tiles), a tile nipper (for smaller cuts and adjustments), and a tile scorer (for scoring tiles before snapping them).

- Preparation and Application Tools: Notched trowels (to apply thin-set mortar, the size of the notch depending on the tile size and type), a rubber float (for smoothing the mortar and ensuring good tile adhesion), spacers (to maintain consistent grout lines), and a grout bag or float (for applying grout).

- Cleaning and Finishing: Sponges, buckets, a grout sponge, and a clean cloth for final wiping. Safety gear is crucial: safety glasses, gloves, and a dust mask.

For example, using a wet saw instead of a hand-held tile cutter significantly reduces chipping and ensures cleaner cuts, especially with larger format tiles. The notched trowel’s size directly affects the amount of mortar and the final bonding strength; a poorly chosen trowel can lead to uneven surfaces or tile failure.

Q 9. How do you calculate the amount of tile needed for a project?

Accurately calculating tile needs avoids costly mistakes and prevents running short mid-project. It involves several steps:

- Measure the area: Accurately measure the length and width of the area to be tiled. For complex shapes, break the area into smaller, easily measurable sections.

- Calculate the square footage: Multiply the length and width to get the total square footage (length x width = square footage).

- Account for waste: Add 10-15% extra to account for cuts, breakage, and mistakes. This percentage can increase for complex patterns or intricate cuts. For example, a room with many corners and obstacles may require 20% extra.

- Consider tile size and format: Large format tiles, while aesthetically pleasing, can sometimes lead to greater wastage due to more complex cuts.

- Check the packaging: Note that tile packaging often specifies the square footage covered per box. This allows for a double check on calculations and ensures the correct amount of tiles is ordered.

For instance, a 10ft x 12ft room is 120 square feet. Adding a 15% waste factor (120 * 0.15 = 18 square feet) gives a total tile requirement of 138 square feet. Remember to round up to the nearest whole box quantity when ordering.

Q 10. Describe your experience with waterproofing tile installations.

Waterproofing is critical in areas prone to moisture, like bathrooms and showers. My experience encompasses various waterproofing methods, including the use of waterproof membranes, such as Schluter-KERDI or similar products. This involves carefully applying the membrane to the substrate, ensuring all seams and corners are properly sealed. I’ve also worked with liquid waterproofing membranes which require meticulous application and several coats for optimal performance.

A critical aspect is ensuring a proper slope for water drainage. I carefully check the substrate for imperfections and ensure a consistent slope towards the drain, typically a minimum of 1/4 inch per foot. Failure to properly waterproof can lead to water damage, mold growth, and structural issues, making thorough and precise execution paramount. I always follow the manufacturer’s instructions diligently and conduct thorough inspections at each stage of the process.

Q 11. What are the common problems encountered during tile installation, and how do you address them?

Common tile installation problems often stem from poor preparation or execution. These include:

- Uneven substrate: An uneven substrate leads to uneven tile setting and potential cracking. This is addressed by leveling the substrate using self-leveling compounds or cement backer board.

- Improper mortar application: Insufficient or excessive mortar weakens the bond, causing tiles to loosen or crack. The correct notched trowel and application techniques are essential.

- Incorrect spacing: Inconsistent grout lines ruin the aesthetic appeal. Spacers are vital for maintaining even gaps.

- Poor grout application: Improperly applied grout can crack or shrink, creating gaps and allowing water penetration. Proper mixing and application are key, as well as allowing sufficient curing time.

- Tile breakage: Using the wrong cutting tools or poor cutting techniques often lead to breakage. Using the appropriate saw and exercising care while cutting are essential to prevent this.

My approach emphasizes careful planning, thorough substrate preparation, and meticulous execution of each step. Addressing problems promptly and systematically, often involving rectifying the underlying cause (like a poorly leveled floor), avoids costly rework and ensures a durable, aesthetically pleasing result. For example, identifying uneven substrate early and using a self-leveling compound prevents the need to remove and replace improperly set tiles.

Q 12. Explain your experience with different types of flooring materials (e.g., hardwood, laminate, vinyl).

My experience extends beyond tiling to other flooring materials. I’m proficient in installing hardwood, laminate, and vinyl flooring.

- Hardwood: This involves understanding wood types, acclimation procedures, proper nailing or gluing techniques, and finishing (sanding, staining, sealing).

- Laminate: Installation includes understanding the locking mechanisms, ensuring proper underlayment selection, and preventing moisture damage.

- Vinyl: This encompasses various types – sheet vinyl, luxury vinyl plank (LVP), and luxury vinyl tile (LVT) – each requiring different installation methods and considerations.

The key is understanding the specific requirements of each material, from substrate preparation to appropriate tools and adhesives. For example, hardwood installation demands precise measuring and cutting to minimize waste and avoid gaps, while laminate relies on a well-prepared subfloor and attention to interlocking the planks. Vinyl requires understanding the expansion and contraction characteristics of the material to prevent buckling or gaps.

Q 13. What is your experience with underlayment selection and installation?

Underlayment plays a crucial role in creating a stable, even, and comfortable floor surface. The selection of underlayment depends heavily on the flooring type being installed and the substrate conditions. For example:

- Hardwood: Requires underlayment that provides moisture protection and cushioning.

- Laminate: Needs underlayment that provides a vapor barrier and sound insulation.

- Vinyl: Can benefit from underlayment for added comfort and sound dampening, although some vinyl products have an integrated underlayment.

My experience includes installing various types of underlayment, from foam-based to rubber and cork, ensuring proper installation according to manufacturer instructions. A key consideration is ensuring the underlayment is compatible with the flooring type, properly sealed around any transitions, and correctly installed to avoid wrinkles, bumps, or voids under the flooring. Incorrect underlayment selection can lead to flooring failure, premature wear, or unwanted noises.

Q 14. How do you ensure proper transitions between different flooring types?

Smooth transitions between different flooring types are essential for both aesthetics and functionality. This often involves using transition strips or reducers. The choice of transition depends on several factors: height difference, flooring types, and aesthetics.

- Height differences: Large height differences might necessitate using a reducer strip that gradually slopes down from a taller floor to a shorter one. Smaller differences can sometimes be accommodated with a simple T-molding.

- Flooring types: The transition piece should be compatible with both flooring materials. For instance, a transition between hardwood and tile might require a specialized metal or wood transition strip.

- Aesthetics: Transition strips are available in various materials and finishes to match the existing flooring.

My approach focuses on carefully measuring the height difference and selecting the appropriate transition strip. Precise installation is crucial to ensure a seamless and aesthetically pleasing transition, preventing tripping hazards and maintaining the integrity of the different flooring materials. I pay close attention to detail and ensure the transition is securely fastened and properly finished to create a smooth and professional finish.

Q 15. What is your experience with measuring and cutting flooring materials?

Accurate measurement and precise cutting are fundamental to successful tiling and flooring projects. My experience spans over 10 years, working with a wide variety of materials including ceramic, porcelain, natural stone, hardwood, and vinyl. I utilize various measuring tools, from simple tape measures and rulers to laser measuring devices, depending on the project’s complexity and scale.

For example, when installing large format porcelain tiles, I use a laser measure for extreme accuracy to ensure perfectly aligned rows and minimize waste. For intricate cuts around pipes or fixtures, I employ a wet saw with a diamond blade for clean, precise cuts, avoiding chipping or fracturing the material. I also know how to effectively use various hand tools like tile nippers and scoring tools for smaller, more detailed cuts.

Before any cutting begins, I always double-check my measurements multiple times to avoid costly mistakes. Think of it like surgery – precision is paramount. A single inaccurate cut can ruin an entire section of flooring and require extensive rework.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with repairing damaged flooring.

Repairing damaged flooring requires a keen eye for detail and a thorough understanding of the material’s properties. My experience covers a broad range of repair techniques, adapting to the specific type of damage and flooring material.

- Cracked Tiles: I’ve repaired cracked ceramic and porcelain tiles using epoxy resin and carefully matched replacement tiles, ensuring a seamless blend with the existing flooring. The key here is to properly prepare the surface and use the correct adhesive for a strong bond.

- Scratched Hardwood: For superficial scratches on hardwood, I’ve used wood fillers and refinishing techniques, restoring the original finish. For deeper damage, I’ve often needed to replace individual planks, taking care to match the color and grain pattern as closely as possible.

- Damaged Vinyl: Repairing vinyl flooring usually involves patching with a compatible vinyl patch and using strong adhesive. I ensure the patch blends seamlessly with the surrounding area, minimizing visibility of the repair.

Successful repair isn’t just about fixing the immediate damage, it’s also about ensuring the structural integrity of the flooring and preventing further problems. Each repair is approached systematically, assessing the extent of the damage, choosing the appropriate materials, and carrying out the work methodically.

Q 17. How do you maintain a clean and organized worksite?

Maintaining a clean and organized worksite is crucial for safety and efficiency. I follow a strict procedure:

- Pre-Job Preparation: Before starting work, I thoroughly cover furniture and other items that cannot be removed, and protect the existing flooring. I organize materials and tools in designated areas, ensuring easy access to everything I need.

- Daily Cleanup: At the end of each day, I remove all debris, sweep and vacuum the work area. Tools are cleaned, organized and stored properly to prevent accidents.

- Waste Disposal: I dispose of all waste materials responsibly, following local regulations for construction waste.

- Protective Gear: Appropriate safety gear like dust masks, eye protection, and gloves are worn at all times.

A clean workspace isn’t just about aesthetics; it directly impacts safety, preventing accidents and allowing for more efficient workflow. It also shows respect for the client’s property.

Q 18. Describe your experience working independently and as part of a team.

I’m comfortable working both independently and as part of a team. Working independently requires self-motivation, excellent time management, and problem-solving skills – all qualities I’ve honed over years of experience. For instance, I’ve successfully completed numerous smaller projects alone, from installing tile backsplashes to refinishing individual hardwood floors.

Teamwork is also a vital aspect of larger projects. I’ve been a part of teams of up to five professionals on large-scale commercial projects. In these situations, effective communication, coordination, and cooperation are essential. I contribute actively to team discussions, sharing my expertise and offering support to my colleagues. Recently, we successfully installed flooring in a large office building, utilizing a team approach that ensured a seamless and timely completion.

Q 19. What is your experience with reading and interpreting blueprints?

Reading and interpreting blueprints is a critical skill for any successful flooring installer. My experience includes working with a variety of blueprints, from simple residential floor plans to complex commercial layouts. I’m proficient in understanding symbols, dimensions, specifications, and notations related to flooring materials, installations, and finishes.

I understand how to translate the blueprint’s information into a practical installation plan, accounting for factors such as door locations, transitions between different flooring materials, and existing structural elements. For example, I can accurately determine the quantity of materials needed based on the blueprint dimensions and factor in waste to avoid running short. I can also identify potential challenges early on, allowing for proactive solutions.

Q 20. How do you manage your time effectively on a project?

Effective time management is essential for staying on schedule and within budget. My approach involves a multi-step process:

- Project Planning: Thorough initial planning, including material ordering and scheduling, is critical. I break down large projects into smaller, manageable tasks with realistic deadlines.

- Prioritization: I prioritize tasks based on their dependency and importance, focusing on critical path activities.

- Regular Monitoring: Throughout the project, I regularly monitor progress, identifying and addressing potential delays proactively. If needed, I adjust my schedule accordingly, and communicate any changes to the client.

- Efficient Workflow: I streamline my workflow to minimize wasted time and maximize productivity, utilizing tools and techniques that enhance efficiency.

Time management is not simply about speed, it’s about strategic planning and effective execution. It allows me to consistently deliver high-quality results on time and within budget.

Q 21. Describe your experience with different types of adhesives and sealants.

My experience with adhesives and sealants is extensive, encompassing various types suited for different flooring materials. Understanding the properties of each adhesive is key to a successful installation.

- Thin-Set Mortar: I regularly use thin-set mortar for ceramic and porcelain tile installations, understanding the importance of proper mixing and application for optimal adhesion.

- Construction Adhesive: This is a versatile adhesive used for hardwood flooring, vinyl, and some stone installations. I’m skilled in selecting the appropriate type for each material and applying it correctly for a strong bond.

- Epoxy Adhesives: For demanding applications and large-format tiles, I use epoxy adhesives, which offer superior strength and water resistance.

- Sealants: I use sealants to protect against moisture and create a finished look, choosing the appropriate type based on the material (e.g., silicone for bathrooms, polyurethane for hardwood).

Knowing the right adhesive for the job—and knowing how to use it correctly—is paramount for a long-lasting, durable installation. I have experience dealing with various adhesion challenges, such as uneven substrates and difficult materials, and have the skills to solve them effectively.

Q 22. How do you handle customer communication and expectations?

Effective customer communication is paramount in the tiling and flooring industry. It’s about building trust and managing expectations from the initial consultation to project completion. I begin by actively listening to understand the client’s vision, needs, and budget. I then present various options, explaining the pros and cons of different materials and installation methods in clear, non-technical terms. This includes providing realistic timelines and cost breakdowns, addressing any concerns upfront. Regular updates throughout the project—via phone calls, emails, or even photos of progress—keep clients informed and engaged. Finally, I always welcome feedback and address any concerns promptly and professionally. For instance, I recently worked with a client who was unsure about the grout color. We spent extra time reviewing samples in different lighting conditions to ensure they felt confident in their final selection. This extra effort resulted in a satisfied client and a positive review.

Q 23. What is your experience with troubleshooting installation issues?

Troubleshooting is an integral part of this job. Experience has taught me to systematically identify the root cause of problems. For example, if tiles are cracking, I’d first assess the subfloor for unevenness or moisture issues, then check the adhesive type and application technique. If grout is cracking, it could be due to improper mixing, insufficient curing time, or movement in the substrate. My approach is to always investigate the problem thoroughly, ensuring I understand the underlying cause before implementing a solution. I’m proficient in using various diagnostic tools, and I’m not afraid to consult with manufacturers or suppliers when necessary to ensure the best outcome. For instance, I once encountered significant expansion in a ceramic tile installation. By using a moisture meter, I discovered excessive subfloor moisture leading to the problem. The solution involved installing a vapor barrier before proceeding with the installation.

Q 24. Describe your experience with working on both residential and commercial projects.

My experience spans both residential and commercial projects, and I’ve found that while the fundamental principles of tiling and flooring remain the same, the scale and demands differ significantly. Residential projects often involve more intricate design elements and personalized touches, requiring close collaboration with homeowners. Commercial projects, on the other hand, necessitate adherence to strict deadlines, detailed specifications, and often involve larger teams and specialized equipment. For example, a recent residential project involved hand-cut mosaic tiles, while a commercial project involved installing large-format porcelain tiles in a high-traffic area, requiring precise leveling and specialized adhesives for durability. I’m comfortable navigating the unique challenges of both environments.

Q 25. What is your experience with estimating project costs and timelines?

Accurate cost and timeline estimation is critical. My process starts with a thorough site assessment, taking precise measurements and identifying any potential complexities. I then create a detailed breakdown of materials, labor, and any additional costs such as disposal fees or permits. My estimations incorporate contingency factors to account for unexpected challenges. I utilize specialized software to aid in this process, ensuring accuracy and consistency. I’ve developed a refined approach over time, making my estimates increasingly reliable. For instance, I’ve learned to factor in potential delays due to weather conditions, material availability, and other variables that might arise during a large-scale project.

Q 26. What are the latest trends in tiling and flooring?

The tiling and flooring industry is constantly evolving. Currently, we see a strong trend towards large-format tiles, offering a sleek and modern aesthetic. Sustainable materials, such as recycled glass tiles and bamboo flooring, are gaining popularity as consumers become more environmentally conscious. Luxury vinyl plank (LVP) and luxury vinyl tile (LVT) continue to grow in demand due to their durability, water resistance, and ease of maintenance. Textured finishes and natural stone-look tiles are also trending, offering a luxurious feel without the high cost of natural stone. Finally, the use of technology is significantly improving efficiency, with innovations like laser-leveling systems and robotic tile cutters gaining ground.

Q 27. Describe your experience with using power tools safely.

Safety is my top priority. I’m thoroughly trained in the safe operation of all power tools commonly used in tiling and flooring, including wet saws, angle grinders, and tile cutters. Before using any tool, I always inspect it for damage and ensure I have the correct personal protective equipment (PPE), including safety glasses, hearing protection, and dust masks. I follow all manufacturer’s instructions and adhere to workplace safety regulations. I also regularly maintain my tools to ensure they’re in optimal working condition and minimize the risk of accidents. My experience has taught me the importance of careful planning and a meticulous approach to minimize any hazards during the operation of power tools.

Q 28. What is your process for quality control during and after installation?

Quality control is a continuous process throughout the project. I begin by inspecting materials upon delivery, ensuring they meet the specified quality standards. During installation, I regularly check for levelness, alignment, and proper adhesive application. Once the installation is complete, I perform a final inspection, carefully checking for any imperfections, such as uneven grout lines or cracked tiles. I use precision tools to ensure accuracy and maintain consistent quality. Client feedback is also an essential part of my quality control process. I encourage clients to provide feedback and address any concerns or issues they might have. This continuous feedback loop helps me refine my processes and consistently deliver high-quality results. Documentation, including photographic records, is kept throughout the project to record every stage of the work and ensure transparency.

Key Topics to Learn for Your Tiling and Flooring Interview

- Materials and Their Properties: Understanding the characteristics of various tiles (ceramic, porcelain, natural stone, etc.) and flooring materials (wood, laminate, vinyl, etc.) – including their durability, water resistance, and maintenance requirements. Practical application: Knowing which material is best suited for different areas (e.g., bathroom vs. living room).

- Installation Techniques: Mastering the practical skills of tiling and flooring installation, including substrate preparation, adhesive selection and application, grouting, and finishing techniques. Practical application: Describing your experience with different installation methods and your problem-solving skills when faced with uneven surfaces or challenging installations.

- Tools and Equipment: Familiarity with the various tools and equipment used in tiling and flooring, including their proper use and maintenance. Practical application: Demonstrating knowledge of safety procedures and best practices for using power tools.

- Measuring and Planning: Accurate calculation of materials needed, understanding layout designs, and creating detailed plans for installations. Practical application: Explaining your process for calculating quantities and minimizing waste.

- Health and Safety: Adhering to safety regulations and best practices to prevent accidents and injuries. Practical application: Describing your experience implementing safety protocols on the job site.

- Troubleshooting and Problem Solving: Identifying and resolving common issues encountered during installations, such as uneven surfaces, cracked tiles, or grout problems. Practical application: Giving examples of how you’ve successfully addressed challenging situations in the past.

- Industry Standards and Codes: Familiarity with relevant building codes and industry best practices. Practical application: Demonstrating an understanding of relevant regulations and how they impact your work.

Next Steps

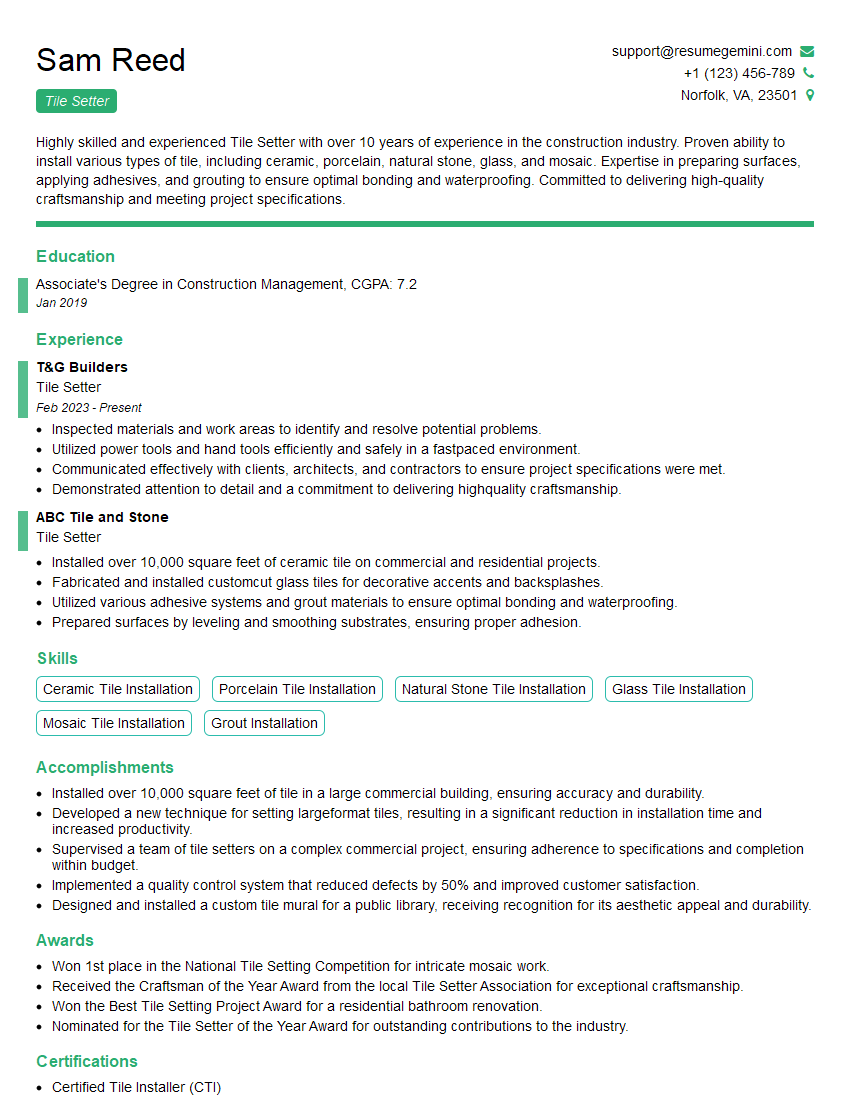

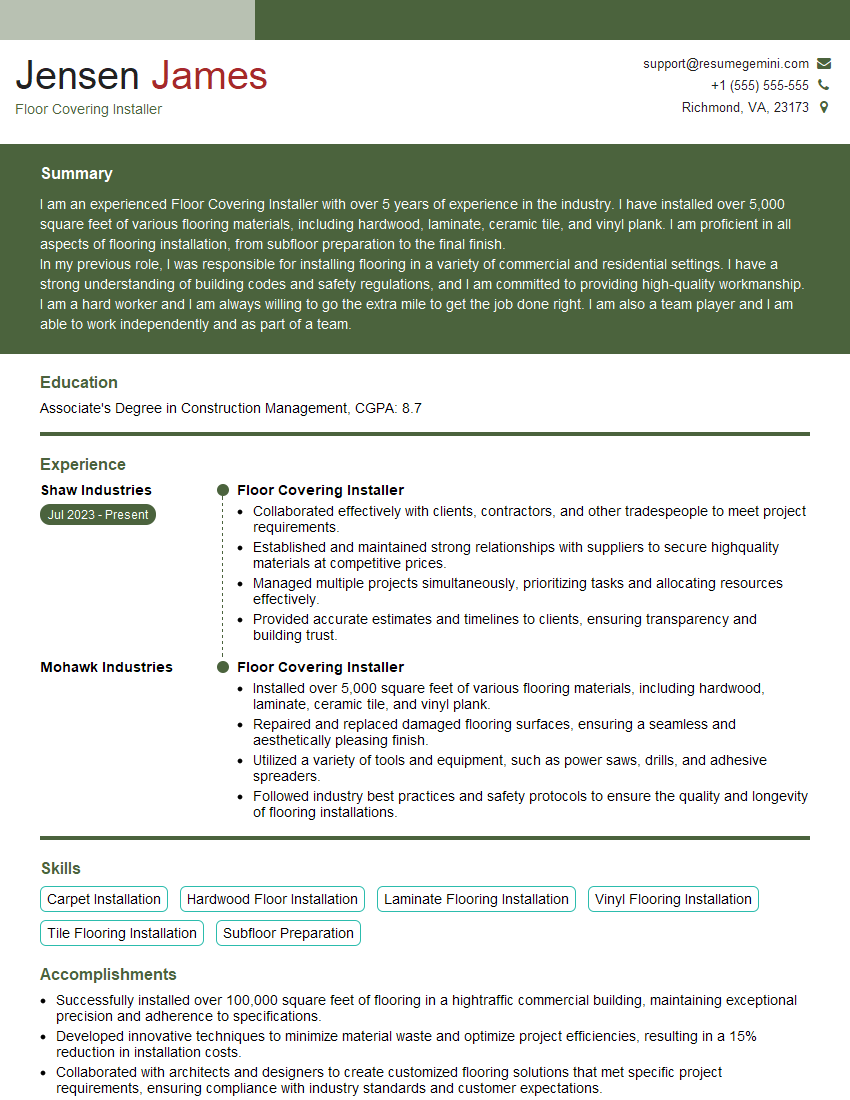

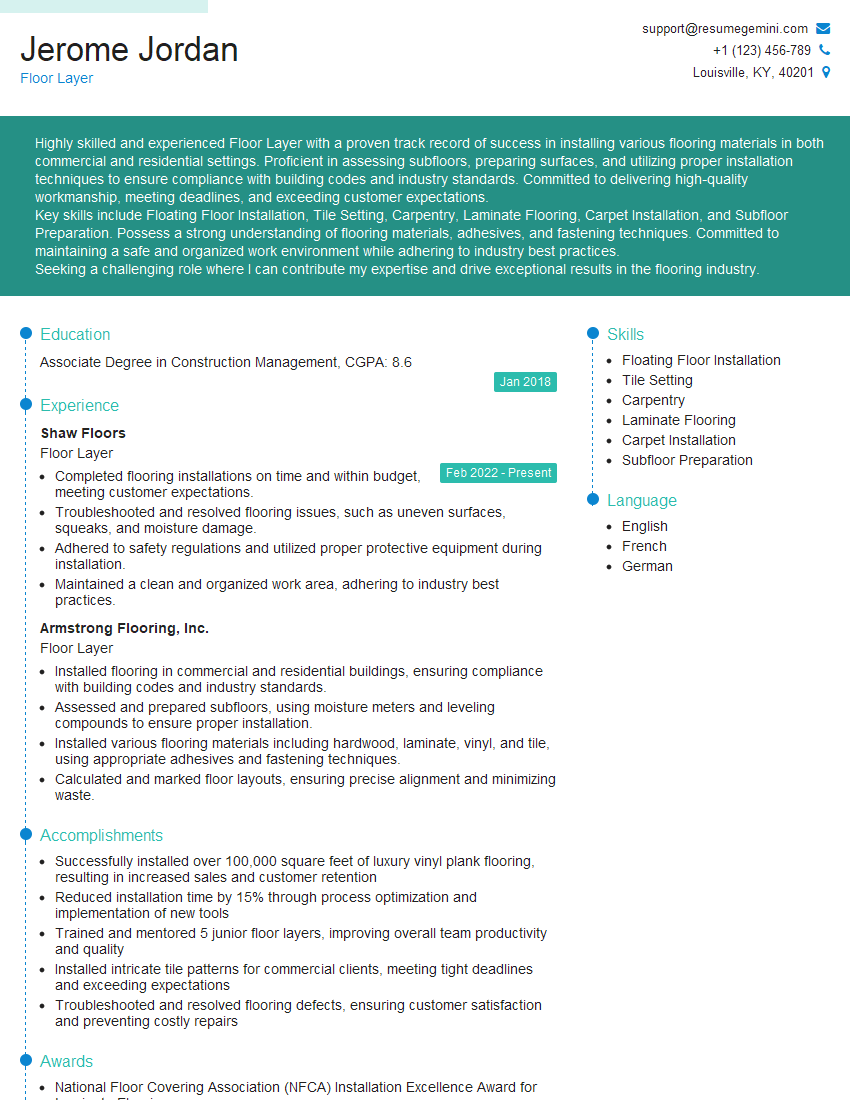

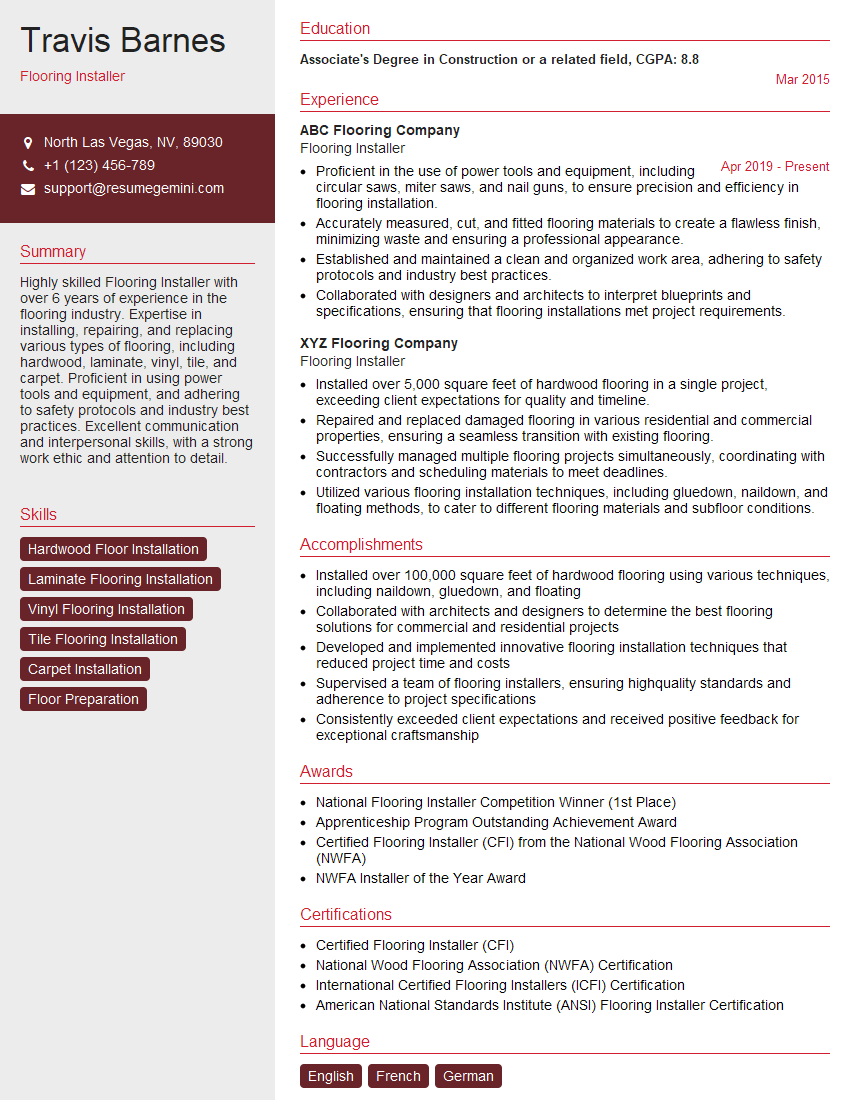

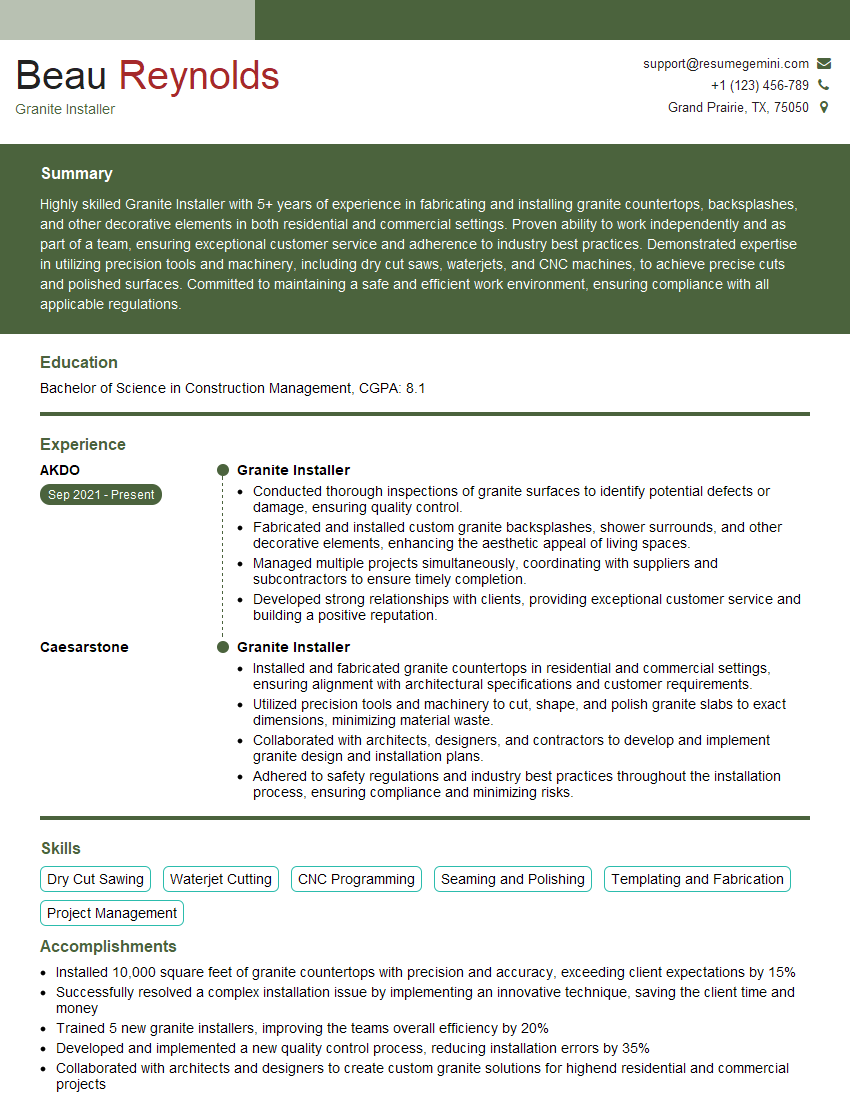

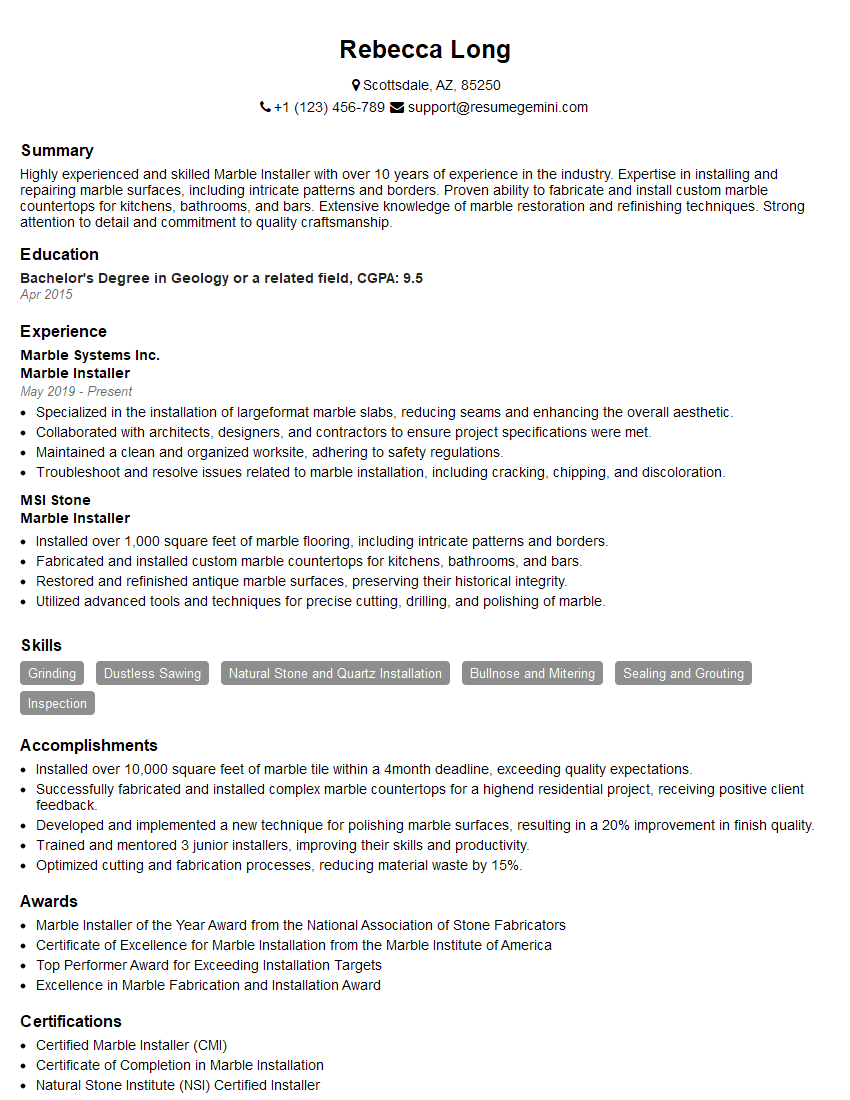

Mastering the skills and knowledge of tiling and flooring opens doors to a rewarding and diverse career path, offering opportunities for advancement and specialization. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. We offer examples of resumes tailored specifically to the Tiling and Flooring industry to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?