Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Trim Work interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Trim Work Interview

Q 1. What types of wood are commonly used for trim work?

The choice of wood for trim work depends heavily on the desired aesthetic, budget, and durability requirements. Some of the most common choices include:

- Pine: A very popular and affordable option, pine is relatively soft and easy to work with, making it ideal for DIY projects. However, it’s more prone to dents and scratches.

- Fir: Similar to pine in terms of workability and cost, fir offers slightly more durability and a straighter grain.

- Oak: A hardwood known for its strength, durability, and beautiful grain pattern. Oak is more expensive than softwoods but offers a superior, long-lasting finish. Different oak varieties (red, white) offer varying color and grain characteristics.

- Maple: Another hardwood, maple is dense and hard, resistant to dents and scratches. It’s a popular choice for a clean, contemporary look.

- Poplar: A relatively inexpensive hardwood, poplar is easy to paint and takes stain well. It’s a good compromise between cost and durability.

Ultimately, the best wood for your trim depends on your specific needs and preferences. For high-traffic areas, hardwoods are recommended. For areas with less wear and tear, softwoods can be a cost-effective choice.

Q 2. Explain the process of installing crown molding.

Installing crown molding is a multi-step process requiring precision and patience. Here’s a breakdown:

- Preparation: Measure the perimeter of the room and purchase enough crown molding, considering waste for cuts. Ensure walls are clean, smooth, and free of any debris.

- Cutting and Mitering: Using a miter saw, cut the molding at 45-degree angles for inside and outside corners. Precise cuts are crucial for a clean, seamless finish. Practice on scrap pieces first.

- Applying Adhesive: Apply a high-quality construction adhesive to the back of the molding, ensuring even coverage. For larger pieces, consider using additional nails or pins for extra security.

- Installation: Starting in a corner, carefully press the molding against the wall and ceiling, ensuring it’s flush and aligned. Use a level to check for plumb and straight lines.

- Securing: Use finishing nails to secure the molding in place. Countersink the nails carefully and fill the holes with wood filler once the adhesive has cured.

- Caulking: Caulk any gaps between the molding and the wall or ceiling. Choose a paintable caulk that matches your wall color.

- Sanding and Finishing: Once the caulk is dry, lightly sand the area to smooth out any imperfections. Prime and paint the crown molding to match your desired décor.

Remember to always work with a partner for longer pieces to ensure proper support and alignment during installation.

Q 3. How do you measure and cut angles for mitered corners?

Accurately measuring and cutting angles for mitered corners is essential for a professional-looking trim installation. Here’s the process:

- Measure Carefully: Precise measurements are crucial. Measure the length of each piece of molding needed for the corner.

- Set the Miter Saw: For inside corners, set the miter saw to a 45-degree angle on one side, and for outside corners, set it to 45 degrees on the other side. This ensures the pieces meet precisely.

- Test Cut: Always make a test cut on a scrap piece of the same molding to ensure the angle is correct before cutting the actual pieces. This prevents wasted material.

- Cut the Molding: Carefully place the molding against the miter saw fence and make the cut.

- Dry Fit: Before applying adhesive, dry fit the pieces together to verify the fit. Make any necessary adjustments before applying adhesive.

Using a speed square or a protractor can help ensure accurate angle measurements, especially when dealing with complex angles. Remember, practice makes perfect when it comes to mitering.

Q 4. Describe your experience with different types of wood adhesives.

My experience encompasses a variety of wood adhesives, each with its strengths and weaknesses:

- Construction Adhesives: These are strong, gap-filling adhesives suitable for most trim work. They offer a strong bond and are relatively quick-setting. Examples include Liquid Nails and similar brands.

- Wood Glues: While not always as gap-filling, wood glues provide a very strong bond when surfaces are perfectly aligned. They are ideal for applications where a clean, invisible bond is desired. Yellow wood glue is a common choice.

- Polyurethane Adhesives: These are very strong, water-resistant adhesives suitable for exterior applications or areas with high humidity. They are less forgiving than other adhesives, so precise alignment is crucial.

The choice of adhesive depends on the specific project requirements and the type of wood being used. For example, I would typically use construction adhesive for crown molding and wood glue for assembling intricate trim pieces.

Q 5. What are the common issues encountered during trim installation?

Common issues encountered during trim installation include:

- Uneven Walls: Inconsistent wall surfaces can make it challenging to achieve a flush finish. Techniques like shimming and using flexible caulk can help mitigate this issue.

- Inaccurate Cuts: Improperly mitered corners or inaccurate length cuts will lead to gaps and unsightly seams. Careful measuring and the use of quality tools are critical.

- Poor Adhesive Application: Insufficient or uneven adhesive application can result in weak bonds and potential failure.

- Nail Holes: Improperly countersunk nail holes can be visible after painting. Careful countersinking and wood filler application are necessary.

- Caulk Gaps: Leaving gaps uncaulked allows for drafts and a less professional finish. Thorough caulking is a must.

Careful planning, attention to detail, and using the right tools significantly reduce the likelihood of encountering these issues. Experience helps to anticipate and avoid these problems proactively.

Q 6. How do you handle discrepancies in wall surfaces?

Discrepancies in wall surfaces are a common challenge. My approach involves several strategies:

- Shimming: Small pieces of wood (shims) can be used to fill gaps and create a level surface for the trim. They are inserted between the wall and the trim before securing it.

- Flexible Caulk: Caulk can bridge minor gaps and imperfections, creating a seamless transition between the trim and the wall. It’s especially useful for uneven surfaces.

- Wood Filler: For larger gaps or imperfections, wood filler can be used to fill the voids, creating a smooth surface for the trim.

- Scribing: For severe wall irregularities, scribing is a technique where the trim is cut to precisely match the contour of the wall. This demands skilled craftsmanship.

The best solution depends on the severity of the discrepancy. For minor imperfections, shimming and caulk are usually sufficient. For larger discrepancies, more advanced techniques like scribing may be required.

Q 7. Explain your experience with installing baseboards and casings.

Baseboards and casings are foundational elements in trim work. My experience involves all aspects of their installation:

- Baseboards: I’m proficient in installing baseboards, including coping (cutting one piece to precisely fit against another), mitering at corners, and using shims for uneven floors. I understand how to account for transitions between different floor coverings.

- Casings: Casings around doors and windows require careful measurement and cutting to ensure a neat and professional look. I utilize various techniques, including mitering and coping, depending on the style and design.

I’ve worked with a variety of materials and styles, from simple, straight baseboards to more elaborate profiles. I’m familiar with installing baseboard shoe molding and other decorative elements to complement the baseboards and overall aesthetic.

In a recent project, I successfully installed intricate casings around arched doorways, requiring precise measurements and skilled craftsmanship. The client was exceptionally pleased with the finished product.

Q 8. What tools and equipment are essential for efficient trim work?

Efficient trim work relies on a well-equipped toolbox. The essentials include precision measuring tools, like a tape measure, combination square, and speed square, ensuring accurate cuts. Cutting tools are crucial; a miter saw (both compound and sliding options are beneficial depending on the project scale and complexity) provides clean, accurate angles for miter joints. A hand saw is useful for smaller cuts and intricate work. Beyond cutting, you’ll need a selection of clamps (various sizes and types to accommodate different applications), a nail gun (for efficient fastening) and various sizes of finishing nails. Finally, safety equipment is paramount and includes safety glasses, hearing protection, and a dust mask to protect against wood dust and debris.

- Precision Measuring: Tape measure, combination square, speed square.

- Cutting Tools: Miter saw (compound and sliding), hand saw.

- Fastening: Nail gun, finishing nails.

- Clamping: Assorted clamps.

- Safety: Safety glasses, hearing protection, dust mask.

Q 9. How do you ensure accurate measurements for trim installation?

Accurate measurements are the foundation of successful trim installation. I always start by carefully measuring the area where the trim will be installed, considering all the angles and potential obstacles. I use a combination square and a tape measure to ensure precision, checking the measurements at multiple points to account for any inconsistencies in the wall. For example, when installing baseboard, I’ll measure the length of each wall section, but I also measure the distance between adjacent walls to ensure a perfect fit at the corners. For angles, I utilize the speed square, marking exact cuts for precise miter joints. Finally, I double-check all measurements before cutting to avoid costly mistakes. It’s like building with LEGOs – each piece needs to be the right size for the structure to stand strong and look beautiful.

Q 10. What safety precautions do you take during trim installation?

Safety is my top priority. Before starting any trim installation, I always assess the workspace for hazards. I ensure the area is well-lit and clear of obstacles. I consistently wear safety glasses to protect my eyes from flying debris. I also use hearing protection, especially when using power tools like the miter saw and nail gun. A dust mask is essential to prevent inhaling wood dust, which can cause respiratory problems. Furthermore, I make sure to use proper lifting techniques when handling heavier pieces of trim to prevent back injuries. I always work according to the manufacturer’s instructions for any equipment or materials I use.

For instance, before using the nail gun, I always check that the nail magazine is properly loaded and that the safety mechanism is working correctly. It’s better to be overly cautious than to risk an accident.

Q 11. Describe your experience with installing wainscoting.

I have extensive experience installing wainscoting, from simple panel designs to more intricate, multi-layered installations. I am familiar with various materials, including wood, MDF, and PVC. My process begins with meticulous preparation, ensuring the wall surface is clean, smooth, and level. I then accurately measure and cut the panels, paying close attention to achieving precise miter joints at the corners. I use a combination of adhesive and fasteners to secure the panels, ensuring a secure and long-lasting installation. I’ve worked on projects featuring both traditional and contemporary wainscoting designs, tailoring my approach to match the client’s aesthetic vision. One particular project involved installing hand-carved wainscoting in a Victorian-era home, where meticulous attention to detail was crucial in preserving the historical character of the space.

Q 12. How do you manage time effectively on a trim installation project?

Effective time management is vital in trim installation. I always begin by creating a detailed plan outlining each step, factoring in potential challenges or delays. This includes accurately estimating the time needed for each phase, from measuring and cutting to installation and finishing. I then prioritize tasks based on their dependencies, ensuring a smooth workflow. I use checklists to track progress and prevent overlooking any steps. For larger projects, I might break down the work into smaller, manageable chunks, assigning deadlines for each. Communication with the client regarding any potential delays or changes is also crucial for maintaining project timelines.

For example, I’ll often prep all the cuts for one wall before moving to the next, maximizing efficiency. This eliminates back-and-forth movement and allows for a smoother workflow.

Q 13. What is your experience with different types of finishing techniques?

I’m proficient in various finishing techniques, including painting, staining, and clear coating. My experience spans different types of finishes, such as gloss, semi-gloss, satin, and matte, each offering a unique aesthetic and level of durability. I understand the importance of proper surface preparation before applying any finish, including sanding and cleaning to create a smooth, even surface. I carefully select the appropriate type of paint, stain, or sealant based on the type of wood and the desired final look. I also utilize different application techniques, such as brushing, rolling, and spraying, to achieve a professional and even finish. I’m adept at troubleshooting issues, such as drips, runs, and uneven coverage, and I can create custom finishes to achieve specific aesthetic results. I often use a combination of techniques to achieve a desired effect. For example, I might stain oak trim to enhance its natural grain and then apply a clear coat for protection.

Q 14. How do you deal with challenging angles or curves in trim work?

Dealing with challenging angles and curves requires precision and adaptability. For angles, I use a miter saw to create precise cuts at various angles. For intricate angles that are difficult to pre-cut, I use a coping saw to carefully cut the trim to fit the shape. When working with curves, I often use flexible trim or carefully cut and shape the trim to match the contour, creating a seamless, professional finish. Careful measurement and marking are paramount, and I sometimes create templates to aid in achieving accurate cuts on complex curves. I always prioritize accuracy over speed, ensuring a perfect fit even in challenging circumstances. Think of it like a tailor – you have to measure, cut and adjust very carefully to ensure a perfect fit for that individual.

Q 15. Explain your understanding of building codes related to trim work.

Building codes concerning trim work primarily focus on safety, accessibility, and fire protection. They dictate minimum dimensions, material requirements, and installation methods to ensure structural integrity and prevent hazards. For instance, codes often specify the required fire-resistant rating for trim around doorways in certain occupancies. They also address accessibility requirements, such as ensuring sufficient space around doors and windows for wheelchair access, influencing trim placement and dimensions. Specific code requirements vary depending on location and the type of building (residential, commercial, etc.), so familiarity with local and national building codes is essential for any trim installer. For example, in some jurisdictions, the type of wood used for trim in certain areas might be restricted due to fire safety regulations.

- Fire Safety: Codes often mandate specific fire-resistant materials for trim near exits and in fire-rated walls.

- Accessibility: Trim installation must not impede accessibility requirements for people with disabilities.

- Structural Integrity: Trim should be properly secured to avoid compromising the structural integrity of the building.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot problems during trim installation?

Troubleshooting trim installation problems involves a systematic approach. I start by identifying the specific issue—is it a gap, a crooked piece, damage to the trim itself, or a problem with the wall surface? Then, I carefully examine the cause. For example, gaps might result from uneven walls or improper measuring. Crooked trim could be due to inaccurate cutting, uneven support, or the wall being out of plumb. If the problem is with the wall, I address that first, using shims or other techniques to create a level surface. If the issue is with the trim itself, I might need to recut the piece or use a filler to address minor imperfections. I frequently use a combination square and level to ensure accuracy throughout the process. For instance, recently I encountered a problem where a baseboard didn’t sit flush against the floor. By using a level, I found the subfloor was uneven and was able to address it by using thin shims before installing the baseboard.

- Visual Inspection: Carefully examine the problem area to identify the root cause.

- Measurements: Accurate measurements and level checks are crucial for identifying uneven surfaces.

- Corrective Actions: Employ appropriate techniques such as shimming, filling, or recutting to rectify the problem.

Q 17. What is your experience with pre-fabricated vs. custom trim?

I have extensive experience with both pre-fabricated and custom trim. Prefabricated trim offers advantages in terms of speed and cost-effectiveness for standardized projects. It comes in consistent sizes and profiles, minimizing on-site cutting and reducing material waste. However, it lacks the flexibility to accommodate unique architectural designs or intricate details. Custom trim, on the other hand, provides unparalleled design freedom, allowing for the creation of unique pieces that perfectly integrate with the specific architectural style of a building. The process is more time-consuming and often more expensive, but the results are often worth it. For example, in a recent renovation, using custom-milled trim allowed us to seamlessly integrate the existing architectural style while addressing the specific requirements of the client.

- Prefabricated Trim: Efficient and cost-effective for standardized projects but lacks design flexibility.

- Custom Trim: Allows for unique designs but is more time-consuming and expensive.

Q 18. Describe your experience working with different types of trim profiles.

My experience encompasses a wide range of trim profiles, from simple colonial profiles to more ornate Victorian styles. I’m proficient in working with various materials, including hardwoods (oak, cherry, maple), softwoods (pine, fir), and engineered wood products (MDF, plywood). Different profiles require different installation techniques and attention to detail. A simple flat profile is relatively straightforward, while more complex profiles might need more precise cutting and fitting. I’ve worked extensively with crown molding, baseboards, casings, chair rails, and other decorative elements. Understanding the nuances of each profile is critical for achieving a professional finish.

- Crown Molding: Requires precise miter cuts and careful alignment for a seamless appearance.

- Baseboards: Need proper fitting against walls and floors, often requiring shimming for uneven surfaces.

- Casings: Demand accurate measurements and careful fitting around doors and windows.

Q 19. How do you maintain the quality and consistency of your trim work?

Maintaining quality and consistency in trim work involves meticulous attention to detail throughout the entire process. It begins with careful planning and accurate measurements. I always use a quality level and measuring tools to ensure accuracy. I take extra care when cutting to ensure clean, precise cuts. This often involves using a miter saw with a fine-tooth blade. After installation, I inspect each piece to ensure it’s properly aligned, secure, and free from gaps or imperfections. I meticulously fill any gaps and sand thoroughly before applying a high-quality finish. Consistent use of quality materials and tools plays a significant role in achieving a uniform finish. For example, I always prime and paint my trim before installation, ensuring a consistent color and finish throughout the project.

- Accurate Measurements: Essential for precise cuts and proper fitting.

- Precise Cutting: Using sharp tools and proper techniques ensures clean cuts.

- Careful Installation: Ensuring proper alignment and security.

- Quality Finishing: Proper priming, painting, and sanding are key to achieving a high-quality finish.

Q 20. What is your experience with using power tools for trim work?

I’m highly proficient in using various power tools for trim work, including miter saws, table saws, routers, and nail guns. I understand the safe and effective operation of each tool, always prioritizing safety. I regularly maintain my tools to ensure they’re functioning optimally, resulting in accurate cuts and efficient work. I’m particularly skilled at using a miter saw for making accurate compound miter cuts necessary for crown molding and other intricate trim pieces. I also use a router to create various profiles and details in the trim. Safety is paramount; I always use appropriate safety gear, including eye protection, hearing protection, and dust masks. For example, before each project, I inspect my blades for sharpness and ensure that the miter saw is properly calibrated to guarantee precise angles.

- Miter Saw: For accurate miter and compound miter cuts.

- Table Saw: For rip cuts and cross cuts of larger trim pieces.

- Router: For creating intricate profiles and details.

- Nail Gun: For efficient and secure fastening.

Q 21. How do you manage material waste during a trim installation project?

Managing material waste is crucial for both environmental responsibility and cost efficiency. My approach starts with meticulous planning and accurate measurements to minimize material waste from the outset. I use efficient cutting techniques and optimize the layout of trim pieces to maximize material utilization. Any scrap wood is carefully saved and repurposed for smaller projects whenever possible. For larger projects, I collaborate with my team to ensure efficient waste management strategies are implemented. For example, in the past I developed a system for categorizing and storing trim scraps based on length and width, helping to utilize leftover material for smaller projects later on. This minimized waste and resulted in significant cost savings.

- Accurate Planning & Measurement: Reduces initial material waste.

- Efficient Cutting Techniques: Optimizes material use.

- Scrap Repurposing: Utilizing scraps for smaller projects whenever possible.

- Team Collaboration: Implementing waste management strategies across the project team.

Q 22. Describe a time you had to problem-solve a difficult trim installation.

One challenging trim installation involved a complex crown molding installation in a room with several angles and an unusually high ceiling. The initial design didn’t account for slight variations in the wall’s alignment, leading to gaps and inconsistencies. My solution involved carefully measuring each section individually, creating custom miter cuts to accommodate the irregularities, and using flexible caulk to fill minor gaps. I also employed a technique called ‘coping,’ where one piece of molding is shaped to precisely fit against another, achieving a seamless joint even on difficult angles. This required patience and precision but resulted in a perfectly fitted and aesthetically pleasing crown molding installation that exceeded the client’s expectations.

Q 23. How do you ensure a smooth and seamless finish on trim work?

Achieving a smooth and seamless finish in trim work requires meticulous attention to detail at every stage. It starts with precise measurements and cuts. Using a high-quality miter saw with a sharp blade ensures clean, accurate cuts, minimizing the need for excessive filling. After installation, I carefully fill any nail holes or gaps with wood filler that matches the trim’s color. Once dry, I sand the filler smooth, ensuring a consistent surface. The final step involves applying several coats of high-quality primer and paint, allowing each coat to dry completely before applying the next. This layering process creates a durable and beautifully finished surface. Think of it like baking a cake – each layer contributes to the final, perfect result.

Q 24. What is your experience with working from blueprints and specifications?

I have extensive experience interpreting blueprints and specifications. I’m proficient in reading architectural drawings to understand the scope of the trim work, including the types of molding, their dimensions, and their placement. I also carefully review specifications regarding materials, finishes, and installation methods. For example, I’ve worked on projects where the blueprints specified custom-milled trim requiring precise ordering and careful handling to avoid damage. I always verify measurements on-site to account for any discrepancies between the plans and the actual structure. This careful approach prevents costly mistakes and ensures the final product meets the project’s requirements precisely.

Q 25. How do you communicate effectively with other tradespeople on a construction site?

Effective communication is crucial on a construction site. I believe in proactive communication – before starting any work, I’ll confirm with other tradespeople, such as electricians or plumbers, about their work schedule and locations to avoid conflicts. For instance, I might coordinate with the electrician to ensure all wiring is completed before I install baseboards. I utilize clear and concise communication, often using visual aids like marked-up blueprints to clarify my intentions and requirements. I also foster a collaborative environment by addressing concerns promptly and respectfully, contributing to a smoother and more efficient workflow. Think of it as a well-orchestrated symphony – each instrument (trade) plays its part in harmony.

Q 26. What are your preferred methods for cleaning up after a trim installation?

Cleanliness is paramount. My cleanup process begins during the installation process – I use drop cloths to protect the floors and carefully dispose of scraps as I go. After completing the installation, I thoroughly sweep and vacuum the area, removing all sawdust, wood chips, and debris. I then carefully wipe down the trim with a damp cloth to remove any dust or residue from the installation process. Finally, I inspect the area to ensure no debris remains. This meticulous approach leaves the job site clean and ready for the next phase of construction. It’s about leaving the space better than I found it.

Q 27. How do you handle customer concerns or requests for changes during a project?

Handling customer concerns is crucial. I actively listen to their concerns, asking clarifying questions to fully understand their perspective. I then calmly explain the situation, offering potential solutions while remaining respectful and professional. If the request involves a change to the original plan, I assess its feasibility, providing a realistic timeline and any potential cost implications. Transparency and clear communication are key. For example, if a customer wants to change the type of molding mid-project, I’ll explain the implications on the schedule and budget before proceeding. The goal is always client satisfaction, achieved through open communication and a commitment to finding mutually agreeable solutions.

Q 28. Describe your experience with installing interior and exterior trim.

I possess extensive experience installing both interior and exterior trim. Interior work frequently involves intricate molding designs, requiring precision cutting and careful attention to detail. This includes crown molding, baseboards, casings, and various decorative trim elements. Exterior trim, on the other hand, often focuses on durability and weather resistance. This typically involves installing siding trim, window and door casings, and fascia boards, requiring materials suited to withstand the elements. I’m familiar with various materials, including wood, composite, and PVC, selecting the appropriate material based on the project’s requirements and location. Each type of trim presents unique challenges and demands specific expertise, both of which I possess and apply consistently.

Key Topics to Learn for Trim Work Interview

- Understanding Trim Work Processes: Grasp the fundamental workflow and stages involved in a typical Trim Work project. Consider the different types of trim materials and their applications.

- Practical Application of Trim Work Techniques: Explore real-world examples of how Trim Work is used in various industries (e.g., construction, automotive, manufacturing). Focus on problem-solving scenarios within these contexts.

- Quality Control and Efficiency in Trim Work: Understand the importance of adhering to quality standards and achieving efficient workflows. Explore methods for optimizing processes and minimizing waste.

- Safety Procedures and Regulations: Familiarize yourself with relevant safety protocols and industry regulations related to Trim Work. This demonstrates a commitment to safe working practices.

- Teamwork and Communication in Trim Work: Highlight your understanding of collaborative work environments and effective communication strategies within a Trim Work team. Discuss conflict resolution and teamwork approaches.

- Technical Proficiency (if applicable): Depending on the specific Trim Work role, brush up on any relevant technical skills, such as using specific software or machinery. Be prepared to discuss your experience and proficiency.

Next Steps

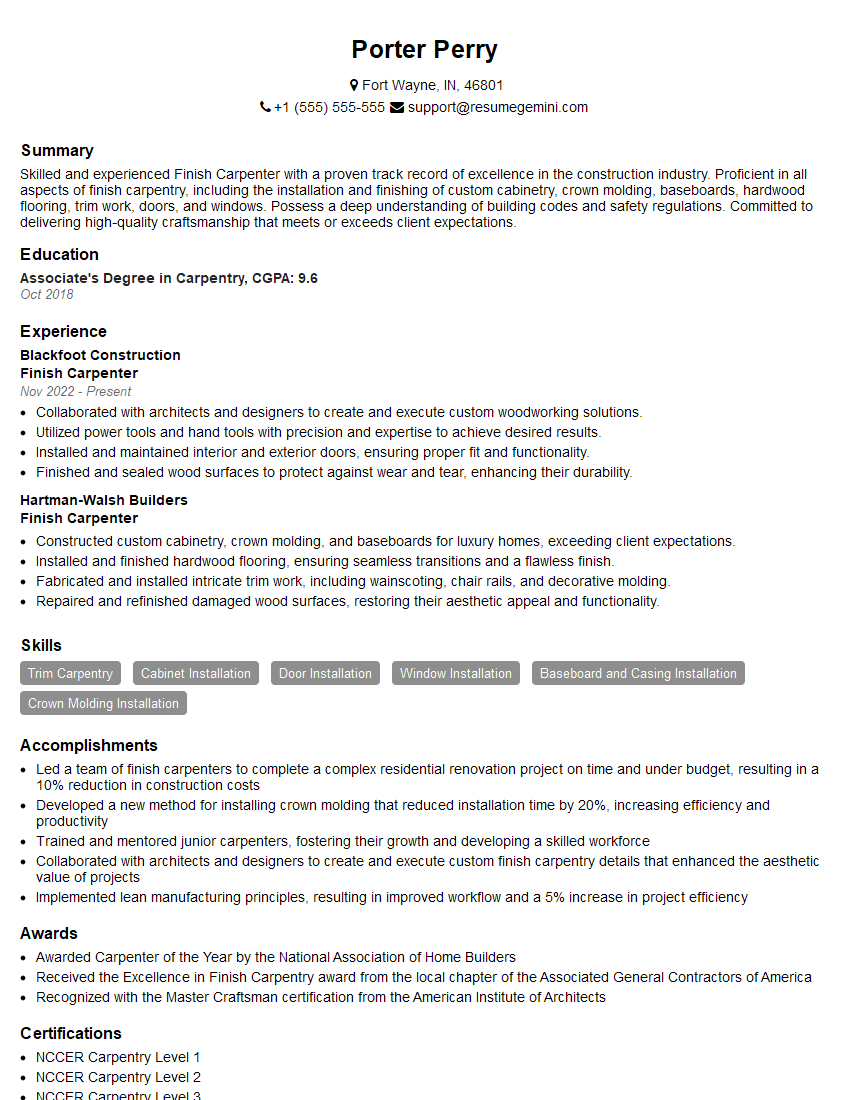

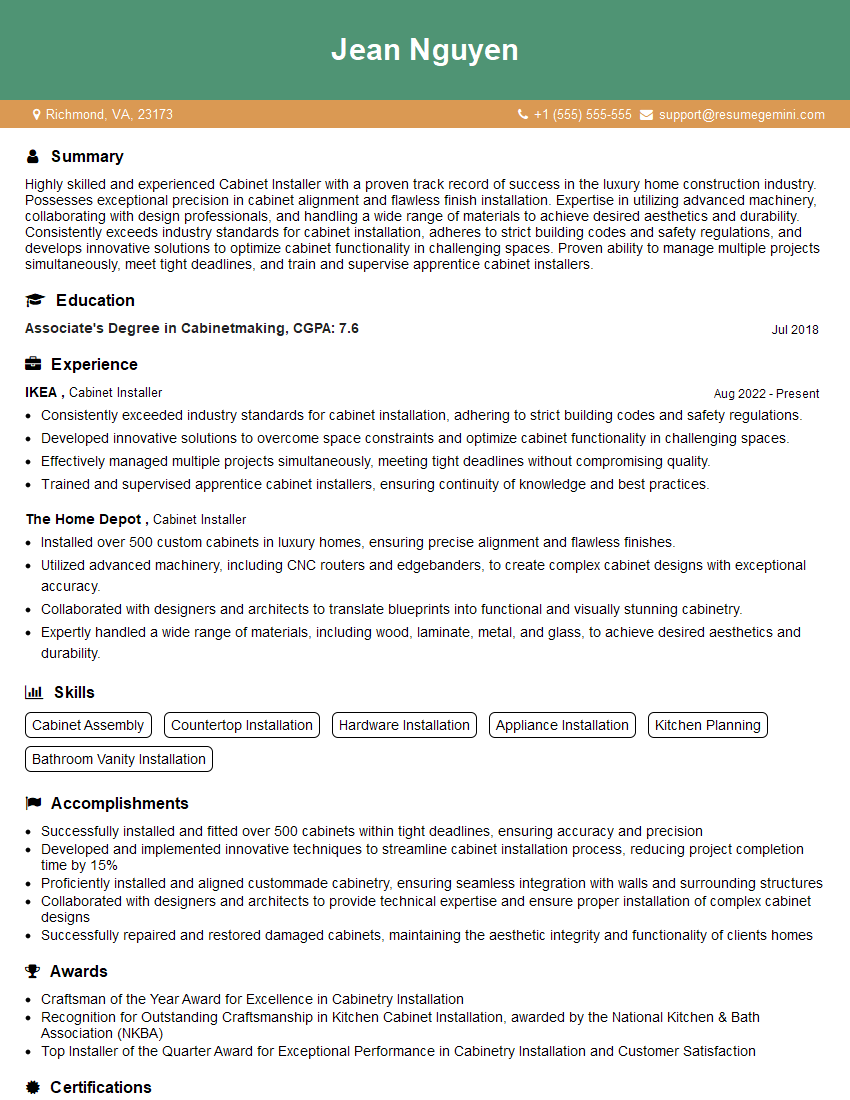

Mastering Trim Work opens doors to exciting career opportunities across diverse industries. Proficiency in this area showcases your practical skills and problem-solving abilities, making you a highly valuable asset. To significantly boost your job prospects, creating a strong, ATS-friendly resume is crucial. We highly recommend using ResumeGemini, a trusted resource that empowers you to build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Trim Work are available to help guide your creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?