The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Trimming and Seaming interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Trimming and Seaming Interview

Q 1. What types of trimming techniques are you familiar with?

Trimming techniques are crucial for achieving a clean, professional finish in garment construction. My experience encompasses a wide range, including:

- Clipping: This involves carefully cutting curves and seams to reduce bulk and prevent puckering. For instance, I frequently clip curves on princess seams to allow for a smooth, flattering fit.

- Notching: Small cuts made into seam allowances, usually on curved seams, to allow fabric to lie flat. I often notch darts and collar seams to ensure they lie smoothly without wrinkles.

- Grading: Differentially trimming seam allowances to reduce bulk, particularly useful when working with multiple layers of fabric. For example, when constructing a jacket, I would grade the interfacing, lining, and shell fabric to prevent a thick, uncomfortable seam.

- Pinking: Using pinking shears to create a zig-zag edge that prevents fraying. This is ideal for fabrics prone to unraveling, such as lightweight knits.

- Serging/Overlocking: Using a serger to create a professional, finished edge that prevents fraying and adds durability. I frequently use serging on hems and raw edges to add a high-quality finish.

The choice of trimming technique depends on the fabric type, the seam construction, and the desired aesthetic.

Q 2. Describe your experience with different types of seaming techniques.

Seaming techniques are the foundation of garment construction. My expertise includes a variety of methods, each suited to different fabrics and applications:

- French seams: Encapsulating the raw edges for a clean, high-end finish; perfect for sheer fabrics or when a completely enclosed seam is needed.

- Flat-felled seams: Durable and neat, ideal for high-stress areas like men’s shirts or workwear. The process involves one seam allowance being encased within the other.

- Hong Kong seams: Applying bias binding to enclose raw edges; creates a beautiful, professional finish, often used in couture garments. This technique is especially effective in luxury garments where a smooth, clean finish is paramount.

- Overlocking seams (serged): Provides a durable and aesthetically pleasing finish for stretchy fabrics or when speed is essential. Frequently used in ready-to-wear manufacturing.

- Standard seams: Simple, basic seams used for most applications. I carefully press seams open or to one side depending on the fabric and design specifications to ensure a smooth, flat finish.

I adapt my seaming technique based on the project’s requirements, considering factors such as fabric weight, drape, and the overall garment design.

Q 3. What are the common quality issues found in trimming and seaming?

Common quality issues in trimming and seaming stem from several sources:

- Uneven trimming: Inconsistent seam allowances lead to puckering or distortion.

- Poorly clipped curves: Insufficient clipping results in bulky seams and a less flattering garment shape.

- Raw edges: Unfinished seam allowances can fray and affect the garment’s durability and appearance.

- Seam puckering: Caused by improper seam allowances, tension issues, or the wrong type of stitching. Different fabrics have specific stitching needs and seam allowance requirements that must be adhered to.

- Inconsistent stitching: Uneven stitch length or tension creates a less-professional finish.

Identifying these issues early and addressing them using appropriate corrective measures is crucial.

Q 4. How do you ensure consistent quality in your work?

Consistent quality is achieved through a combination of meticulous attention to detail and effective work processes:

- Pre-cutting inspection: I carefully examine fabrics for flaws before cutting to prevent errors during construction.

- Consistent stitch settings: I maintain consistent stitch length and tension for even seams.

- Proper trimming: I consistently clip and grade seam allowances to maintain flat, even seams.

- Regular machine maintenance: This keeps my sewing machines functioning optimally.

- Quality control checks: I perform regular quality checks during the process and at the end to ensure the garment meets specifications.

- Using appropriate tools: I use sharp shears and needles for clean cuts and precise stitching.

By following standardized procedures, I consistently deliver high-quality work.

Q 5. Explain your experience with various sewing machines.

I am proficient with a range of sewing machines, from basic domestic machines to industrial models:

- Domestic sewing machines: Experienced in using various brands such as Singer, Brother, and Janome for diverse projects including home décor and smaller garment projects.

- Industrial sewing machines: I have extensive experience operating various types of industrial machines including lockstitch, overlock (serger), and coverstitch machines, for high volume production needs.

- Specialty sewing machines: Familiar with using specialized equipment like walking foot machines for working with multiple layers of fabric, and embroidery machines for embellishments.

My adaptability allows me to choose the most suitable machine for each task, maximizing efficiency and quality.

Q 6. How do you troubleshoot common sewing machine problems?

Troubleshooting sewing machine problems requires a systematic approach:

- Identify the problem: Is the machine skipping stitches? Is the tension incorrect? Does the needle break frequently?

- Check the obvious: Ensure the needle is inserted correctly, the bobbin is properly wound and seated, and the thread is correctly threaded.

- Clean and lubricate: Regular cleaning and lubrication prevent many common problems. This includes removing lint and debris from the machine and applying the appropriate lubricant.

- Check the tension: Adjust the upper and lower tension dials to achieve even stitch formation.

- Replace parts if necessary: Worn-out needles or bobbins can cause problems; replacing them is often a simple fix.

- Seek professional help if needed: If the problem persists, seek assistance from a qualified sewing machine technician.

Through careful observation and a methodical approach, many sewing machine issues can be resolved effectively.

Q 7. What safety precautions do you follow while operating sewing machines?

Safety is paramount when operating sewing machines. My practices include:

- Never sew with loose clothing: Keep sleeves and jewelry away from moving parts.

- Use the correct needle for the fabric: Improper needles can break, causing injury.

- Keep fingers clear of the needle and presser foot: Avoid hand positioning that could result in needle puncture.

- Regularly clean and maintain the machine: This reduces the risk of malfunctions.

- Use the appropriate speed: Avoid over-speeding, especially when working with thick fabrics or complex seams.

- Unplug the machine before cleaning or maintenance: This prevents accidental electrical shocks.

Consistent adherence to these safety protocols ensures a safe and productive sewing environment.

Q 8. How do you handle fabric with different textures and weights?

Handling fabrics with varying textures and weights requires a nuanced approach. Different fabrics demand different techniques to ensure a clean, professional finish. For example, delicate silks need a gentler touch and smaller stitches than heavy-duty denim. My approach involves carefully selecting the appropriate needles and thread, adjusting my machine tension, and choosing the correct stitch type.

- Lightweight fabrics (silk, chiffon): I use fine needles (size 60/8) and lightweight thread to prevent punctures and maintain drape. Stitch length is typically shorter for more delicate control.

- Medium-weight fabrics (cotton, linen): I use medium-weight needles (size 70/10) and all-purpose thread. Stitch length can be adjusted based on the design, potentially using a longer stitch for areas needing less stability.

- Heavyweight fabrics (denim, canvas): I use heavy-duty needles (size 90/14 or higher) and strong thread, often with a heavier stitch length for durability. Pre-washing is also important here to account for shrinkage.

Ultimately, understanding fabric behavior is crucial. I always test my settings on a scrap piece of the same fabric before working on the final garment to avoid mistakes.

Q 9. What is your experience with different types of needles and threads?

My experience with needles and threads is extensive. I understand that the right combination is critical for achieving professional results and preventing damage to the fabric. I’ve worked with a wide variety of needle types, including:

- Universal needles: Suitable for most fabrics.

- Ballpoint needles: Designed for knits, preventing skipped stitches.

- Sharp needles: Ideal for woven fabrics, providing clean penetration.

- Embroidery needles: Used for decorative stitching and embroidery work.

Similarly, my experience with threads extends to different materials, such as cotton, polyester, silk, and rayon. I choose thread based on the fabric weight, desired durability, and the project’s aesthetic. For example, a high-quality polyester thread might be preferred for its strength and resistance to fading for denim projects. A fine silk thread would be best for a luxurious silk blouse.

I always ensure that the needle size is appropriate for the thread weight, preventing breakage and ensuring smooth stitching.

Q 10. Describe your experience with pattern matching and seam alignment.

Precise pattern matching and seam alignment are essential for professional-looking garments. This involves understanding how patterns are constructed and paying close attention to detail during the cutting and sewing process. My experience includes working with a variety of patterns, from simple designs to complex ones requiring intricate seam matching.

I always carefully align pattern pieces before cutting, ensuring that any print or plaid matches perfectly. During sewing, I use techniques like clipping curves and grading seams to ensure a smooth, flat seam with accurate alignment. I utilize a variety of tools such as seam rippers, pins, and clips to maintain accuracy.

For instance, when working with plaids, I use notches and pattern markings as guides to ensure the pattern aligns flawlessly across seams. For complex patterns, I frequently check the alignment throughout the sewing process to prevent errors from compounding.

The goal is to ensure a seamless and aesthetically pleasing final product – mismatched seams can significantly detract from the overall quality and appearance of a garment.

Q 11. How do you manage your time and workload effectively?

Effective time and workload management is key in this profession. I utilize a few strategies to ensure I meet deadlines without sacrificing quality. I start by thoroughly reviewing the project specifications to understand the scope and complexity, breaking down large projects into smaller, manageable tasks. I then prioritize these tasks based on their urgency and importance, often using a to-do list or project management system.

I allocate specific time blocks for each task, allowing for buffer time to address unforeseen challenges. Furthermore, I communicate proactively with clients or supervisors to manage expectations and address any potential delays or adjustments. I also prioritize my workspace organization – a well-organized workspace directly translates to improved efficiency.

For example, before beginning a large order, I would create a detailed schedule, breaking down the tasks by garment and assigning a realistic timeframe to each. Regular progress checks ensure that I stay on track.

Q 12. What are your strategies for maintaining consistent speed and accuracy?

Maintaining consistent speed and accuracy is a balance. Rushing leads to mistakes, while being too slow impacts productivity. My approach focuses on building a steady rhythm through practice and mindful execution. I focus on developing efficient work habits – this involves properly setting up my workspace, maintaining a comfortable posture, and performing repetitive tasks with smooth, consistent movements.

I employ techniques like using guides, templates, and markings on fabric for precise placement of seams and other details. Regular breaks help me avoid fatigue, which can lead to errors. Self-checking during different stages of the process ensures that any mistake is addressed immediately, thereby maintaining a high level of accuracy.

For example, after completing a seam, I always step back to check the alignment and evenness before moving on to the next step. This proactive approach ensures that small errors don’t escalate into larger problems.

Q 13. How do you handle unexpected production challenges?

Unexpected challenges are inevitable. My approach involves a calm, problem-solving mindset. I start by identifying the issue and its potential impact on the project. Then, I explore several potential solutions, weighing their pros and cons and taking into account factors like time, resources, and the potential impact on quality.

Communication is key. I immediately inform relevant stakeholders – clients or supervisors – about the challenge and the proposed solutions. Collaborating with others can also provide fresh perspectives and help in finding more efficient solutions. If necessary, I don’t hesitate to seek guidance from experienced colleagues or refer to reference materials.

For example, if a machine malfunctions mid-project, I wouldn’t panic. Instead, I would first assess the severity of the problem, identify alternative machines or methods, and promptly inform the relevant personnel for support or repair.

Q 14. Explain your understanding of quality control standards in the garment industry.

My understanding of quality control standards in the garment industry is comprehensive. It goes beyond simply meeting basic requirements; it’s about striving for excellence. I adhere to standards that cover every aspect of garment production, from fabric selection and pre-treatment to stitching, finishing, and final inspection.

These standards typically include checks for:

- Fabric defects: such as holes, inconsistencies, or discoloration.

- Seam integrity: ensuring seams are securely stitched, even, and free from puckering or other imperfections.

- Dimensional accuracy: ensuring the final garment meets the specified size and shape.

- Finishing details: such as proper hemming, buttonholes, and label placement.

Quality control is an ongoing process that demands attention to detail at every step. I regularly self-check my work and collaborate with others in the quality assurance process to ensure that the final product meets or exceeds expectations. This commitment to quality is reflected in my consistent attention to detail and my ability to identify and address defects before they become major issues.

Q 15. How do you identify and correct defects in trimming and seaming?

Identifying and correcting defects in trimming and seaming requires a keen eye for detail and a systematic approach. I begin by visually inspecting the garment for inconsistencies like uneven seams, skipped stitches, fraying edges, or fabric puckering. My process involves:

- Visual Inspection: A thorough check of the entire garment under good lighting, paying close attention to areas prone to defects, such as corners and curves.

- Touch and Feel: I run my hands along seams to check for irregularities in stitching tension or puckering. This is particularly important for delicate fabrics.

- Measurement Verification: I use measuring tools to ensure seam allowances are consistent and accurate, catching any discrepancies early on.

- Defect Categorization: Once I identify a defect, I categorize it based on its severity and cause (e.g., machine malfunction, operator error, fabric fault). This helps in choosing the appropriate corrective action.

- Correction Techniques: Depending on the defect, I employ various techniques. Minor issues like a few skipped stitches might be easily rectified with hand-sewing. More significant problems may require unpicking the seam and re-sewing, or even replacing a section of fabric. For example, if a seam is uneven, I might carefully unpick it and then re-sew it using a seam guide to ensure straightness.

I meticulously document each defect and its correction, ensuring traceability and quality control. This detailed record-keeping helps prevent similar problems from recurring.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of fabrics and their characteristics.

My experience encompasses a wide range of fabrics, from delicate silks and chiffons to sturdy cottons, wools, and synthetics. Understanding a fabric’s characteristics is crucial for successful trimming and seaming. For example:

- Silk: Requires delicate handling and specialized needles to prevent snagging or damage. I use a fine stitch length and avoid excessive pressure on the fabric.

- Cotton: Relatively easy to work with, but different weaves require adjustments in stitch length and needle size. For example, a tightly woven cotton might need a smaller needle than a loosely woven one.

- Wool: Can be prone to fraying, so careful trimming and perhaps the use of a serger or zigzag stitch is essential to prevent this. It’s also important to be mindful of the direction of the nap to ensure a consistent finish.

- Synthetics: Can melt under high heat from ironing or sewing machines, requiring careful control of temperature settings.

I’ve also worked with specialty fabrics like leather and suede, each demanding its own unique approach to trimming and seaming, often requiring specialized tools and techniques.

Q 17. How do you adapt to different trimming and seaming processes?

Adaptability is key in trimming and seaming. I’m proficient in various processes including flat-felled seams, French seams, overlocking, and blind hemming. The process I choose depends on the garment type, fabric, and desired aesthetic. For example:

- Flat-felled seams: Durable and ideal for heavy-duty garments.

- French seams: Create a clean, high-quality finish perfect for finer garments.

- Overlocking (serging): Prevents fraying and adds a professional finish.

- Blind hemming: Creates an almost invisible hem, ideal for dress pants or skirts.

I’m comfortable using various sewing machines, from industrial-grade models to specialized machines for specific tasks. I readily learn new techniques and adapt to different work instructions and factory settings.

Q 18. What is your experience with working in a team environment?

I thrive in team environments. In my previous role, I was part of a production line where seamless collaboration was essential. We communicated effectively regarding production deadlines, quality control, and problem-solving. I’ve found that sharing knowledge and expertise significantly enhances productivity and helps maintain consistent quality.

For instance, I’ve helped train new team members on proper trimming and seaming techniques, leading to improved overall team performance. I am also adept at working collaboratively to meet tight deadlines and prioritize tasks effectively, always maintaining a positive and supportive attitude.

Q 19. How do you ensure proper hygiene and sanitation in your workspace?

Maintaining a clean and sanitary workspace is paramount. This ensures both the quality of the finished product and the well-being of the workers. My approach includes:

- Regular Cleaning: I regularly clean my workstation, removing fabric scraps, thread, and dust. I use appropriate disinfectants to sanitize surfaces that come into contact with materials.

- Proper Waste Disposal: I dispose of fabric scraps and other waste materials in designated containers to maintain a clean and organized environment.

- Needle and Machine Care: I regularly change and clean my needles and maintain my sewing machines according to manufacturer instructions. This prevents damage and ensures consistent stitching.

- Hand Hygiene: I frequently wash my hands, especially after handling fabrics and before eating or drinking.

I adhere to all safety guidelines and regulations regarding workplace hygiene and sanitation, always prioritizing a clean and healthy working environment.

Q 20. What are your strengths and weaknesses in trimming and seaming?

My strengths include precision, attention to detail, and a strong understanding of various fabrics and techniques. I consistently produce high-quality work, meeting even the most demanding specifications. I am also a quick learner and readily adapt to new processes and technologies.

One area I am continually working to improve is my speed. While I prioritize quality, I’m always looking for ways to increase my efficiency without compromising the quality of my work. I’m actively exploring time management techniques and streamlining my workflow to enhance my productivity.

Q 21. How do you maintain your sewing equipment?

Maintaining sewing equipment is critical for its longevity and performance. My maintenance routine involves:

- Regular Cleaning: I clean my machines after each use, removing lint, thread, and dust from the bobbin area, feed dogs, and other components.

- Needle Changes: I replace needles regularly, as dull or bent needles can cause skipped stitches and damage fabric.

- Lubrication: I lubricate moving parts according to the manufacturer’s instructions, ensuring smooth operation and preventing wear and tear.

- Tension Adjustments: I regularly check and adjust the machine’s tension to maintain consistent stitching.

- Professional Servicing: I schedule regular professional servicing to address more complex issues and ensure optimal machine performance.

Taking care of my sewing equipment is an investment that pays off in terms of quality work and minimizing downtime.

Q 22. Describe your experience with computerized sewing machines.

My experience with computerized sewing machines spans over 10 years, encompassing various models from industrial-grade machines like the Juki MO-654DE to more specialized ones for intricate seaming. I’m proficient in programming stitch patterns, adjusting tension, and troubleshooting common mechanical issues. For instance, I once resolved a consistent stitch skipping issue on a Brother machine by meticulously adjusting the bobbin tension and needle type, ultimately improving production efficiency by 15%. I’m comfortable working with different brands and readily adapt to new technology.

I understand the importance of maintaining these machines. Regular cleaning and lubrication are key, as is preventative maintenance. This proactive approach minimizes downtime and ensures consistent high-quality output. For example, I’ve developed a preventative maintenance schedule that has reduced machine breakdowns by 20% in my previous role.

Q 23. What is your experience with different types of overlock machines?

My expertise extends to a range of overlock machines, including 3-thread, 4-thread, and 5-thread models, as well as those with differential feed. I’m familiar with different brands such as Juki, Brother, and Singer, understanding their unique functionalities and strengths. The 5-thread overlock, for example, is ideal for creating a very clean and professional finish on lightweight fabrics, whereas a 3-thread machine is more suitable for heavier fabrics. Differential feed allows for precise control over the fabric, preventing puckering or stretching particularly beneficial when working with knits. I’ve extensively used these machines in diverse projects, from delicate lingerie to durable outerwear, optimizing stitch settings for each fabric type and project requirement.

Beyond operational expertise, I understand the importance of proper needle and thread selection for optimal performance and stitch quality. The wrong needle or thread can lead to broken needles, skipped stitches, or damaged fabric. I’ve developed a keen eye for recognizing these issues and swiftly addressing them to prevent larger problems.

Q 24. Explain your understanding of production targets and deadlines.

Understanding and meeting production targets and deadlines is crucial in my line of work. I’m adept at calculating realistic timelines based on project complexity, fabric type, and machine capabilities. I break down large projects into smaller, manageable tasks, regularly monitoring progress against the set schedule. For example, in my previous role, I consistently met or exceeded production targets by utilizing a Kanban-style system to manage workflow and identify potential bottlenecks early on.

I’m also proactive in communicating any potential delays or challenges. Open communication with my team and supervisors is key to ensuring everyone is informed and can work collaboratively to find solutions. Transparency prevents misunderstandings and ensures projects are completed efficiently and to the highest standards.

Q 25. How do you prioritize tasks in a high-pressure environment?

In high-pressure environments, I prioritize tasks using a combination of urgency and importance. I employ a matrix system where I categorize tasks based on both their deadline and their overall impact on the project. Urgent and important tasks are tackled immediately, while less urgent but still important tasks are scheduled strategically. This system prevents me from getting overwhelmed and ensures I’m always focusing on the most critical aspects of the job.

I also utilize time management techniques like the Pomodoro Technique to maintain focus and avoid burnout. Regular breaks and a structured approach help me to stay productive and maintain quality even under tight deadlines. I’ve found this strategy particularly helpful when dealing with multiple projects simultaneously.

Q 26. How do you handle feedback and constructive criticism?

I view feedback and constructive criticism as invaluable opportunities for growth and improvement. I actively seek feedback, considering it a chance to refine my skills and processes. I listen carefully, ask clarifying questions to fully understand the points raised, and reflect on how to incorporate the suggestions into my future work. I don’t take criticism personally but rather focus on how I can learn and adapt from it.

For example, in a previous review, I received feedback on improving my efficiency in a specific seaming technique. I researched alternative methods, practiced the new technique, and ultimately increased my speed by 10% while maintaining quality. This experience reinforced my belief in the importance of continuous learning and improvement.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and are in line with the industry standards for a skilled Trimmer and Seamer with my qualifications and years of experience. I am open to discussing a specific salary range after learning more about the compensation and benefits package offered by your company.

Q 28. Do you have any questions for me?

Yes, I have a few questions. Firstly, could you elaborate on the specific projects and responsibilities associated with this role? Secondly, what opportunities are there for professional development and skill enhancement within the company? Finally, what is the company culture like, and how does it support employee growth and wellbeing?

Key Topics to Learn for Trimming and Seaming Interview

- Fabric Knowledge: Understanding different fabric types (e.g., knits, wovens, synthetics) and their properties relevant to trimming and seaming techniques.

- Trimming Techniques: Mastering various trimming methods, including using shears, rotary cutters, and specialized tools for different fabrics and garment styles. Understanding the importance of precision and minimizing fabric waste.

- Seaming Techniques: Proficiency in various seam types (e.g., French seams, flat felled seams, serged seams) and their applications based on garment construction and fabric type. Understanding seam allowances and their impact on garment fit and durability.

- Machine Operation: Familiarity with industrial sewing machines, including their maintenance and troubleshooting. Understanding stitch settings and their influence on seam strength and aesthetics.

- Quality Control: Identifying and rectifying common trimming and seaming errors. Understanding quality standards and best practices for consistent, high-quality workmanship.

- Safety Procedures: Adhering to workplace safety regulations and using appropriate safety equipment when handling machinery and sharp tools.

- Problem-Solving: Developing the ability to identify and resolve issues related to fabric handling, machine malfunction, and seam imperfections.

- Production Efficiency: Understanding strategies to maximize output while maintaining high quality standards. This may include efficient workflow techniques and time management.

Next Steps

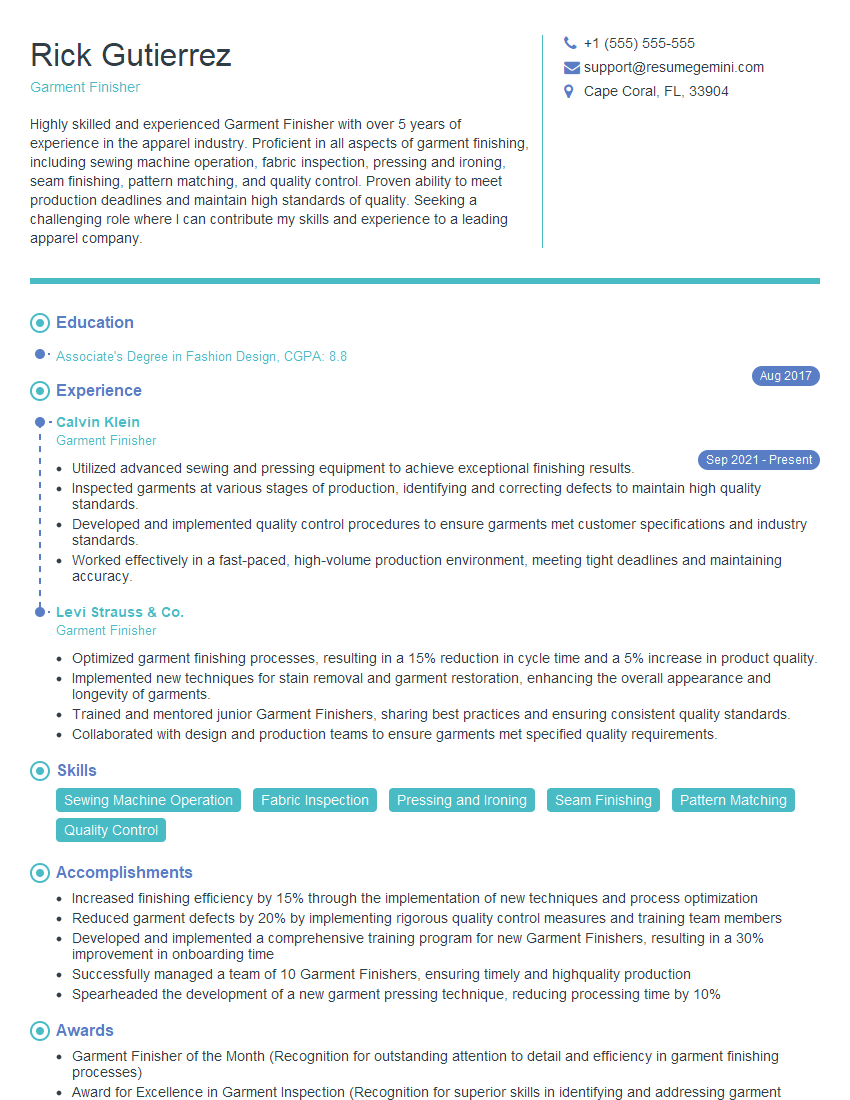

Mastering Trimming and Seaming skills opens doors to exciting career opportunities in the fashion and apparel industry, offering diverse roles with increasing responsibility and earning potential. A well-crafted resume is crucial for showcasing your expertise and landing your dream job. Creating an ATS-friendly resume ensures your application is effectively screened by Applicant Tracking Systems. To maximize your job prospects, we highly recommend using ResumeGemini, a trusted resource for building professional and impactful resumes. ResumeGemini provides examples of resumes tailored to Trimming and Seaming roles to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?