Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Understanding Fabric Properties interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Understanding Fabric Properties Interview

Q 1. Explain the difference between woven and knitted fabrics.

Woven and knitted fabrics are fundamentally different in their construction methods, leading to distinct properties. Woven fabrics are created by interlacing two sets of yarns at right angles – the warp (lengthwise) and weft (crosswise). Think of a traditional woven tapestry; the threads are intricately crossed over and under each other to form a stable structure. Knitted fabrics, on the other hand, are formed by interlocking loops of a single yarn. Imagine a chain where each loop is connected to the next; this creates a more flexible and stretchy fabric.

- Woven Fabrics: Typically stronger, more durable, and less stretchy than knitted fabrics. They often have a crisper hand (feel) and drape more rigidly. Examples include denim, twill, and linen.

- Knitted Fabrics: Often softer, more drapable, and more stretchy than woven fabrics. They tend to have a softer hand and can conform more readily to the body’s shape. Examples include jersey, rib knit, and purl knit.

The choice between woven and knitted fabrics depends heavily on the intended garment and its desired properties. A sturdy pair of jeans benefits from the strength of woven fabric, while a comfortable t-shirt utilizes the softness and stretch of a knit.

Q 2. Describe the properties of cotton, wool, silk, and polyester fabrics.

Each of these fabrics possesses unique properties due to their fiber composition and structure:

- Cotton: A natural fiber known for its softness, breathability, and absorbency. It’s relatively inexpensive and easy to care for, making it a staple in clothing. However, it wrinkles easily and can shrink after washing.

- Wool: Another natural fiber, wool is prized for its warmth, softness, and moisture-wicking properties. It’s naturally resilient and can retain its shape well. However, it can be more expensive than cotton and may require special cleaning.

- Silk: A luxurious natural fiber renowned for its smoothness, luster, and drape. It’s incredibly soft and comfortable against the skin but is delicate and requires careful handling. Its drape is particularly exquisite and prized in high-end garments.

- Polyester: A synthetic fiber known for its durability, wrinkle resistance, and water resistance. It’s less expensive than natural fibers and often used in blends to enhance the properties of other fabrics. However, it doesn’t breathe as well as natural fibers and can feel less soft.

The choice of fabric often depends on the season, desired comfort, and garment requirements. For instance, summer clothing often uses breathable cotton, while winter coats might utilize warm wool or synthetic fibers like polyester for warmth and durability.

Q 3. What are the different types of fabric finishes and their effects?

Fabric finishes are treatments applied to fabrics to modify their properties and enhance their appearance. They range from simple to complex processes.

- Calendering: Pressing the fabric to impart a smooth, glossy, or embossed finish.

- Mercerization: Treating cotton fabric with alkali to improve its luster, strength, and dye affinity.

- Sanforizing: A process to pre-shrink fabrics, minimizing shrinkage during washing.

- Waterproofing: Applying a coating to make the fabric water-resistant.

- Flame Retardant: Treating the fabric to make it less flammable.

- Softening: Applying chemicals to give the fabric a softer hand.

The type of finish used will directly impact the final characteristics of the fabric. A mercerized cotton will be noticeably smoother and stronger than untreated cotton. A water-resistant finish is crucial for outerwear, while a flame-retardant finish is essential for certain types of protective clothing. Understanding these finishes helps in selecting appropriate fabrics for diverse applications.

Q 4. How do fiber length and diameter affect fabric properties?

Fiber length and diameter significantly influence fabric properties. Longer fibers generally lead to stronger, smoother, and more lustrous fabrics. Think of a long strand of yarn compared to many short ones – the long strand creates a much more continuous, less prone to breakage, and therefore stronger yarn.

- Fiber Length: Longer fibers like those in Egyptian cotton result in finer, stronger yarns, leading to smoother, more durable fabrics. Shorter fibers might create a weaker, fuzzier, and less smooth fabric.

- Fiber Diameter: Finer fibers typically create fabrics with a smoother surface and softer hand (feel). Coarser fibers lead to fabrics that are more textured and less smooth.

For example, the high-quality yarns used in fine luxury fabrics are made from longer, finer fibers. Conversely, fabrics made from shorter, coarser fibers may be more suitable for utility items, where strength is a more important factor than softness.

Q 5. Explain the concept of fabric drape and its importance in garment design.

Fabric drape refers to the way a fabric hangs and falls. It’s determined by factors like fiber type, yarn structure, fabric construction, and finishing. A good example to visualize this is the difference between a stiff linen shirt and a flowing silk scarf.

Drape is crucial in garment design as it significantly impacts the garment’s silhouette and overall aesthetic. A fabric with poor drape might result in a garment that looks stiff and shapeless, while a fabric with excellent drape can create a flowing, elegant look. Designers meticulously select fabrics with the correct drape to achieve their desired design aesthetic.

Consider the difference between a structured blazer, which typically uses a crisp, sturdy fabric with minimal drape, versus a flowing evening gown, which often employs fabrics with excellent drape, like silk chiffon or silk charmeuse. The drape directly impacts the garment’s form and functionality.

Q 6. What are the key factors influencing fabric shrinkage?

Fabric shrinkage is the reduction in size of a fabric after washing or other treatments. Several factors contribute to this:

- Fiber Type: Natural fibers like wool and cotton are more prone to shrinkage than synthetics. Wool fibers, in particular, are known for their tendency to shrink.

- Yarn Construction: The way yarns are spun and twisted affects shrinkage. Loosely spun yarns are more likely to shrink.

- Fabric Construction: Knitted fabrics generally shrink more than woven fabrics.

- Finishing Treatments: Some finishing treatments can reduce shrinkage, while others might increase it.

- Washing Conditions: High temperatures and harsh detergents can increase shrinkage.

Understanding these factors is key in pre-treating fabrics and choosing appropriate washing methods. Pre-shrinking fabrics before garment construction is a standard practice in the garment industry to prevent shrinkage problems after the garment is made.

Q 7. How does fabric weight affect garment construction and drape?

Fabric weight significantly affects both garment construction and drape. Heavier fabrics are more substantial and drape less readily, often resulting in structured garments.

- Garment Construction: Heavier fabrics require stronger needles and seams to withstand the stress of stitching. They are also more difficult to manipulate and sew, requiring more experience and skill from the sewist.

- Drape: Lighter fabrics drape more easily and create softer, flowing silhouettes, whereas heavier fabrics hang more rigidly, creating a more structured look. For example, a light chiffon will drape beautifully, creating a soft, fluid silhouette, while heavy denim creates a strong, structured look.

Choosing the correct weight fabric is crucial. A lightweight fabric would not be suitable for a winter coat, while a heavy fabric might be too cumbersome for a summer dress. The fabric weight choice should be carefully considered alongside the design and intended use of the garment.

Q 8. Explain the difference between tensile strength and tear strength.

Tensile strength and tear strength are both crucial indicators of a fabric’s durability, but they measure different aspects of its resistance to force. Tensile strength refers to the fabric’s ability to withstand pulling forces along its length or width before breaking. Imagine stretching a rubber band – its tensile strength is how much force it can handle before snapping. Tear strength, on the other hand, measures the fabric’s resistance to the propagation of a tear once it has already started. Think of accidentally snagging your favorite sweater; the tear strength determines how easily that snag will run into a large hole.

In essence, tensile strength is about overall pulling resistance, while tear strength is about resisting the propagation of a tear. A fabric can have high tensile strength but low tear strength, making it strong in a straight pull but vulnerable to snags and tears.

For example, denim typically possesses high tensile strength due to its tight weave, but it may have relatively lower tear strength compared to a tightly woven nylon fabric. This explains why denim is strong and durable but susceptible to rips and tears.

Q 9. Describe the different methods used to test fabric durability.

Fabric durability is assessed through several standardized tests that measure different aspects of its resistance to wear and tear. These tests often involve specialized machinery that simulates real-world conditions.

- Tensile Strength Test: Measures the maximum force a fabric can withstand before breaking under tension, as discussed earlier.

- Tear Strength Test: Evaluates a fabric’s resistance to tearing, using a device that initiates a tear and measures the force required for its propagation.

- Abrasion Resistance Test: Simulates rubbing and friction to assess the fabric’s resistance to wear and pilling (the formation of small balls of fiber). This is crucial for garments that experience frequent friction, such as socks or workwear.

- Bursting Strength Test: Measures the fabric’s resistance to sudden pressure or impact, crucial for applications like airbags or protective clothing.

- Flex/Bend Test: Evaluates the fabric’s resistance to repeated bending and flexing, which is important for garments that are frequently folded or stretched, like shirts or trousers.

The specific tests employed depend on the intended use of the fabric. For example, a fabric for a durable outdoor jacket will undergo more rigorous abrasion and tear strength testing than a fabric for a delicate blouse.

Q 10. How does fabric colorfastness affect the garment’s lifespan?

Colorfastness, or the ability of a dyed fabric to retain its color under various conditions, significantly impacts a garment’s lifespan. Poor colorfastness leads to fading, bleeding (color running into other fabrics during washing), and discoloration, which diminishes the garment’s appearance and value. A garment that fades quickly or bleeds in the wash looks worn out much faster, reducing its perceived lifespan, even if the fabric itself is structurally sound.

For example, a brightly colored shirt with poor colorfastness might appear faded and dull after just a few washes, while a garment with excellent colorfastness retains its vibrant color even after prolonged use and washing. This significantly affects the garment’s overall lifespan and the consumer’s satisfaction.

Q 11. What are the common fabric defects and how are they identified?

Various fabric defects can compromise the quality and durability of a garment. These defects can be categorized into weaving imperfections, finishing defects, and fiber-related problems.

- Weaving Defects: These include broken ends (broken yarns), missed ends (missing yarns), slubs (thickened areas in the yarn), and holes.

- Finishing Defects: These might include uneven dyeing, creases, shrinkage problems (uneven or excessive shrinkage after washing), and staining.

- Fiber-Related Defects: These can involve fiber damage from processing, short fibers leading to weaker fabric, or the presence of impurities in the fibers.

Identifying these defects often requires visual inspection, alongside specialized tests like microscopy or strength tests. For example, a broken end in a woven fabric is easily visible as a gap in the fabric structure. Uneven dyeing can be identified by comparing color consistency across different areas of the fabric. Advanced equipment can be utilized for more detailed analysis.

Q 12. Explain the relationship between fabric structure and its performance.

The structure of a fabric, encompassing its weave type (plain, twill, satin, etc.), yarn count (number of yarns per inch), and fiber type, directly dictates its performance characteristics. A tightly woven fabric, like high-density canvas, typically exhibits higher strength, durability, and water resistance than a loosely woven fabric like voile.

For instance, a tightly woven fabric with long, strong fibers will have superior tensile strength and abrasion resistance compared to a loosely woven fabric with short, weak fibers. The weave itself also plays a crucial role. Twill weaves offer greater strength and durability compared to plain weaves, making them ideal for workwear or outerwear.

Consider the difference between a tightly woven denim fabric, strong and durable, versus a loosely woven cheesecloth, which is lightweight and delicate. This variation in performance stems directly from the differences in fabric structure.

Q 13. How do you determine the appropriate fabric for a specific garment?

Selecting the right fabric for a garment requires a multifaceted approach, considering several factors:

- Garment Function: Is it for formal wear, sportswear, outerwear, or casual wear? This dictates the needed durability, breathability, and drape.

- End-Use Conditions: Will the garment be exposed to harsh weather, frequent washing, or friction? This informs the necessary properties like water resistance, abrasion resistance, and colorfastness.

- Aesthetic Requirements: What look and feel are desired? This drives choices regarding drape, texture, and color.

- Cost Considerations: Budget constraints will influence the choice of fibers and processing techniques.

For example, a lightweight, breathable fabric like linen is suitable for summer clothing, while a heavy-duty, water-resistant fabric like Gore-Tex is ideal for winter jackets. The choice involves a careful balancing act between functionality, aesthetics, and cost.

Q 14. Discuss the impact of different dyeing methods on fabric properties.

Different dyeing methods can significantly impact fabric properties. The choice of method depends on factors such as fiber type, desired color, and cost considerations.

- Reactive Dyeing: Forms a strong chemical bond with the fiber, resulting in excellent colorfastness and wash durability. Commonly used for cellulosic fibers like cotton.

- Disperse Dyeing: Used for synthetic fibers like polyester, the dyes are dispersed into the fiber and have moderate colorfastness.

- Acid Dyeing: Used for wool and silk, the dyes are applied in an acidic solution resulting in good colorfastness, but may require more precise control.

For instance, reactive dyeing is preferred for garments that need high colorfastness (e.g., work uniforms), while disperse dyeing may suffice for casual wear where the washing frequency is lower. Choosing the right dyeing method can dramatically affect the overall lifespan and quality of the garment.

Q 15. Explain the importance of fabric sourcing and sustainability.

Fabric sourcing and sustainability are paramount in the textile industry, impacting environmental and social responsibility. Sourcing responsibly involves choosing suppliers committed to ethical labor practices, minimizing environmental impact through reduced water and energy consumption, and prioritizing sustainable materials. This encompasses selecting fibers like organic cotton, recycled materials, or innovative sustainable alternatives like Tencel or hemp. For example, a company might source organic cotton from farms certified by the Global Organic Textile Standard (GOTS), ensuring the cotton is grown without harmful pesticides and fertilizers. Ignoring sustainable sourcing can lead to reputational damage, increased production costs due to resource scarcity, and ultimately, a less environmentally friendly product. The long-term benefits of responsible sourcing include improved brand image, reduced environmental footprint, and access to high-quality, ethically produced materials.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does fabric handle influence the design and production process?

Fabric handle, or drape, significantly influences design and production. It’s the way a fabric feels and behaves—its texture, stiffness, and flow. A fabric with a stiff handle, like canvas, might be ideal for structured garments such as a tote bag, while a fluid drape, like silk charmeuse, lends itself better to flowing dresses. The handle dictates pattern design: crisp fabrics might require simpler cuts to show off their texture, while drapey fabrics inspire more complex shapes. Production methods also adapt. A delicate fabric might demand gentler machinery to prevent damage, whereas a robust fabric allows for more aggressive manufacturing processes. For instance, a lightweight chiffon would require specialized sewing machines with fine needles to avoid tearing, whereas denim’s durability allows for industrial-strength sewing.

Q 17. Describe the different types of fabric blends and their properties.

Fabric blends combine different fibers to leverage the best qualities of each. Common blends include cotton/polyester (combining cotton’s softness with polyester’s durability and wrinkle resistance), linen/cotton (blending linen’s breathability with cotton’s softness), and wool/silk (combining wool’s warmth with silk’s luxurious feel). The properties of a blend depend on the fiber proportions and types. A 50/50 cotton/polyester blend will have a different drape and durability than a 70/30 blend. For example, a cotton/spandex blend is often used in activewear, leveraging cotton’s breathability and comfort with spandex’s stretch and recovery. The specific properties, like strength, drape, wrinkle resistance, and moisture wicking, are carefully balanced through the blend composition and processing techniques.

Q 18. What are the advantages and disadvantages of using natural vs. synthetic fibers?

Natural fibers, such as cotton, wool, silk, and linen, are derived from plants or animals. They are often biodegradable, breathable, and possess unique textures. However, they can be expensive, require more processing, and may be less durable than synthetics. Synthetic fibers, like polyester, nylon, and acrylic, are manufactured from petrochemicals. They are usually more affordable, durable, and wrinkle-resistant but may not be as breathable and can contribute to environmental concerns due to their non-biodegradability and production processes. For instance, organic cotton offers superior breathability and environmental friendliness compared to polyester but may be more prone to wrinkling and shrinkage. The choice depends on the intended application; performance apparel might prioritize synthetic fibers for their moisture-wicking properties, whereas a summer dress might benefit from the breathability of linen.

Q 19. How do you assess the quality of a fabric sample?

Assessing fabric quality involves a multi-sensory approach. Firstly, visual inspection checks for evenness of weave, color consistency, and the absence of defects. Then, tactile assessment involves examining the fabric’s hand (drape and feel), texture, and weight. Testing for strength and durability might involve pulling the fabric gently to check for tearing or pilling. Microscopic examination can reveal fiber type, fineness, and the density of the weave. A burn test (carefully and safely performed) can identify fiber composition. Finally, considering the manufacturing processes and certifications (e.g., GOTS for organic cotton) provides further information on ethical and sustainable practices. This holistic approach helps determine if the fabric meets the desired quality standards for the intended application.

Q 20. Explain the concept of fabric hand and how it is evaluated.

Fabric hand describes the tactile feel and drape of a fabric. It encompasses several aspects: drape (how the fabric falls), texture (smooth, rough, soft), weight (light, medium, heavy), and stiffness (crisp, soft, limp). Evaluating hand involves physically interacting with the fabric: feeling its texture, observing its drape when held, and assessing its weight. A descriptive vocabulary is crucial, using terms like ‘soft,’ ‘crisp,’ ‘smooth,’ ‘rough,’ ‘drapey,’ ‘stiff,’ ‘firm,’ etc., to communicate the fabric’s properties. For example, a cashmere sweater’s hand would be described as luxuriously soft, while a linen shirt’s hand might be described as crisp and slightly stiff. Understanding hand is vital for selecting appropriate fabrics for specific designs and garments.

Q 21. Describe different methods of fabric testing for abrasion resistance.

Abrasion resistance, a fabric’s ability to withstand rubbing and wear, is measured through various tests. The Martindale test uses a machine to rub a fabric sample against a standardized surface under controlled conditions, measuring the number of cycles until significant wear occurs. The Wyzenbeek test is similar, using a specified fabric specimen and a defined pressure and speed. Both tests quantify abrasion resistance, providing a numerical value that indicates the fabric’s durability. Visual inspection following testing assesses the degree of surface damage—pilling, fuzzing, or fiber breakage. The choice of test depends on the specific fabric type and application; a heavy-duty fabric like canvas might undergo a Martindale test, while delicate fabrics might be assessed using a less aggressive method, focusing on visual changes after gentle rubbing. The results are crucial for predicting a garment’s lifespan and choosing suitable fabrics for different applications.

Q 22. How do different fiber types react to various cleaning methods?

Different fiber types react dramatically differently to various cleaning methods. Understanding these reactions is crucial for preserving the fabric’s integrity and extending its lifespan. For example, delicate fibers like silk or wool require gentle hand washing or specialized dry cleaning to avoid damage. Harsh detergents or machine washing can cause shrinkage, felting (matting of fibers), or even fiber breakage. On the other hand, robust fibers like cotton or polyester are typically more resilient and can withstand machine washing, although even these benefit from using appropriate detergents and water temperatures.

- Delicate Fibers (Silk, Wool, Cashmere): Require gentle hand washing with cool water and a mild detergent. Avoid wringing or harsh scrubbing. Dry flat away from direct sunlight.

- Semi-Delicate Fibers (Linen, Rayon): Can usually tolerate machine washing on a delicate cycle with cool water. Avoid high spin speeds.

- Durable Fibers (Cotton, Polyester, Nylon): Generally machine washable, though always check the garment’s care label for specific instructions on water temperature and drying methods.

Imagine trying to wash a cashmere sweater the same way you’d wash a pair of cotton jeans – disaster! The cashmere would shrink and felt, ruining the garment. Therefore, always check the fabric content label and follow the care instructions carefully.

Q 23. What is the importance of understanding fabric flammability?

Understanding fabric flammability is paramount for safety reasons, especially in industries such as apparel manufacturing, upholstery, and home furnishings. Flammable fabrics pose a significant fire hazard, and understanding their behavior is critical for preventing accidents and ensuring compliance with safety regulations. Factors such as fiber type, fabric construction (weave, knit), and any applied finishes (e.g., flame retardants) influence a fabric’s flammability.

For example, natural fibers like cotton and linen are more flammable than synthetic fibers like nylon or polyester. However, the weave structure can also impact flammability; a tightly woven fabric will burn more slowly than a loosely woven one. Flame retardant treatments are often applied to fabrics to enhance fire safety, particularly in applications where fire risk is higher, such as children’s sleepwear or upholstery.

Failure to consider fabric flammability can lead to severe consequences, including injuries and fatalities. Therefore, rigorous testing and adherence to safety standards are essential.

Q 24. Explain the role of fabric properties in garment comfort and fit.

Fabric properties significantly influence garment comfort and fit. Factors like fiber type, fabric weight, drape, and texture all contribute to the overall wearing experience. For instance, lightweight fabrics like cotton voile or silk are breathable and comfortable in warm weather, while heavier fabrics like wool or fleece offer warmth and insulation in cold weather.

- Fiber Type: Natural fibers like cotton and linen are breathable and absorbent, making them comfortable in warmer climates. Synthetics like polyester offer durability and wrinkle resistance.

- Fabric Weight: Lightweight fabrics are comfortable in warmer weather, while heavier fabrics are better suited for colder weather.

- Drape: The way a fabric hangs and flows affects the garment’s silhouette and how it falls on the body.

- Texture: The surface feel of the fabric influences comfort and aesthetics. Smooth fabrics feel luxurious, while textured fabrics might offer visual interest and breathability.

Consider the difference between a crisp cotton shirt and a soft cashmere sweater. The cotton shirt is breathable and suitable for everyday wear, while the cashmere sweater provides luxurious warmth and comfort. Understanding how different fabric properties contribute to comfort and fit allows designers and manufacturers to create garments suited for different climates, activities, and personal preferences.

Q 25. How can you identify the fiber content of a fabric?

Identifying the fiber content of a fabric can be done through several methods, ranging from simple visual inspection to sophisticated laboratory tests. Visual inspection can offer clues, but it’s not always definitive. For example, linen has a characteristic slightly rough texture, while silk displays a beautiful sheen. However, the most reliable methods involve:

- Burn Test: A small, inconspicuous sample of the fabric is carefully burned. The smell, the way it burns (fast or slow, melts or chars), and the residue left behind can provide clues about fiber type. This method requires caution and should only be done by trained professionals.

- Microscopic Examination: A small sample is examined under a microscope to identify the fiber’s cross-sectional shape and surface characteristics. This provides a more precise identification.

- Chemical Tests: Several chemical tests can differentiate between different fiber types based on their chemical composition. These tests are usually done in a laboratory setting.

- Fabric Label: The most straightforward way is to check the garment label. Legally, the label must specify the fiber content.

While the burn test can be informative, it should be approached cautiously, as improper handling could result in injury. For definitive identification, particularly for blends, laboratory testing is recommended.

Q 26. Describe the different types of fabric counts and their significance.

Fabric counts describe the density of yarns in a woven fabric. They’re expressed as the number of warp yarns (running lengthwise) and weft yarns (running widthwise) per inch or per centimeter. Understanding fabric counts is crucial because they directly affect the fabric’s weight, durability, and drape.

- Plain Weave Count: Expressed as warp yarns x weft yarns per inch (e.g., 60 x 60). A higher count indicates a denser, heavier, and more durable fabric.

- Twill Weave Count: The count is slightly more complex due to the diagonal structure. It still represents the density of yarns, but the interpretation of the feel and drape is subtly different from plain weave.

- Satin Weave Count: Similar to plain weave, the count reflects the density of yarns. However, the smooth, lustrous surface is due to the floating yarns, which also affect the drape and strength.

For example, a high thread count sheet (e.g., 300 thread count) is typically softer, smoother, and more durable than a lower thread count sheet. But the type of yarn (e.g., cotton, linen) also affects the overall quality. The count provides just one piece of the puzzle.

Q 27. Explain the concept of fabric breathability and its measurement.

Fabric breathability refers to a fabric’s ability to allow air and moisture vapor to pass through it. It’s essential for comfort, especially in clothing worn during physical activity or in warm climates. A breathable fabric helps regulate body temperature by allowing sweat to evaporate, preventing overheating and discomfort. This is different from permeability, which refers to the ability of a liquid to pass through.

Breathability is measured using various methods, often involving testing the fabric’s resistance to air and moisture vapor transfer. Common methods include:

- Air Permeability Test: Measures the rate at which air passes through a fabric sample under controlled conditions.

- Moisture Vapor Transmission Rate (MVTR) Test: Measures the rate at which water vapor passes through a fabric sample.

Higher values for both air permeability and MVTR indicate better breathability. For example, fabrics like cotton and linen have a relatively high breathability, which is why they’re often preferred for clothing worn in hot and humid environments. Synthetic fabrics, while often offering water resistance, may have lower breathability and can trap moisture, leading to discomfort.

Q 28. How do you interpret fabric testing reports?

Interpreting fabric testing reports requires a solid understanding of textile science and the specific tests conducted. Reports usually include a variety of tests, each assessing a different property. It’s critical to understand what each test measures and how the results are presented (e.g., numerical values, graphs). Common tests include:

- Tensile Strength: Measures the fabric’s resistance to pulling forces.

- Bursting Strength: Measures the fabric’s resistance to pressure applied from both sides.

- Abrasion Resistance: Measures the fabric’s resistance to wear and tear.

- Colorfastness: Measures the fabric’s resistance to fading when exposed to light, washing, or rubbing.

- Shrinkage: Measures the amount a fabric shrinks after washing or dry cleaning.

For example, a high tensile strength indicates a durable fabric suitable for applications requiring significant stress. Low abrasion resistance might suggest a fabric prone to wear and tear. A fabric testing report should be analyzed holistically, considering all the test results to fully understand the fabric’s properties and suitability for its intended application.

Interpreting these reports requires both technical knowledge and an understanding of the context – the intended use of the fabric will dictate which properties are most critical.

Key Topics to Learn for Understanding Fabric Properties Interview

- Fiber Types and Properties: Understanding natural (cotton, wool, silk, linen) and synthetic (polyester, nylon, acrylic) fibers; their characteristics (strength, durability, absorbency, drape), and how these impact fabric performance.

- Yarn Construction: Exploring different yarn types (spun, filament), ply, twist, and their influence on fabric texture, strength, and drape. Practical application: analyzing yarn count and its relation to fabric weight and quality.

- Fabric Structures: Mastering the knowledge of various weaves (plain, twill, satin), knits (jersey, rib), and their impact on fabric properties like texture, durability, and stretch. Problem-solving: identifying a fabric’s structure based on its visual characteristics and hand feel.

- Fabric Finishes: Understanding different finishing techniques (mercerization, dyeing, printing, water-repellency) and their effect on the final fabric properties. Practical application: analyzing how a finish alters a fabric’s performance, drape, and appearance.

- Fabric Testing and Quality Control: Familiarizing yourself with common fabric testing methods (tensile strength, abrasion resistance, colorfastness) and their importance in ensuring quality and meeting industry standards. Problem-solving approach: interpreting test results to identify potential fabric defects or weaknesses.

- Fabric Care and Maintenance: Understanding the impact of different washing, drying, and ironing methods on various fabrics and recommending appropriate care instructions based on fabric composition and construction.

Next Steps

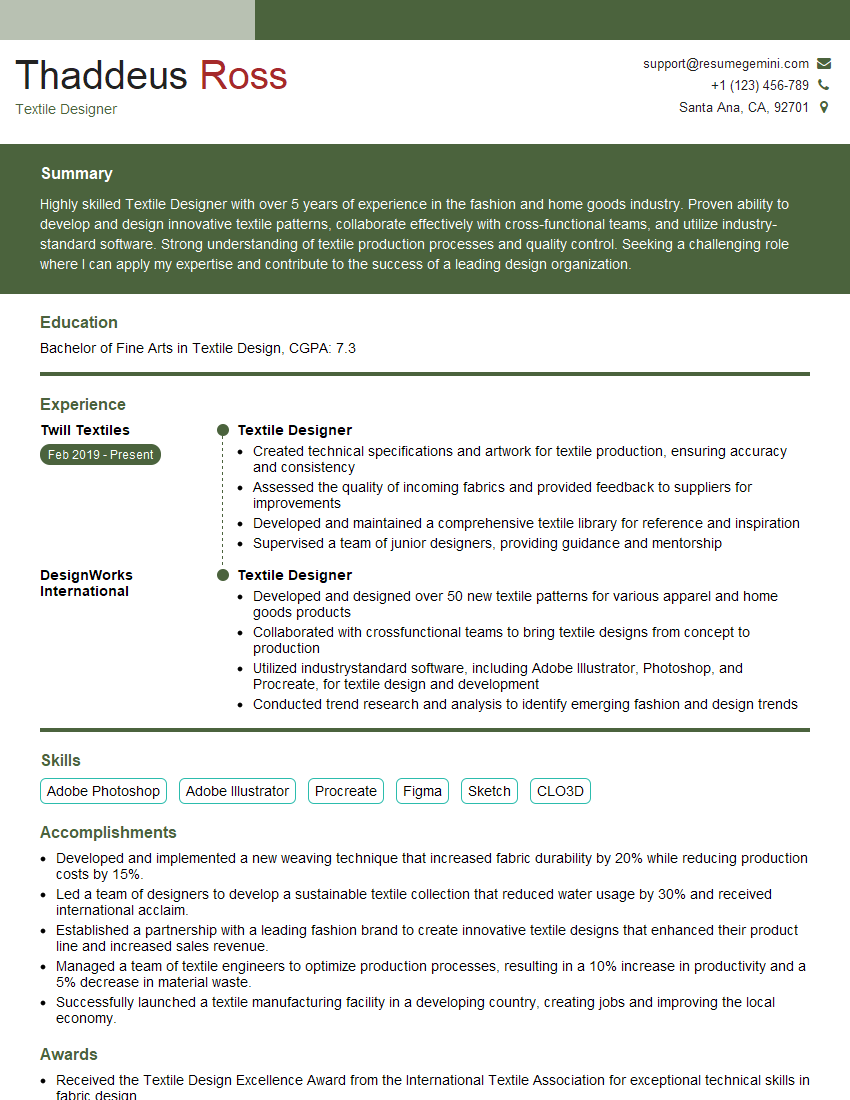

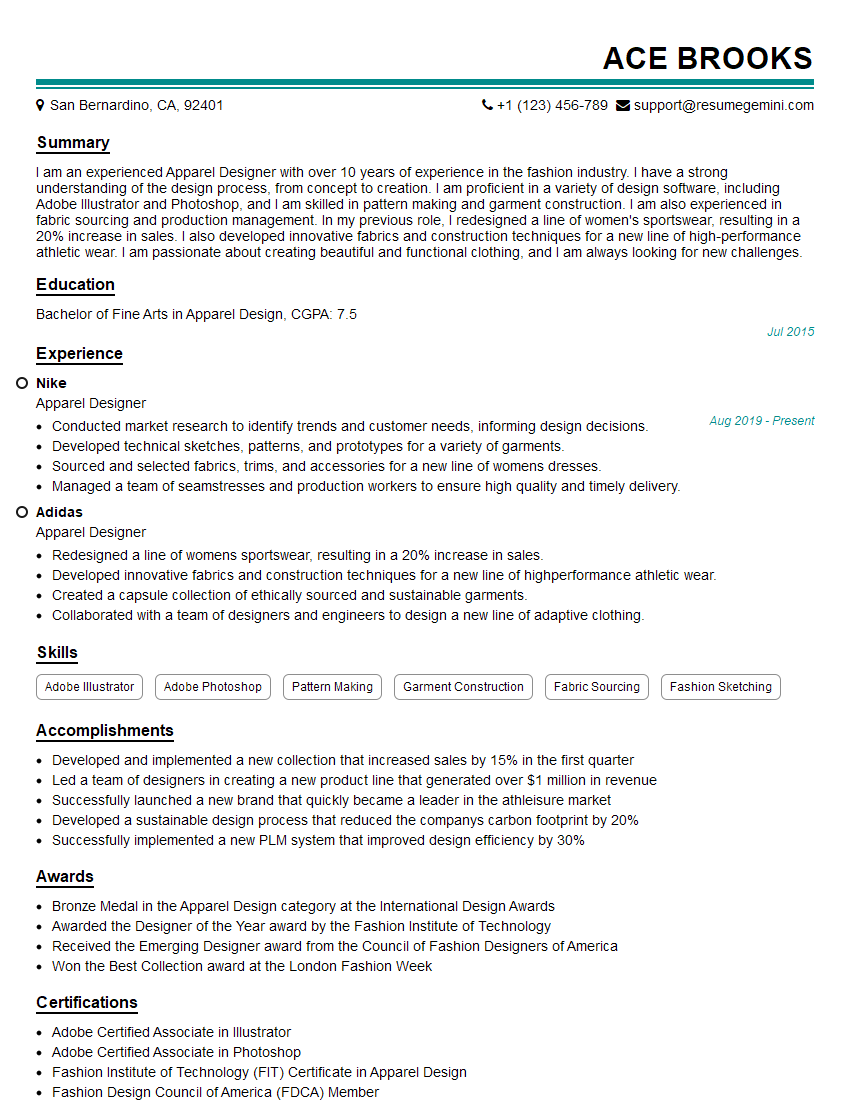

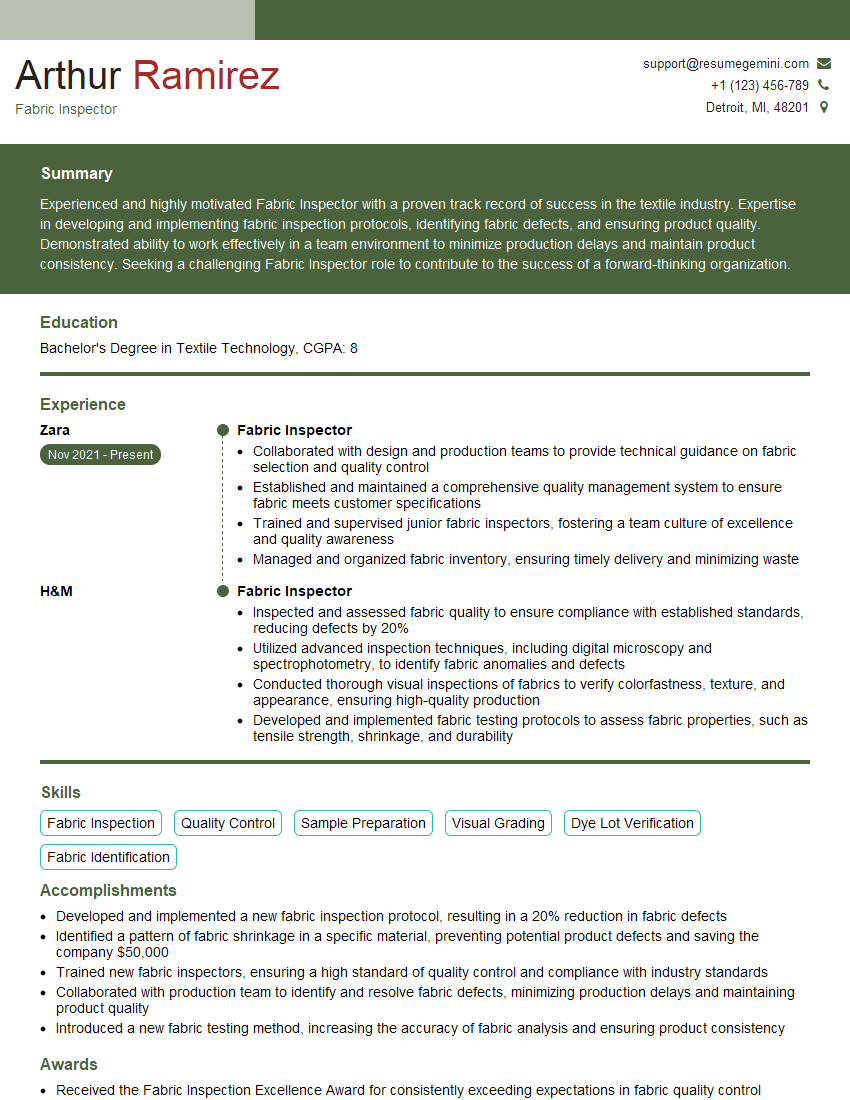

Mastering the understanding of fabric properties is crucial for career advancement in the textile and fashion industries. A strong grasp of these concepts demonstrates expertise and problem-solving skills highly valued by employers. To maximize your job prospects, focus on building an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you create a professional and impactful resume that gets noticed. We provide examples of resumes tailored to roles requiring expertise in Understanding Fabric Properties to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456