Unlock your full potential by mastering the most common Vibration Analysis and Mitigation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Vibration Analysis and Mitigation Interview

Q 1. Explain the difference between free and forced vibration.

Free vibration occurs when a system is disturbed from its equilibrium position and then allowed to oscillate without any external force acting on it. Think of a plucked guitar string – once you let go, it vibrates at its natural frequencies until the energy dissipates due to damping. The frequency at which it vibrates is determined solely by the system’s physical properties, such as mass, stiffness, and damping.

Forced vibration, on the other hand, occurs when a system is subjected to a continuous or periodic external force. Imagine the same guitar string, but now we’re continuously applying a force to it using a bow. The string now vibrates at the frequency of the applied force, which can be different from its natural frequencies. This can lead to resonance if the forcing frequency matches a natural frequency, resulting in a dramatic increase in amplitude.

The key difference lies in the presence or absence of an external force. Free vibration is governed by the system’s inherent properties, while forced vibration is influenced by the characteristics of the external force.

Q 2. Describe different types of vibration dampers and their applications.

Several types of vibration dampers exist, each designed to mitigate vibrations in specific applications.

- Viscous Dampers: These dampers use a viscous fluid (like oil or silicone) to dissipate energy. Imagine a shock absorber in a car; the fluid slows down the movement of the piston, reducing vibrations. They are commonly used in buildings and bridges to reduce seismic vibrations.

- Dry Friction Dampers: These utilize friction between two surfaces to absorb energy. Think of brakes on a bicycle – friction converts kinetic energy into heat. They are effective at high amplitudes but have less damping at low amplitudes.

- Tuned Mass Dampers (TMDs): These are essentially large masses attached to a structure through springs and dampers. They are designed to oscillate out of phase with the structure’s vibrations, counteracting them. A famous example is the TMD in Taipei 101, which helps mitigate wind-induced vibrations.

- Active Dampers: These use sensors and actuators to actively counteract vibrations. They measure the vibration and then apply an opposing force to reduce it. They are more complex but offer greater control over damping.

The choice of damper depends on factors like the frequency range of the vibration, the amplitude, the environmental conditions, and the cost.

Q 3. How do you identify the natural frequencies of a structure?

Identifying the natural frequencies of a structure involves determining the frequencies at which the structure will vibrate freely when disturbed. There are several ways to do this:

- Experimental Modal Analysis: This involves exciting the structure with an external force (e.g., an impact hammer or shaker) and measuring its response using accelerometers. The resulting data is then analyzed to identify the natural frequencies and mode shapes. This is a widely used method for complex structures.

- Finite Element Analysis (FEA): This numerical method uses computer software to model the structure and predict its dynamic behavior, including its natural frequencies. It’s a valuable tool for design optimization and avoiding resonance issues before construction.

- Simple Formulae: For simpler structures like beams or strings, we can use simplified equations based on material properties and geometry to estimate natural frequencies. These calculations are less accurate for more complex geometries.

The choice of method depends on the complexity of the structure, the required accuracy, and available resources.

Q 4. What are the common methods for measuring vibration?

Vibration measurements are crucial in vibration analysis. Common methods include:

- Accelerometers: These are the most common sensors, measuring acceleration. They are relatively inexpensive, robust, and widely available. The measured acceleration can be integrated to obtain velocity and displacement.

- Velocity sensors (Velocity Pickups): These directly measure velocity and are often preferred for low-frequency applications.

- Displacement sensors (LVDTs): These measure displacement and are useful for measuring large displacements or very low frequencies.

- Laser vibrometers: These non-contact sensors use laser light to measure vibration velocity. They are particularly useful for measuring vibrations in hard-to-access locations or delicate structures.

The choice of sensor depends on the frequency range of interest, the amplitude of vibration, and the environmental conditions.

Q 5. Explain the concept of modal analysis and its importance in vibration analysis.

Modal analysis is a crucial technique used to characterize the dynamic behavior of a structure. It involves identifying the structure’s natural frequencies (resonant frequencies), mode shapes (the pattern of vibration at each natural frequency), and damping ratios (how quickly the vibrations decay).

Imagine a building swaying in the wind. Modal analysis helps determine the building’s natural frequencies, so we can design it to avoid resonance with wind gusts. If the building’s natural frequency aligns with the frequency of the wind, significant damage can occur. By identifying these modes, engineers can design structures that avoid resonant frequencies and enhance stability.

The importance of modal analysis lies in its ability to predict how a structure will respond to dynamic loads, enabling engineers to design safer and more robust structures. It is a powerful tool for troubleshooting vibration problems and optimizing designs.

Q 6. What are the different types of vibration sensors and their principles of operation?

Various vibration sensors are used depending on the application’s specific requirements. Here are a few types and their operating principles:

- Piezoelectric Accelerometers: These rely on the piezoelectric effect, where a material generates an electric charge when subjected to mechanical stress (acceleration). The charge is proportional to the acceleration, allowing for measurement.

- Electromagnetic Velocity Pickups: These use a coil of wire moving within a magnetic field; the induced voltage is proportional to the velocity of the coil’s movement.

- Capacitive Displacement Sensors: These measure changes in capacitance between two plates as the distance between them (displacement) varies. Changes in capacitance reflect displacement.

- Optical Sensors (Laser Vibrometers): These utilize the Doppler effect; the frequency shift in a laser beam reflected from a vibrating surface is proportional to the velocity of that surface.

The selection of the most appropriate sensor depends on factors such as the frequency range, amplitude, environmental conditions, and required accuracy.

Q 7. How do you interpret a frequency spectrum?

A frequency spectrum is a graphical representation of the amplitude or power of different frequency components in a signal. It’s essentially a breakdown of the vibration signal into its constituent frequencies. The horizontal axis represents frequency (usually in Hertz or Hz), and the vertical axis represents amplitude or power (often in decibels or dB).

Interpreting a frequency spectrum involves identifying the dominant frequencies – those with the highest amplitudes. These often correspond to the natural frequencies of the system or the frequencies of external forces. High amplitude peaks near the structure’s natural frequencies could indicate resonance and potential problems.

For example, a sharp peak at 100Hz in a machine’s vibration spectrum might indicate that a component is vibrating at its natural frequency of 100Hz, potentially leading to fatigue and failure. Analyzing the spectrum allows for pinpointing the sources of vibration and designing appropriate mitigation strategies.

Q 8. Describe the process of conducting a vibration test.

Conducting a vibration test involves a systematic process aimed at quantifying and characterizing vibrations in a machine or structure. It begins with defining the objectives – what specific aspects of vibration are we interested in measuring? Are we looking for overall vibration levels, specific frequencies, or the response to a certain input? Then comes sensor placement, crucial for accurate data acquisition. Accelerometers, velocity transducers, or displacement sensors are strategically placed based on the anticipated vibration modes and sources. The choice of sensor depends on the frequency range of interest and the amplitude of the vibrations.

Next comes the data acquisition phase. Specialized equipment, like data loggers or spectrum analyzers, records the sensor signals. The sampling rate must be chosen carefully to capture the highest frequencies of interest, following the Nyquist-Shannon sampling theorem. Simultaneously, operational data, such as speed, load, and temperature, is also recorded to correlate with the vibration measurements. After data acquisition, signal processing and analysis are done. This often involves Fast Fourier Transforms (FFTs) to convert time-domain signals into frequency-domain spectra. This allows us to identify the dominant frequencies and amplitudes of vibration, giving clues about the source and nature of the problem. Finally, the results are interpreted, often leading to a report that includes recommendations for mitigation or further investigation.

Example: Imagine testing a large industrial fan. We might place accelerometers on the motor bearings, the fan blades, and the supporting structure. We’d then run the fan at different speeds, recording the vibration data. Analyzing the FFTs of this data might reveal a strong peak at a specific frequency indicating a resonance problem or imbalance in the fan blades.

Q 9. Explain the concept of resonance and its implications.

Resonance is a phenomenon where a system vibrates with maximum amplitude at a specific frequency, known as the resonant frequency. This occurs when the frequency of an external force matches the system’s natural frequency of vibration. Think of pushing a child on a swing – you push at the natural frequency of the swing to achieve maximum amplitude. In machinery, resonance can be catastrophic. Even relatively small external forces at the resonant frequency can lead to dangerously large vibrations, causing damage to components, premature failure, and even structural collapse.

Implications: High-amplitude vibrations due to resonance lead to increased stress and strain on machine components, resulting in fatigue, cracking, and eventual failure. It can also lead to noise pollution and operational disruptions. Resonance can be difficult to predict accurately without sophisticated modeling techniques like Finite Element Analysis (FEA).

Example: An improperly designed bridge can collapse if a passing truck excites a resonance condition. Similarly, an unbalanced rotor in a pump can induce large vibrations in the pump casing if its operating speed is near a resonant frequency of the casing.

Q 10. What are some common sources of vibration in rotating machinery?

Rotating machinery is a significant source of vibration, and several factors contribute to this. Unbalance is a primary culprit – an uneven distribution of mass in a rotating component leads to centrifugal forces that cause vibration. Misalignment between shafts or components induces forces and moments that generate vibrations. Looseness of parts (e.g., bolts, bearings) causes impacts and erratic motions. Bearing defects, such as wear, damage, or improper lubrication, can produce characteristic vibration signatures.

Further, gear meshing inaccuracies result in repetitive impacts and vibrations. Aerodynamic forces in fans and compressors can excite resonant vibrations. Fluid-induced forces (e.g., in pumps) and electrical imbalances in motors all contribute to the complexity of vibration sources in rotating equipment.

Example: An unbalanced washing machine drum causes noticeable vibration during the spin cycle. A misaligned motor coupling in a pump can lead to increased vibration and bearing wear.

Q 11. How do you identify and diagnose vibration problems in rotating equipment?

Identifying and diagnosing vibration problems in rotating equipment is a systematic process. It begins with collecting vibration data using accelerometers, as described earlier. The data is then analyzed using spectral analysis techniques (FFT). Characteristic frequency peaks in the spectrum can help pinpoint the source. For example, imbalances usually produce peaks at the rotational frequency (1x), while misalignment often exhibits peaks at 2x and higher harmonics. Bearing defects often produce distinct frequencies related to the bearing geometry and operating conditions.

Data Analysis Techniques: We use several sophisticated signal processing techniques like order analysis (analyzing vibration data in relation to the rotational speed) which is particularly useful in analyzing data from rotating machinery operating at variable speeds. Time-waveform analysis helps detect impulsive events (like impacts). Orbit plots are beneficial to analyze the motion of rotating components like the rotor shaft. Combining these analysis techniques helps in precise fault diagnosis.

Example: A sharp peak at the rotational frequency (1x) in the spectrum of a motor suggests an imbalance. A series of peaks at multiples of the rotational frequency could signify gear problems. High-frequency peaks might suggest bearing damage. Visual examination and further diagnostic tests are often crucial to confirm the diagnosis.

Q 12. Explain different techniques for vibration mitigation.

Vibration mitigation techniques aim to reduce or eliminate unwanted vibrations. These methods can be broadly classified into passive and active techniques. Passive techniques involve modifying the system’s physical characteristics to reduce its susceptibility to vibration. Examples include:

- Adding damping: Using materials like rubber or viscoelastic polymers to absorb vibration energy.

- Stiffening structures: Increasing the rigidity of components to increase their natural frequencies and move them away from excitation frequencies.

- Dynamic vibration absorbers: Adding a secondary mass-spring system tuned to absorb energy at specific frequencies.

- Isolation: Mounting machines on vibration isolators (e.g., springs, elastomers) to reduce the transmission of vibrations to the surrounding structure.

Active techniques involve actively controlling the vibrations using sensors and actuators. These might include:

- Active vibration control: Using feedback control systems to counteract vibrations in real-time.

- Active balancing: Actively adjusting the mass distribution of rotating components to minimize imbalance.

The choice of technique depends on the specific application, cost, complexity, and the required level of vibration reduction.

Example: Installing vibration isolators under a compressor reduces the transmission of vibrations to the building. Active balancing of a motor reduces vibrations due to rotor imbalance.

Q 13. What is the role of Finite Element Analysis (FEA) in vibration analysis?

Finite Element Analysis (FEA) is a powerful computational tool used to model and analyze the structural behavior of systems, including their response to vibration. In vibration analysis, FEA allows engineers to predict natural frequencies, mode shapes, and dynamic responses of complex structures under various loading conditions. It uses a numerical method to divide the structure into a finite number of elements, each with simpler characteristics, enabling easier calculation of the overall system’s behavior.

Applications in Vibration Analysis: FEA helps predict resonance frequencies, allowing engineers to design systems to avoid resonance conditions. It enables the optimization of structural design for minimizing vibration transmission. It can be used to analyze the effectiveness of vibration mitigation techniques before implementation. FEA also aids in understanding complex vibration phenomena in structures and predicting the effects of modifications on vibration levels.

Example: Before building a new bridge, engineers use FEA to model the bridge’s response to wind loads and traffic vibrations. This helps ensure that the design avoids resonance and can withstand expected dynamic loads.

Q 14. How do you perform a modal survey?

A modal survey is an experimental technique used to determine the dynamic characteristics of a structure, specifically its natural frequencies (resonant frequencies) and mode shapes (the pattern of vibration at each resonant frequency). It’s crucial for understanding how a structure will respond to dynamic forces. The process typically involves exciting the structure with an external force (e.g., an impact hammer or shaker) and measuring its response using accelerometers at multiple points. The data acquired is then processed to identify the natural frequencies and mode shapes.

Procedure: The structure is excited at various points, and the response is measured at multiple locations using accelerometers. This data is analyzed using modal analysis software to extract the natural frequencies and mode shapes. Data processing often involves curve-fitting techniques to accurately estimate the modal parameters. Multiple excitation points and measurement locations are necessary to ensure sufficient data for accurate modeling of the structure’s dynamic characteristics.

Applications: Modal surveys are commonly used in structural health monitoring, machine design, and troubleshooting vibration problems in buildings and other structures. It helps identify potential resonance issues, assess the structural integrity, and inform modifications to reduce unwanted vibrations.

Example: A modal survey on a large industrial machine might reveal a natural frequency close to the operating speed, indicating a potential resonance issue. This information allows engineers to modify the machine’s design or operating parameters to avoid resonance.

Q 15. Describe the concept of Operational Deflection Shapes (ODS).

Operational Deflection Shapes (ODS) are a powerful visualization tool in vibration analysis. Imagine you’re looking at a machine vibrating – ODS show you the *shape* the machine takes at its peak vibration. Instead of just seeing a single value of vibration at a point, ODS gives you a visual representation of how the entire structure moves during a specific frequency of vibration. This is achieved by measuring the vibration at multiple points on the structure and then synchronizing and plotting these measurements.

For example, let’s say we’re analyzing a tall building’s response to wind. A simple vibration measurement at the top might just give you the amplitude. But an ODS would reveal *how* the whole building sways – does it sway like a rigid body, or are certain floors moving more than others? This helps pinpoint areas of high stress and potential weakness. The data is often presented as a 3D model of the structure, with arrows indicating the direction and magnitude of displacement at each measurement point for a specific mode shape (a characteristic vibration pattern).

ODS are crucial for diagnosing structural problems. They help identify resonance frequencies, locate points of high stress, and evaluate the effectiveness of vibration mitigation strategies. They’re indispensable in industries like aerospace, civil engineering, and rotating machinery maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common vibration troubleshooting techniques?

Vibration troubleshooting is a systematic process. We start by collecting data, then analyze, diagnose, and finally implement solutions. Here are some common techniques:

- Data Acquisition: This involves using accelerometers, proximity probes, or other sensors to measure vibration levels and frequencies at various points on the machine. Proper sensor placement is critical for accurate data.

- Spectral Analysis: Analyzing the frequency content of the vibration data using Fast Fourier Transforms (FFT). This helps identify dominant frequencies and pinpoint the source of the vibration (e.g., imbalance, misalignment, resonance). Imagine listening to a chord on a guitar – an FFT would decompose that sound into its constituent notes (frequencies).

- Order Analysis: This technique is particularly useful for rotating machinery. It relates vibration frequencies to the rotational speed of the machine, allowing you to pinpoint issues like imbalances or gear meshing problems. It’s like noticing a repetitive squeak that gets faster or slower based on engine RPM.

- Time Waveform Analysis: Examining the raw vibration signal in the time domain can reveal transient events, such as impacts or shocks. It’s like watching a video compared to looking only at snapshots.

- Modal Analysis: Used to determine the natural frequencies and mode shapes of a structure. This allows for prediction of how a structure will respond to different excitation forces and identification of resonant frequencies to avoid.

- Visual Inspection: A simple yet effective technique, often providing clues for further investigation. Look for loose bolts, misalignment, wear and tear, and other obvious causes.

Troubleshooting is often an iterative process. You might find a problem, address it, and then need to revisit the analysis to ensure the problem is completely resolved.

Q 17. What are the advantages and disadvantages of different vibration isolation techniques?

Vibration isolation aims to minimize the transmission of vibrations from a source to a sensitive receiver. Several techniques exist, each with trade-offs:

- Passive Isolation: This uses materials with high damping and low stiffness, such as rubber, springs, or elastomers.

- Advantages: Simple, cost-effective, requires minimal maintenance.

- Disadvantages: Limited effectiveness at low frequencies, susceptible to temperature and aging effects, may not be suitable for high-amplitude vibrations.

- Active Isolation: This uses sensors and actuators to actively counteract vibrations.

- Advantages: Highly effective over a wide frequency range, can handle high-amplitude vibrations, adaptable to changing conditions.

- Disadvantages: More complex and expensive, requires power, may be susceptible to control system failures.

- Semi-active Isolation: Combines aspects of passive and active isolation. For instance, using adjustable dampers.

- Advantages: Good compromise between cost and performance, can be more robust than purely active systems.

- Disadvantages: Can be complex to design and tune.

The choice of technique depends on factors such as the frequency and amplitude of the vibration, the sensitivity of the equipment being protected, and the budget constraints.

Q 18. How do you analyze vibration data using signal processing techniques?

Signal processing techniques are crucial for extracting meaningful information from vibration data. The process often involves these steps:

- Data Acquisition: Collecting the vibration data using appropriate sensors and sampling rates. The sampling rate must be at least twice the highest frequency of interest (Nyquist-Shannon theorem).

- Preprocessing: Cleaning and preparing the data. This may include filtering to remove noise, detrending to remove unwanted trends, and resampling to change the data rate.

- FFT (Fast Fourier Transform): Converting the time-domain signal (vibration amplitude vs. time) into the frequency domain (amplitude vs. frequency). This reveals the dominant frequencies present in the signal.

- Order Analysis: If the vibration source is rotating machinery, order analysis relates vibration frequencies to the rotational speed, providing valuable insights into the source of vibration.

- Wavelet Transform: A more advanced technique that can analyze signals with non-stationary characteristics, meaning signals where the frequency content changes over time. This can help detect transient events.

- Statistical Analysis: Calculating statistics such as mean, standard deviation, kurtosis, and skewness to further characterize the signal and assess the severity of vibration.

Software packages like MATLAB, LabVIEW, and specialized vibration analysis software are commonly used for these analyses. The choice of techniques depends on the specific problem and the data collected.

Q 19. Explain the concept of shock and its impact on machinery.

Shock is a sudden, transient vibration with a high amplitude and short duration. Imagine hitting a table – that’s a shock event. Unlike continuous vibrations, shocks involve sudden changes in velocity and acceleration.

The impact of shock on machinery can be significant. Repeated shocks can cause fatigue and damage to machine components, leading to premature failure. It can loosen fasteners, crack welds, cause bearing damage, and lead to malfunction. For example, a sudden impact during transportation can severely damage delicate instruments or even cause catastrophic failure in a critical component.

Shock testing is often conducted to assess a machine’s resistance to these sudden events. The severity of the shock is typically characterized by its peak acceleration or the shape of the shock pulse. Shock mounts and other isolation systems are designed to mitigate the effects of shock on equipment.

Q 20. What are some common standards related to vibration analysis and mitigation?

Several standards guide vibration analysis and mitigation. These ensure consistency and help compare results across different projects and organizations. Some key examples include:

- ISO 10816: This series of standards provides guidelines for evaluating the vibration levels of machinery under operating conditions. It’s widely used in various industries.

- API 617: Covers the vibration standards for centrifugal compressors.

- API 618: Covers the vibration standards for reciprocating compressors.

- ISO 2041: This standard addresses mechanical vibration and shock – measurement and evaluation of machine vibration.

- ANSI/ASA S12.54: Deals with the measurement and evaluation of sound and vibration.

The specific standard to use will depend on the type of machinery and the application. These standards provide acceptance criteria and guidelines to ensure that machines are operating safely and within acceptable vibration limits.

Q 21. How do you assess the risk associated with excessive vibration?

Assessing the risk associated with excessive vibration requires a multi-faceted approach. It involves considering several factors:

- Vibration Levels: Comparing measured vibration levels to accepted limits defined in relevant standards (like ISO 10816). Exceeding these limits indicates a potential risk.

- Frequency Content: The frequency of the vibration is crucial. Vibration at a machine’s natural frequency (resonance) can amplify the effects and cause more significant damage.

- Duration of Exposure: Prolonged exposure to even low levels of vibration can be harmful. Continuous vibration is generally more damaging than short bursts.

- Type of Machinery: The consequences of excessive vibration differ greatly depending on the type of machine and its criticality. Failure of a pump is far less serious than failure of a nuclear reactor component.

- Criticality of the Equipment: A failure of a critical piece of equipment (e.g., in an aircraft engine) could have far greater consequences than the failure of less critical equipment (e.g., a washing machine).

- Potential Consequences of Failure: What are the potential consequences if the equipment fails due to excessive vibration? Consider the damage to the equipment itself, potential injuries to personnel, environmental hazards, or economic losses.

Risk assessment often involves a combination of quantitative data (vibration measurements) and qualitative factors (consequences of failure). A risk matrix can be used to visualize and prioritize risks, helping to allocate resources effectively for mitigation efforts.

Q 22. Explain different types of vibration isolators and their selection criteria.

Vibration isolators are crucial components in mitigating unwanted vibrations. They act as a buffer between a vibrating machine and its supporting structure, reducing the transmission of vibrations. Several types exist, each with its strengths and weaknesses.

- Passive Isolators: These are the most common and rely on the inherent properties of materials to absorb or redirect vibrations. Examples include:

- Rubber Isolators: Simple, cost-effective, and suitable for low-frequency vibrations. Their effectiveness diminishes at higher frequencies.

- Spring Isolators: Provide excellent isolation at their natural frequency but require careful selection to avoid resonance issues. Steel springs are common, but air springs offer adjustable stiffness.

- Metal Isolators: Often used for higher load applications and provide better durability than rubber. They can be designed for specific frequency ranges.

- Viscoelastic Isolators: Incorporate damping material to dissipate vibrational energy, effective over a broader frequency range than simple springs or rubber.

- Active Isolators: These employ sensors and actuators to counteract vibrations in real-time. They are more complex and expensive but offer superior performance, particularly in high-precision applications.

- Semi-Active Isolators: These combine features of both passive and active isolators. They use passive elements but adjust their properties (like damping) based on real-time feedback, offering a compromise between cost and performance.

Selection Criteria: The choice of isolator depends on factors like:

- Frequency of vibration: Isolators are most effective at frequencies above their natural frequency.

- Amplitude of vibration: Higher amplitude vibrations require isolators with greater capacity.

- Load capacity: Isolators must be able to support the weight of the equipment.

- Environmental conditions: Temperature, humidity, and other factors can impact isolator performance.

- Cost: Passive isolators are generally less expensive than active or semi-active ones.

- Space constraints: The available space can limit the size and type of isolator.

For example, a delicate scientific instrument might necessitate an active isolator for superior vibration control, while a heavy industrial machine might utilize multiple spring or viscoelastic isolators for cost-effectiveness.

Q 23. Describe your experience with vibration analysis software (e.g., MATLAB, ANSYS).

I possess extensive experience using various vibration analysis software packages. My primary tools have been MATLAB and ANSYS. In MATLAB, I’ve used toolboxes like the Signal Processing Toolbox to perform Fast Fourier Transforms (FFTs) on vibration data to identify dominant frequencies and analyze harmonic content. I’ve also utilized custom scripts for data processing, filtering, and visualization.

% Example MATLAB code snippet for FFT analysis [f,X] = fft(vibrationData); plot(f,abs(X)); %Plot frequency spectrum With ANSYS, I’ve conducted Finite Element Analysis (FEA) simulations to predict the vibrational behavior of complex mechanical systems. This has been invaluable in designing and optimizing vibration mitigation strategies before physical implementation. For example, I’ve modeled the vibrational response of a turbine blade to identify resonant frequencies and implement design changes to reduce stress and prevent failure. The software allowed me to analyze mode shapes, natural frequencies, and stress distributions under various operating conditions.

Q 24. Explain your experience using vibration monitoring equipment.

My experience with vibration monitoring equipment spans a variety of technologies. I’m proficient in using accelerometers, proximity probes, and velocity transducers to acquire vibration data. I’ve worked with both handheld data acquisition units and permanently installed monitoring systems, encompassing wired and wireless data transmission methods. Data acquisition typically involves proper sensor placement, calibration, and signal conditioning to ensure the accuracy and reliability of the measurements.

I’m familiar with the intricacies of different sampling rates, anti-aliasing filters, and data logging protocols. For instance, in a recent project involving a large industrial pump, we deployed a network of accelerometers strategically positioned along the pump casing and connected to a central data acquisition system. This provided comprehensive spatial data that we could analyze to pinpoint the source of a problematic vibration.

Q 25. How do you handle conflicting requirements in vibration mitigation projects?

Conflicting requirements are common in vibration mitigation projects. For example, a project might require both high isolation and minimal space, which can be mutually exclusive. To handle these, I employ a structured approach:

- Clearly Define All Requirements: Document all constraints and objectives, including performance goals, budget limitations, space restrictions, and operational needs.

- Prioritize Requirements: Rank requirements based on their importance using techniques like weighted scoring or pairwise comparisons. This clarifies which constraints are most critical.

- Explore Trade-offs: Investigate various options and assess the compromises involved in satisfying different requirements. For example, a smaller, less effective isolator might be preferable to a larger, more effective one if space is highly limited.

- Iterative Design and Optimization: Use simulation tools (like ANSYS) to evaluate different design solutions and optimize for the most critical requirements. This allows iterative adjustments to find the best compromise.

- Collaboration and Communication: Open communication with stakeholders is vital to ensure everyone understands the trade-offs and agrees on the final solution. This might involve presenting different scenarios and their implications.

For instance, in a recent project involving a precision manufacturing machine, we had conflicting requirements for vibration isolation and floor space. By prioritizing vibration isolation and utilizing a custom-designed active isolator with a smaller footprint, we successfully mitigated the vibration while minimizing the space impact.

Q 26. Describe a situation where you had to troubleshoot a complex vibration problem.

I once encountered a complex vibration problem in a high-speed centrifugal pump. The pump experienced excessive vibrations, causing operational disruptions and potential damage. Initial investigations using simple vibration analysis tools identified high levels of vibration at specific frequencies, but the source remained elusive. We systematically investigated potential causes:

- Comprehensive Data Acquisition: We deployed multiple accelerometers at various locations on the pump and its supporting structure, recording data at high sampling rates.

- Advanced Signal Processing: We used advanced signal processing techniques in MATLAB, including order tracking and spectral analysis, to identify the specific frequency components and their relationship to the pump’s rotational speed. This revealed harmonic components indicating imbalance.

- FEA Validation: We used ANSYS to model the pump’s dynamic behavior and validate our findings. The simulation confirmed that an imbalance in the impeller was the primary cause of the vibrations.

- Corrective Action: Based on the simulation results, the impeller was dynamically balanced, eliminating the excessive vibrations. Post-balancing vibration measurements confirmed the success of the corrective action.

This case highlighted the importance of using a combination of experimental data acquisition, advanced signal processing, and FEA simulation to diagnose and solve complex vibration problems. A methodical approach was crucial to accurately pinpoint the root cause.

Q 27. How do you ensure data accuracy and reliability in vibration analysis?

Data accuracy and reliability are paramount in vibration analysis. Several measures ensure this:

- Sensor Calibration and Verification: Regular calibration of accelerometers, proximity probes, and other sensors against traceable standards is essential. Calibration ensures measurements are accurate and traceable. Verification checks ensure the calibration remains valid.

- Proper Sensor Placement: The location of sensors is crucial. Sensors should be positioned to capture relevant vibrations and minimize noise. Careful consideration of mounting techniques minimizes errors.

- Signal Conditioning: Appropriate signal conditioning, including filtering and amplification, is necessary to minimize noise and interference. This enhances the signal-to-noise ratio, making the data cleaner.

- Data Validation: Before analyzing data, it must be validated. Check for inconsistencies, spikes, or artifacts that might indicate errors. Data plausibility checks based on engineering knowledge are helpful.

- Statistical Analysis: Utilizing statistical methods helps quantify uncertainty and variability. This provides confidence intervals and assesses measurement precision.

- Data Redundancy: Employ multiple sensors or multiple measurements from the same sensor to compare and validate data, improving confidence in the results.

For example, in a critical rotating machinery application, we used multiple accelerometers and compared their data to validate the measurements. Any significant discrepancies would trigger a review of sensor placement or data acquisition procedures. By diligently following these steps, we significantly reduced the chances of erroneous conclusions due to faulty data.

Q 28. Explain your understanding of predictive maintenance strategies using vibration analysis.

Predictive maintenance (PdM) strategies using vibration analysis are crucial for preventing catastrophic failures and optimizing maintenance schedules. By analyzing vibration data, we can identify developing faults well before they lead to equipment downtime. This approach is cost-effective, enhances safety, and improves overall equipment effectiveness (OEE).

The process typically involves:

- Baseline Data Acquisition: Establishing a baseline of ‘normal’ vibration characteristics for each machine is essential. This serves as a benchmark for future comparisons.

- Continuous Monitoring: Regularly monitoring vibration levels using sensors and data acquisition systems. This data is analyzed to detect deviations from the baseline.

- Fault Detection and Diagnosis: Using advanced signal processing and diagnostic techniques (like FFT, time-waveform analysis, and spectral analysis) to identify specific faults like imbalance, misalignment, bearing defects, or looseness.

- Predictive Modeling: Developing predictive models that forecast the remaining useful life (RUL) of components based on the identified fault progression. This allows for proactive maintenance scheduling.

- Maintenance Scheduling: Using the RUL predictions to schedule maintenance at the optimal time – before a failure occurs but not prematurely.

For example, detecting a gradual increase in specific frequency components in the vibration spectrum of a rolling element bearing can indicate impending bearing failure. This allows for timely replacement of the bearing, preventing catastrophic failure and costly unplanned downtime. PdM using vibration analysis transforms reactive maintenance into a proactive and cost-effective strategy.

Key Topics to Learn for Vibration Analysis and Mitigation Interview

- Fundamentals of Vibration: Understanding basic concepts like frequency, amplitude, resonance, damping, and different types of vibrations (free, forced, damped).

- Modal Analysis: Learn how to identify natural frequencies and mode shapes of structures using experimental and analytical techniques. Practical application: Predicting resonant frequencies to avoid structural damage in machinery.

- Vibration Measurement Techniques: Mastering the use of accelerometers, proximity probes, and other sensors for data acquisition. Practical application: Diagnosing machine malfunctions through vibration signature analysis.

- Signal Processing and Analysis: Familiarity with Fast Fourier Transforms (FFT), spectral analysis, and order tracking. Practical application: Isolating specific frequency components to pinpoint the source of vibration.

- Vibration Isolation and Damping Techniques: Understanding passive and active isolation methods, including vibration dampers, isolators, and tuned mass dampers. Practical application: Designing systems to minimize vibration transmission to sensitive equipment or the environment.

- Predictive Maintenance using Vibration Analysis: Applying vibration data to predict potential failures and schedule maintenance proactively. Practical application: Reducing downtime and maintenance costs through early fault detection.

- Finite Element Analysis (FEA) in Vibration: Using FEA software to model and simulate vibration behavior of complex structures. Practical application: Optimizing designs to minimize vibration and noise.

- Case Studies and Problem Solving: Develop your ability to analyze real-world vibration problems and propose effective mitigation strategies. This involves critical thinking and applying theoretical knowledge to practical scenarios.

Next Steps

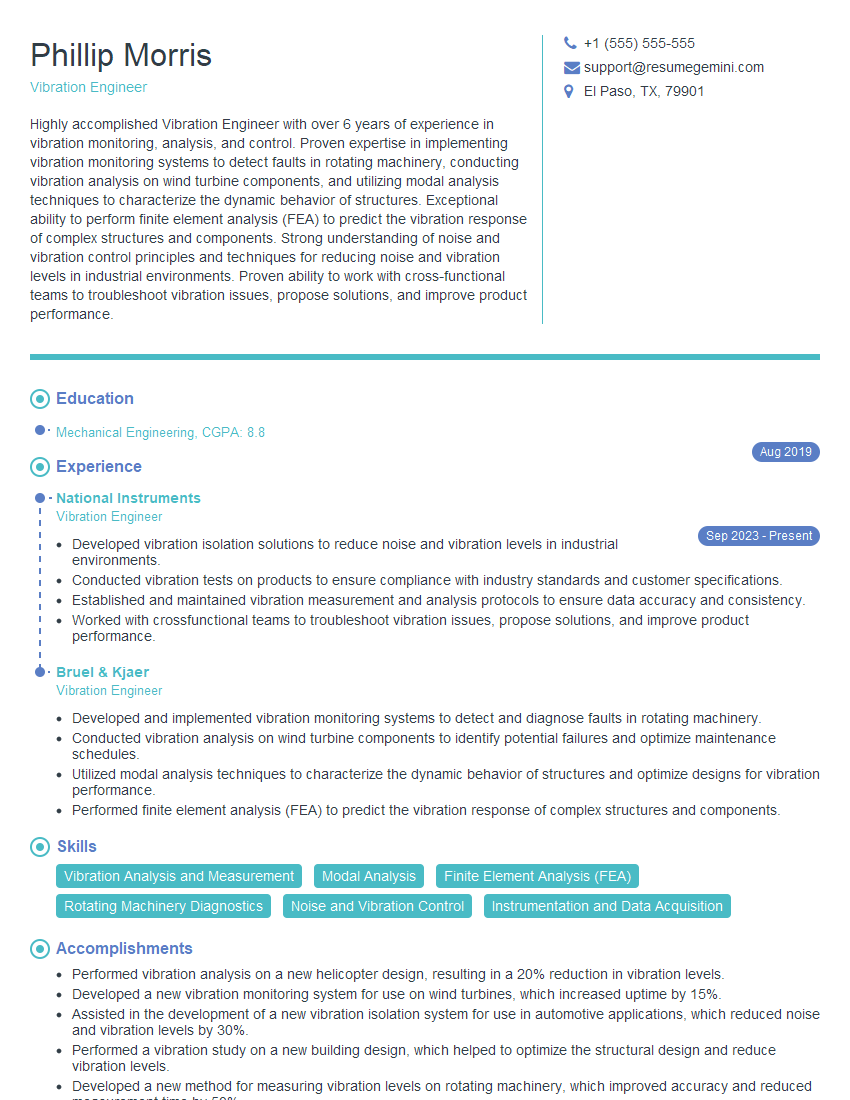

Mastering Vibration Analysis and Mitigation opens doors to exciting career opportunities in diverse industries, offering excellent growth potential and high demand. A strong resume is crucial for showcasing your skills and experience to potential employers. An ATS-friendly resume is essential for navigating Applicant Tracking Systems, increasing your chances of getting your application noticed. To create a professional and effective resume that highlights your expertise, we encourage you to utilize ResumeGemini, a trusted resource for building impactful resumes. ResumeGemini provides examples of resumes tailored to Vibration Analysis and Mitigation to help guide you. This will significantly enhance your job prospects and accelerate your career journey in this exciting field.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?