Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Zemax Optical Design Software interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Zemax Optical Design Software Interview

Q 1. Explain the difference between sequential and non-sequential ray tracing in Zemax.

Zemax offers two primary ray tracing methods: sequential and non-sequential. Sequential ray tracing is ideal for systems where light travels through a series of optical elements in a predictable, linear path. Think of it like a well-organized assembly line – each component processes the light before passing it to the next. This method is efficient and fast, making it perfect for designing traditional lens systems. Non-sequential ray tracing, conversely, simulates light’s interaction with complex geometries, allowing for the inclusion of scattered light, diffraction effects from rough surfaces, and complex reflective and refractive elements. This is akin to modeling a chaotic scene – like light bouncing around in a room – where precise path prediction is difficult. It’s computationally more intensive, used for systems like illumination design, free-space optical communication, and systems with scattering effects.

Example: Designing a simple camera lens would generally utilize sequential ray tracing due to its well-defined path. In contrast, designing a projector where light scattering from the screen is important would likely leverage non-sequential ray tracing.

Q 2. Describe your experience with different optimization algorithms in Zemax (e.g., Damped Least Squares, Merit Function).

My experience encompasses a wide range of Zemax optimization algorithms. The Damped Least Squares (DLS) algorithm is a workhorse, particularly effective when starting from a well-designed system. It balances speed and accuracy, making small, controlled adjustments to parameters in order to refine the performance against a merit function. However, it can sometimes get stuck in local minima. For more complex optimization scenarios or when the initial design is far from optimal, I often utilize more robust algorithms such as the Global Optimization algorithms within Zemax, these methods are particularly helpful when the landscape of the merit function is characterized by many local minima. These advanced methods effectively explore a broader region of the parameter space. The merit function itself is crucial, defining the optimization goals; I typically incorporate multiple operands to balance different aspects like spot size, wavefront error, and chromatic aberration. I have extensive experience in defining merit functions to prioritize specific design requirements based on the application’s needs. The weighting of individual operands in a merit function is crucial to prioritize design goals. For example, prioritizing image sharpness over distortion would require careful weighting of the MTF operands and distortion operands within the merit function.

Example: In optimizing a high-resolution telescope objective, I might use DLS for fine-tuning after using a global optimization method to find a good starting point. The merit function would include operands for RMS spot radius, wavefront error (e.g., PV, RMS), and possibly chromatic aberration.

Q 3. How do you define and analyze optical aberrations in Zemax?

Optical aberrations represent deviations from perfect image formation. Zemax provides comprehensive tools to define and analyze these aberrations. Common aberrations include spherical aberration (blurring due to different focal points for different ray heights), coma (asymmetrical blurring causing comet-like shapes), astigmatism (blurring due to different focal points for tangential and sagittal rays), field curvature (image plane not being flat), and distortion (magnification varying across the field). Zemax’s analysis features include various aberration plots (e.g., spot diagrams, ray fans, wavefront maps) that visually represent these defects. These tools quantify the magnitude and type of aberrations, enabling targeted optimization efforts to improve image quality.

Example: A spot diagram illustrates the distribution of rays at the image plane. A large spot size indicates significant aberration, while a tightly clustered spot indicates good image quality. Analyzing the ray fan shows how different ray heights converge (or diverge) at the image plane.

Q 4. Explain how you would design a simple achromatic doublet using Zemax.

Designing an achromatic doublet in Zemax involves selecting two glasses with different dispersive properties to minimize chromatic aberration. Here’s a step-by-step approach:

- Lens Data Editor: Define the two lenses within the system. Select appropriate glass materials from Zemax’s database, choosing glasses with contrasting Abbe numbers (indicating their dispersive properties). I’d typically choose one crown glass and one flint glass.

- Initial Parameters: Set initial radii of curvature, thicknesses, and air gaps. A good starting point often involves equal radii, but precise values are determined through optimization.

- Optimization: Define a merit function to minimize chromatic aberration at specific wavelengths (e.g., using the wavefront aberration or spot size at the design wavelengths). I would use operands for chromatic focal shift and lateral color.

- Optimization Algorithm: Use an appropriate algorithm such as DLS or a global optimization method to refine the design parameters based on your merit function.

- Analysis: After optimization, analyze the performance using spot diagrams, ray fans, and chromatic aberration plots. Iterate on the design, refining the merit function and potentially glass choices if necessary, to achieve the desired level of chromatic correction.

Example: I might choose BK7 (crown glass) and SF2 (flint glass) for their contrasting refractive indices and Abbe numbers. The optimization would aim to minimize the difference in focal length across a range of wavelengths (typically in the visible spectrum).

Q 5. How do you use tolerancing analysis in Zemax to assess the robustness of an optical system?

Tolerancing analysis in Zemax assesses the robustness of an optical system to manufacturing and assembly variations. It determines how sensitive the system’s performance is to deviations in lens parameters (curvatures, thicknesses, separations, etc.) or environmental factors (temperature, pressure). This analysis typically involves Monte Carlo simulations or other statistical methods to model the variations in manufacturing. The results show the probability distribution of performance metrics (e.g., RMS spot size, MTF) given the specified tolerances. This allows me to establish realistic manufacturing tolerances without overly compromising image quality or increasing production costs.

Example: By setting tolerances for lens thicknesses and radii, I can model the impact of those tolerances on the system’s performance using Monte Carlo analysis in Zemax. This might indicate that tighter tolerances on one element have more significant impact on image quality than tolerances on other elements, providing critical information for production.

Q 6. Describe your experience with Zemax’s macro programming language.

I’m proficient in Zemax’s macro programming language (ZPL), leveraging it to automate repetitive tasks, customize analyses, and implement complex algorithms. This empowers me to create custom tools for analyzing specific aspects of my designs, creating batch processing scripts for numerous design iterations and streamlining workflows. I’ve used ZPL to create automated reports, perform complex parameter sweeps, and customize user interfaces.

Example: I’ve developed ZPL macros to automate the process of optimizing a lens system for multiple wavelengths, generating comprehensive reports, and comparing multiple design iterations automatically, drastically reducing time and error.

Q 7. How do you analyze the Modulation Transfer Function (MTF) in Zemax?

The Modulation Transfer Function (MTF) describes an optical system’s ability to transfer contrast at different spatial frequencies. Zemax allows for analyzing the MTF through various means. A common method involves using the diffraction MTF analysis to evaluate the system’s performance taking into account diffraction effects. Another method involves geometric analysis, which is faster but neglects diffraction. The results are typically presented as graphs plotting MTF versus spatial frequency, showing how contrast decreases as spatial frequency increases. High MTF values at high spatial frequencies indicate a sharp image. MTF analysis is essential to assess image resolution and quality.

Example: A high MTF value at 50 cycles/mm indicates that the system effectively transfers contrast at this spatial frequency, suggesting good resolution. Analyzing MTF across different field angles reveals how resolution varies across the image field.

Q 8. Explain the concept of field curvature and how you correct it in Zemax.

Field curvature is an optical aberration where the image of a plane object is not formed on a plane, but rather on a curved surface. Imagine trying to focus a camera on a distant wall – if you perfectly focus the center, the edges might be blurry. That blurriness at the edges is a manifestation of field curvature. In essence, different parts of the image plane require different amounts of focus.

Correcting field curvature in Zemax involves several strategies. The most common approach is through careful lens design. This might involve:

- Choosing appropriate lens shapes: Aspheric lenses, for example, offer more design freedom than spherical lenses and can effectively reduce field curvature. By carefully controlling the aspheric surface’s curvature profile, we can flatten the focal plane.

- Using lens element combinations: Combining lenses with different refractive indices and curvatures can cancel out the field curvature introduced by individual elements. This often requires iterative design optimization using Zemax’s optimization tools.

- Employing field lenses: A field lens is placed in the image space to help redirect light rays toward the image plane. It effectively re-images the pupil, improving field curvature and sometimes even vignetting.

In Zemax, I typically use the optimization merit function to minimize field curvature. This involves setting up operands like RMS spot size or wavefront error at different field points. The optimization process iteratively adjusts lens parameters until the field curvature is reduced to an acceptable level. I might also use Zemax’s tolerance analysis to assess how sensitive the final design is to manufacturing variations, ensuring manufacturability.

Q 9. How would you model diffractive optical elements (DOEs) in Zemax?

Modeling diffractive optical elements (DOEs) in Zemax is straightforward, leveraging its powerful surface type definitions. DOEs manipulate light using diffraction rather than refraction, allowing for compact designs with unique functionalities like beam shaping or wavelength separation. In Zemax, this involves defining a diffractive surface type.

The key is specifying the diffractive profile. This is typically done through a Binary, Multi-Level, or Kinoform profile, each offering a different level of design complexity and manufacturing feasibility. A Binary DOE has only two phase levels (typically 0 and π), while Multi-Level DOEs have multiple phase levels for finer control. Kinoform profiles offer continuous phase variation, providing the most design freedom but often requiring more sophisticated fabrication techniques.

For example, to model a binary DOE that adds a specific phase shift to the incident light, I’d specify the surface type as ‘Diffractive’, choose the ‘Binary’ profile, and input the desired phase shift (usually in wavelengths). Zemax then automatically calculates the corresponding surface profile based on the chosen parameters. The diffraction order and efficiency can be examined within the analysis tabs. For more complex DOEs, I might import a surface sag map from external design software.

Zemax surface type: Diffractive; Profile: Binary; Phase Shift: 0.5λQ 10. Describe your experience with different types of optical surfaces in Zemax (e.g., aspheric, freeform).

I have extensive experience working with various optical surfaces in Zemax, including standard spherical surfaces, and more complex aspheric and freeform surfaces. Aspheric surfaces deviate from a perfect sphere, offering greater design flexibility compared to purely spherical surfaces. This allows for correction of aberrations and compact designs.

Freeform surfaces offer even greater flexibility, as they have no axis of symmetry. This provides unmatched control over the wavefront, allowing for the design of highly complex optical systems with minimized aberrations. Freeform surfaces are particularly important for advanced applications like illumination design and imaging systems with wide fields of view.

I often use Zemax’s built-in tools for defining these surfaces, including the ability to specify the surface sag using polynomials, Q-coefficients (for aspheres), or directly importing a surface profile from CAD software. For freeform surfaces, I might use a Zernike polynomial representation or a directly imported surface data. The choice depends on the design requirements and the availability of suitable data.

For example, I once used aspheric lenses to correct coma in a large-aperture telescope design, significantly improving the image quality. In another project, I leveraged freeform surfaces to achieve uniform illumination in a head-mounted display, which was impossible to achieve with conventional optical elements.

Q 11. How do you perform stray light analysis in Zemax?

Stray light analysis in Zemax is crucial for evaluating the performance of optical systems in real-world conditions. Stray light is unwanted light that reaches the image plane, degrading image quality and potentially damaging sensitive detectors. Zemax offers several tools to analyze and mitigate stray light.

The most common approach is using Zemax’s Non-Sequential mode. This mode simulates the propagation of light rays through the system, accounting for reflections, scattering, and diffraction from all surfaces, including those not directly contributing to the image formation. By defining appropriate materials, surface properties (roughness, reflectivity), and apertures, I can accurately model how stray light propagates.

Another essential method is using the ‘Scattering’ analysis feature within the Sequential mode. This allows you to simulate the scattering of light from surface imperfections. This provides a quantitative assessment of the scattering contribution to stray light. I can then use optimization to reduce the impact of scattering, for instance, by improving surface quality or using anti-reflection coatings.

Analyzing the results involves examining the irradiance distribution on the image plane and identifying the sources of stray light. Based on this analysis, I can modify the system design, for instance, by adding baffles, light traps, or using coatings to minimize stray light levels. The goal is to meet stringent requirements for image contrast and signal-to-noise ratio.

Q 12. Explain your experience using Zemax for illumination system design.

I have significant experience using Zemax for illumination system design. Illumination design often involves non-imaging optics and requires tools capable of handling complex light sources and interactions with various optical components. Zemax’s Non-Sequential mode is perfectly suited for this.

I typically use this mode to model LED or laser sources, and simulate their propagation through lenses, reflectors, and other optical elements to achieve the desired illumination pattern on a target plane. This involves defining the source properties (e.g., intensity distribution, color temperature), optical element geometries, and material properties.

For example, I used Zemax to design a uniform illumination system for a projector. This involved optimizing the shape and position of reflectors and lenses to achieve a uniform illumination on the screen. I used the Non-Sequential ray tracing capabilities to simulate the light path from the source to the screen, and the optimization tools to fine-tune the system parameters for optimal uniformity.

I have also designed systems using freeform surfaces for illumination. The ability to create custom surface shapes provides unparalleled flexibility to shape the light distribution according to specific requirements, enabling the creation of more efficient and compact illumination systems.

Q 13. How do you handle polarization effects in your Zemax models?

Handling polarization effects in Zemax models is crucial for accurate simulation, particularly in systems with polarizing elements like polarizers, waveplates, or Brewster windows. Ignoring polarization can lead to significant errors in predicting system performance.

Zemax handles polarization through its polarization ray tracing capabilities. When enabled, each ray is assigned a Jones vector, representing its polarization state. This vector is then updated as the ray propagates through the optical system, taking into account the effect of each optical element on the polarization state.

To incorporate polarization, I specify the polarization properties of optical elements, such as the orientation and transmission axes of polarizers or the retardance and fast axis of waveplates. Zemax then calculates the change in polarization state as the light travels through the system. The output data includes information on the polarization state of each ray at various points, allowing for the analysis of the overall polarization performance.

I’ve used these features to design polarizing beam splitters and design systems that minimize polarization-dependent losses. Accurate polarization modelling is critical in applications like interferometry, ellipsometry, and polarization-sensitive imaging, where polarization significantly affects the results.

Q 14. Describe your experience with Zemax’s physical optics propagation (POP) feature.

Zemax’s Physical Optics Propagation (POP) feature is a powerful tool for modeling the propagation of light as a wave, rather than as a collection of rays. This is particularly useful when dealing with phenomena like diffraction and interference, which are not accurately captured by ray tracing alone.

POP is especially important when the system’s dimensions are comparable to the wavelength of light. For example, analyzing the performance of high-resolution microscopes, lithography systems, or diffractive optical elements often requires POP.

To utilize POP, I define the desired diffraction grid size and the sampling interval. I then specify the source’s properties, such as its spatial coherence and spectral distribution. Zemax uses the angular spectrum method to propagate the light wavefield through the optical system, accounting for diffraction effects at each element. I then analyze the results in terms of intensity distributions, diffraction patterns, and other relevant wave-optical parameters.

I’ve found POP invaluable in situations where ray tracing alone produced inaccurate results. For instance, in designing a high-resolution imaging system, POP helped me accurately predict the point spread function, accounting for diffraction limitations, which was critical for determining the system’s resolution capabilities.

Q 15. Explain the process of setting up and interpreting a spot diagram in Zemax.

A spot diagram in Zemax visually represents the distribution of rays intersecting the image plane after passing through the optical system. It’s crucial for assessing image quality. Setting one up involves first defining the system’s parameters and then accessing the Spot Diagram analysis within Zemax. You specify the field points (different points in the object field), wavelengths, and number of rays to trace. The resulting diagram shows the ray intersections as a scatter plot, with each dot representing a ray’s intersection point on the image plane.

Interpreting the diagram involves looking at the spot size (the area the spots occupy), spot shape (ideally circular and compact), and spot centroid (its central point). A small, tightly clustered, circular spot indicates good image quality, while a large, spread-out spot indicates aberrations and poor image quality. For example, a large spot size might indicate significant spherical aberration, while an elongated spot shape could be a sign of astigmatism. Analyzing spot diagrams allows for quick assessment and iterative design improvements.

For example, if you design a camera lens, you’d use the spot diagram to evaluate the sharpness of images across the sensor at various points in the field of view. A large spot size in the corner of the image might indicate the need for corrective measures to reduce aberrations in the peripheral field.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use Zemax to analyze the performance of an optical system with different wavelengths?

Zemax allows for comprehensive analysis of optical systems across various wavelengths. This is crucial as different wavelengths often behave differently within the system, leading to chromatic aberrations (color fringing). To analyze performance across multiple wavelengths, you define the wavelength range and number of wavelengths in the system’s setup. You can then use various analysis tools such as Spot Diagrams, Modulation Transfer Function (MTF), and Transverse Ray Aberrations to evaluate performance at each wavelength. This reveals how well the system corrects chromatic aberration and how image quality varies across the spectrum.

For instance, you could define a wavelength range from 400nm to 700nm (visible spectrum) and specify 10 wavelengths within this range. By comparing MTF curves or spot diagrams across these wavelengths, you can easily identify if chromatic aberration is present and its severity. You might see improved results after optimizing the system with dispersive elements like achromats or apochromats to minimize chromatic effects.

Example: Setting up wavelengths in Zemax involves using the 'Wavelengths' tab in the system's property editor.Q 17. How do you design a system for a specific spectral range in Zemax?

Designing for a specific spectral range involves careful selection of optical materials and system parameters. Zemax facilitates this by allowing you to define the wavelengths of interest during system setup. This influences the choice of glass types (considering their refractive index and dispersion characteristics at those specific wavelengths) and the design of the system itself.

Consider designing a system for the near-infrared (NIR) region (700nm-1500nm) for a sensor used in remote sensing. You’ll need to select glasses with low absorption and good transmission in that range. You might need to incorporate filters to block unwanted wavelengths outside of your design specifications. The optimization process would focus on minimizing aberrations specifically within the specified NIR range, potentially using optimization operands that weigh performance at these wavelengths more heavily. You would carefully review analyses like MTF and spot diagrams specifically within the NIR range to ensure performance is optimized across the entire spectral range.

Q 18. Explain your process for optimizing a system for minimum distortion.

Optimizing a system for minimum distortion involves a multi-step process. Distortion, a geometric aberration, is commonly quantified by the percentage distortion value, which describes how much an object’s shape deviates from its ideal representation. First, understand that reducing distortion usually necessitates a trade-off with other performance metrics (like resolution). In Zemax, I would first define distortion as an optimization merit function operand. This involves minimizing the difference between the actual and ideal image height. Then, I employ a suitable optimization algorithm (often Damped Least Squares) to adjust lens parameters (curvatures, thicknesses, airspaces, etc.) towards a solution minimizing distortion.

Monitoring both the distortion value and other relevant metrics (like RMS spot size or MTF) is crucial during the optimization process. This allows for a balanced design considering the trade-offs involved. For example, I might set a target for maximum permissible distortion while trying to maintain satisfactory resolution. I would use Zemax’s merit function editor to carefully weigh the relative importance of reducing distortion with other performance metrics during the optimization run. Regularly reviewing analysis results (like distortion plots and spot diagrams) during the optimization is key to ensuring the desired design is achieved.

Q 19. How do you optimize for different performance metrics simultaneously in Zemax?

Simultaneous optimization for multiple performance metrics in Zemax is achieved using the merit function. This powerful tool allows defining multiple operands, each representing a performance characteristic (e.g., RMS spot size, distortion, chromatic aberration, etc.). Each operand is weighted according to its relative importance. This weighting allows the optimization algorithm to balance the competing demands of various performance parameters.

For example, you might want to minimize both RMS spot size and distortion simultaneously. You would create a merit function that includes operands for RMS spot size, distortion, and possibly others like MTF, all with different weights assigned to each, depending on the desired balance. The optimization process then works to minimize the weighted sum of these operands, leading to an optimized design which balances the trade-offs between competing performance characteristics.

Example: A merit function might include: WEIGHT1*RMS spot size + WEIGHT2*Distortion + WEIGHT3*MTF at 50 lp/mm.Q 20. Explain the concept of vignetting and how you mitigate it in your designs.

Vignetting is the reduction in image brightness at the edges of the field of view, caused by the blocking of light rays by apertures or lens elements within the optical system. It manifests as a gradual darkening of the image towards the periphery. Mitigating vignetting requires careful consideration of lens diameters, aperture stops, and the overall system design.

In Zemax, vignetting can be analyzed using various tools, including the ray trace and vignetting analysis features. Identifying the vignetting cause often involves examining the ray trace to see which elements are obscuring light rays. Mitigating it might involve increasing the diameter of limiting apertures (but this may lead to increased cost and size). Alternatively, you can carefully design lens shapes and spacings to minimize ray blocking without increasing the overall size. One strategy could be to strategically offset lens elements to prevent obscuration, or design larger lenses to ensure less blockage of peripheral rays. Careful review of the ray trace analysis is key to identifying problem areas and applying appropriate solutions.

Q 21. Describe your experience with Zemax’s tolerance analysis tools.

Zemax’s tolerance analysis tools are essential for assessing the robustness of an optical design against manufacturing and environmental variations. I have extensive experience using these tools, primarily the Monte Carlo analysis and the sensitivity analysis. Monte Carlo analysis simulates the effects of random variations in lens parameters (like radii, thicknesses, and refractive indices) on system performance, providing a statistical understanding of the likely range of performance given manufacturing tolerances. Sensitivity analysis quantifies the impact of individual parameters on system performance, indicating which parameters require tighter tolerances.

For example, if I’m designing a high-precision telescope, I’d use tolerance analysis to determine the tolerances needed for various lens parameters to keep the system performance within acceptable limits. The results would show which elements are most critical and guide the manufacturing process, helping maintain performance under real-world conditions. I typically use the results of the tolerance analysis to establish realistic manufacturing tolerances, leading to a cost-effective and reliable product. This ensures that the final product meets the design specifications despite variations in manufacturing conditions.

Q 22. How do you perform a sensitivity analysis in Zemax?

Sensitivity analysis in Zemax helps determine how changes in design parameters affect the overall system performance. It’s crucial for understanding the robustness of your design and identifying critical tolerances. You perform this analysis primarily using the Tolerance Analysis feature.

Here’s how it works: You select the parameters you want to analyze (e.g., lens radii, thicknesses, refractive indices). Zemax then systematically varies each parameter within a specified range, recalculating the optical performance metrics (like RMS spot size, MTF, etc.) for each variation. The results are presented graphically, showing the sensitivity of each metric to each parameter. This allows you to identify parameters that significantly impact performance, which is invaluable for manufacturing considerations and design optimization. For example, if the RMS spot size is highly sensitive to a lens thickness, you know that this thickness needs to be tightly controlled during manufacturing. You can use Monte Carlo analysis, which is a type of tolerance analysis that considers random variations in multiple parameters at the same time and produces a statistical distribution of the performance metrics.

Example: Let’s say I’m designing a telescope. A sensitivity analysis might reveal that the system’s resolution (MTF) is very sensitive to changes in the primary mirror’s radius of curvature. This information will inform my choice of manufacturing tolerances for that mirror.

Q 23. Describe your experience using different analysis features in Zemax (e.g., ray tracing, spot diagrams, MTF).

My experience with Zemax’s analysis features is extensive. I regularly use ray tracing to understand light propagation through the system, identifying aberrations and potential vignetting. Spot diagrams provide a visual representation of how well the system focuses light, showing the distribution of spot sizes in the image plane. I often analyze the Modulation Transfer Function (MTF) to quantify the system’s ability to resolve fine details, and this is usually my primary metric when evaluating image quality. Other analyses I frequently employ are FFT MTF, diffraction MTF and geometric MTF analyses.

For example, during the design of a high-resolution camera lens, I would use ray tracing to identify and correct coma and astigmatism, examine the spot diagram to assess image sharpness, and utilize the MTF analysis to evaluate the system’s performance across various spatial frequencies. This integrated approach ensures the final design meets the required specifications.

Beyond these, I’m proficient in using other analyses such as field curvature, distortion, and chromatic aberration analysis. The choice of which analyses to use depends heavily on the specific application and design requirements. For instance, in designing a laser scanner, distortion analysis would be paramount.

Q 24. How would you model and analyze a system with multiple lenses and optical components?

Modeling multi-lens systems in Zemax is straightforward. I typically start by defining each lens individually, specifying its material, surface curvatures, thicknesses, and any coatings. Then, I use Zemax’s powerful lens editor to assemble the components into a complete system, defining the air spaces and separations between them. This process involves careful consideration of the system’s overall layout and the intended optical path.

During analysis, I use the tools mentioned previously (ray tracing, spot diagrams, MTF) to evaluate the performance of the entire system. I might also need to perform optimization to fine-tune the design parameters for optimal performance. This might involve setting optimization targets for specific performance criteria, such as minimizing spot size or maximizing MTF. For example, a complex zoom lens could consist of many lens elements, each with different functions, and requires iterative design and thorough analysis using a multitude of Zemax features.

Example: Designing a complex camera objective lens might involve 10-15 individual lenses. Each lens could be modeled as a separate component, with specific glasses, coatings, and shapes selected to minimize aberrations like chromatic aberration, spherical aberration, and coma. I would use Zemax to simulate the entire system to ensure optimal performance.

Q 25. Explain your experience with the Zemax OpticStudio interface and its various functionalities.

I’m very familiar with the Zemax OpticStudio interface. Its intuitive layout makes it efficient to design, analyze, and optimize optical systems. The main window presents a comprehensive overview of the current design, including the lens data editor, the 3D layout, and various analysis windows. I find its modular structure very beneficial, as it allows for easy manipulation and modification of the design.

I frequently use the Lens Data Editor to input and modify lens parameters, the 3D Layout for visualization, and the Analysis features for performance evaluation. The Optimization Wizard is particularly helpful for automating the optimization process. I’m also comfortable using the Macro Programming features to automate repetitive tasks and customize workflows. For instance, I have developed macros to automate specific design steps that streamline my daily tasks.

I appreciate the extensive library of materials and coatings available, and I’m adept at importing and exporting data in various formats, ensuring seamless collaboration and integration with other software tools.

Q 26. How do you evaluate the manufacturability of an optical design in Zemax?

Evaluating manufacturability within Zemax involves using the tolerance analysis tools, as mentioned earlier. This helps determine the sensitivity of the design to manufacturing variations. Tight tolerances on certain parameters might lead to increased manufacturing costs and complexity. Therefore, the goal is to find a balance between optical performance and manufacturing feasibility.

Beyond tolerance analysis, I consider factors like lens element shapes, material availability, and the feasibility of coatings. Complex aspheric surfaces might be challenging and expensive to manufacture. Similarly, specialized materials might have limited availability, impacting cost and lead time. I also factor in the potential for assembly errors and the impact these errors could have on the overall system performance. The use of Zemax’s tolerance analysis coupled with a thorough understanding of manufacturing processes allows me to design systems that are both performant and realistically manufacturable. I often iterate on designs, trading off slight performance degradation for improved manufacturability.

Q 27. How do you handle non-ideal optical components in your Zemax models?

Zemax allows for the modeling of non-ideal components through various features. For example, surface imperfections like roughness can be modeled using the surface roughness parameters. Decentering and tilt can be incorporated to simulate real-world manufacturing imperfections. Diffraction effects, scattering, and absorption can also be included in the model to achieve greater realism.

For instance, if I’m working with a lens that has known decentering, I can explicitly model this within the Zemax design. This will help predict the impact of this imperfection on the optical performance. Similarly, if a lens surface has known roughness I can add this to the model. By incorporating these non-ideal effects, I can create more realistic simulations that better predict the system’s performance under real-world conditions. This allows for more accurate predictions and improved decision-making during the design process.

Q 28. Explain your workflow for designing and optimizing an optical system in Zemax.

My workflow for designing and optimizing optical systems in Zemax usually follows these steps:

- Define Requirements: I begin by clearly defining the system’s specifications, including field of view, wavelength range, image quality requirements (MTF, spot size), and any other relevant constraints.

- Initial Design: I start with an initial design, often using Zemax’s built-in tools or by importing a previous design. This might be a simple lens or a more complex starting point.

- Analysis: I then perform thorough analysis using ray tracing, spot diagrams, MTF, and other relevant analyses to evaluate the initial design’s performance against the requirements.

- Optimization: Based on the analysis results, I use Zemax’s optimization capabilities to refine the design. I define merit functions that represent the design goals and use optimization algorithms to find the best design that meets these goals.

- Tolerance Analysis: Once a satisfactory design is achieved, I perform a thorough tolerance analysis to assess its manufacturability and sensitivity to manufacturing variations.

- Verification: Finally, I verify the design using rigorous simulations and potentially build a prototype to confirm the theoretical predictions. This might involve further refinements and iterations based on the results.

Throughout this process, I use Zemax’s various tools and features to efficiently manage the design, analyze results, and refine the system. This iterative process ensures that the final design is optimal, meets the requirements, and is manufacturable.

Key Topics to Learn for Zemax Optical Design Software Interview

- Optical System Setup and Optimization: Understanding how to define lenses, surfaces, and materials within Zemax; mastering optimization techniques to achieve desired performance metrics (e.g., minimizing aberrations).

- Aberration Theory and Correction: A strong grasp of different aberration types (spherical, chromatic, coma, etc.) and how to correct them using Zemax’s tools and analysis features. Practical application: Designing an achromatic doublet lens.

- Tolerance Analysis: Understanding manufacturing tolerances and their impact on optical performance; using Zemax’s tolerance analysis tools to assess system robustness and manufacturability.

- Ray Tracing and Spot Diagrams: Interpreting ray trace results to understand light propagation through the optical system; analyzing spot diagrams to assess image quality.

- Diffraction and MTF Analysis: Understanding diffraction effects and using Modulation Transfer Function (MTF) analysis to characterize image quality and resolution.

- Non-Sequential Ray Tracing: Modeling complex optical systems with scattering, reflections, and other non-paraxial effects. Practical Application: Simulating illumination systems or free-space optical communication systems.

- Polarization Analysis: Understanding the impact of polarization on optical system performance and using Zemax to model polarization effects.

- Material Properties and Selection: Understanding the optical properties of various materials and selecting appropriate materials for specific applications.

- System-Level Design and Integration: Understanding how to integrate optical design with mechanical and electronic components.

- Advanced Features (as applicable to your experience): Explore features like physical optics propagation (POP), thermal analysis, or specific modules relevant to your target role.

Next Steps

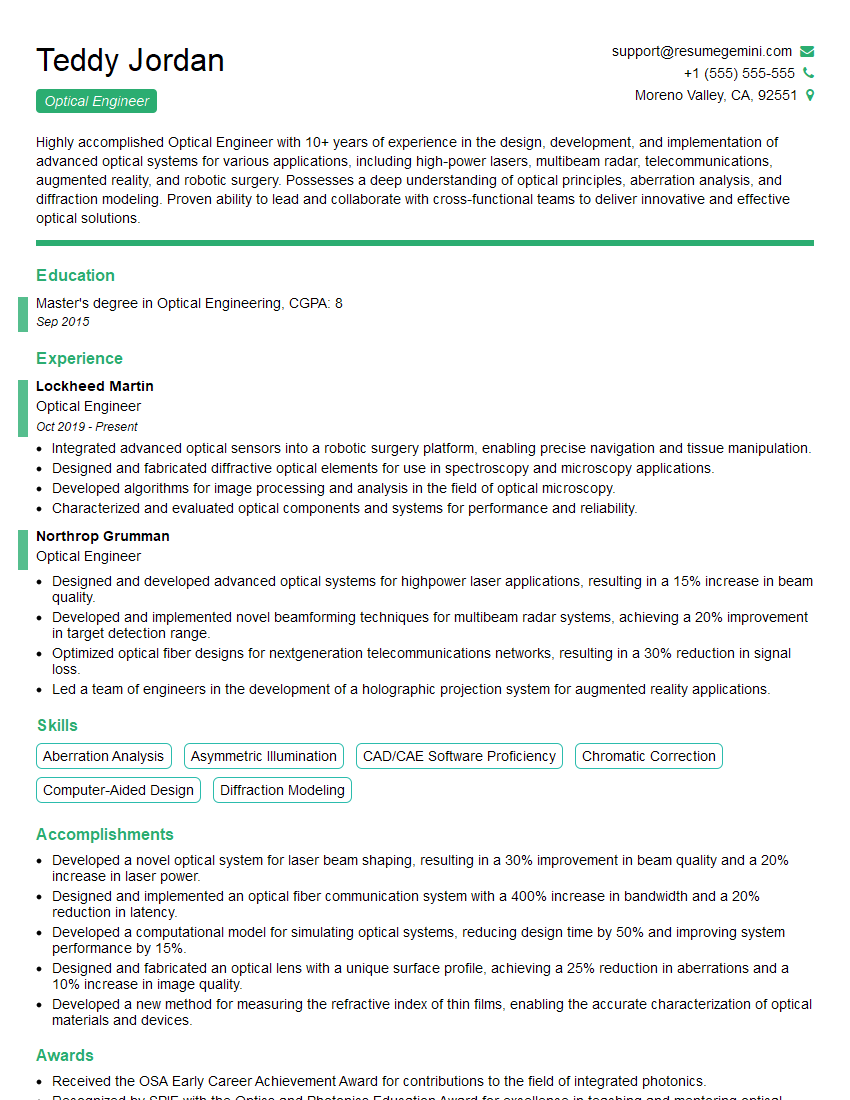

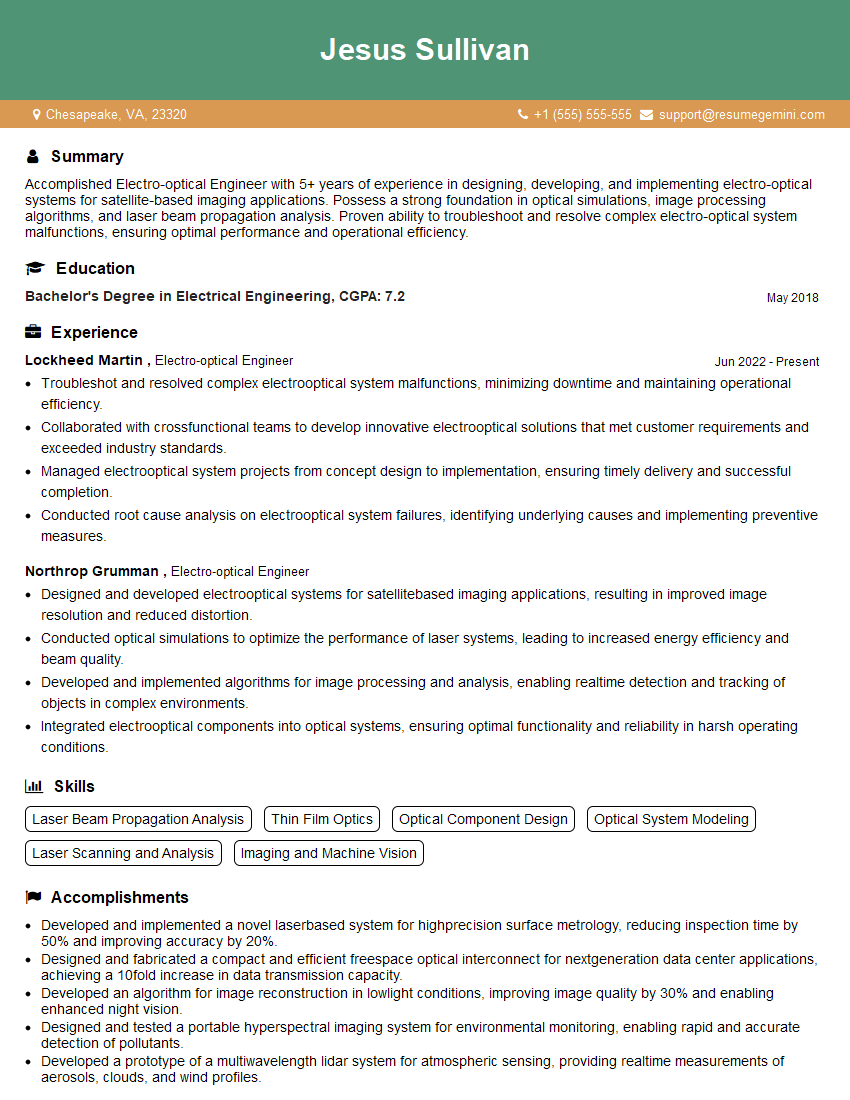

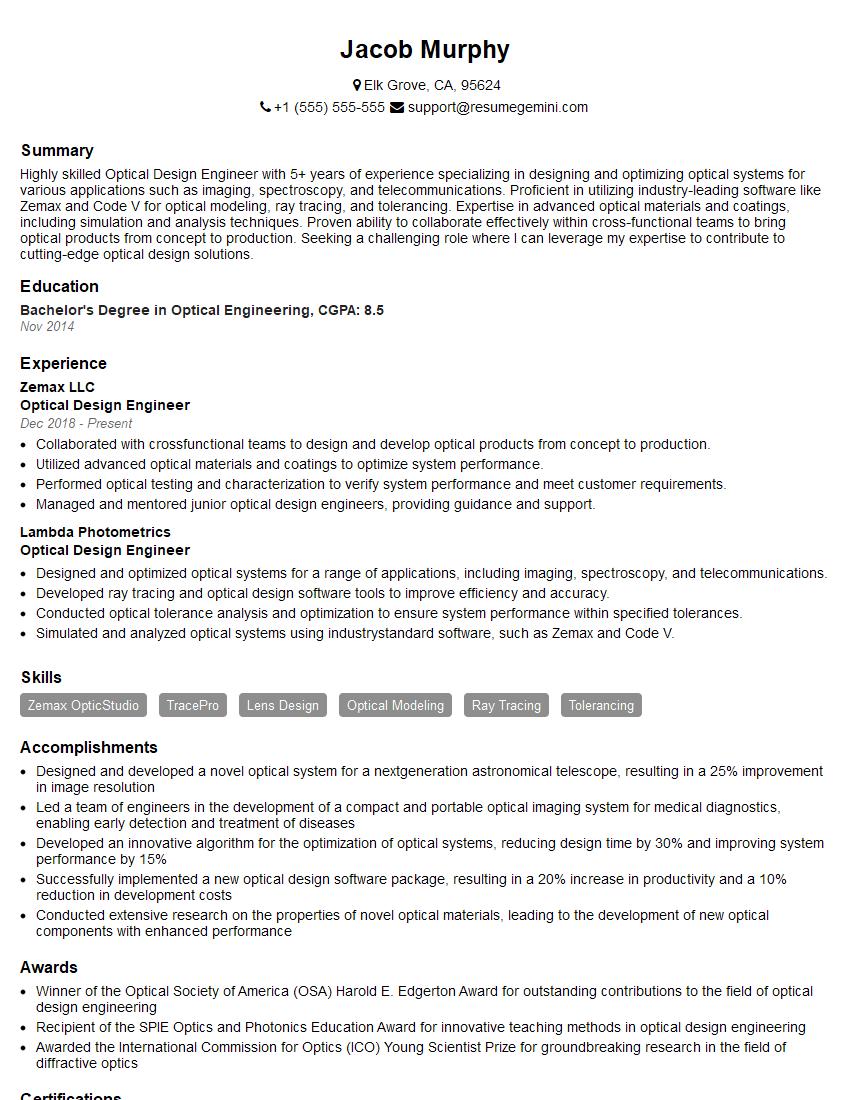

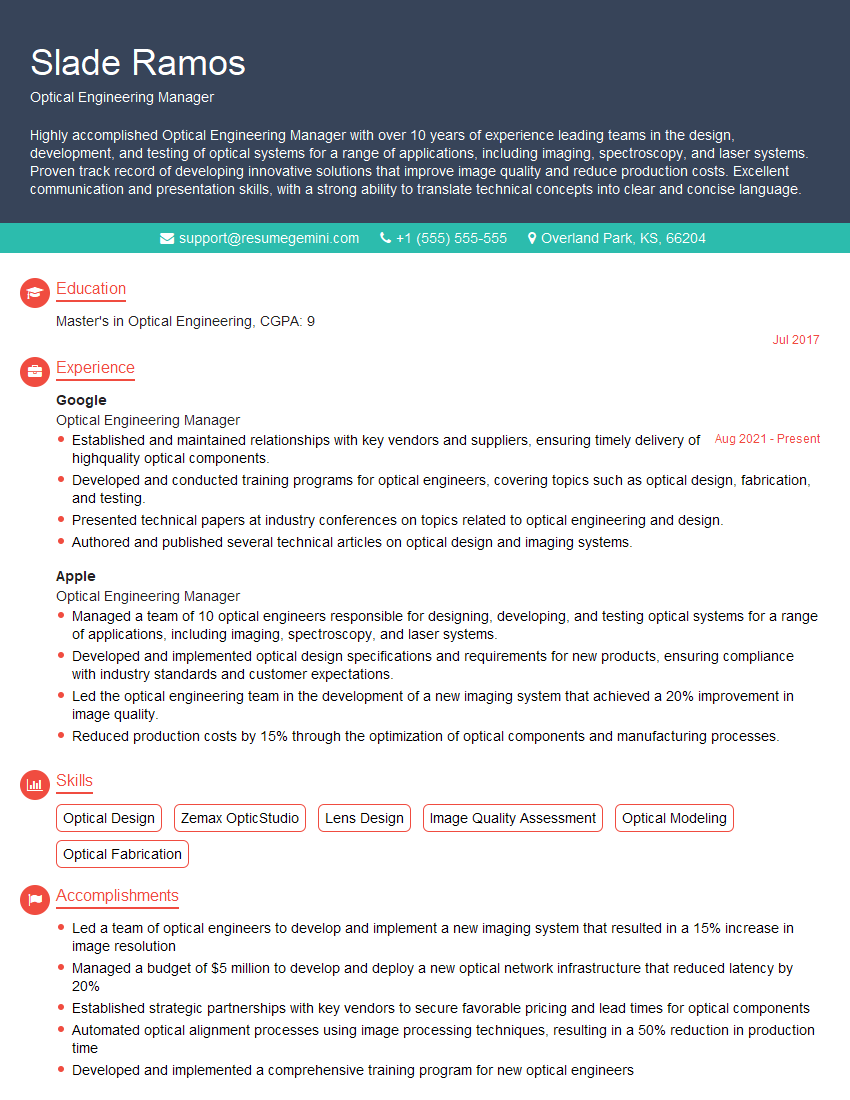

Mastering Zemax Optical Design Software is crucial for career advancement in the optical engineering field, opening doors to exciting opportunities in research, development, and manufacturing. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your Zemax skills effectively. Examples of resumes tailored to Zemax Optical Design Software are available, providing valuable templates and guidance to showcase your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?